Method for preparing molten glass body by utilizing complementarity of two fly ash components

A kind of molten glass, complementary technology, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of poor stability of glass body, high energy consumption, limited use, large energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

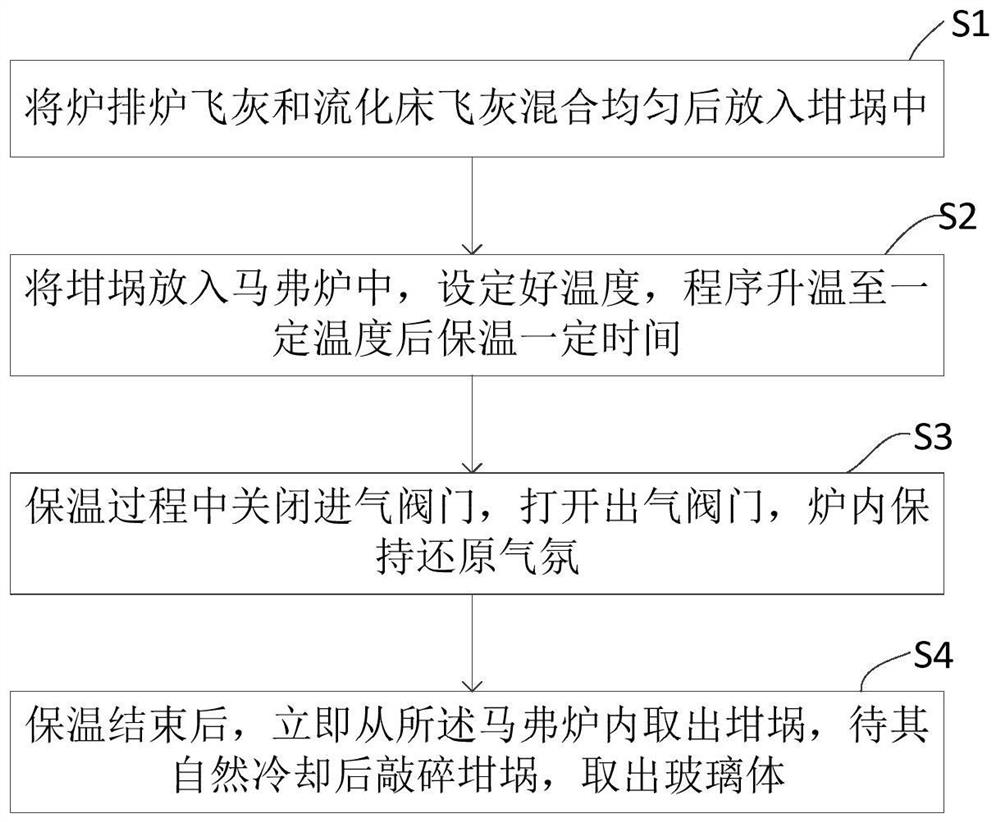

[0038] refer to figure 1 , a method for preparing a molten glass body utilizing the complementarity of two fly ash components, comprising the following processes:

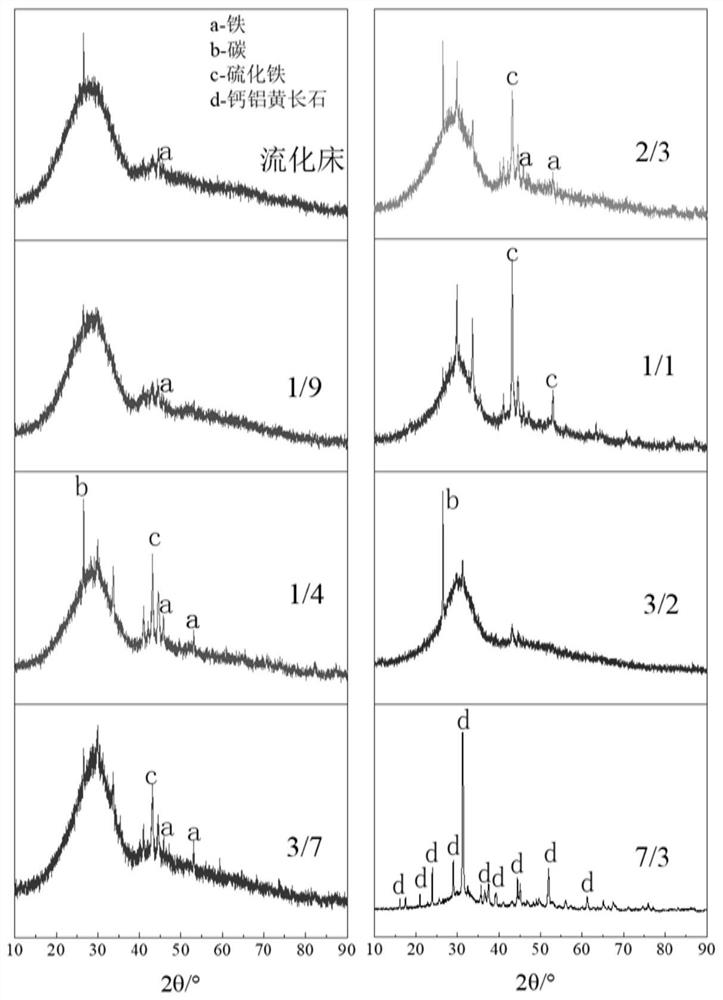

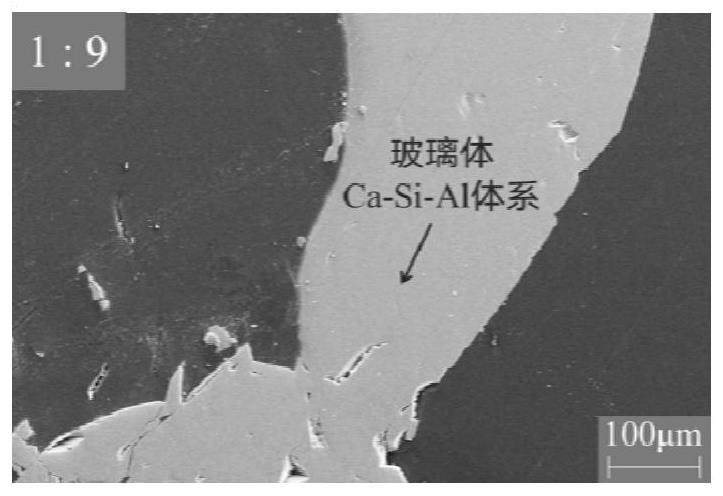

[0039]Step 1: Use the grid sampling method to collect the grate furnace fly ash produced by the mechanical incinerator and the fluidized bed fly ash produced by the fluidized bed incinerator. The mass ratio is 0.12-1.6, the mass ratio of Si element in grate furnace fly ash and fluidized bed fly ash is 0.03-0.43, and the mass ratio of Al element in grate furnace fly ash and fluidized bed fly ash is 0.02-0.29 , then put the grate furnace fly ash and the fluidized bed fly ash into the vortex oscillator with a mass ratio of 1:9, shake for 10 minutes and mix them evenly, then put them into the graphite crucible, and the graphite crucible needs to be covered with a crucible lid to prevent Volatilization of heavy metals and other elements during high temperature process;

[0040] Step 2: Put the graphite crucible into t...

Embodiment 2

[0044] A method for preparing a molten glass body by utilizing the complementarity of the two fly ash components, the specific preparation process is the same as in Example 1, but the grate furnace fly ash and the fluidized bed fly ash are in a mass ratio of 1:4.

Embodiment 3

[0046] A method for preparing a molten glass body by utilizing the complementarity of two fly ash components, the specific preparation process is the same as that of Example 1, but the grate furnace fly ash and the fluidized bed fly ash are in a mass ratio of 3:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com