Method mixing decoration waste and soil to treat organic polluted soil

A technology of organic pollution and mixed treatment, applied in the field of solid waste resource utilization and soil remediation, to achieve the effect of easy access to raw materials, co-disposal of waste, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

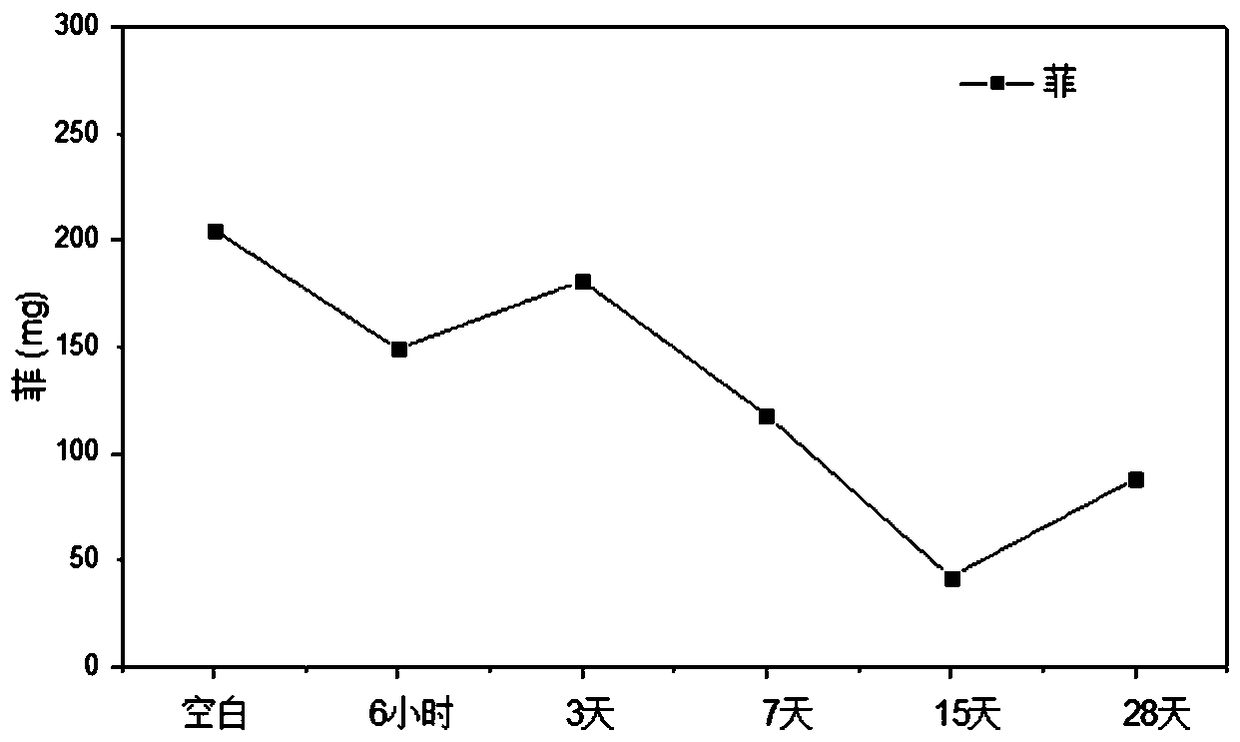

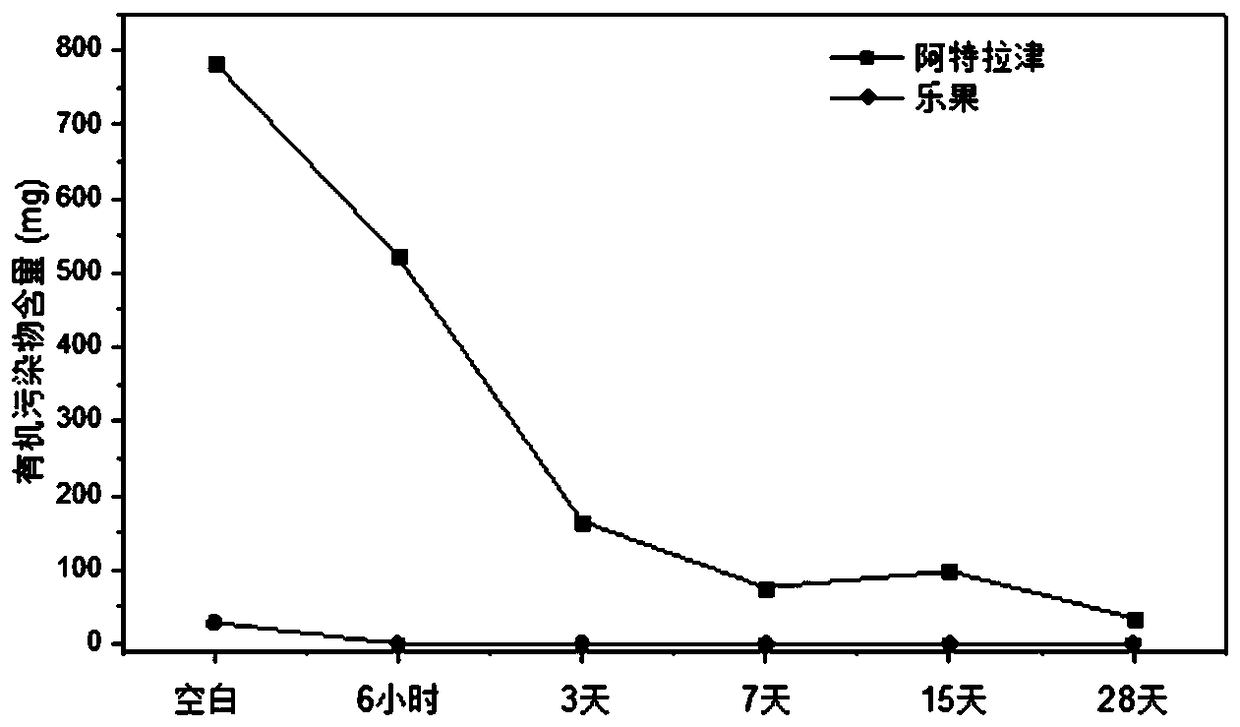

[0043] Take mixed decoration waste from a certain place in Shanghai, sieve out the large pieces of debris, and use a jaw crusher to crush it. According to construction aggregate: brick: wood / chip: cardboard / chip: muck=5:3:5:5: 2 Ratio preparation of mixed decoration waste system, mixed with three simulated contaminated soils of phenanthrene, dimethoate and atrazine according to decoration waste: soil weight ratio of 1:2, and the obtained mixed solid waste was filled in a 500mL zero headspace extractor, Add oxygen-free water to about 5 cm above the surface of the waste, and let it stand. A total of 5 cans were set up as a batch experiment for comparison. At the same time, a blank control was set up, and clean soil was added to the polluted soil to simulate the polluted soil-decoration waste mixed system. The ambient temperature of the whole process control is 15±1 o c.

[0044] On the 1st day (6 hours), 3rd day, 7th day, 15th day and 28th day of reaction, select 1 tank for s...

Embodiment 2

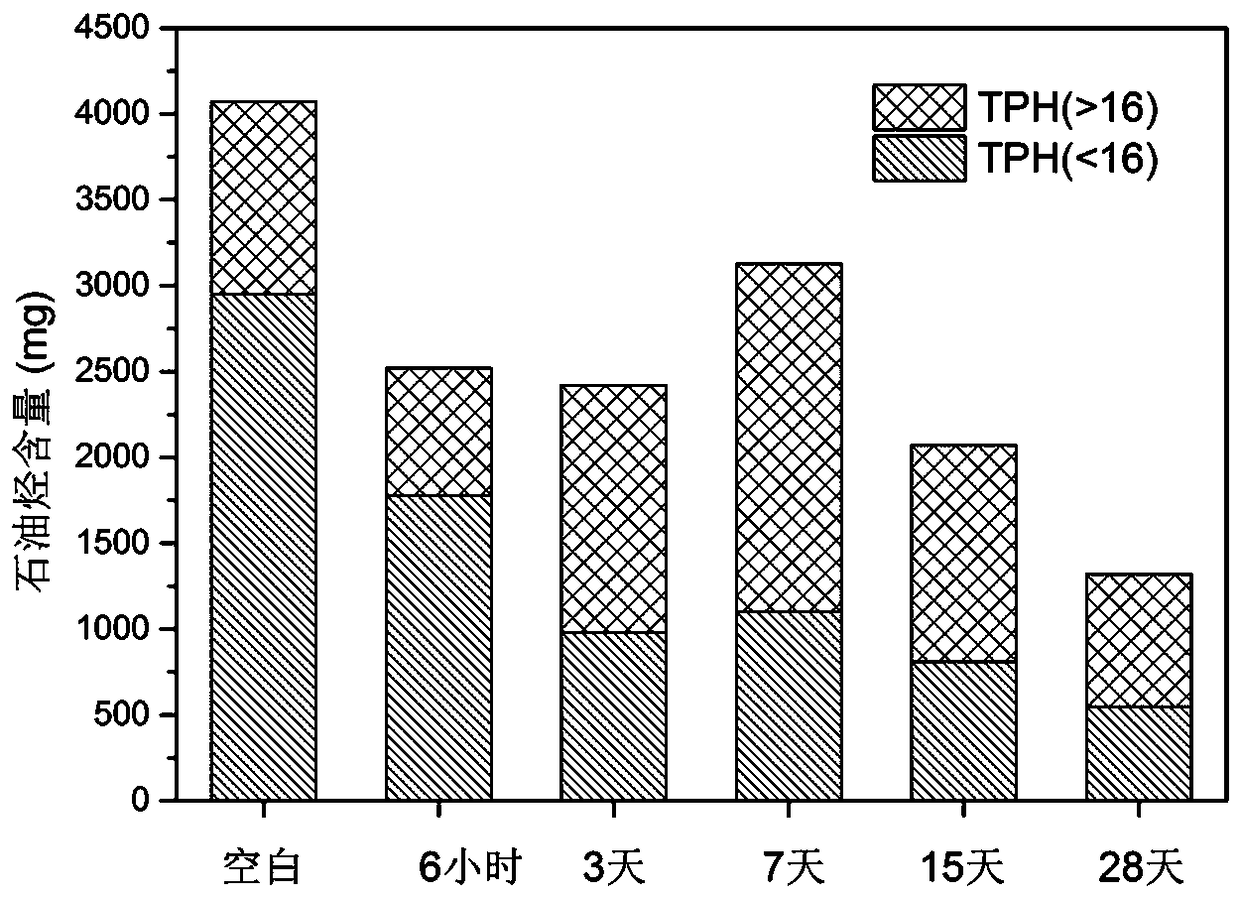

[0046]Using the mixed decoration waste system in Example 1, mixed with the polluted soil obtained from a polluted site in Yangpu District according to the decoration waste: soil weight ratio of 1:2, wherein the polluted soil was tested, and its main organic pollutants were petroleum hydrocarbons, xylene and Toluene and other monocyclic aromatic hydrocarbons, phenols. The mixed solid waste obtained by mixing was filled into a 500 mL zero headspace extractor, oxygen-free water was added to cover the waste surface by about 10 cm, and it was sealed and left standing. A total of 5 cans were set up as a batch experiment for comparison. At the same time, a blank control was set up, and clean soil was added to the polluted soil to simulate the polluted soil-decoration waste mixed system. The ambient temperature of the whole process control is 20±1 o c.

[0047] On the 1st day (6 hours), 3rd day, 7th day, 15th day and 28th day of reaction, select 1 tank for sampling, pipette all sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com