Construction method of vertical engineering barrier system for neutralizing acid mine wastewater

A technology of acid mine wastewater and construction method, which is applied in water conservancy projects, mining wastewater treatment, neutralization water/sewage treatment, etc. problem, to achieve the effect of strong adaptability and excellent governance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

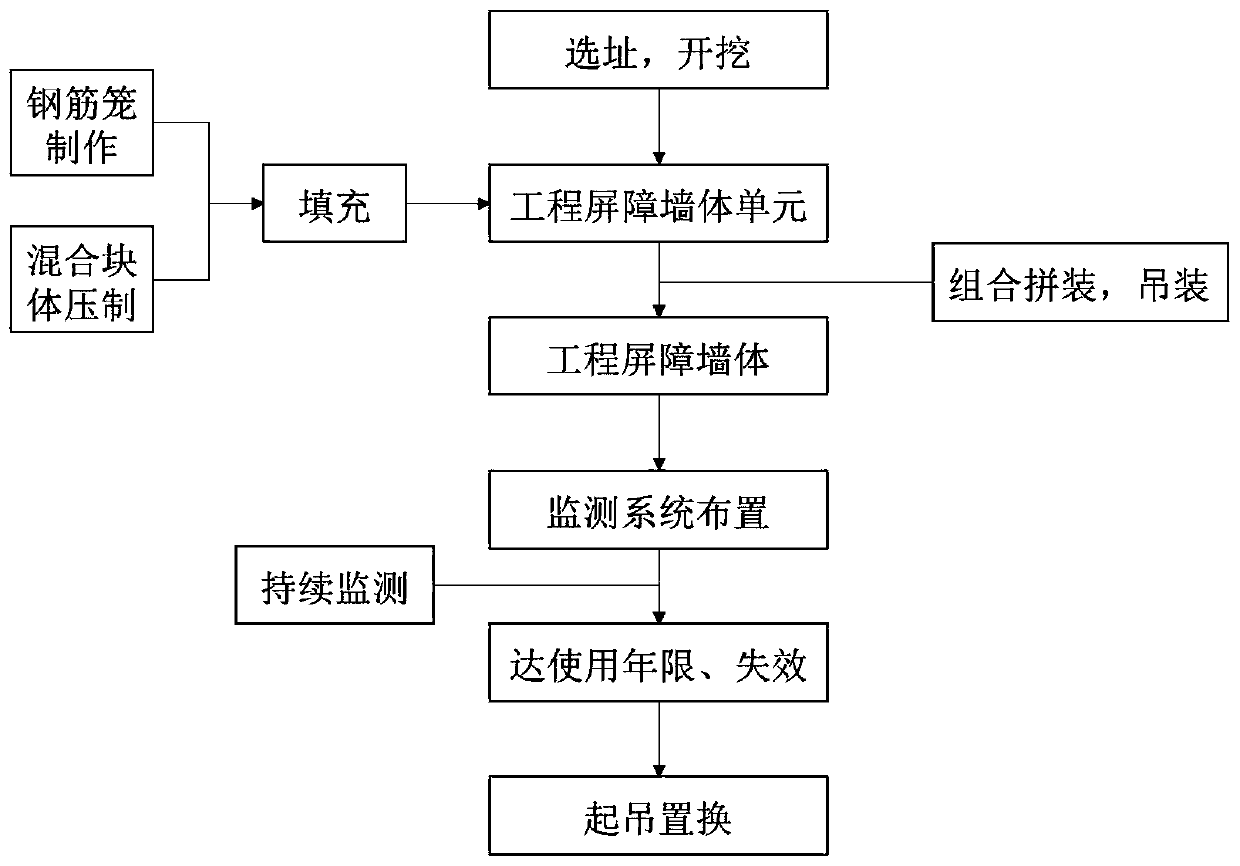

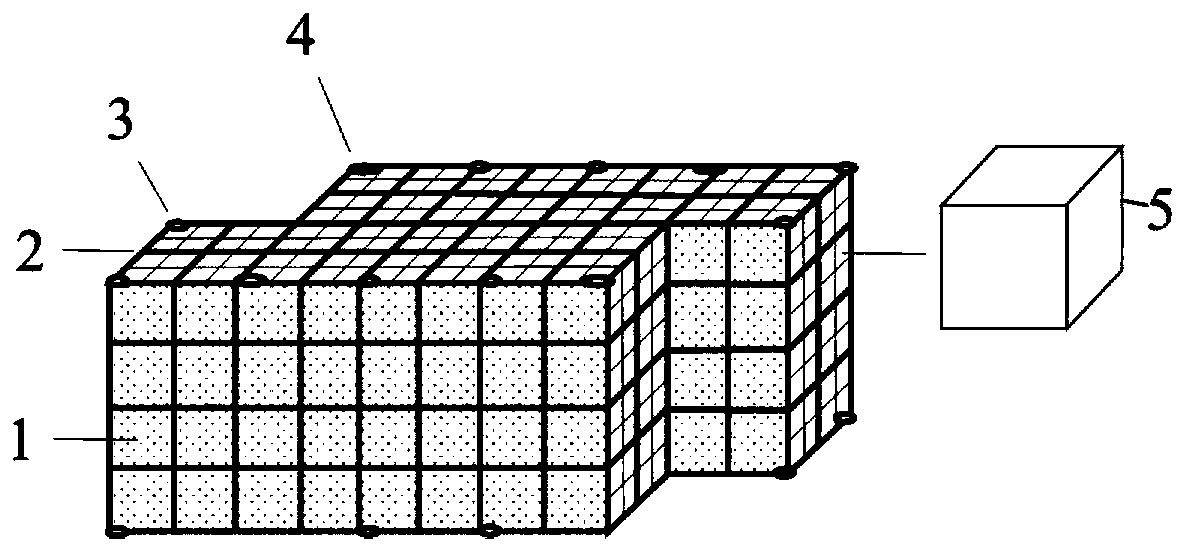

[0049] Refer to attached figure 1 , figure 2 and image 3 , the present embodiment provides a strip-shaped engineering barrier wall assembled from engineering barrier wall units, and the specific operation steps are as follows:

[0050] (1) According to the location of acid mine wastewater pollution source, surrounding engineering geology, hydrogeological conditions and blocking direction, it is determined to use a belt-shaped engineering barrier wall to block acid mine wastewater, select a construction site, excavate ditches, and excavate The depth reaches the underground water-resisting layer, which is 5m (selected according to the site conditions), and the excavation length reaches the boundary of the water-resisting strata on both sides, and the excavation width is 0.6m;

[0051] (2) Make the external reinforcement cage of the engineering barrier wall unit, and lay geotextiles on the inner side of the reinforcement cage in the seepage direction of the acid mine wastewat...

Embodiment 2

[0057] Refer to attached figure 1 , figure 2 and Figure 4 , the present embodiment provides a ring-shaped engineering barrier wall assembled from engineering barrier wall units, and the specific operation steps are as follows:

[0058] (1) According to the location of acid mine wastewater pollution source, surrounding engineering geology, hydrogeological conditions and blocking direction, it is determined to use a ring-shaped engineering barrier wall to block acid mine wastewater, select a construction site, excavate ditches, and excavate The depth reaches the underground aquifer, which is 6m (selected according to the site conditions). The excavated annular ditch should completely surround the pollution source, and the excavation width of the ditch is 0.6m;

[0059] (2) Make the external reinforcement cage of the engineering barrier wall unit, and deploy geotextiles on the inside of the reinforcement cage in the direction of seepage; Figure 4 The direction of the middle...

Embodiment 3

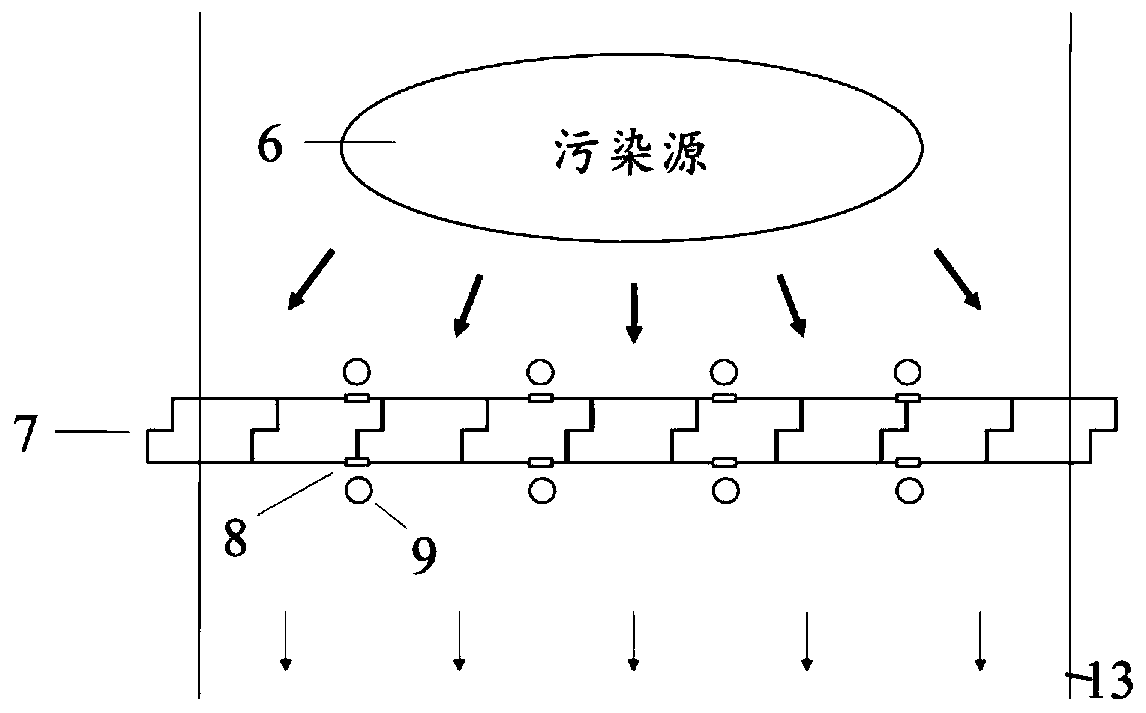

[0065] Refer to attached figure 1 , figure 2 and Figure 5 , the embodiment of the present invention provides an engineering barrier system in the form of a multiple retardation in-situ reaction zone assembled by a neutralization engineering barrier wall unit and a retardation engineering barrier wall unit. The specific operation steps are as follows:

[0066] (1) According to the location of the acid mine wastewater pollution source, the surrounding engineering geology, hydrogeological conditions and the blocking direction, it is determined to use the multiple blocking engineering barrier system formed by the triple engineering barrier to neutralize and block the acid mine wastewater, and select three The construction site of the road engineering barrier, excavate ditches, the excavation depth reaches the underground water-resisting layer, which is 6m (selected according to the site conditions), the excavation length reaches the boundaries of the water-resisting strata on b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com