Garbage and sludge pyrolysis system and garbage treatment system

A technology for sludge and garbage, applied in pyrolysis treatment of sludge, special forms of dry distillation, petroleum industry, etc., can solve the problems of high sludge disposal cost, secondary pollution of groundwater and soil, serious land scarcity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

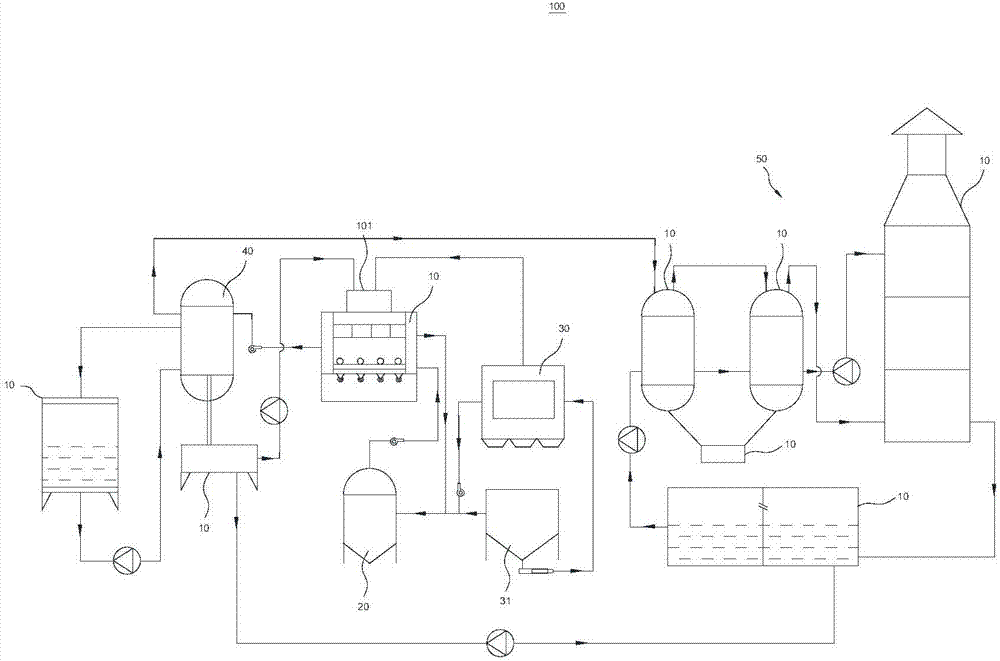

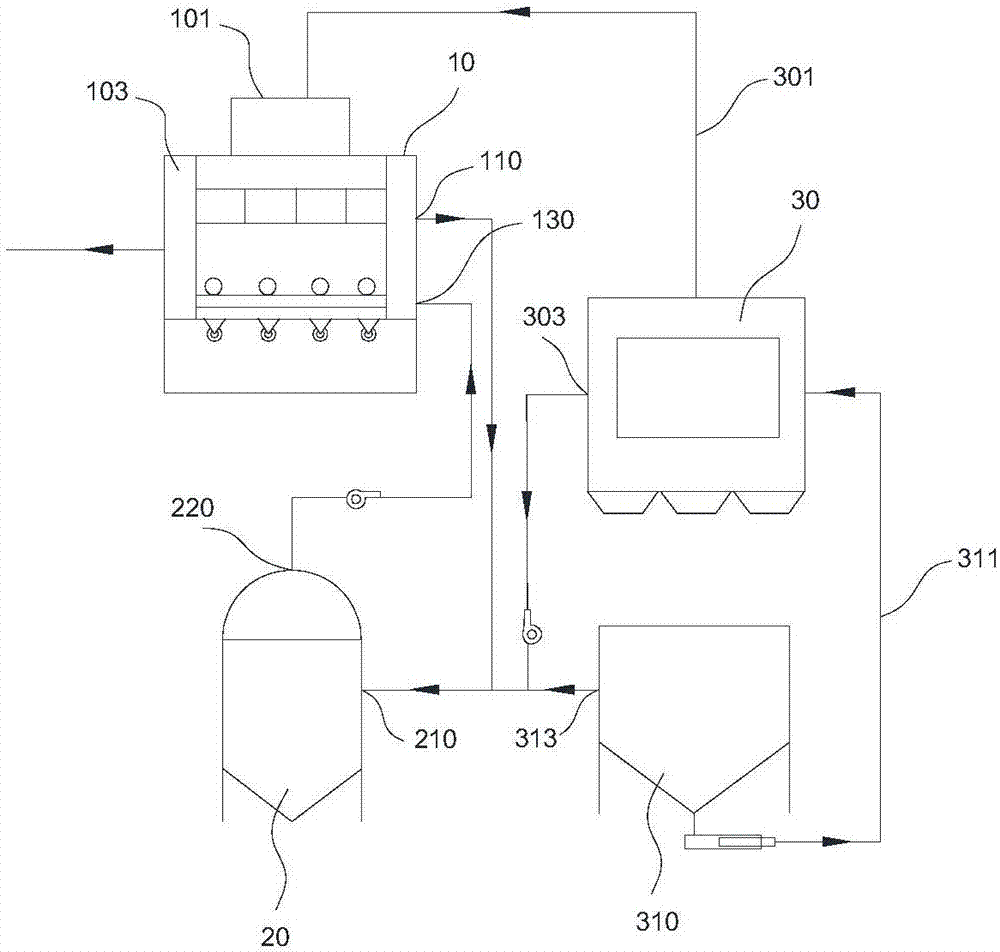

[0032] Please refer to figure 1 , please refer to the attached figure 1 , this embodiment provides a garbage and sludge pyrolysis system 100 , which includes a pyrolysis gasifier 10 , an air preheater 20 , a sludge processor 30 , a condenser 40 and a tail gas treatment device 50 .

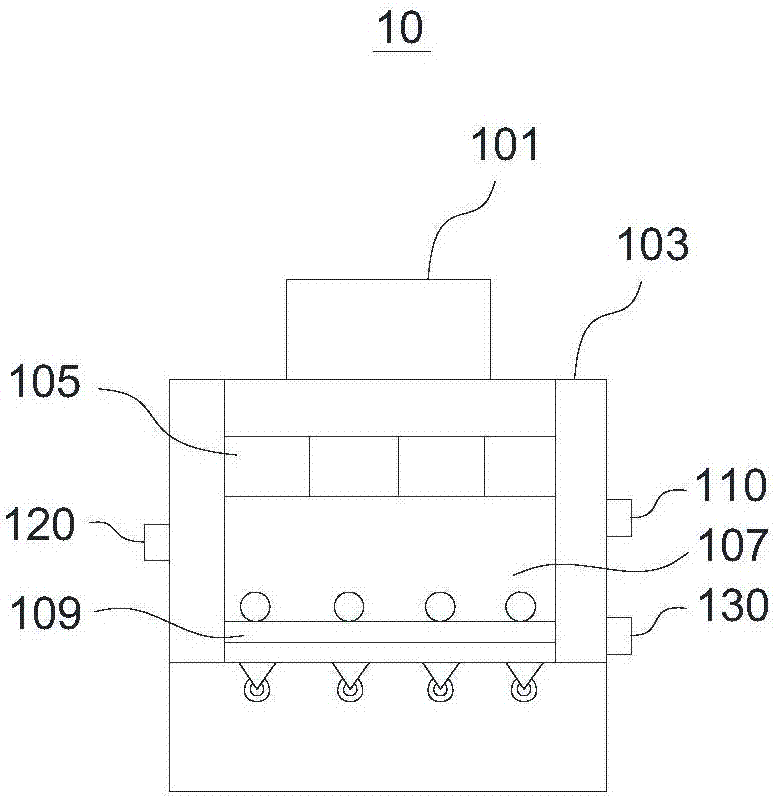

[0033] Further, please refer to the attached figure 2, the pyrolysis gasification furnace 10 includes a furnace body 103 and a feeding tank 101 connected to the furnace body 103 . In this embodiment, the pyrolysis gasification furnace 10 includes a drying chamber 105 , a gasification chamber 107 and a combustion chamber 109 which communicate with each other from top to bottom. Garbage or sludge is added from the feeding tank 101 and reaches the combustion chamber 109 for combustion. The heat rises from the combustion chamber 109 to the gasification chamber 107 and the drying chamber 105 in turn, providing the heat required by the gasification chamber 107 and the drying chamber 105.

[0034] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com