Method for preparing road material from high-water-content sludge/engineering residue soil

A technology for engineering dregs and silt, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost, low production efficiency, complicated operation, etc., achieve high added value and reduce treatment costs , The effect of simple dehydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

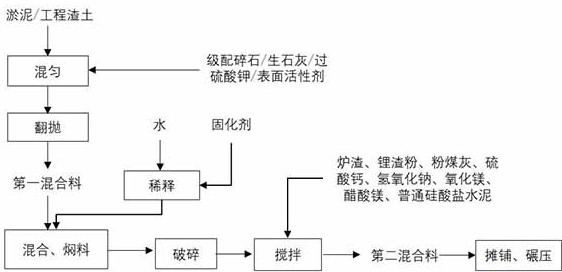

[0054] A method for preparing road materials from high water content silt and dregs, comprising the steps of:

[0055] (1) Mix 10kg of silt and construction dregs with a mass ratio of 1:1, 200g of quicklime, 5kg of graded crushed stone, 3g of potassium persulfate, and 50g of lignosulfonate. The moisture content of silt / engineering dregs is reduced below the optimum moisture content.

[0056] (2) Dilute 1g of C.S.S. Technology, Inc.'s EN-1 curing agent with 305g of water, add the dehydrated raw materials, stir well, and simmer overnight for later use.

[0057] (3) Use a two-stage non-sieve bottom wet material crusher to crush the raw materials after stewing until the particle size is less than 2cm, and transport them to the mixing equipment. 300g of domestic waste pyrolysis furnace slag, 200g of lithium slag powder, 300g of fly ash, 50g of calcium sulfate, 50g of sodium hydroxide, 100g of magnesium oxide, 1g of magnesium acetate, and 750g of ordinary portland cement are evenly...

Embodiment 2

[0062] A method for preparing road materials from high water content silt and dregs, comprising the steps of:

[0063] (1) Mix 10kg of silt and construction dregs with a mass ratio of 1:3, 100g of quicklime, 3kg of graded crushed stone, 5g of potassium persulfate, and 80g of naphthalenesulfonate, turn over and throw 3 times, and dry to the sludge / The water content of engineering dregs is reduced to below the optimum water content.

[0064] (2) Dilute 2g of Yifusen soil curing agent of Zhongke Shenglian with 260g of water, add the dehydrated raw materials, stir well and stew for 24 hours for later use.

[0065] (3) Use a two-stage wet material crusher without a sieve bottom to crush the raw materials after stewing until the particle size is less than 2cm, and transport them to the mixing equipment. 500g of domestic waste pyrolysis furnace slag, 500g of lithium slag powder, 1000g of fly ash, 100g of calcium sulfate, 50g of sodium hydroxide, 300g of magnesium oxide, 3g of magn...

Embodiment 3

[0069] A method for preparing road materials from high water content silt and dregs, comprising the steps of:

[0070] (1) Mix 10kg of silt and construction dregs with a mass ratio of 2:1, 300g of quicklime, 30kg of graded crushed stone, 10g of potassium persulfate, and 200g of sulfonated melamine-formaldehyde resin, turn over 3 times, and dry to The moisture content of silt / engineering dregs is reduced below the optimal moisture content.

[0071] (2) Dilute 5g of C.S.S. Technology, Inc.'s EN-1 curing agent with 500g of water, add the dehydrated raw materials, stir well, and stew overnight for later use.

[0072] (3) Use a two-stage wet material crusher without a sieve bottom to crush the raw materials after stewing until the particle size is less than 2cm, and transport them to the mixing equipment. 100g of domestic waste pyrolysis furnace slag, 100g of lithium slag powder, 300g of fly ash, Add 20g of calcium sulfate, 20g of sodium hydroxide, 100g of magnesium oxide, 1g of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com