Method for synergistically preparing glass body from hazardous waste incineration ash residues and for decarburizing

A technology for hazardous waste and incineration of ash and slag, which is applied in the removal of solid waste, glass production, chemical instruments and methods, etc., can solve the problems of high cost of iron oxide scale, increased ash melting treatment cost, and increased treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

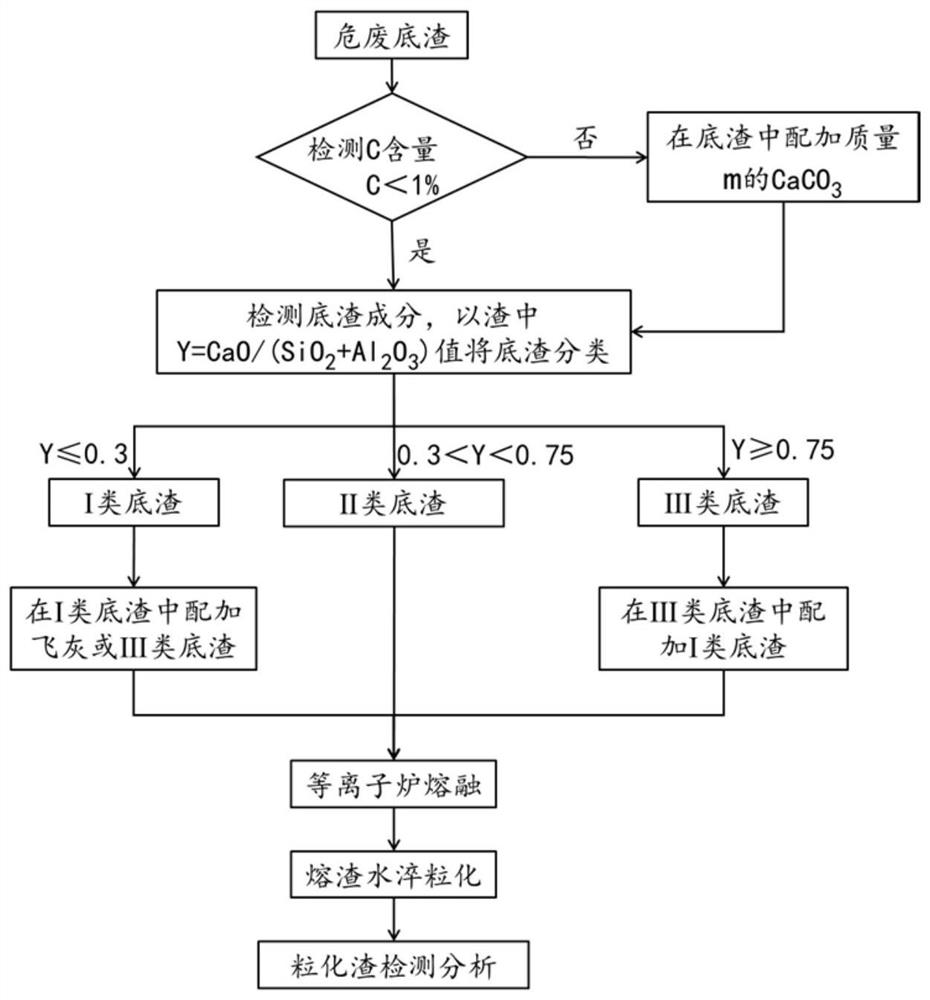

[0056] Example 1 Class I slag mixed with fly ash

[0057] The carbon content and chemical composition of the bottom slag and fly ash of the 1# hazardous waste incineration plant were analyzed. The main components of the bottom slag are shown in Table 1 below. The carbon content in the bottom slag is 0.8%, and there is no need to add CaCO 3 As a decarburizer: according to CaO and SiO in bottom slag and fly ash 2 、Al 2 o 3 Component contents are recorded in Table 1.

[0058] Main component content / % of bottom slag and fly ash in Table 1 Example 1

[0059]

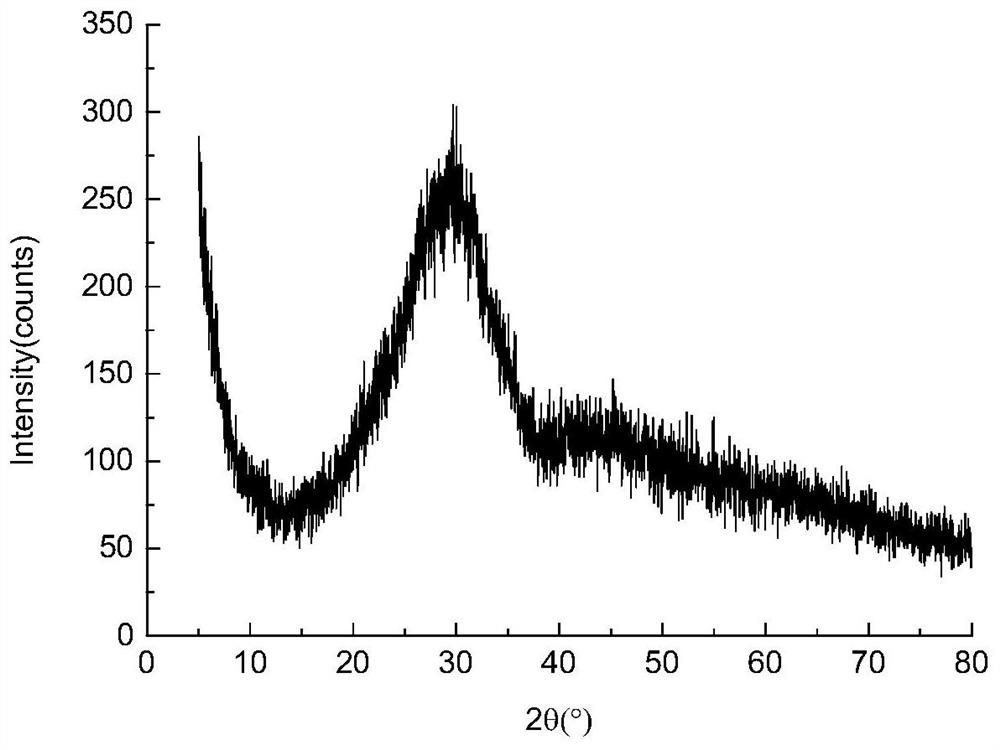

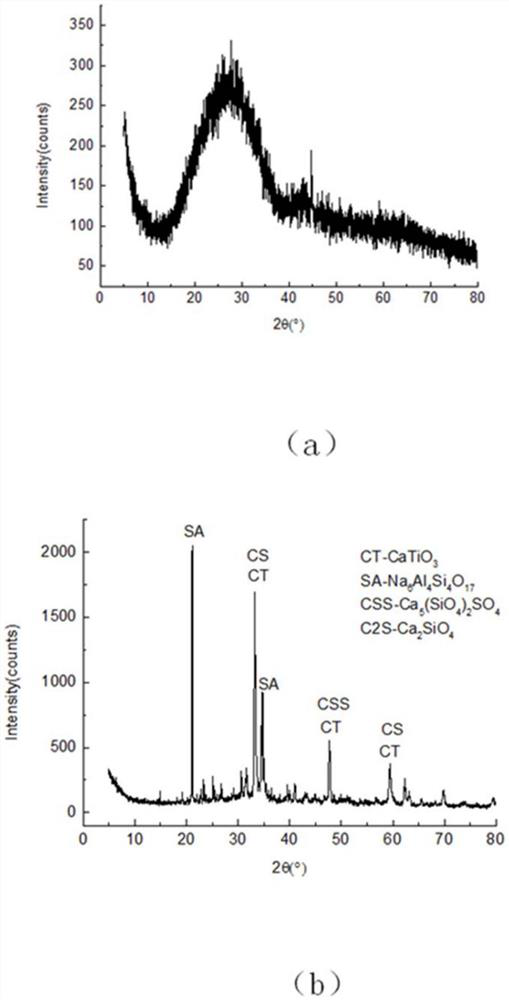

[0060] 1# bottom slag passes through the ratio Y=CaO / (SiO 2 +Al 2 o 3 ) = 0.24, belonging to Class I slag, it is necessary to add fly ash to 1# bottom slag for compounding, now take 100 parts of bottom slag and 40 parts of fly ash and mix them evenly. The purpose of matching bottom slag and fly ash is to make Y=CaO / (SiO 2 +Al 2 o 3 )=0.51, which is in the range of 0.3-0.75. The prepared mixture is put into the p...

Embodiment 2

[0062] Embodiment 2 adds decarburizing agent CaCO 3 The final type III slag is combined with the type I slag to prepare the glass body

[0063] The carbon content and chemical composition of the bottom slag of the 2# hazardous waste incineration plant were analyzed. The main components of the bottom slag are shown in Table 2: the original bottom slag is Class II slag, and the residual carbon content in the bottom slag is 6.9%, and CaCO needs to be added 3 as a decarburizer;

[0064] Main component content / % of bottom slag and fly ash in Table 2 Example 2

[0065]

[0066] When the bottom slag is 100 parts, CaCO 3 The amount of addition m=100×M1×W1 / 12=100×100×6.9% / 12=57.5 parts, add CaCO 3 The composition of the bottom slag (named: 2-1# bottom slag) is shown in Table 3.

[0067] Table 3 Main component content of 2-1# bottom slag / %

[0068]

[0069] In 2-1# bottom slag, Y=CaO / (SiO 2 +Al 2 o 3 )=1.06, belonging to Class III slag. According to the CaO and SiO in 2-1...

Embodiment 3

[0072] Embodiment 3 adds decarburizing agent CaCO 3 The final type II slag, the method for preparing glass by melting

[0073]The carbon content and chemical composition of the bottom slag of the 3# hazardous waste incineration plant were analyzed. The main components of the bottom slag are shown in Table 4: the carbon content in the bottom slag is 2.4%, and CaCO needs to be added 3 as a decarburizer.

[0074] Main component content / % of bottom slag in table 4 embodiment 3

[0075]

[0076] When the bottom slag is 100 parts, CaCO 3 The amount of addition m=100×M1×W1 / 12=100×100×2.4% / 12=20 parts, add CaCO 3 The composition of the bottom slag (named: 3-1# bottom slag) is shown in Table 5.

[0077] Table 5 Main component content of 3-1# bottom slag / %

[0078]

[0079] In 3-1# bottom slag, Y=CaO / (SiO 2 +Al 2 o 3 )=0.4, which belongs to Class II slag. Put Class II slag directly into the plasma furnace, and the temperature of the plasma furnace is raised to 1450°C. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com