Method for performing aerobic humification on residual vegetable added with high-humus-containing river sediment

A technology for river sediment and humus, which is applied in the field of resource utilization of organic waste, can solve the problems of long humification time and incomplete composting of coriander, achieve easy attachment by microorganisms, improve the level of humification, and speed up the humification. Effects of the rotting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

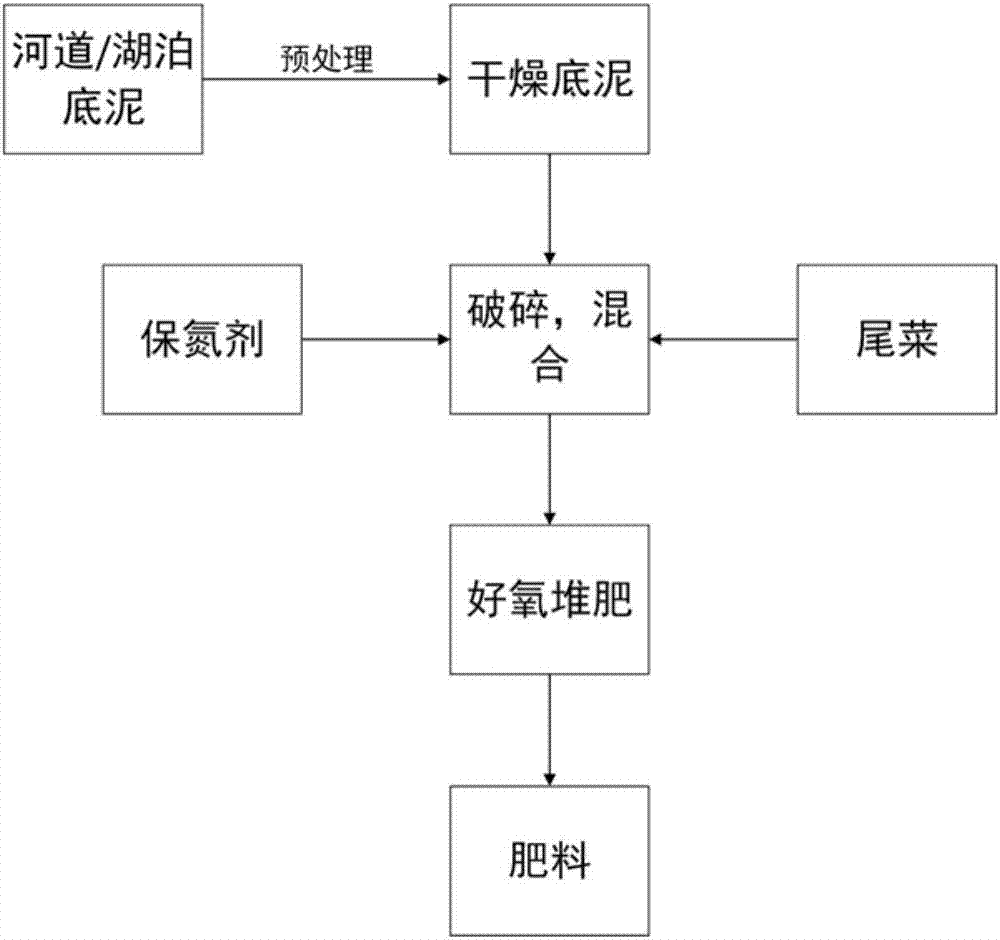

[0033] The technological process of the tail vegetable aerobic humification method of adding the river bottom mud containing high humus in this embodiment is as follows figure 1 As shown, it specifically includes the following steps:

[0034] Step (1): Take the river bottom mud, add a washing agent to remove heavy metals in the river bottom mud, and then dry the washed river bottom mud until the water content is less than 50%, to obtain dry bottom mud;

[0035] Step (2): respectively measuring the total organic carbon, total organic nitrogen and C / N ratio of the dried bottom sludge and the tail vegetables, and then uniformly mixing the dry bottom sludge and the tail vegetables with the nitrogen-enhancing agent, and crushing to obtain a mixed stock;

[0036] Step (3): Put the mixed stock into the humification bin, carry out aerobic humification with forced ventilation, turn the pile every 5 days, and measure the total organic carbon, total organic nitrogen and total humificatio...

Embodiment 2

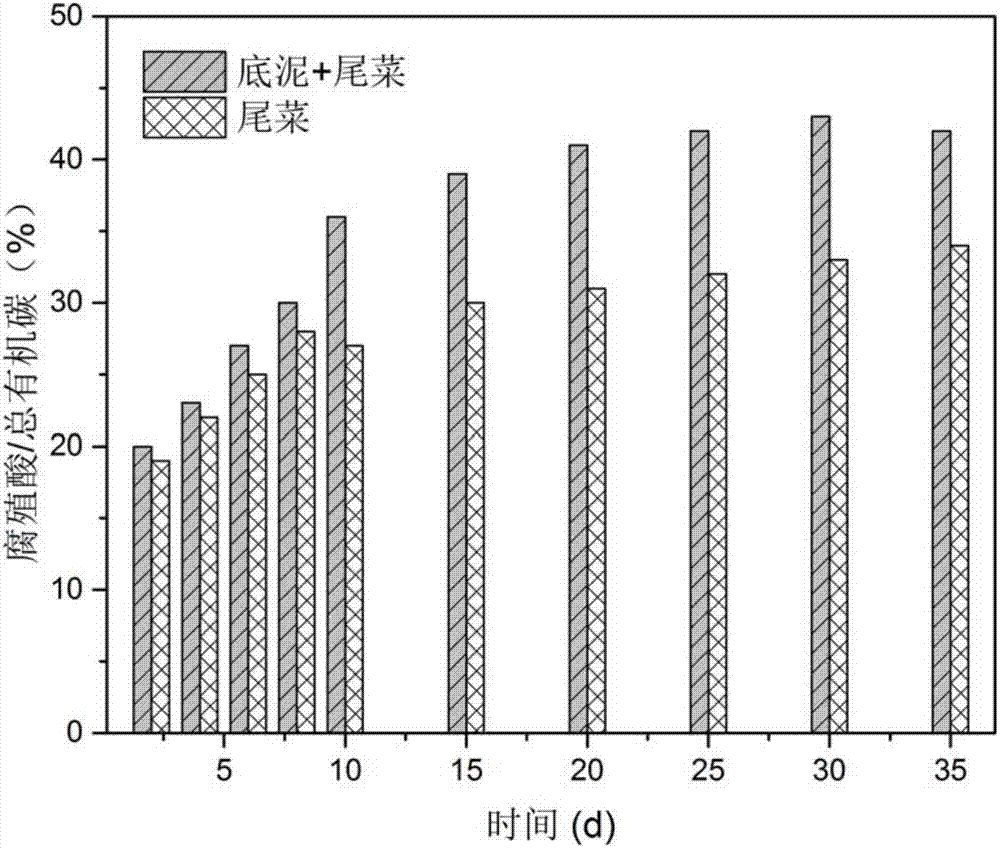

[0042] Take 10kg of sediment from a certain river in Shanghai, add 10L of 1mol / L rhamnolipid solution, turn over and soak for 24 hours, then filter, and dry in the sun until the water content is less than 50%. Measure the TC (total carbon), TN (total nitrogen) and C / N ratio of the dry bottom sludge and the tail vegetables, then, mix the dry bottom mud and the tail vegetables according to the ratio of 1:5 and crush them to make the particle size of the mixed pile Less than 10 microns, moisture content 60%, C / N ratio 30:1. Add a small amount of superphosphate and mix, put the mixed stock into the large fermentation bin, and carry out aerobic humification by means of continuous ventilation, and turn the stock once every 7 days. The total humic acid content in the fermentation process is measured, and the humified product is obtained when the content of each component is basically stable.

[0043] At the same time, take 60kg of tail vegetables, without adding bottom mud, and othe...

Embodiment 3

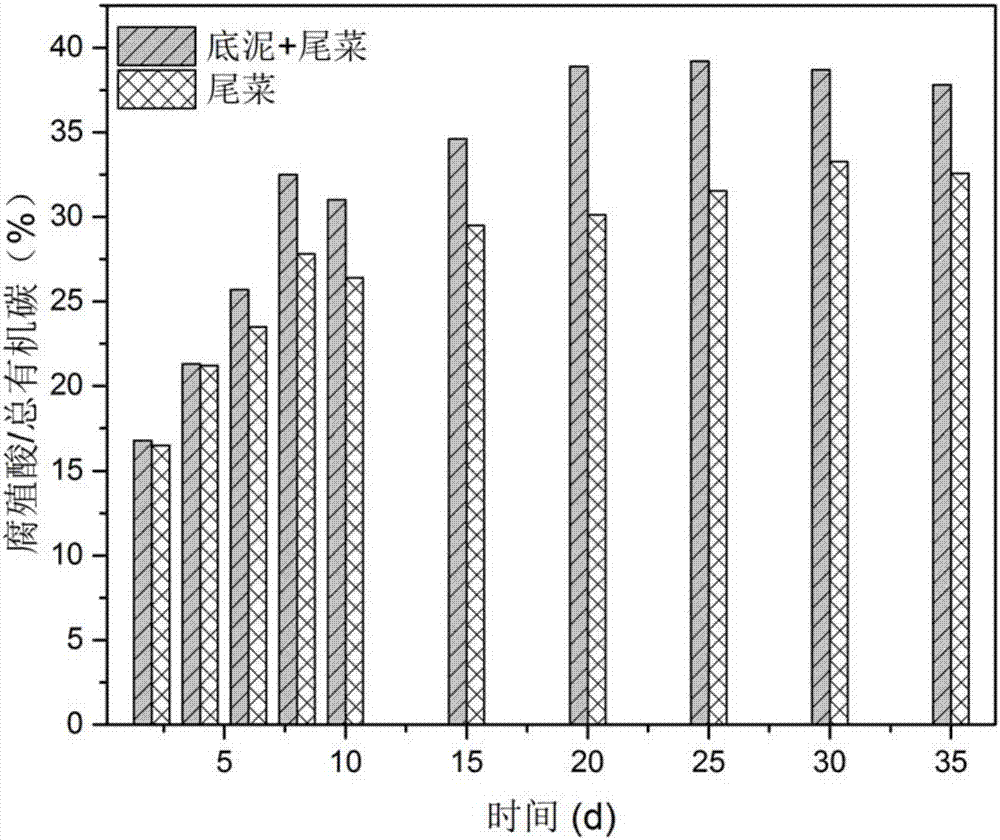

[0046]Take 10kg of sediment from a lake in Shanghai, add 10L of 1mol / L citric acid solution, turn over and soak for 24 hours, then filter, and dry in the sun until the water content is less than 50%. Measure the TC (total carbon), TN (total nitrogen) and C / N ratio of the dry bottom sludge and the tail vegetables, then, mix the dry bottom mud and the tail vegetables according to the ratio of 1:5 and crush them to make the particle size of the mixed pile Less than 10 microns, moisture content 60%, C / N ratio 30:1. Add a small amount of superphosphate and mix, put the mixed stock into the large fermentation bin, and carry out aerobic humification by means of continuous ventilation, and turn the stock once every 7 days. The total humic acid content in the fermentation process is measured, and the humic fertilizer is obtained when the content of each component is basically stable.

[0047] At the same time, take 60kg of tail vegetables, without adding bottom mud, and other operatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com