Method for removing multiple pollutants in copper smelting waste acid by using Bayer process red mud

A Bayer process red mud and copper removal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing material cost and forming iron arsenate for a long time. , to achieve the effect of reducing economic cost, reducing secondary pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

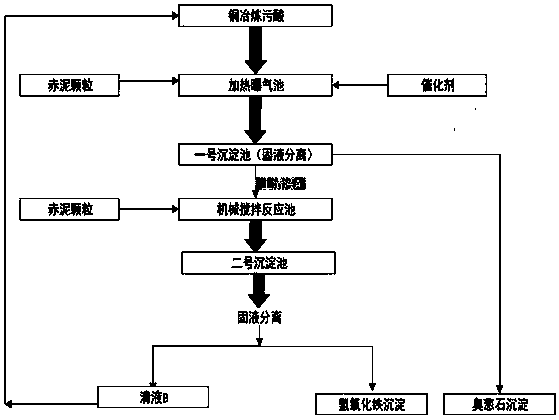

[0036] A kind of method that this embodiment provides utilizes red mud of Bayer method to remove multiple pollutants in copper smelting sewage acid, such as figure 1 shown, including the following steps:

[0037] Step 1. Slowly add the copper smelting dirty acid solution into the heated aeration tank, continue aerating while heating, control the temperature at 82°C, and oxidize the trivalent arsenic in the dirty acid to pentavalent arsenic; the present invention adopts the method of aeration Oxidize trivalent arsenic to pentavalent arsenic to prepare for the subsequent precipitation reaction, without the use of oxidants, reducing the cost of raw materials;

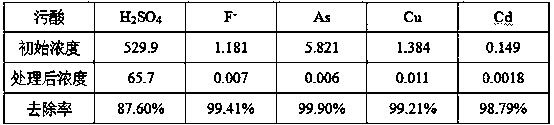

[0038] Step 2, then add Bayer process red mud particles to the heated aeration tank after step 1 treatment, the Bayer process red mud selected in this embodiment contains Fe 2 o 3 :29.39wt%, CaO:11.02wt%, Na 2 0:3.16wt%, the iron-arsenic mol ratio in the regulation reaction system is about 1.0, and the pH value of react...

Embodiment 2

[0047] A kind of method that this embodiment provides utilizes red mud of Bayer method to remove multiple pollutants in copper smelting sewage acid, such as figure 1 shown, including the following steps:

[0048] Step 1. Slowly add the copper smelting dirty acid solution into the heated aeration tank, continue aeration while heating, control the temperature at 72°C, and oxidize the trivalent arsenic in the dirty acid to pentavalent arsenic; the present invention adopts the method of aeration Oxidize trivalent arsenic to pentavalent arsenic to prepare for the subsequent precipitation reaction, without the use of oxidants, reducing the cost of raw materials;

[0049] Step 2, then add Bayer process red mud particles to the heated aeration tank after step 1 treatment, the Bayer process red mud selected in this embodiment contains Fe 2 o 3 :28wt%, CaO:9wt%, Na 2 0:2wt%, adjust the iron-arsenic molar ratio in the reaction system to be about 0.85, and the pH value of the reaction ...

Embodiment 3

[0058] A kind of method that this embodiment provides utilizes red mud of Bayer method to remove multiple pollutants in copper smelting sewage acid, such as figure 1 shown, including the following steps:

[0059] Step 1. Slowly add the copper smelting dirty acid solution into the heated aeration tank, continue aerating while heating, control the temperature at 94°C, and oxidize the trivalent arsenic in the dirty acid to pentavalent arsenic; the present invention adopts the method of aeration Oxidize trivalent arsenic to pentavalent arsenic to prepare for the subsequent precipitation reaction, without the use of oxidants, reducing the cost of raw materials;

[0060] Step 2, then add Bayer process red mud particles to the heated aeration tank after step 1 treatment, the Bayer process red mud selected in this embodiment contains Fe 2 o 3 :31wt%, CaO:13wt%, Na 2 0:4wt%, adjust the iron-arsenic molar ratio in the reaction system to be about 1.18, and the pH value of the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com