A method for preparing foam glass from solid waste

A foam glass and waste glass technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of failure to achieve co-processing of multiple types of solid waste, failure to use solid waste containing organic substances, and low capacity for solid waste co-utilization. problems, to achieve the effect of anti-seepage maintenance costs, improve economic and environmental benefits, and no post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

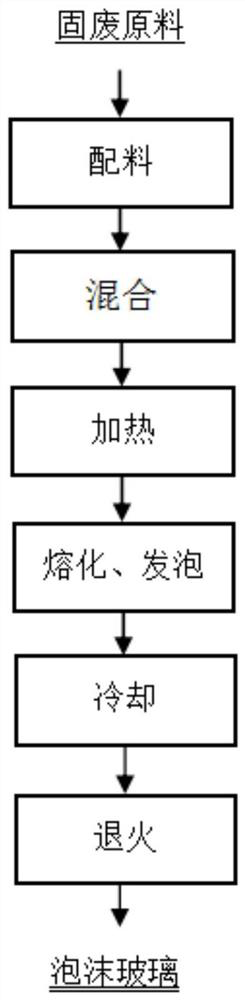

Method used

Image

Examples

Embodiment 1

[0033] Oil sludge, sludge, fly ash, waste glass and quartz sand are used as raw materials, and their contents are 60.0%, 5.0%, 5.0%, 5.0% and 25.0% respectively. Mix the proportioned raw materials evenly to obtain a mixture, the particle size is less than 2.00 mm, and the dispersion is greater than 55%. After the mixture is heated to 700°C to melt and foam, it is quickly lowered to 500°C to obtain foam glass, and then slowly cooled to room temperature to obtain foam glass products. The thermal conductivity of foam glass is 0.01 W / (m K); the flame retardant performance is tested according to GB / T 5464-2010, the temperature rise in the furnace is less than 50°C, the mass loss rate is less than 50%, and the continuous burning time is less than 20s.

Embodiment 2

[0035] Oil sludge, sludge, fly ash, waste glass and quartz sand are used as raw materials, and their contents are 5.0%, 60.0%, 5.0%, 5.0% and 25.0% respectively. Mix the proportioned raw materials evenly to obtain a mixture, the particle size is less than 1.80mm, and the dispersion is greater than 50%. After the mixture is heated to 1500°C to melt and foam, it is quickly lowered to 700°C to obtain foam glass, and then slowly cooled to room temperature to obtain foam glass products. The thermal conductivity of foam glass is 0.11W / (m K); the flame retardant performance is tested according to GB / T 5464-2010, the temperature rise in the furnace is less than 45°C, the mass loss rate is less than 45%, and the continuous burning time is less than 14s.

Embodiment 3

[0037] Oil sludge and fly ash are used as raw materials, and their contents are 5.0% and 95.0% respectively. Mix the proportioned raw materials evenly to obtain a mixture, the particle size is less than 1.80mm, and the dispersion is greater than 70%. After the mixture is heated to 1400°C to melt and foam, it is quickly lowered to 650°C to obtain foam glass, and then slowly cooled to room temperature to obtain foam glass products. The thermal conductivity of foam glass is 0.06W / (m K); the flame retardant performance is tested according to GB / T 5464-2010, the temperature rise in the furnace is less than 47°C, the mass loss rate is less than 34%, and the continuous burning time is less than 17s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com