Method for preparing high-strength geopolymer cementing material from aluminum ash

A geopolymer and gelling material technology, which is applied in the field of green disposal and resource utilization of solid waste, can solve the problems of difficult secondary pollutant treatment, low strength of geopolymer products, aluminum nitride pollution, etc., and achieve environmental protection Small burden, reduced consumption, and the effect of avoiding the release of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

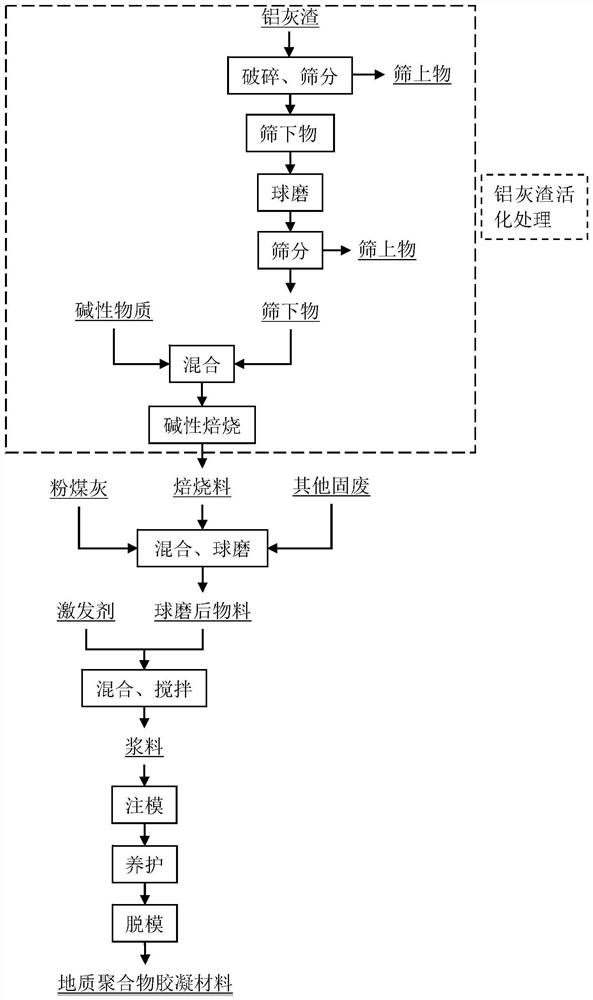

Method used

Image

Examples

Embodiment 1

[0027] The extrusion crushing device was used to crush the aluminum ash for 30 minutes. The crushed aluminum ash was sieved through a 30-mesh screen to remove coarse materials such as metal aluminum. The weight of the underscreen accounted for 91% of the total weight of the crushed material. The crushed material was dry-milled in a ball mill for 60 minutes, and the aluminum ash slag after ball milling was sieved through a 300-mesh sieve to remove difficult-to-grind materials, and the weight of the underscreen accounted for 98% of the total weight of the ball-milled materials. The ball-milled and sieved aluminum ash was mixed with alkali and calcined at 200 °C for 5 h. The alkali is sodium hydroxide, and the amount of alkali is 30% of the weight of aluminum ash. Mix aluminum ash slag activation material with high-calcium fly ash (calcium oxide content 12%), red mud, steel slag and ball mill. In the mixed material: aluminum ash slag activation material 60 wt.%, fly ash 20 wt.%, ...

Embodiment 2

[0029] The aluminum ash slag was crushed for 60 min by extrusion crushing device, and the crushed aluminum ash slag was sieved through a 30-mesh screen to remove coarse materials such as metal aluminum, and the weight of the underscreen accounted for 97% of the total weight of the crushed material. The crushed material was dry-milled in a ball mill for 240 minutes, and the aluminum ash slag after ball milling was sieved through a 300-mesh sieve to remove difficult-to-grind materials. The ball-milled and sieved aluminum ash was mixed with alkali and calcined at 1100°C for 1 h. The alkali is potassium hydroxide, and the alkali consumption is 5% of the weight of aluminum ash. The aluminum ash slag activation material is mixed with low calcium fly ash (calcium oxide content 7%), red mud, steel slag and ball milled. In the mixed material: aluminum ash slag activation material 30 wt.%, fly ash 40wt.%, red Mud 10 wt.%, steel slag 20 wt.%. Add a mixture of potassium hydroxide and wa...

Embodiment 3

[0031]The extrusion crushing device was used to crush the aluminum ash for 40 minutes. The crushed aluminum ash was sieved through a 30-mesh screen to remove coarse materials such as metal aluminum. The weight of the underscreen accounted for 98% of the total weight of the crushed material. The crushed material was dry-milled in a ball mill for 200 minutes, and the aluminum ash slag after ball milling was sieved through a 300-mesh sieve to remove difficult-to-grind materials, and the weight of the undersize accounted for 99% of the total weight of the ball-milled materials. The ball-milled and sieved aluminum ash was mixed with alkali and calcined at 900 °C for 2 h. The alkali is a mixture of potassium hydroxide and sodium hydroxide, and the amount of alkali used is 30% of the weight of aluminum ash. Mix aluminum ash slag activation material with high-calcium fly ash (calcium oxide content 15%), slag, steel slag and ball mill. In the mixed material: aluminum ash slag activatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com