Method of enriching valuable metals through collaborative smelting of gold-antimony deposit and auriferous pyrite cinder

A technology of pyrite slag and valuable metals, which is applied in the field of non-ferrous metallurgy, can solve the problems of large output of slag, difficulty in comprehensive utilization, and long recycling process, so as to reduce the smelting temperature, reduce the consumption of primary resources, Optimizing the effect of the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

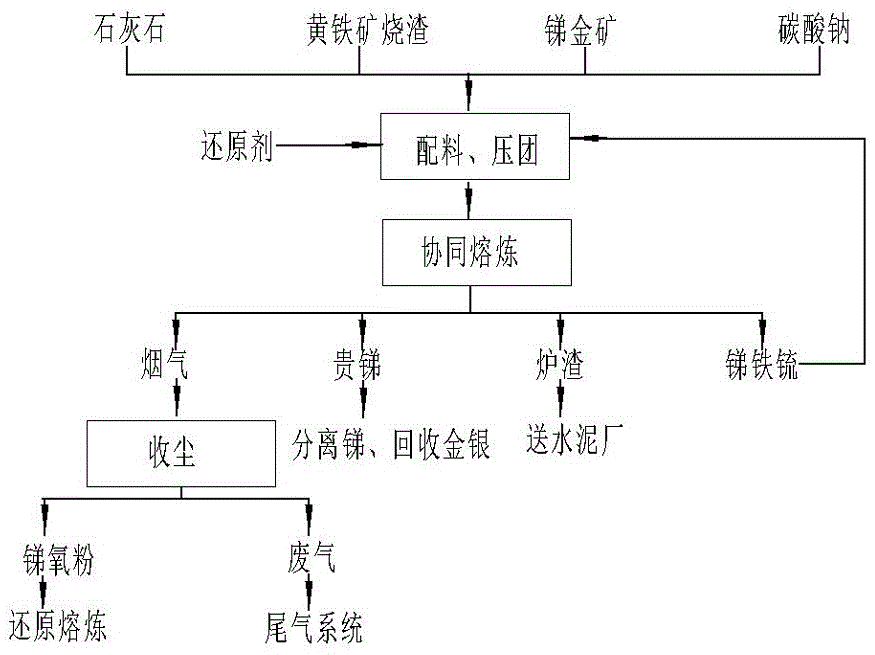

[0045] The process flow chart is attached figure 1 shown. The main components of the gold-containing antimony concentrate as the test raw material in this example are (wt.%): Sb 37.21, Fe 13.27, S 30.60, Cu 0.085, Pb 0.18, Bi 0.026, As 0.034, SiO 2 7.14、Al 2 o 3 2.26, CaO 0.079, Au 56.6g / t; the composition (wt.%) of pyrite slag is: TFe 53.54, Cu 0.24, Zn0.17, Pb 0.08, MgO 0.49, CaO 1.82, SiO 2 10.41, Al 2 o 3 2.56, S 0.52, Au 5.08g / t, Ag36.47g / t; the chemical composition (wt. %) of reducing agent coke powder is: C 84.56, S 2.79, SiO 2 5.17, CaO 1.03, Al 2 o 3 3.94, MgO 0.42; the chemical composition (wt. %) of limestone is: SiO 2 1.20, CaO 53.07, Al 2 o 3 0.94, MgO1.42.

[0046] S1. Weigh 200g of antimony-gold ore, 60g of pyrite slag, 40g of coke powder, 10g of sodium carbonate, and 20g of limestone of the above ingredients, and mix all the materials evenly and put them into a corundum crucible.

[0047] S2. Put the material into an electric furnace for volat...

Embodiment 2

[0049] Test raw materials, reagents and steps are the same as in Example 1.

[0050] S1. Weigh 200g of antimony-gold ore, 40g of pyrite slag, 20g of coke powder, 40g of sodium carbonate and 10g of limestone of the above components.

[0051] S2. After mixing all materials evenly, put them into a corundum crucible, put them into an electric furnace and volatilize and melt at 900°C for 4.0 hours.

[0052] After cooling, the products were separated to obtain 66.83g of crude antimony, 4.55g of antimony iron matte, 169.02g of slag, and 2.17g of dust were collected. According to chemical analysis, the contents of antimony in the above products were 97.40%, 46.02%, 2.01% and 72.33%, respectively, and the percentages of the total antimony in the raw materials were 92.03%, 1.86%, 3.01% and 3.15%, respectively. The contents of gold and silver in crude antimony are 168g / t and 32.20g / t respectively, and the calculated direct recovery rates of gold and silver are 89.06% and 84.33% respecti...

Embodiment 3

[0054] Test raw materials, reagents and steps are the same as in Example 1.

[0055] S1. Weigh 1000g of antimony-gold ore, 300g of pyrite slag, 300g of coke powder, 20g of sodium carbonate and 65g of limestone of the above components.

[0056] S2. After mixing all the materials evenly, put them into a corundum crucible, put them into an electric furnace and volatilize and melt at 1200°C for 1.0h.

[0057] After cooling, the products were separated to obtain 338.01 g of crude antimony, 20.71 g of antimony iron matte, 1005.65 g of slag, and 20.49 g of dust were collected. According to chemical analysis, the contents of antimony in the above products were 93.01%, 42.19%, 1.52% and 72.07%, respectively, and the percentages of the total antimony in the raw materials were 92.72%, 1.66%, 2.33% and 5.09%, respectively. The contents of gold and silver in crude antimony are 183g / t and 40.17g / t respectively, and the calculated direct recovery rates of gold and silver are 97.80% and 98.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com