Method for repairing organic-heavy metal composite contaminated soil by coupling chemical oxidation with biochar enhanced microorganisms

A technology of microbial remediation and oxidation coupling, applied in the field of enhanced remediation of organic-heavy metal compound polluted soil, can solve the problems of pollutants that are difficult to completely remove oxidant ecological risks, compound pollution, etc., to solve ecological risk problems, promote complete removal, and ensure restoration efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

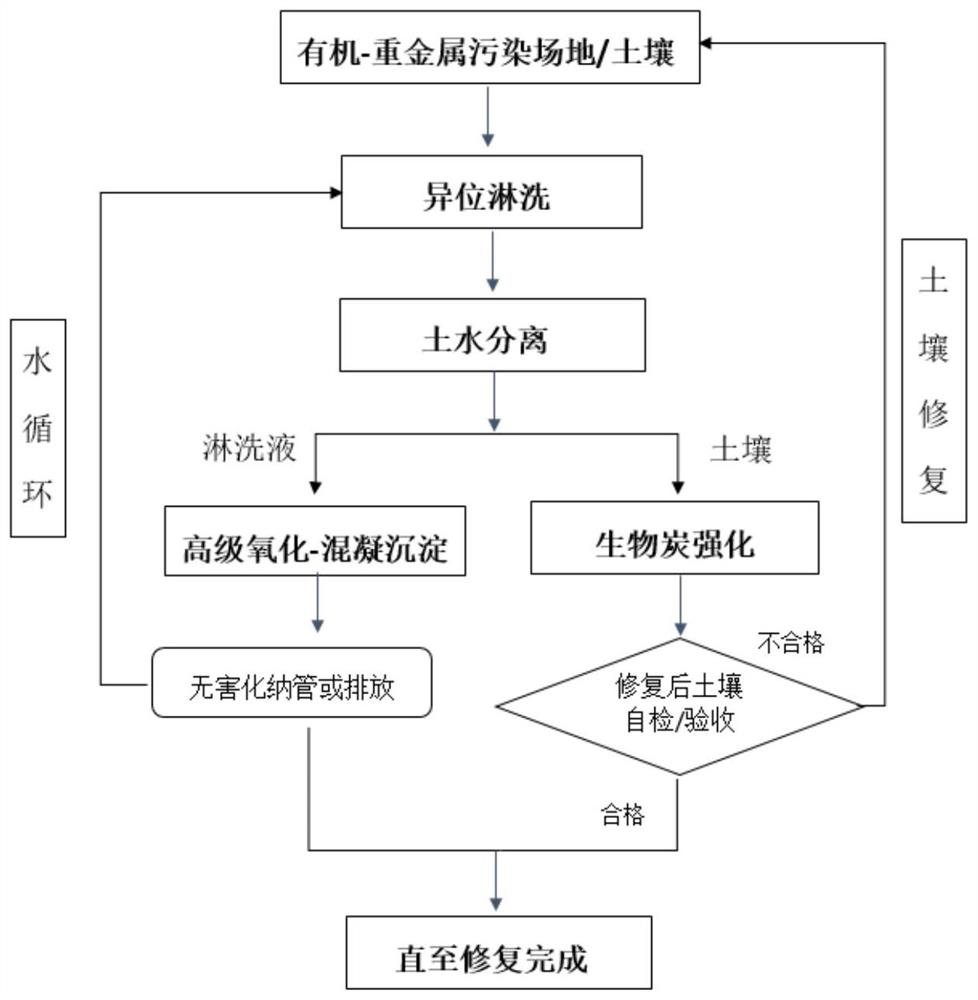

[0028] Such as figure 1 As shown, this example provides a method for chemical oxidation coupled with biochar to strengthen microbial remediation of organic-heavy metal compound polluted soil, using ectopic remediation, including the following steps:

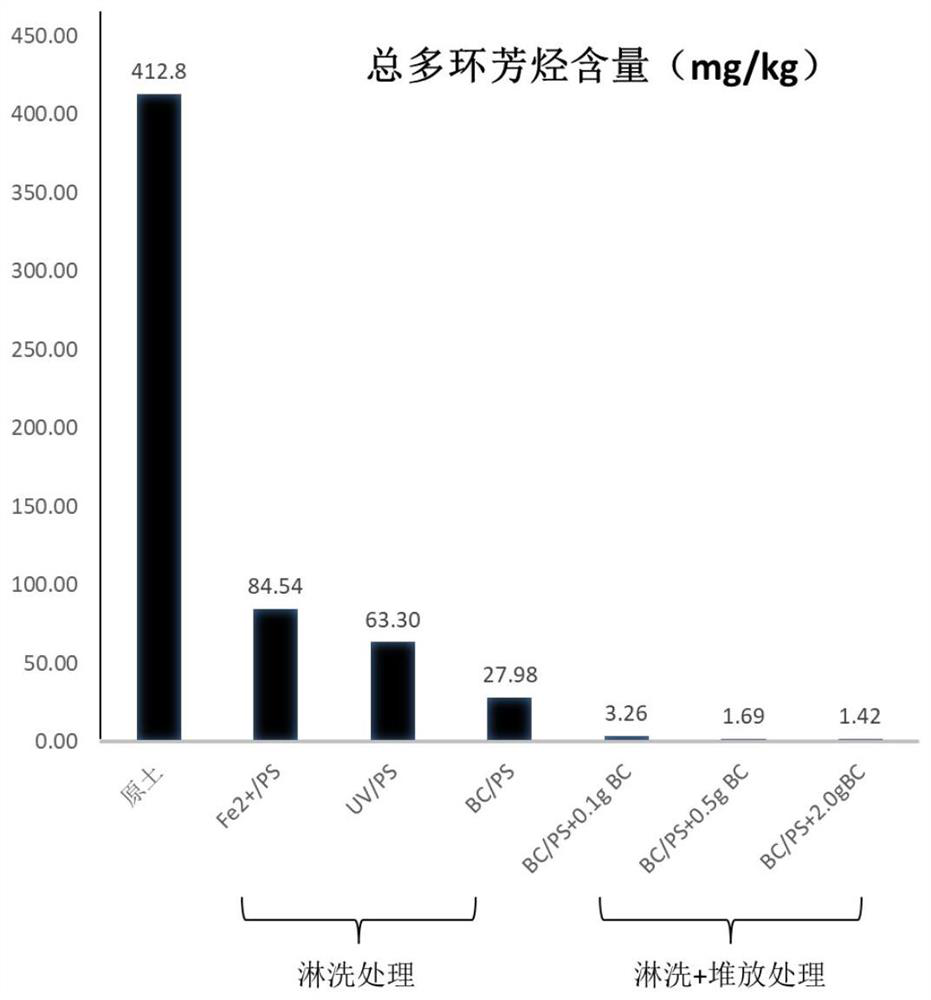

[0029] Step S100: Rinse: crush 100kg of soil with a mixing cutter, send it to a drum stone washing machine, remove stones and coarse sand larger than 4mm, and send it to the leaching tank (using a large stainless steel + resin tank) , add water in different proportions (1:3, 1:4, 1:5 volume ratio), adjust the pH to 5, add sodium persulfate powder to make the concentration of sodium persulfate in the reaction tank 0.5 ~ 0.8mM, add sulfuric acid Ferrous and biochar powder activated potassium persulfate, the dosage ratio is as follows, or the method of activation by ultraviolet light irradiation, stirring vigorously (200-300r / min) for 30 minutes, then stirring at a stirring rate of 100-150r / min for 15 minutes Minutes stand.

[003...

Embodiment 2

[0042] Step S100 is the same as that in Embodiment 1, and will not be repeated here.

[0043] Step S101: Use an acid-resistant filter press to filter the soil-water mixed liquid in step S100, and the final dehydration efficiency reaches 85%. The filtered water is introduced into the reaction pool through the conduit. Collect the mud cake, and pile it into the soil stacking reaction tank after the quality reaches 100kg.

[0044] Step S102, spraying biochar powder in the soil reactor tank, the dosage is 0.1g / kg (biochar / soil) dosage ratio, keep the soil moisture content above 60%, adjust the pH of the pile soil to be 7, the pile body The temperature is 37 degrees Celsius, and the soil is piled up for 14 days.

[0045] Step S103, soil pile acceptance: the unqualified soil returns to step S100 or step S101 until the repair is qualified, and the repair is completed.

[0046] Also includes the following steps:

[0047] Step S104, place the eluate separated in step S101 in advanc...

Embodiment 3

[0050] Step S100 is the same as that in Embodiment 1, and will not be repeated here.

[0051] Step S101: Use an acid-resistant filter press to filter the soil-water mixed liquid in step S100, and the final dehydration efficiency reaches 85%. The filtered water is introduced into the reaction pool through the conduit. Collect the mud cake, and pile it into the soil stacking reaction tank after the quality reaches 100kg.

[0052] Step S102, spray biochar powder in the soil reactor tank, the dosage is 0.5g / kg (biochar / soil) dosage ratio, keep the soil moisture content more than 60%, adjust the pH of the pile soil to be 7, the pile body The temperature is 37 degrees Celsius, and the soil is piled up for 14 days.

[0053] Step S103, soil pile acceptance: the unqualified soil returns to step S100 or step S101 until the repair is qualified, and the repair is completed.

[0054] Also includes the following steps:

[0055] Step S104, place the eluate separated in step S101 in advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com