Processing and recycling method for waste aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and recycling methods, which is applied in the field of recycling and industrial waste treatment, can solve the problems of great harm to the ecological environment and human health, achieve high recovery rate and purity, clean treatment process, and high degree of recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

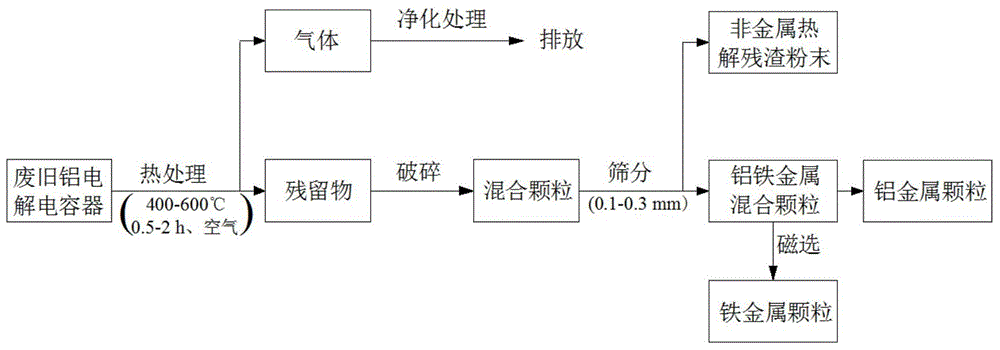

Image

Examples

Embodiment 1

[0029] First, raise the temperature of the muffle furnace to 500°C and keep it at a constant temperature, then put the waste aluminum electrolytic capacitor disassembled from the waste printed circuit board into the muffle furnace and heat it for 60 minutes to heat the non-metallic components. The pyrolysis process of waste aluminum electrolytic capacitors loses 38.08% of the weight during the pyrolysis process. The tail gas generated during the pyrolysis process naturally flows out through the gas discharge channel and is discharged after being adsorbed by activated carbon; the pyrolysis residues of waste aluminum electrolytic capacitors are taken out and sent to into the shearing crusher, the crushing time is 45 seconds, and the dissociation degree of metal and non-metal materials is 100%; then the crushed materials are screened with a 0.18mm screen to completely separate the metal components from the non-metal components, Thereby obtain aluminum-iron metal mixed particle, ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com