Incorporated double settling zone tridimensional circulating oxidation ditch facility and method of operating thereof

A three-dimensional circulation and oxidation ditch technology, applied in chemical instruments and methods, separation methods, precipitation and separation, etc., can solve the problems of large floor space, increased water flow resistance, poor operation adjustment performance, etc., and achieves good effect and unique reflux method. , Improve the effect of hydraulic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

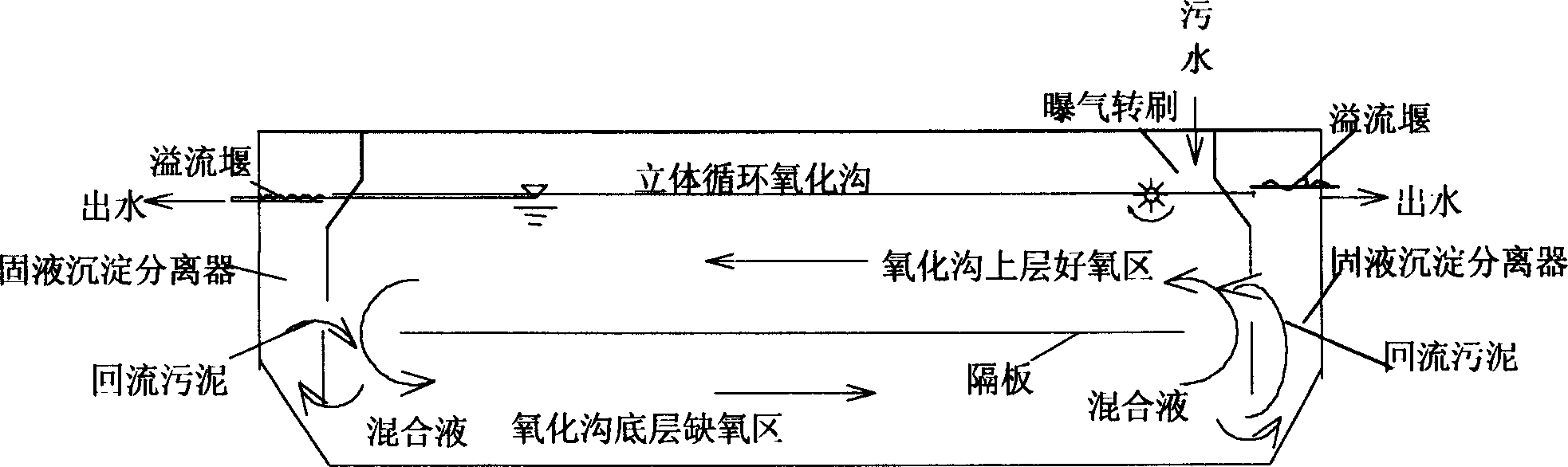

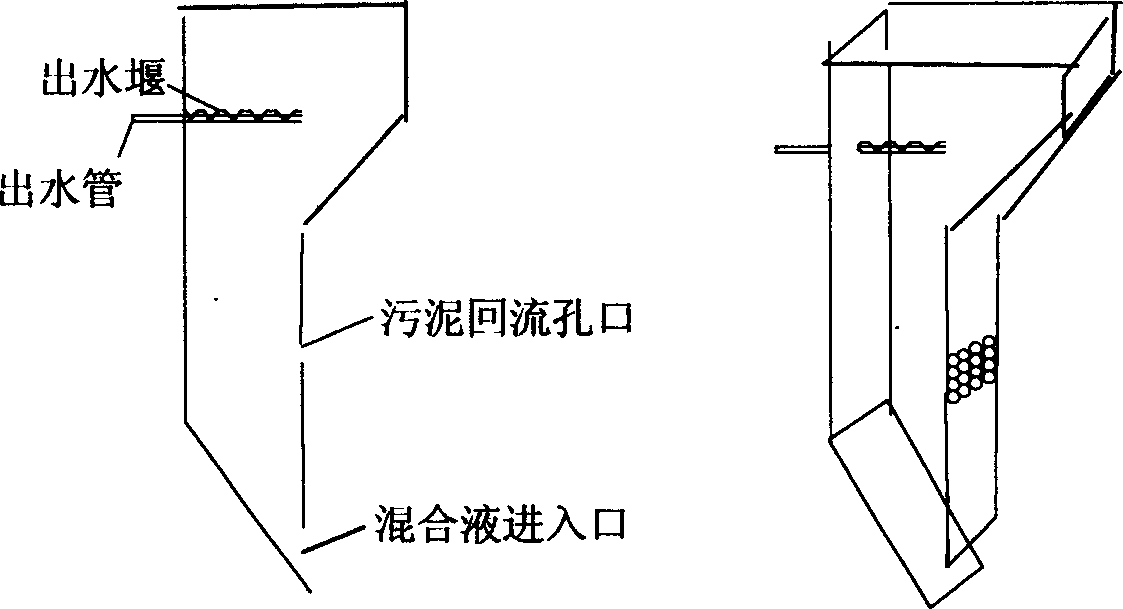

[0038] A three-dimensional circulation integrated oxidation ditch, the oxidation ditch is divided into upper and lower parts by a partition, and there are channels on both sides, the upper part is an aerobic area, and the lower part is an anoxic area; on the side wall of the upper part of the three-dimensional circulation oxidation ditch There is a water inlet, and an aeration brush driven by a motor is installed in front of the water inlet; solid-liquid sedimentation separators are respectively installed on the side walls at both ends of the three-dimensional circulation oxidation ditch, and the solid-liquid sedimentation separator is separated by a sloping plate. The inlet of the mixed solution is covered as an inclined opening, and an overflow weir and a water outlet are provided on the upper side wall, and a sludge return port is opened on the other side wall at the lower part of the three-dimensional circulation oxidation ditch.

[0039] The sewage containing COD of 110-440m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com