Lateral precipitation and stereoscopic circulation integrated oxidation ditch equipment and operation method

A technology of three-dimensional circulation and lateral precipitation, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as large footprint and poor system operation and regulation performance, and achieve Small footprint, improved matching, and simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

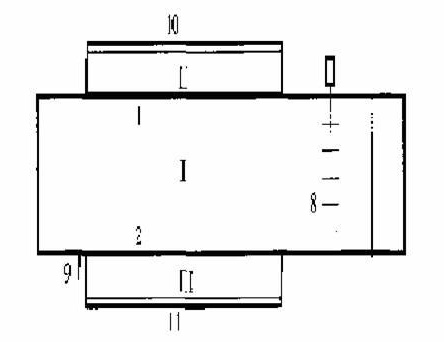

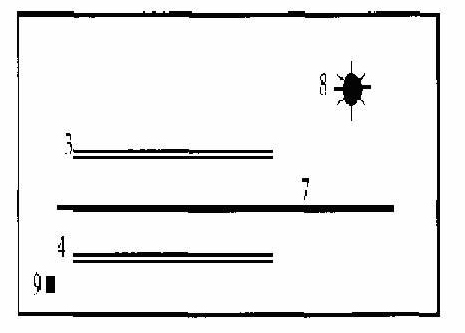

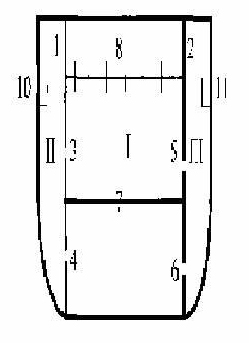

[0035] See figure 1 , figure 2 and image 3 .

[0036] The integrated oxidation ditch equipment of lateral sedimentation stereo circulation includes stereo circulation oxidation ditch I, left lateral sedimentation solid-liquid separator II and right lateral sedimentation solid-liquid separator III.

[0037] The lateral sedimentation solid-liquid separator is respectively located on the left side and the right side of the three-dimensional circulation oxidation ditch, and the left lateral precipitation solid-liquid separator and the left side wall of the three-dimensional circulation oxidation ditch which is an inner hollow box A left wall 1 is shared, and the right wall 2 of the three-dimensional circulation oxidation ditch shares the right wall 2 with the right lateral sedimentation solid-liquid separator.

[0038] Inside the three-dimensional circulation oxidation ditch which is an inner hollow box, there is a transverse partition 7 to divide the three-dimensional circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com