Sewage denitrogenation dephosphorylation treatment method by using biological film to filter

A technology for denitrification, dephosphorization, and treatment methods, applied in the field of sewage treatment, can solve the problems of increased operating costs, high membrane module costs, and high operating costs, and achieves reduction of pool volume and area, easy operation and operation, and project saving. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

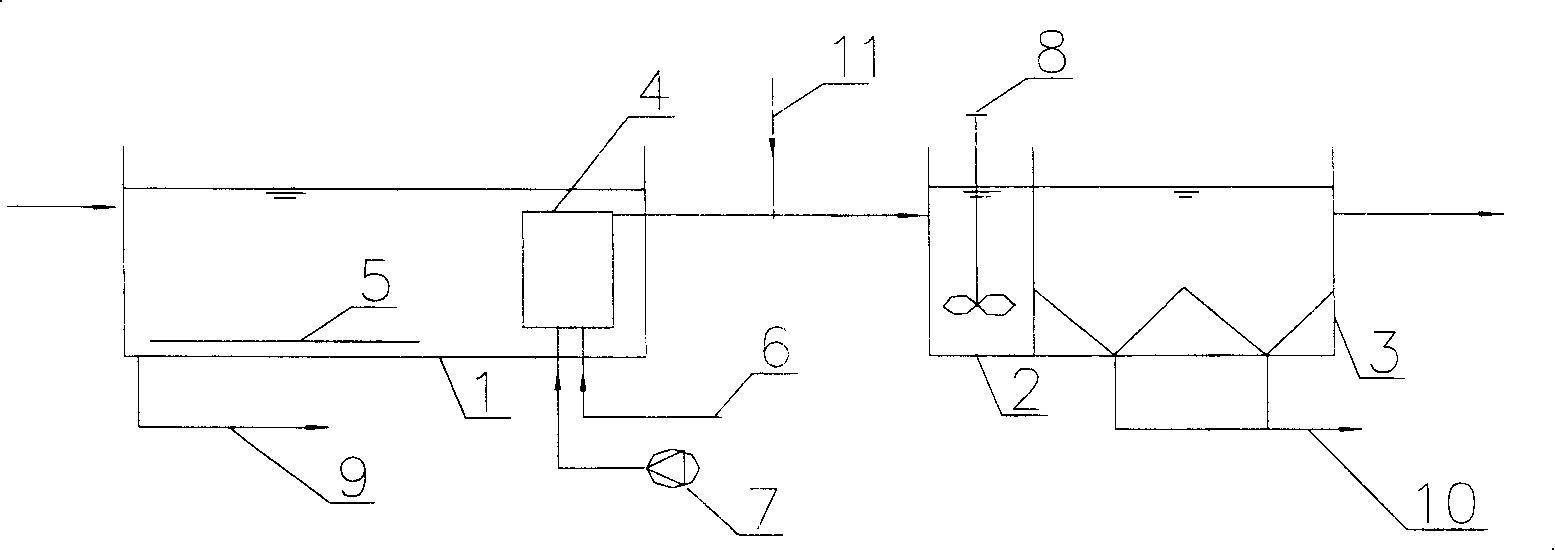

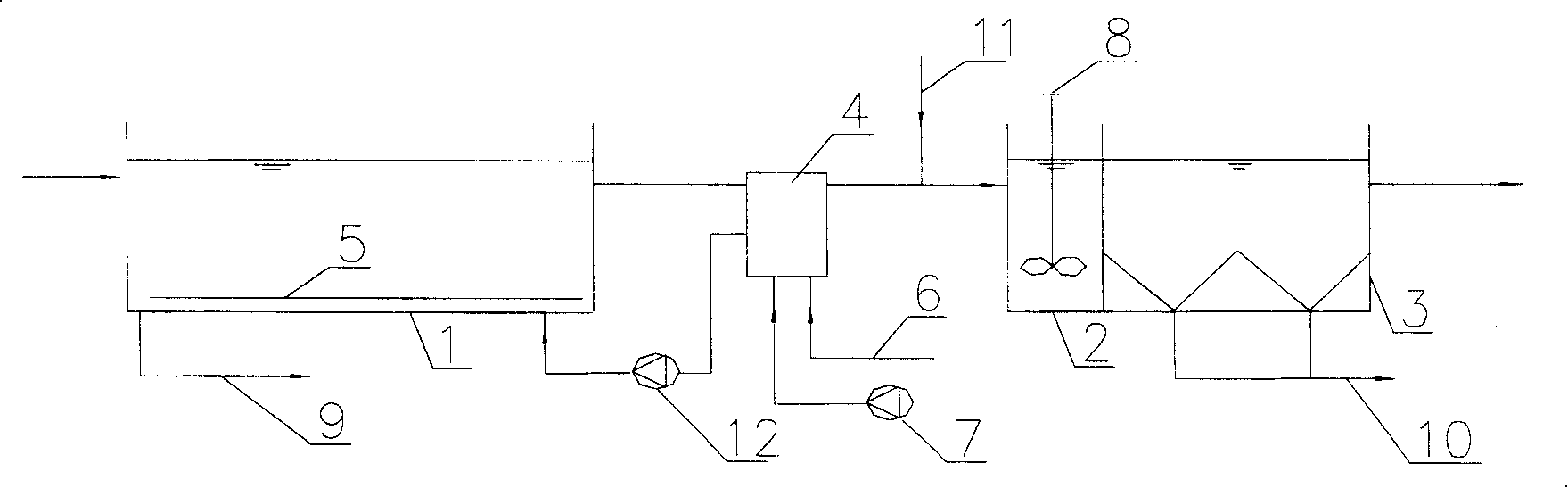

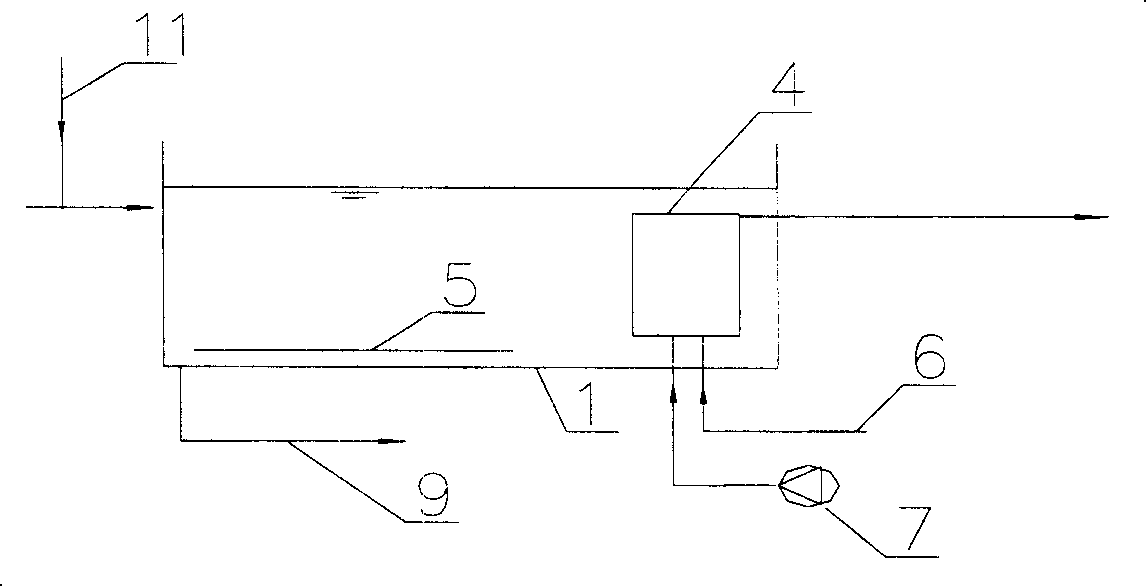

[0011] Below in conjunction with accompanying drawing and embodiment 1, the present invention will be further described.

[0012] In the method of the present invention, a biofilm filter is set in the aeration tank to replace the traditional secondary sedimentation tank for mud-water separation; the specific operation process is: firstly, the sewage enters the activated sludge aeration tank (1), and a filter is installed in the aeration tank (1). The aerator (5) performs aeration, and the organic matter and ammonia nitrogen in the sewage are oxidized, decomposed and nitrified under the action of microorganisms in the aeration tank, and a biofilm filter (4) is set in the aeration tank, and the biofilm filter (4) It is composed of stainless steel or filter cloth filter screen. The average pore size of the stainless steel or filter cloth filter screen is 10-200 μm. The activated sludge forms a dynamic biofilm on the filter screen. After the sewage is filtered by the biofilm filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com