Developing solution wastewater treatment system

A wastewater treatment system and developer technology, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. Biochemical treatment of problems such as the reduction of the carbon-nitrogen ratio of the effluent, to achieve the effects of improving biochemical properties, saving the area occupied by system equipment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

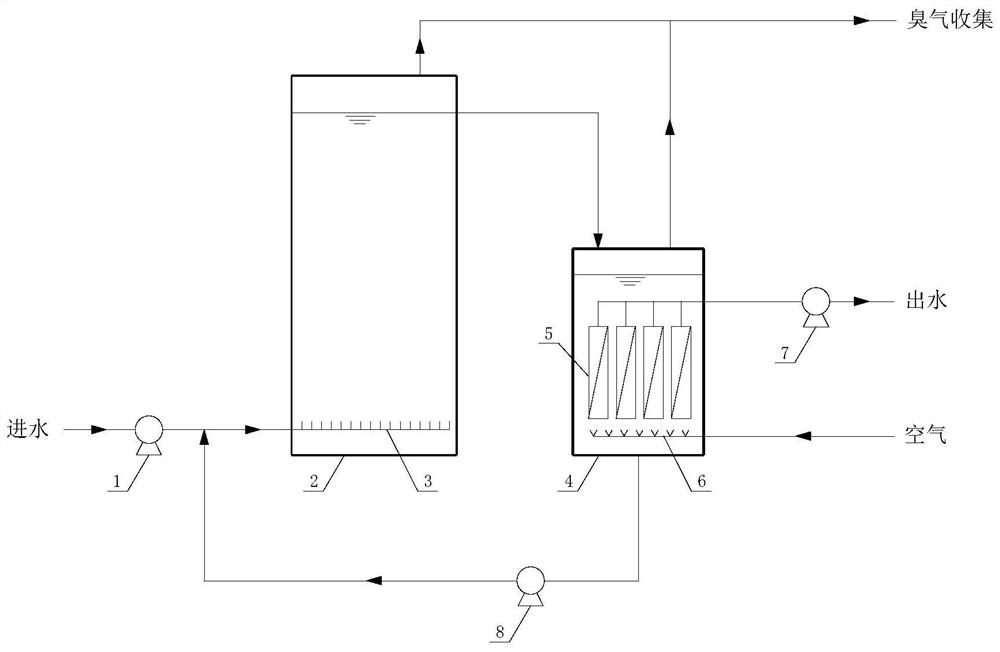

[0023] as attached figure 1 Shown, a kind of developing solution wastewater treatment system of the present invention is mainly made up of TMAH decomposition reaction tank 2 and membrane separation tank 4, and TMAH decomposition reaction tank 2 is bioreactor, is anaerobic or low dissolved oxygen environment in the pond, and TMAH decomposition reaction The dissolved oxygen in pool 2 is less than 0.5mg / L, and the TMAH in the developer wastewater is decomposed into organic amine compounds such as trimethylamine, dimethylamine and monomethylamine through the action of hydrolyzing microorganisms; the sludge concentration in TMAH decomposition reaction pool 2 is 8g / L L--20g / L; pH value between 6.5--7.5; its volume load is greater than 2 kgTMAH / m 3 d.

[0024] As a further improvement, the TMAH decomposition reaction tank 2 is a closed water tank, the water inlet is located at the bottom of the reaction tank, the water inlet is connected to the outlet pipe of the external water inle...

Embodiment 2

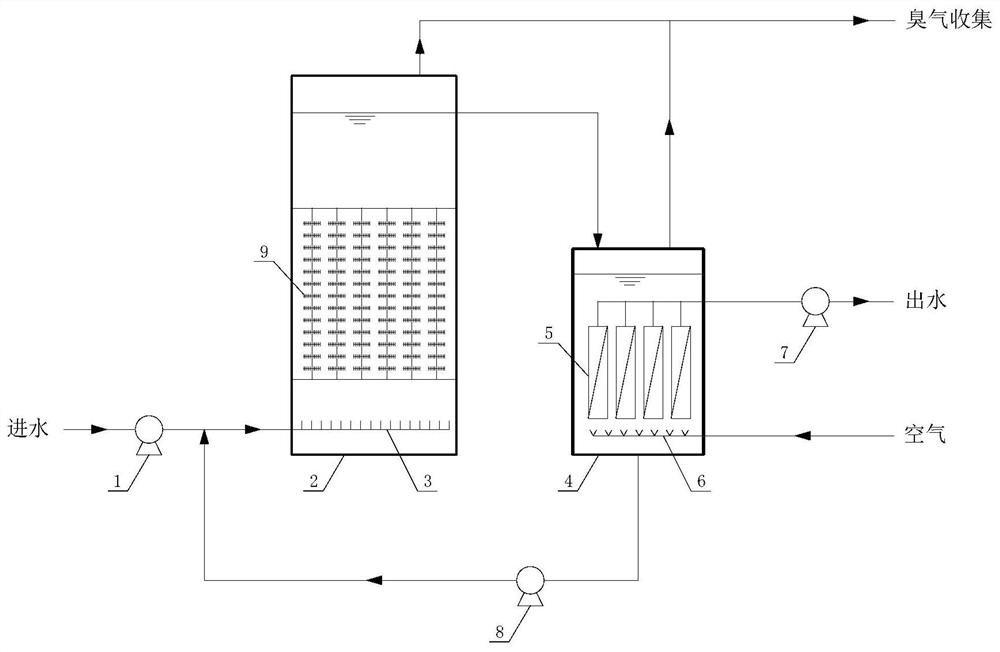

[0039] Improvement is made on the basis of a kind of developing liquid wastewater treatment system in embodiment 1, as attached figure 2As shown, biological filler is set in the TMAH decomposition reaction tank, so that the hydrolysis microorganisms can attach to the filler, so as to increase the sludge concentration in the reaction tank, thereby improving the efficiency of TMAH decomposition. Biological fillers are commercially available combined fillers or braided fillers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com