Box-type postprocessor assembly

A post-processor and assembly technology, applied in the field of auto parts, to achieve the effect of strong noise reduction, low back pressure, and reduced radiation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] Taking the selective catalytic reduction post-processor as an example, the structural design and manufacturing process of the assembly will be described in detail below.

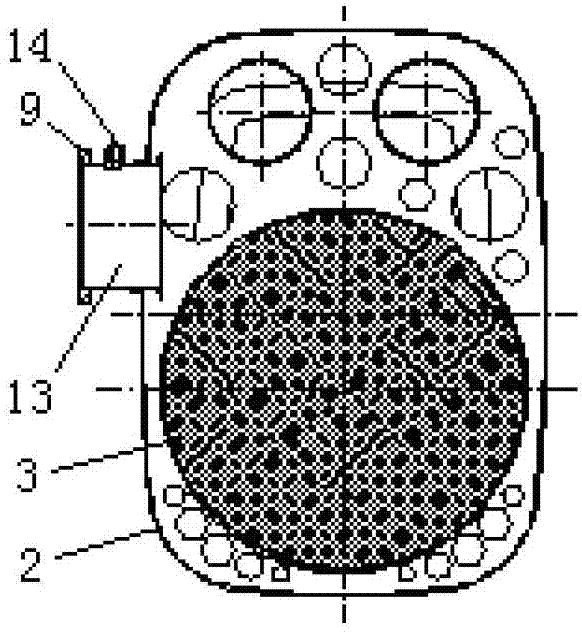

[0030] The device of the present invention that can reduce engine exhaust pollutants and exhaust noise has a box-like shape, a flange connection to the air inlet, a temperature sensor 14, and a nitrogen-oxygen sensor 16 behind the post-processing unit. .

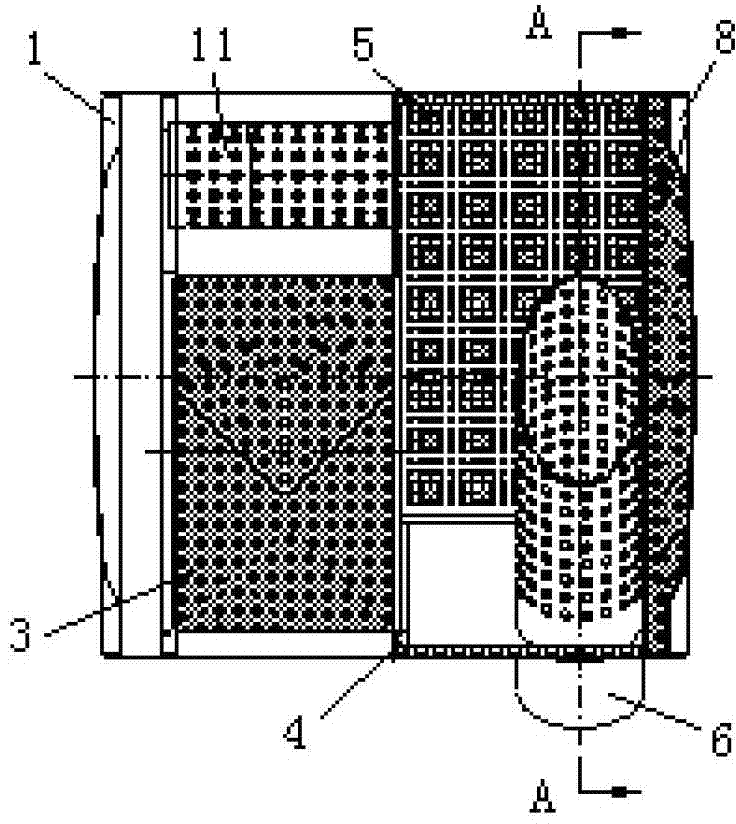

[0031] The device of the present invention that can reduce engine exhaust pollutants and exhaust noise includes a mixing unit, a post-processing unit, and a noise reduction unit. noise effect.

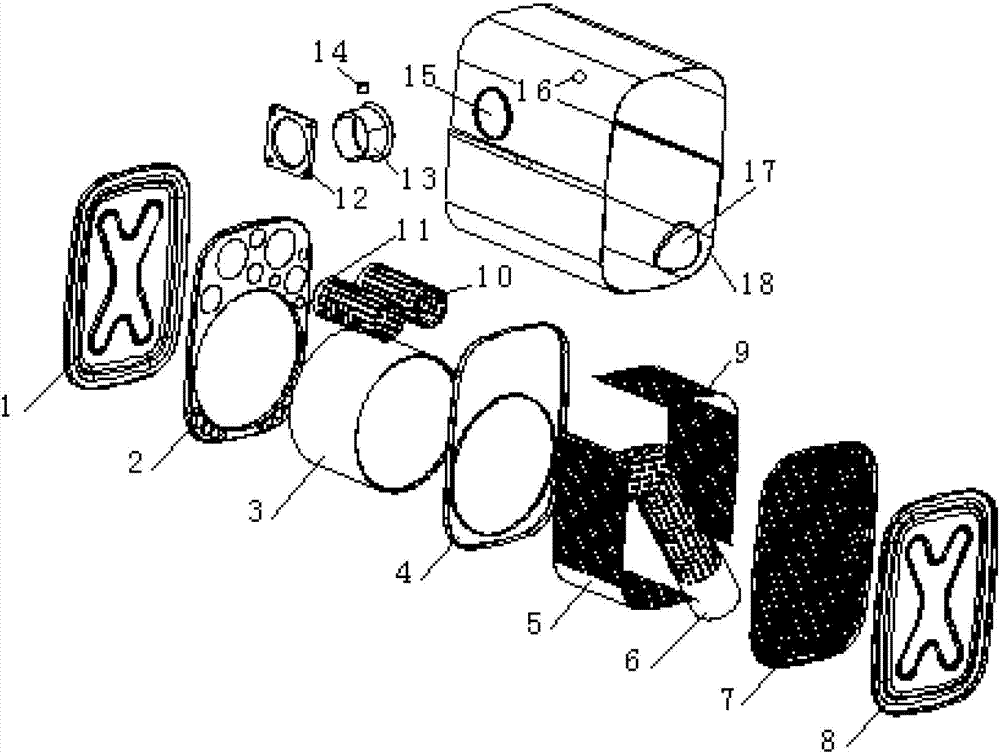

[0032] like figure 1 As shown, the mixing unit in the present invention is formed by the intake pipe 13, the shell 18, the partition I2, the partition II4, the aftertreatment package assembly 3, the sound absorption pipe I10, the sound absorption pipe II11, the left end cover 1 and the right end cover 8 The post-proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com