Door closing device

A door closer and door shaft technology, applied in the field of auxiliary buffer structure, can solve the problems of insufficient oil volume, oil leakage of the door closer, easy wear, etc., and achieve the effect of reducing the filling amount and preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

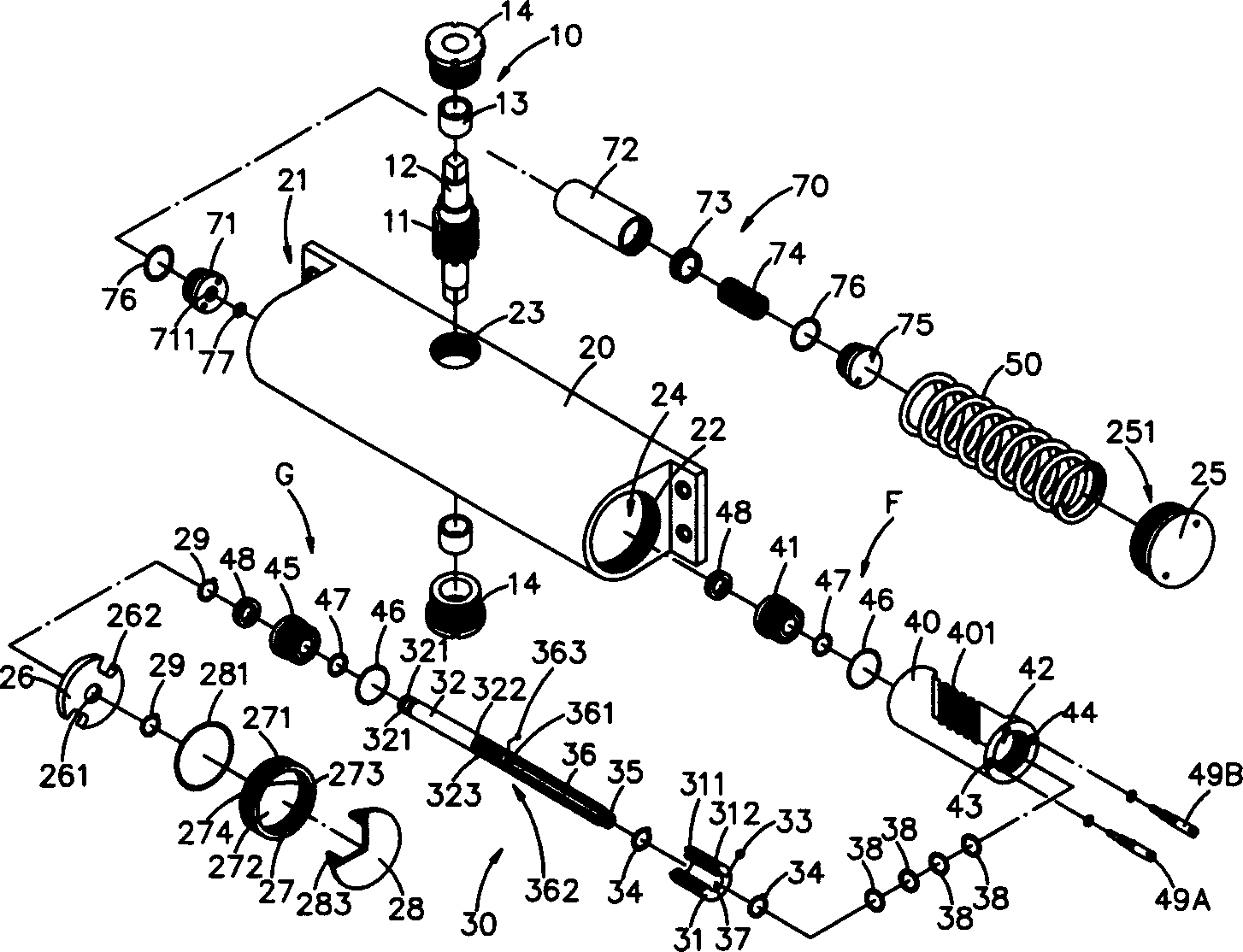

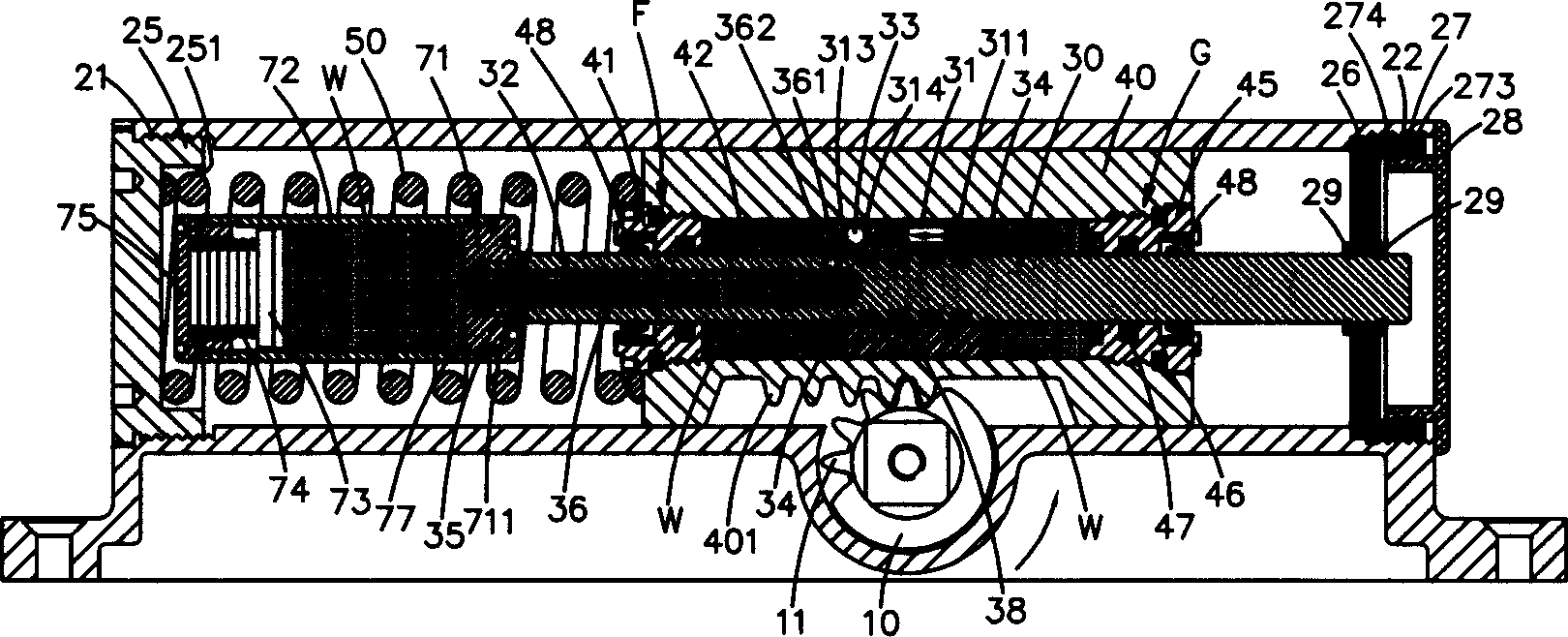

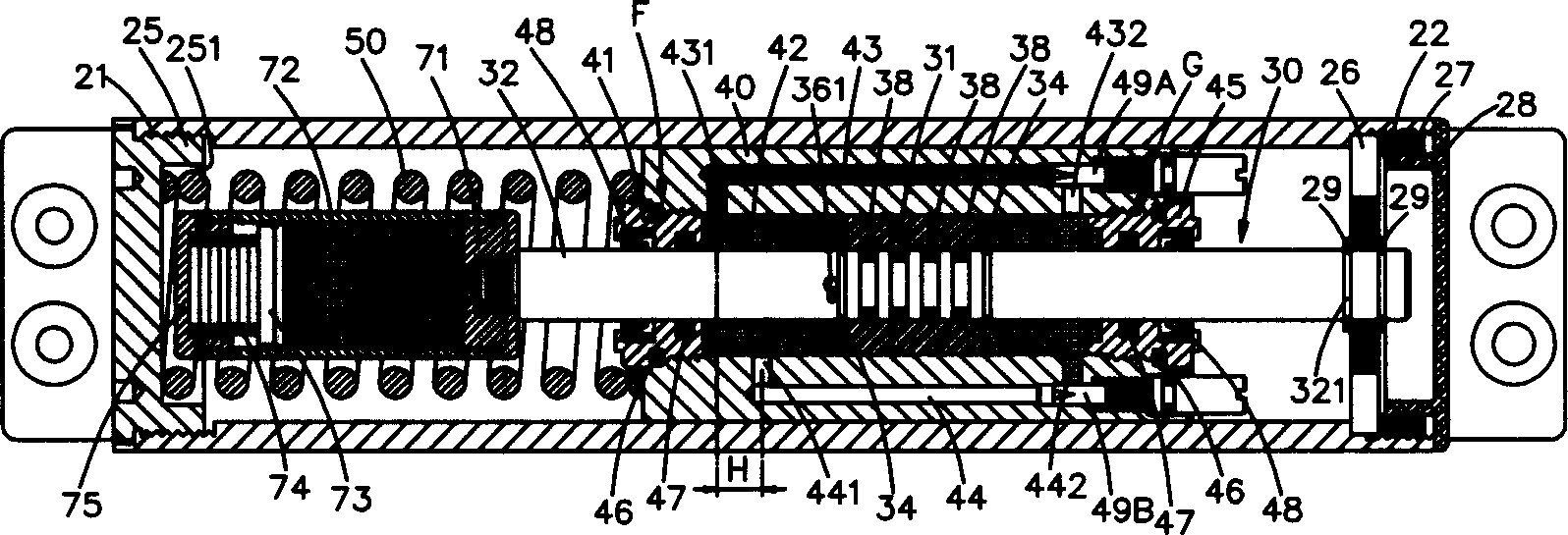

[0094] In order to achieve the above-mentioned purpose, technology, means and other effects of the present invention, hereby enumerate a preferred embodiment and describe it in detail in conjunction with the drawings. It is believed that the purpose, characteristics and other advantages of the present invention should be obtained from it. One in-depth and specific understanding; first please refer to the best embodiment shown in the 1st, 2, and 3 figures [because the embodiment figure numbers are numerous, please refer to the numbering in the 4th to 10th figures], the present invention is It is composed of a door shaft 10, a door closer body 20, a piston shaft 30, an actuating cylinder 40, a door closing spring 50, and an oil supply cylinder 70. The detailed structure is as follows:

[0095] The door shaft 10 is composed of a shaft body 12, two bearings 13 and a fixed cover 14, and the shaft body 12 is rotated with the door panel switch. gear 11.

[0096] The door closer body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com