Oil filter for treating dirty oil in electrical cabinet profile bending machine

A cabinet profile and bending machine technology, applied in the direction of filtration circuit, filtration separation, liquid degassing, etc., can solve the problem of inconspicuous filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

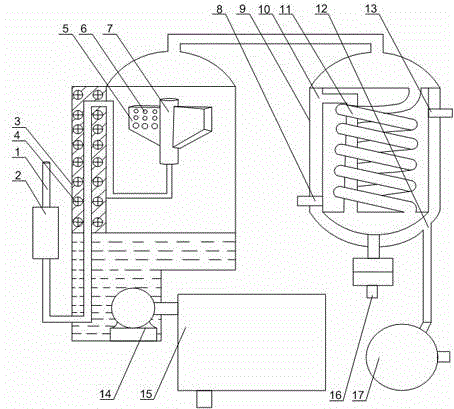

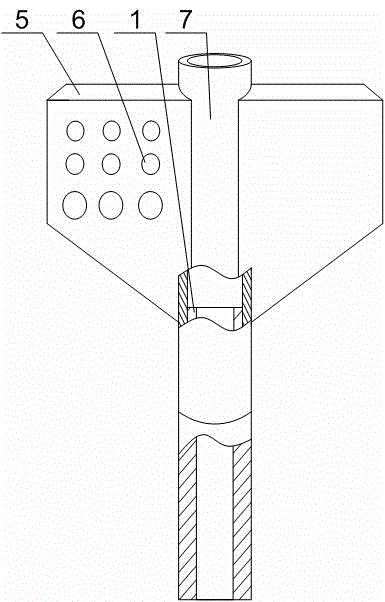

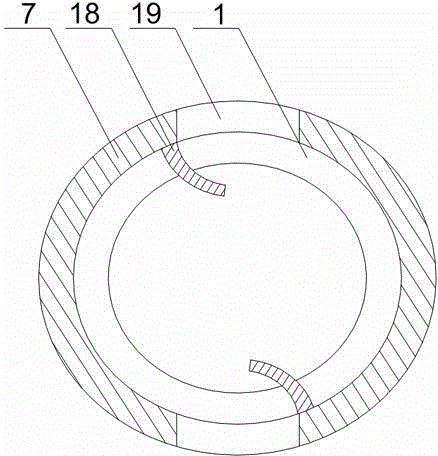

[0022] Such as Figure 1~Figure 3 As shown, this embodiment includes a filter tank 3 and an oil guide pipe 1 that runs through the outer wall of the filter tank 3 and is placed at the upper end of the filter tank 3. The top of the filter tank 3 communicates with the condensation tank 9 and is fixed on the side wall of the filter tank 3. There is a heating chamber, and the oil guide pipe 1 runs through the heating chamber, and a heater 4 is installed in the heating chamber, and an oil injection column 7 connected with the oil guide pipe 1 is rotated at the end of the oil guide pipe 1, and the oil injection column Hollow wing plates 5 are fixed on both sides of 7, and a plurality of oil injection holes 6 are opened on the opposite sides of the two wing plates 5, and a through hole communicating with the oil injection holes 6 is opened on the oil injection column 7, and the filter An oil pump 14 is fixed at the bottom of the tank 3, and the oil outlet end of the oil pump 14 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com