Patents

Literature

110results about How to "Convenient for centralized collection and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

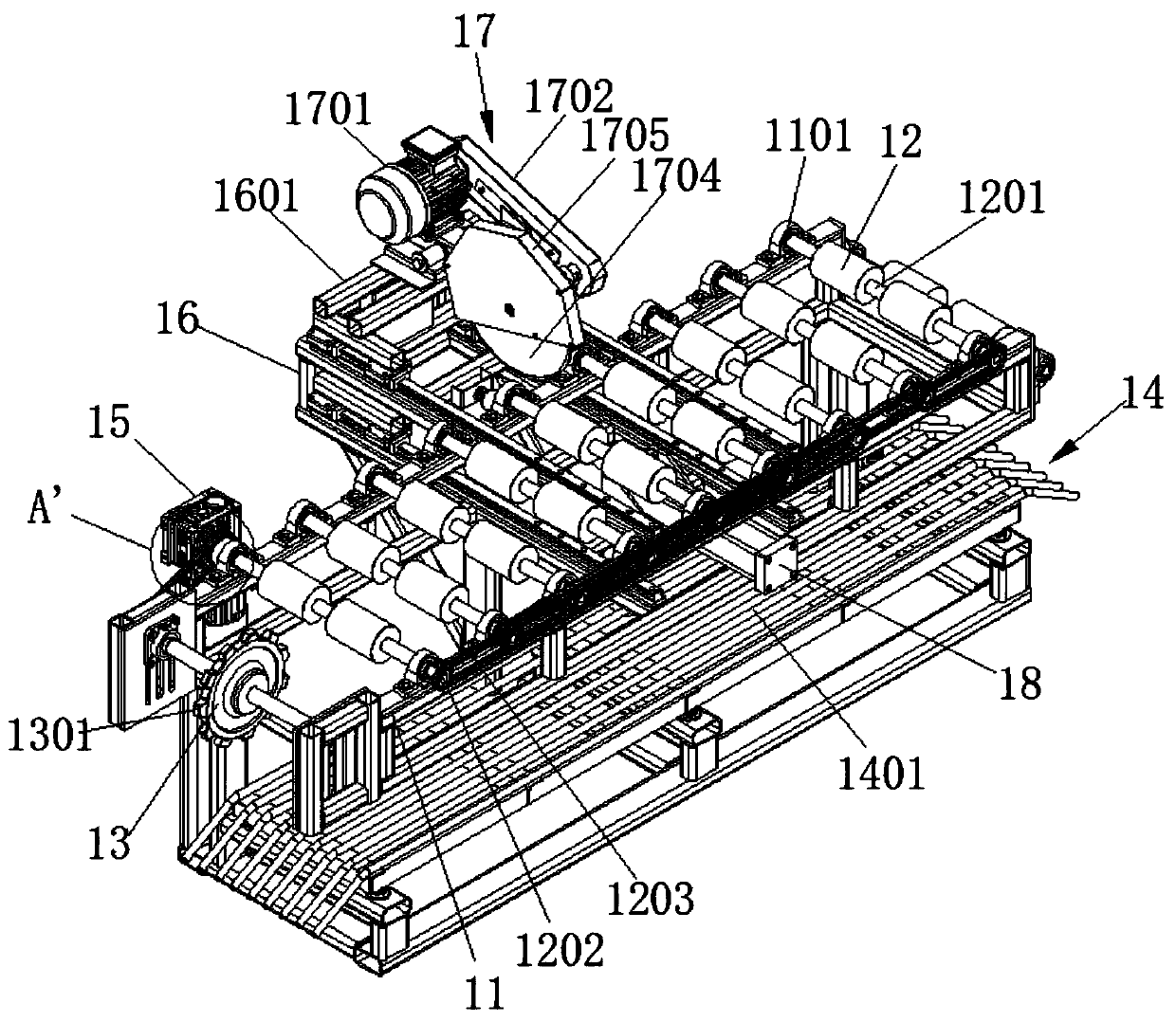

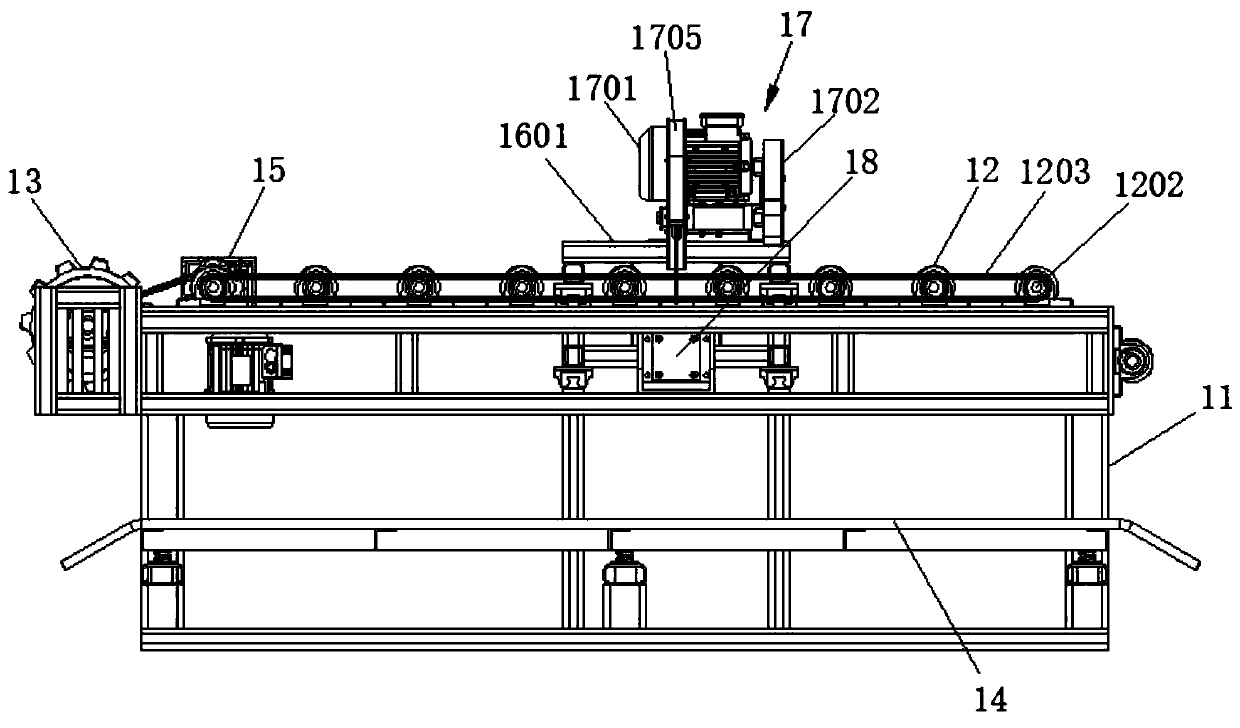

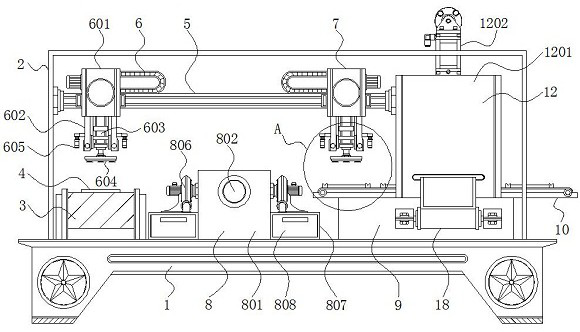

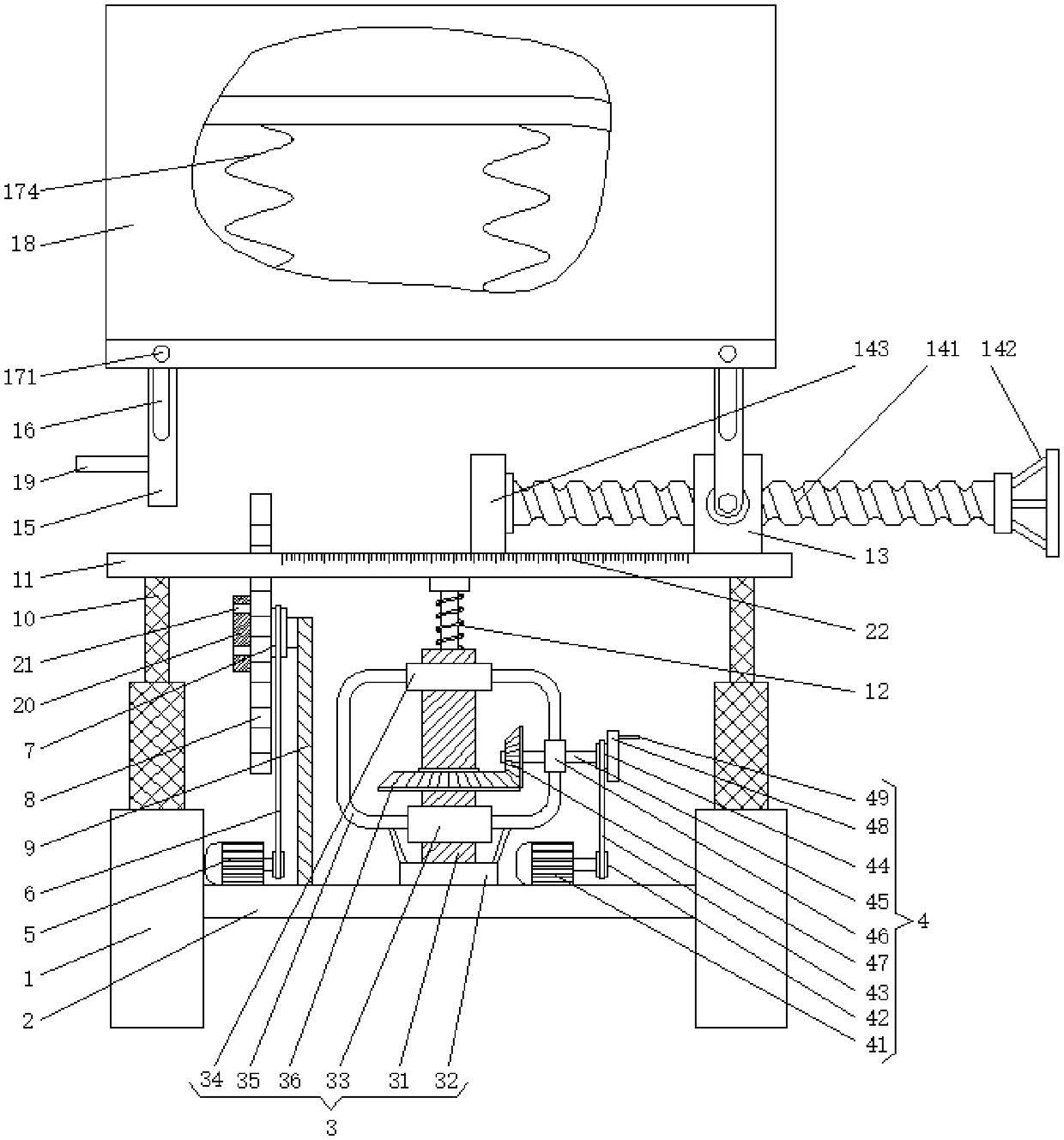

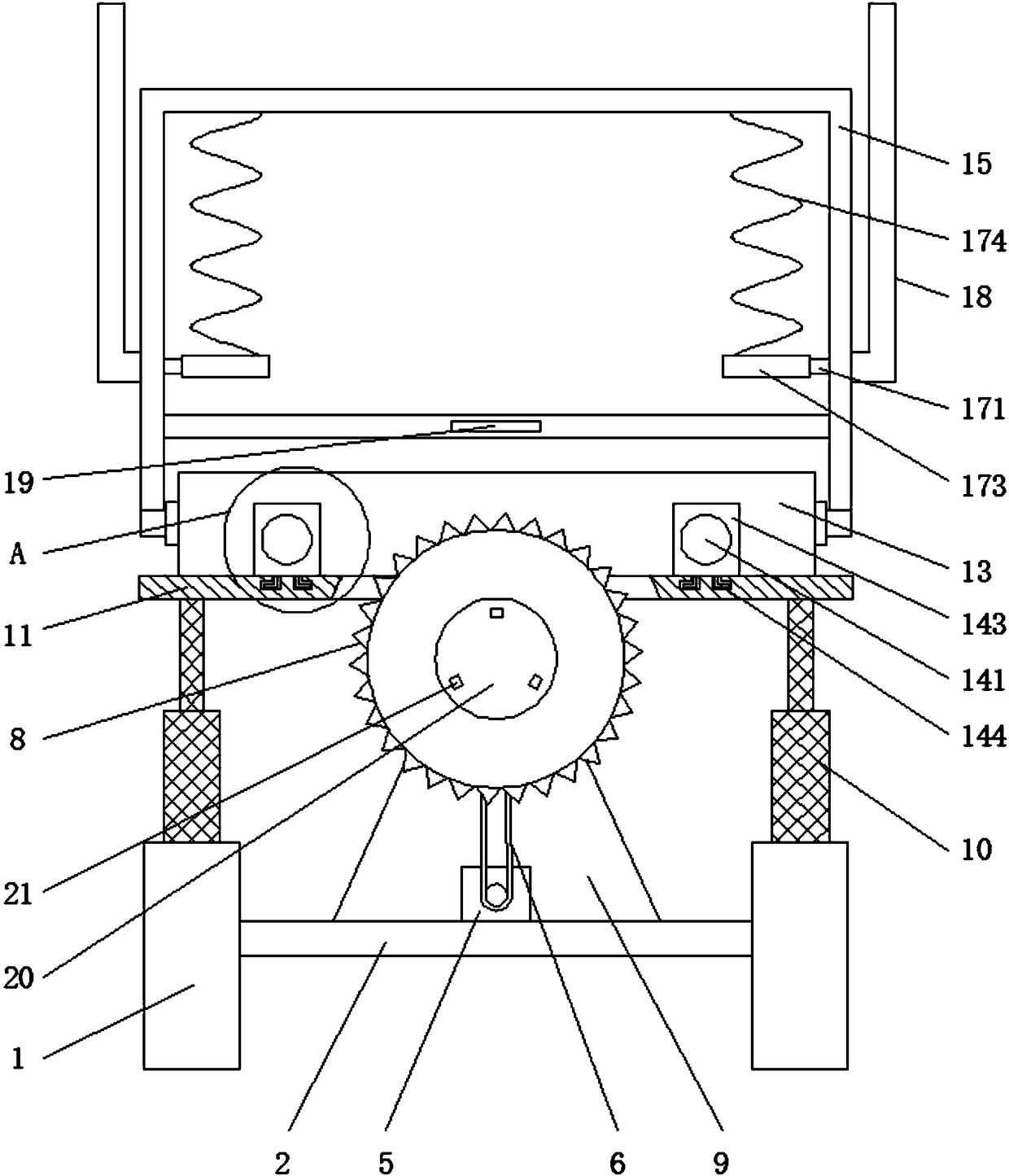

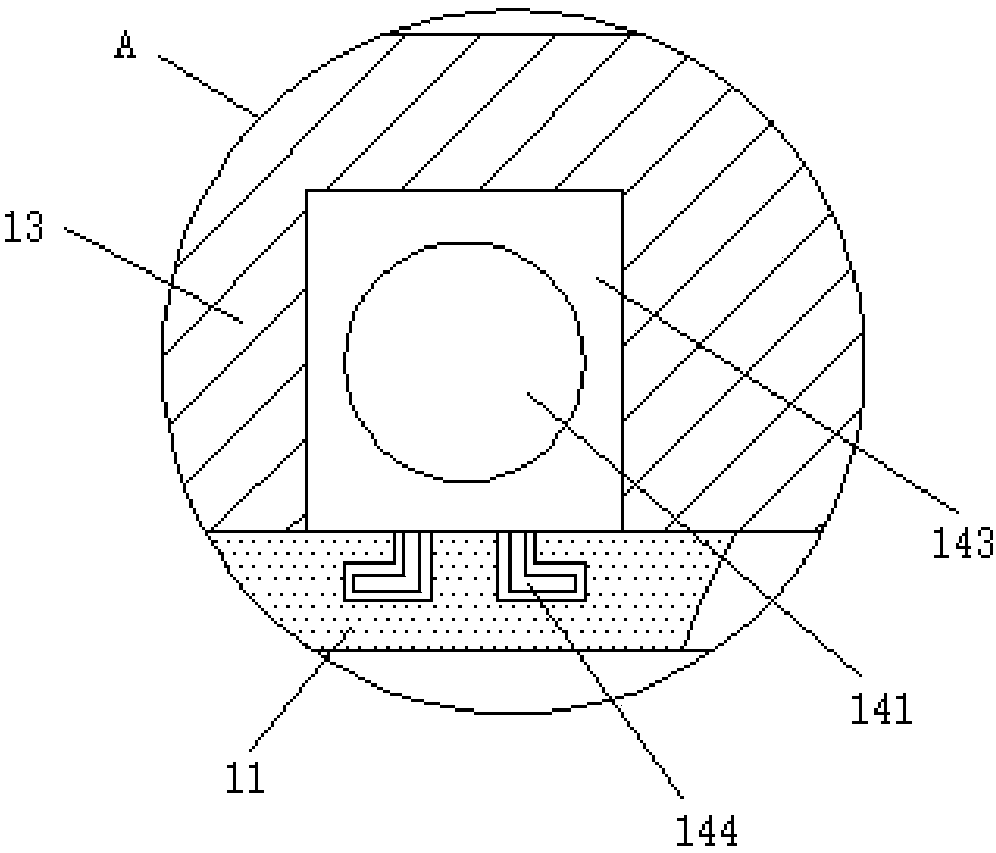

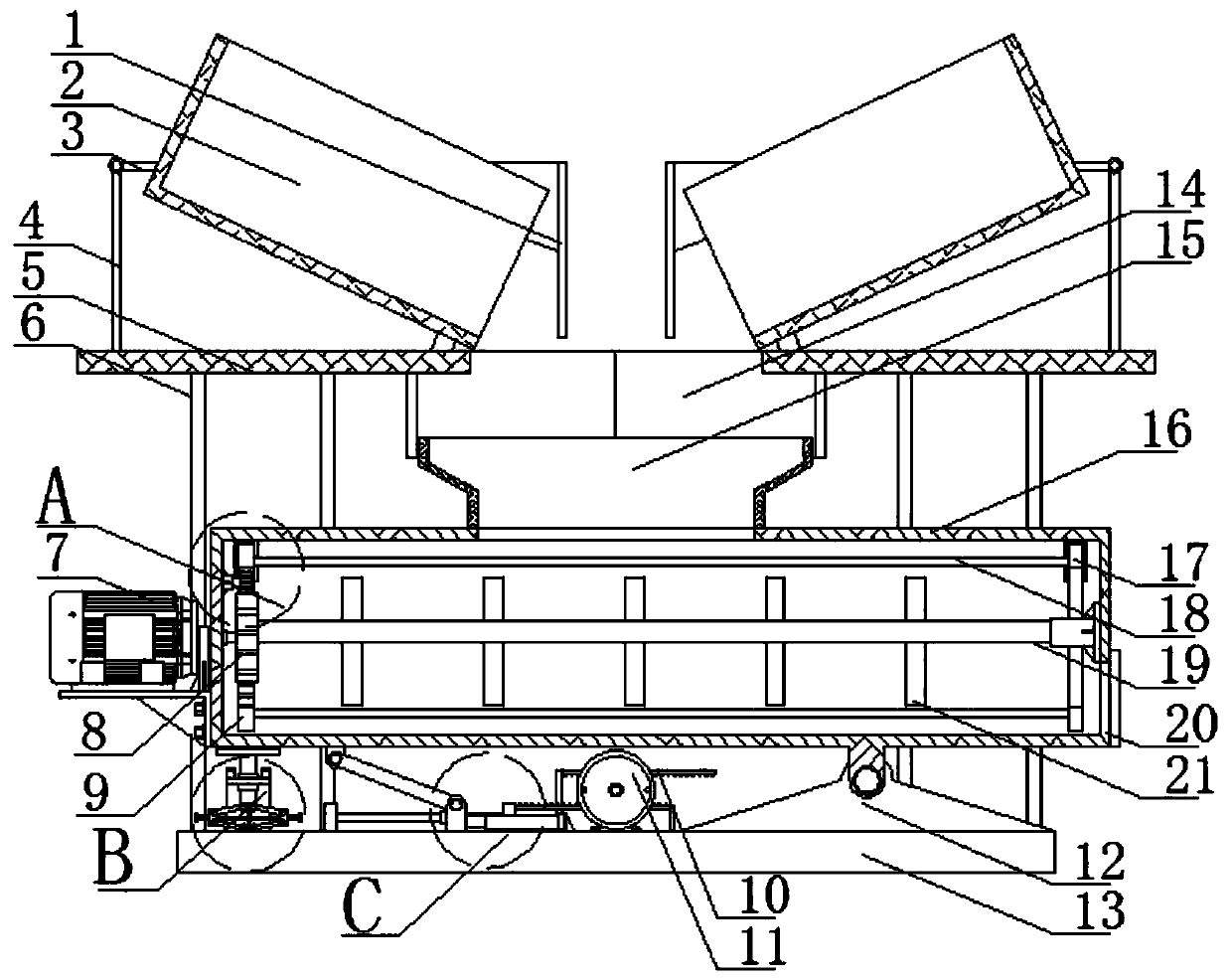

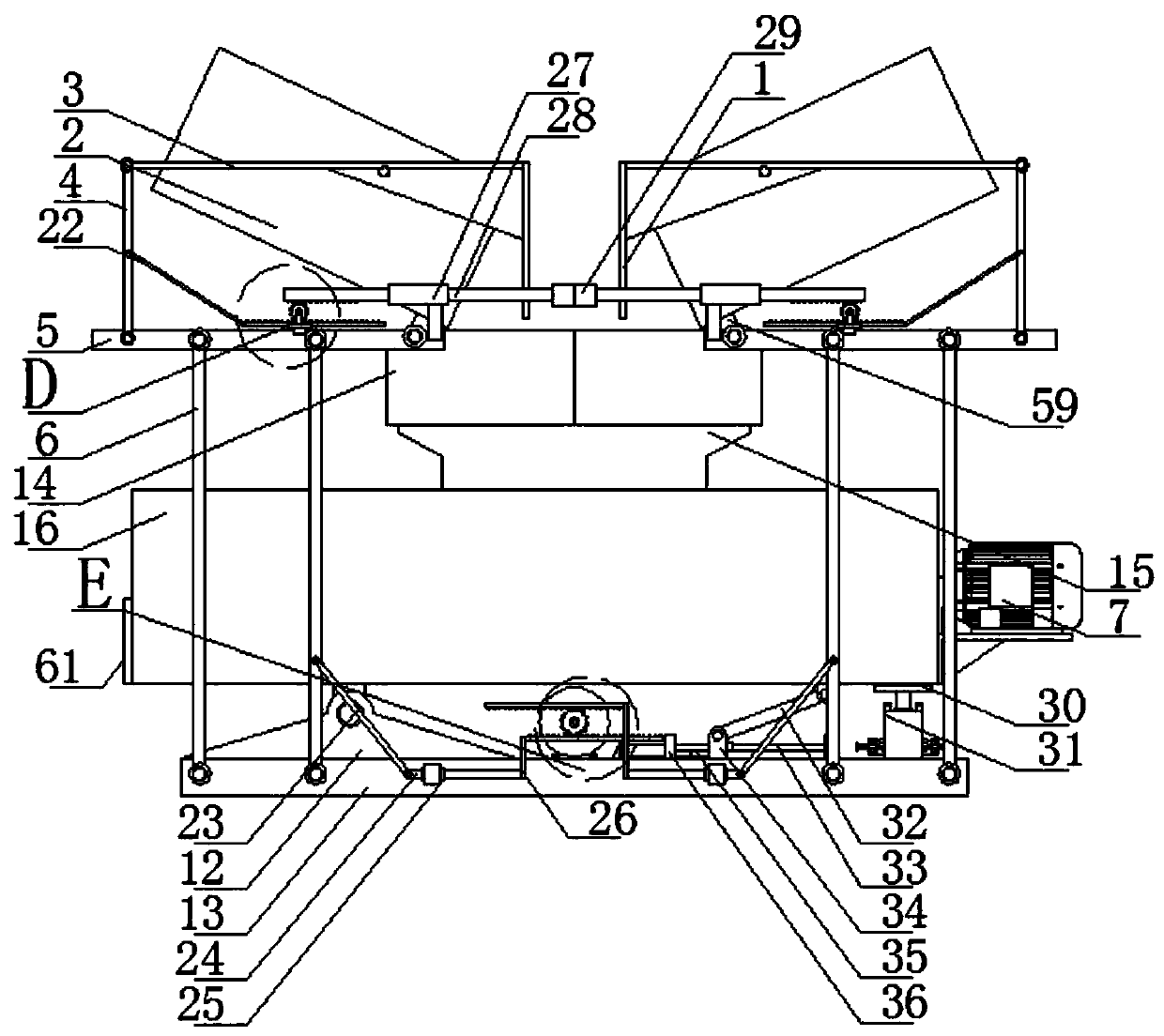

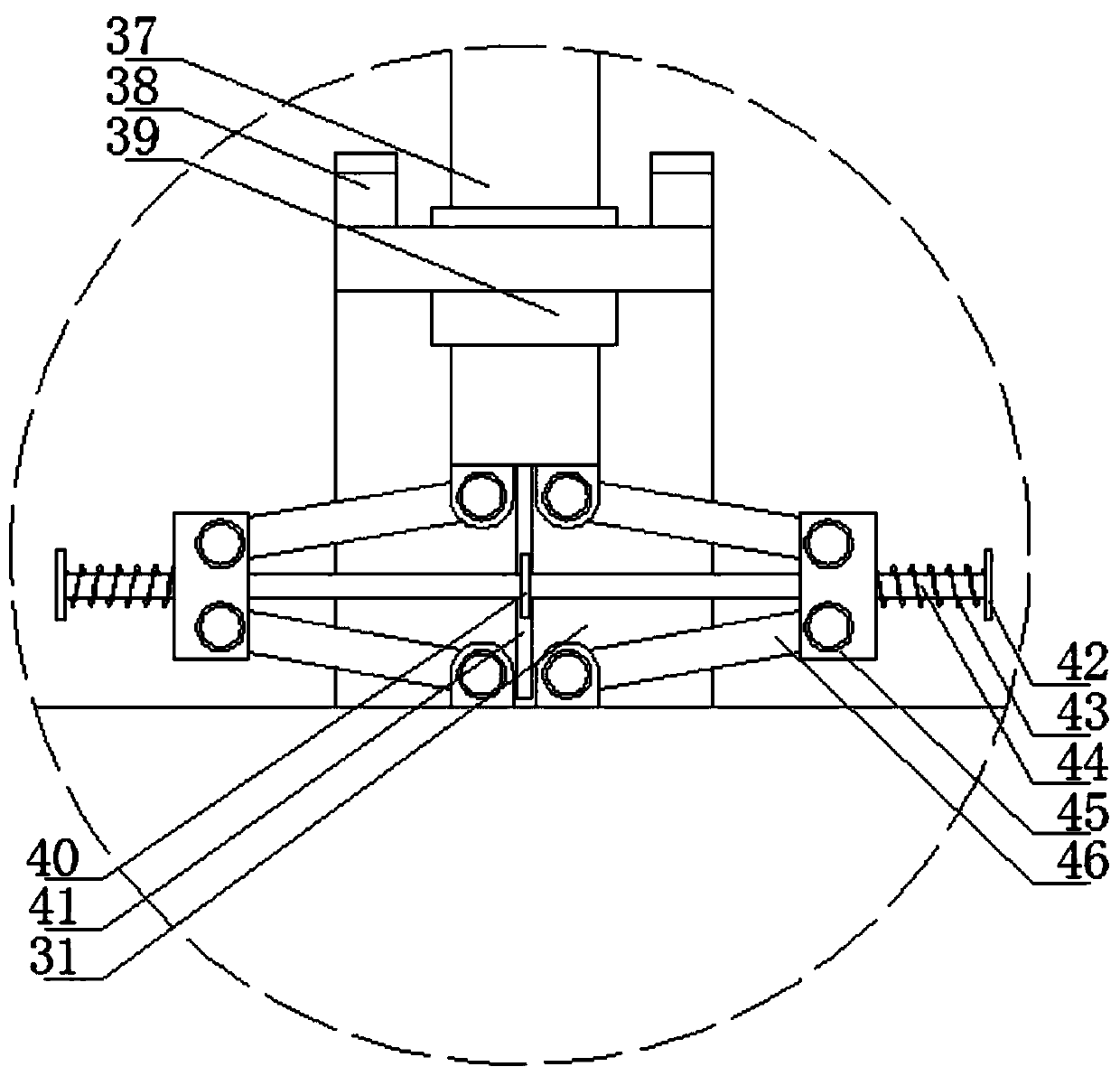

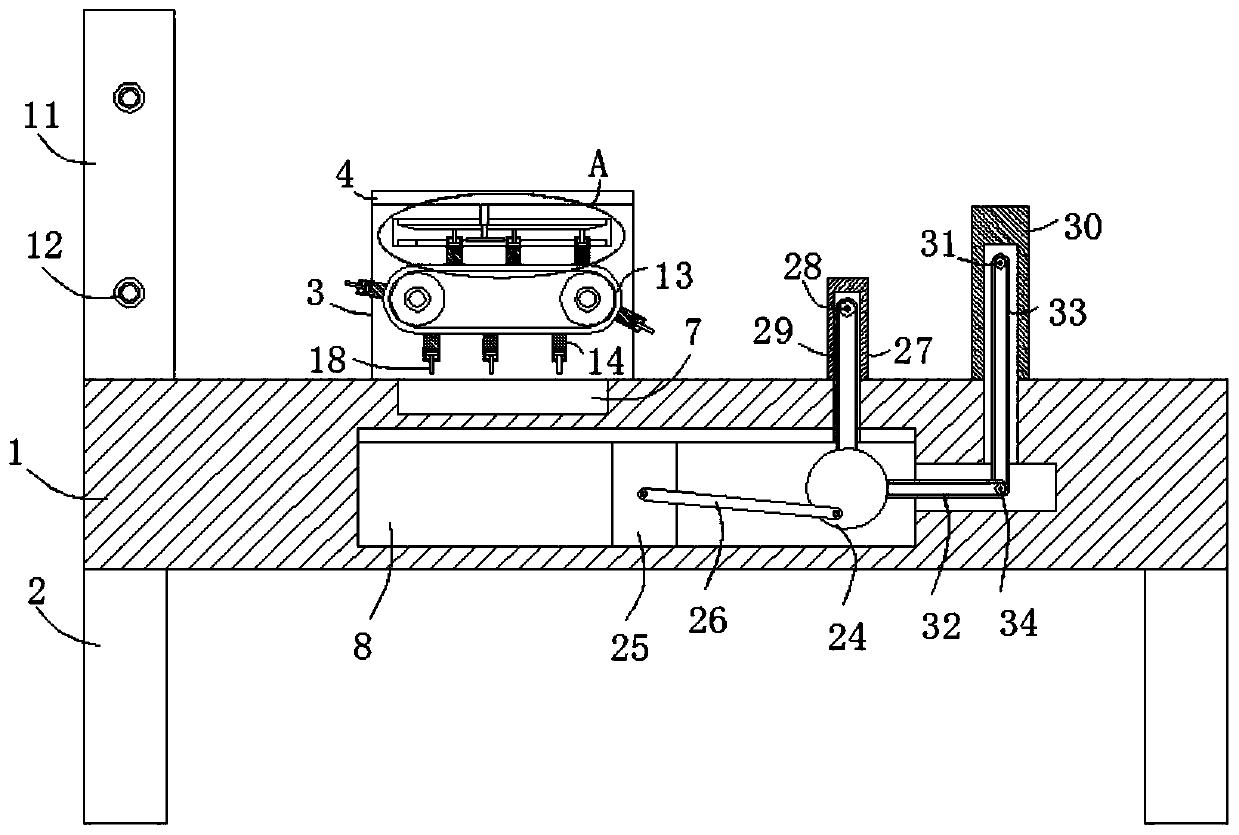

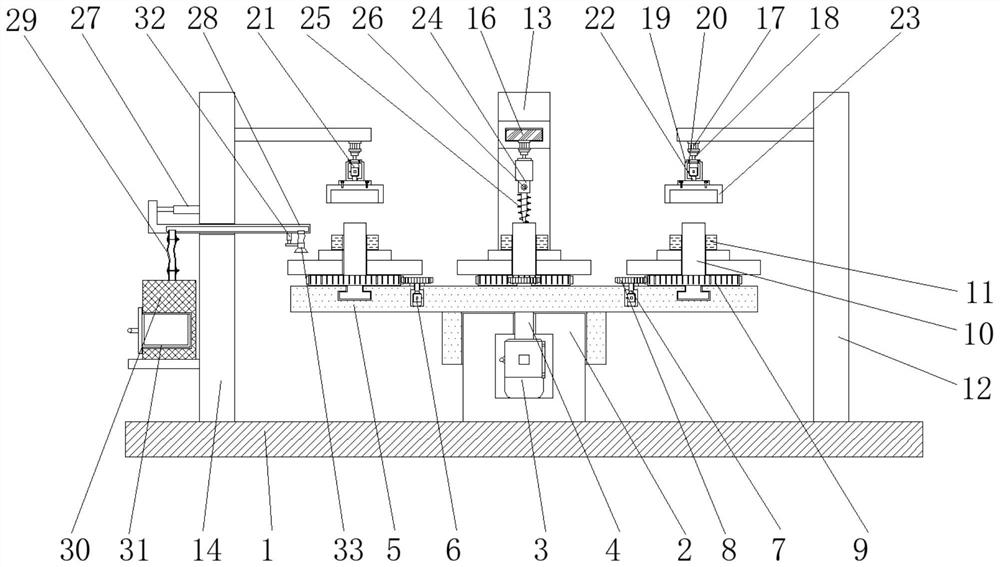

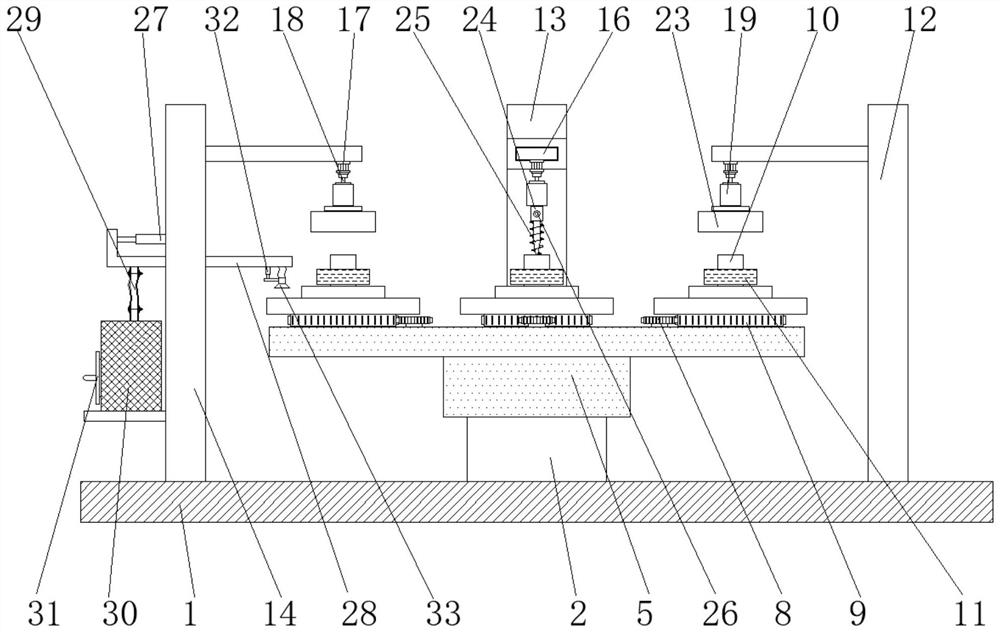

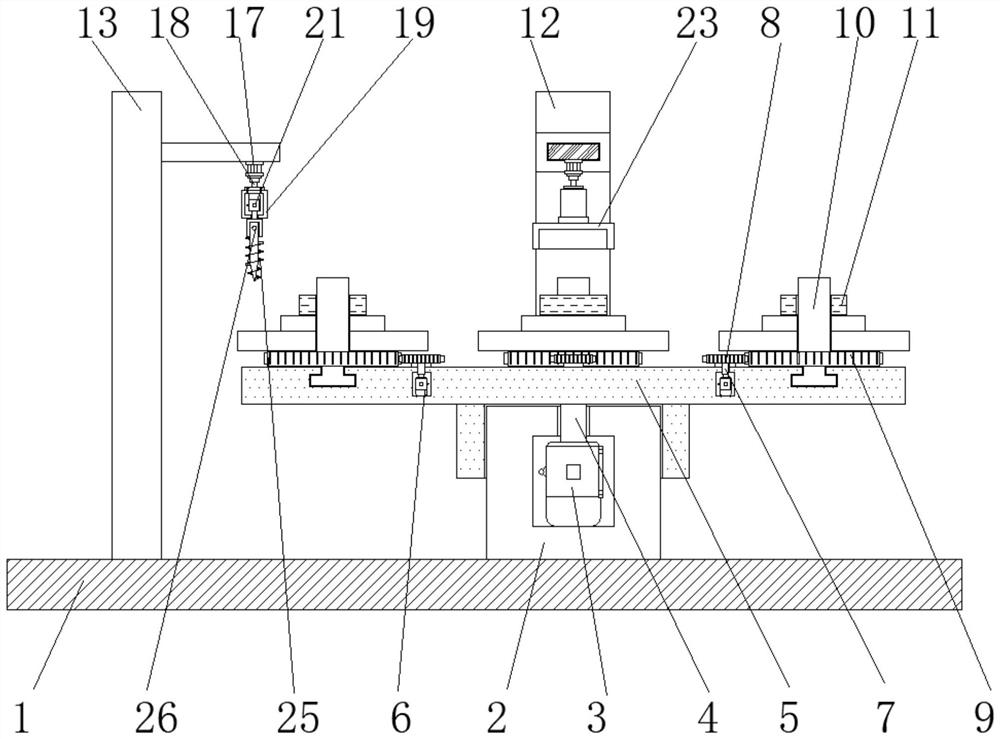

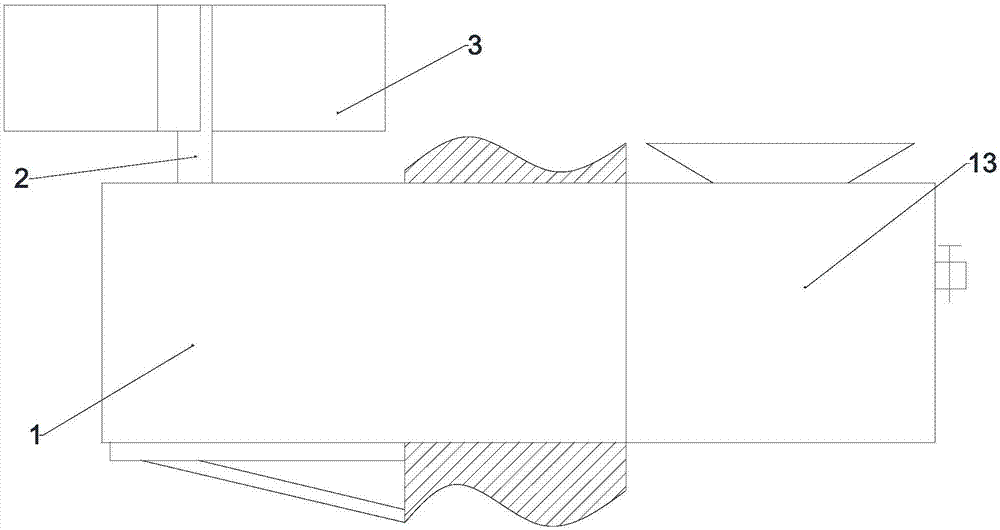

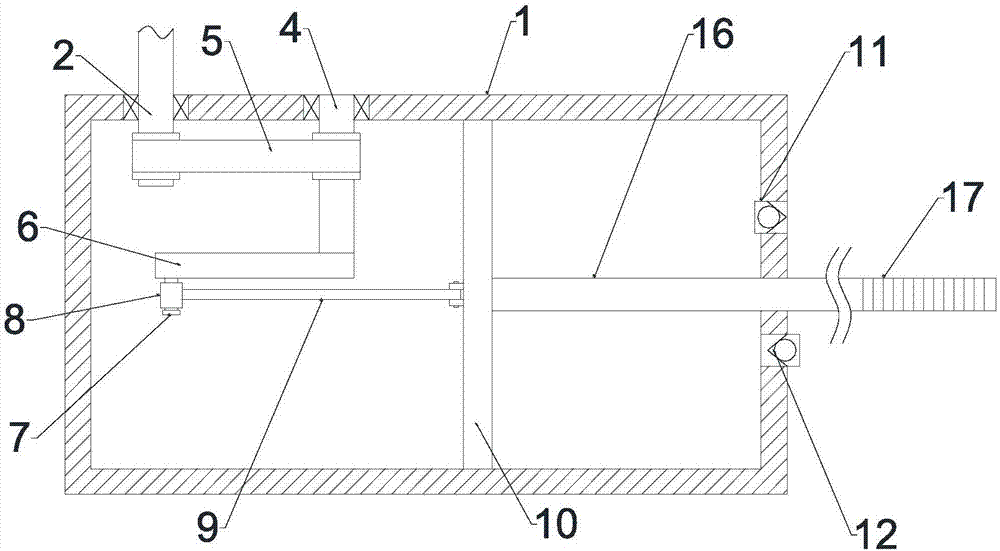

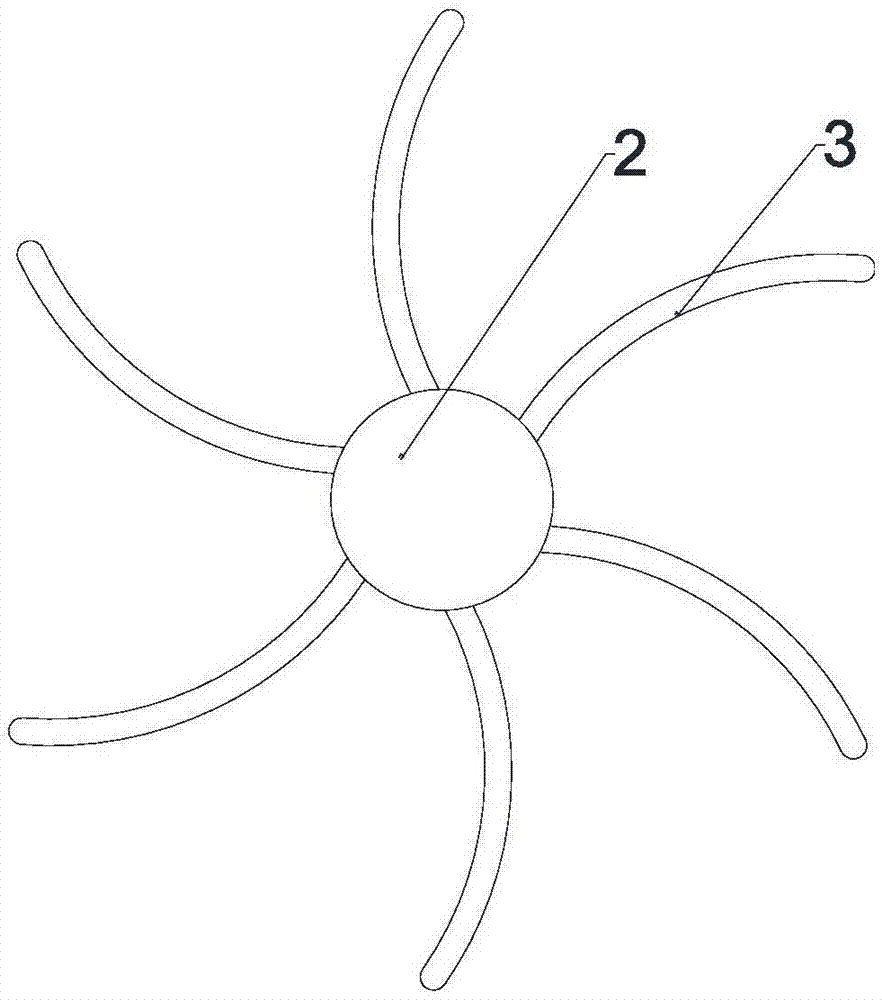

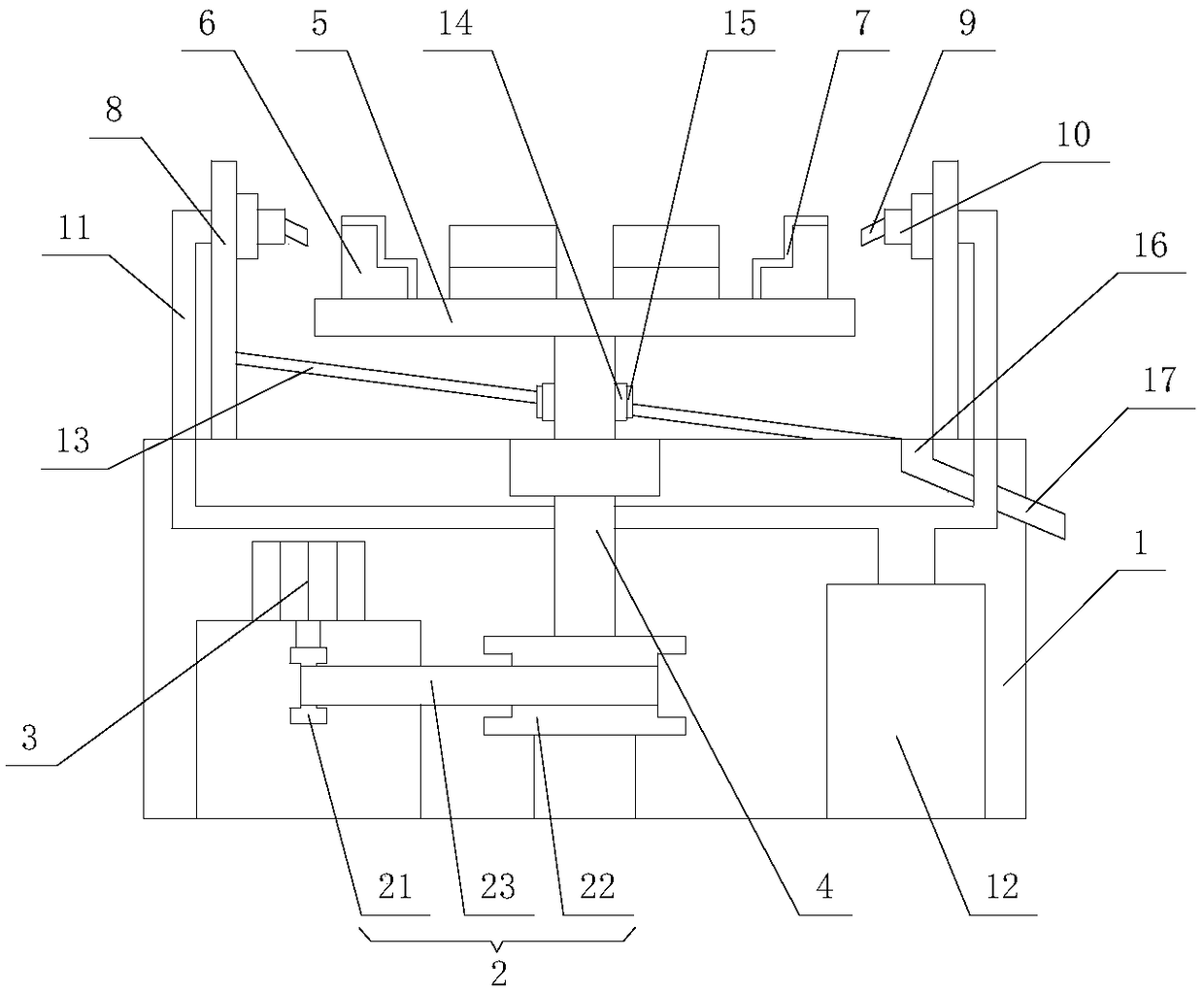

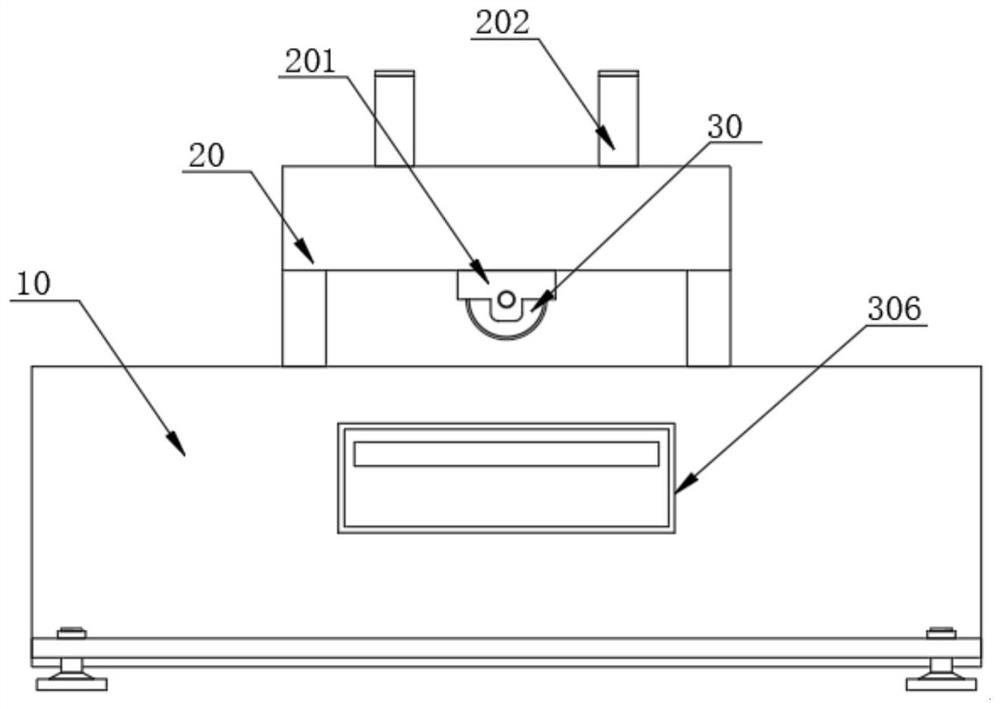

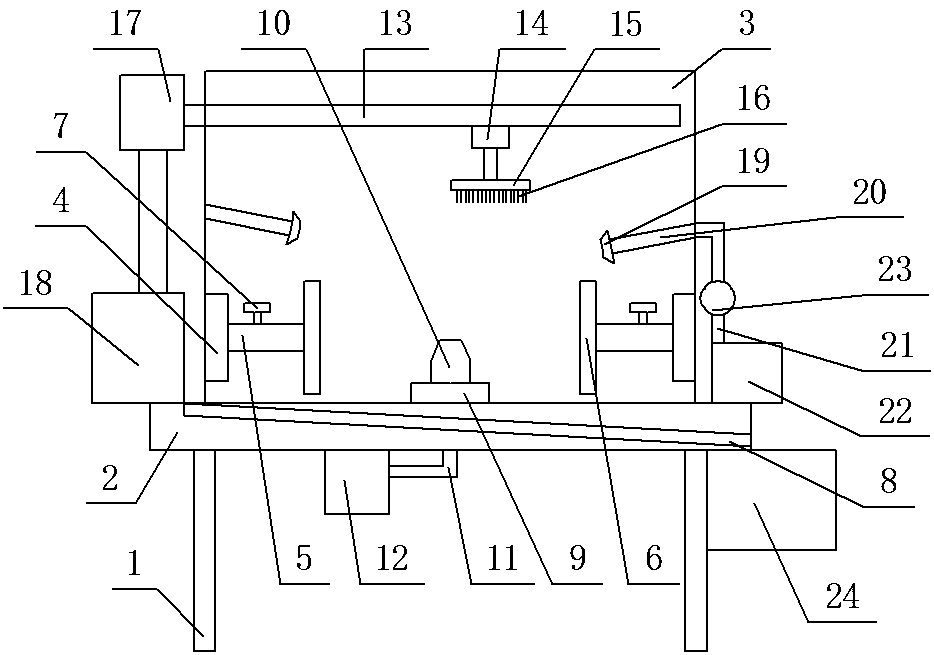

Robot intelligent welding production line

ActiveCN110394573ATo achieve the purpose of beating and removingAchieve the effect of autonomyWelding/cutting auxillary devicesAuxillary welding devicesSlagBall screw

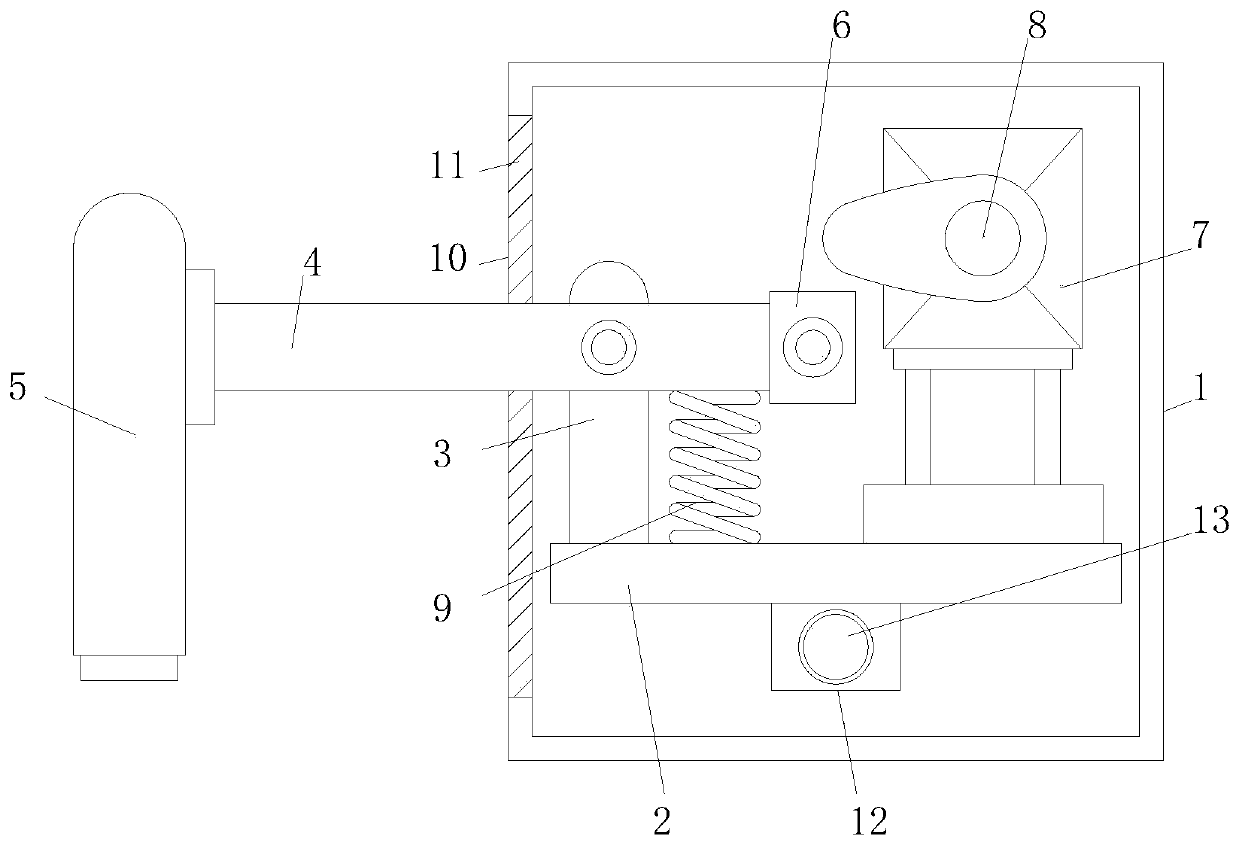

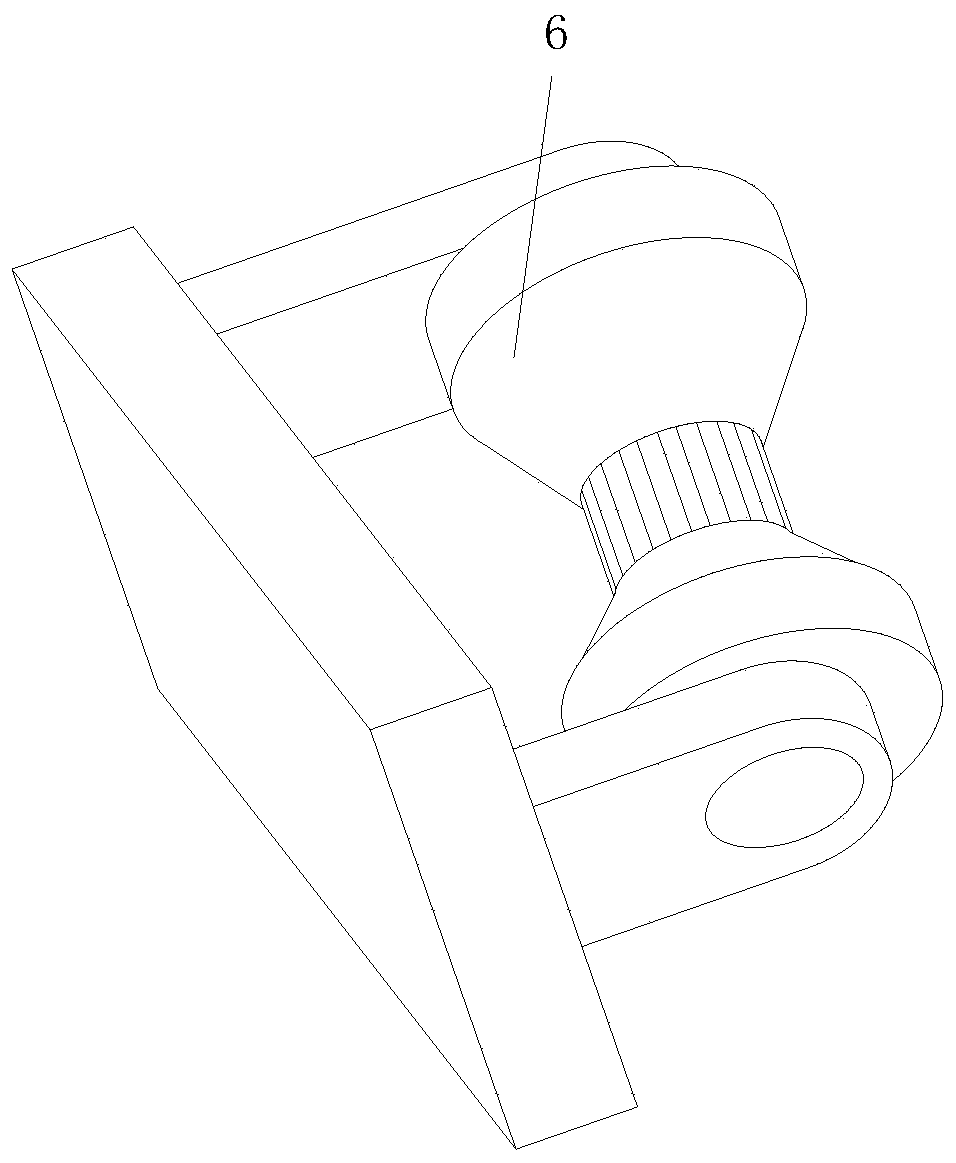

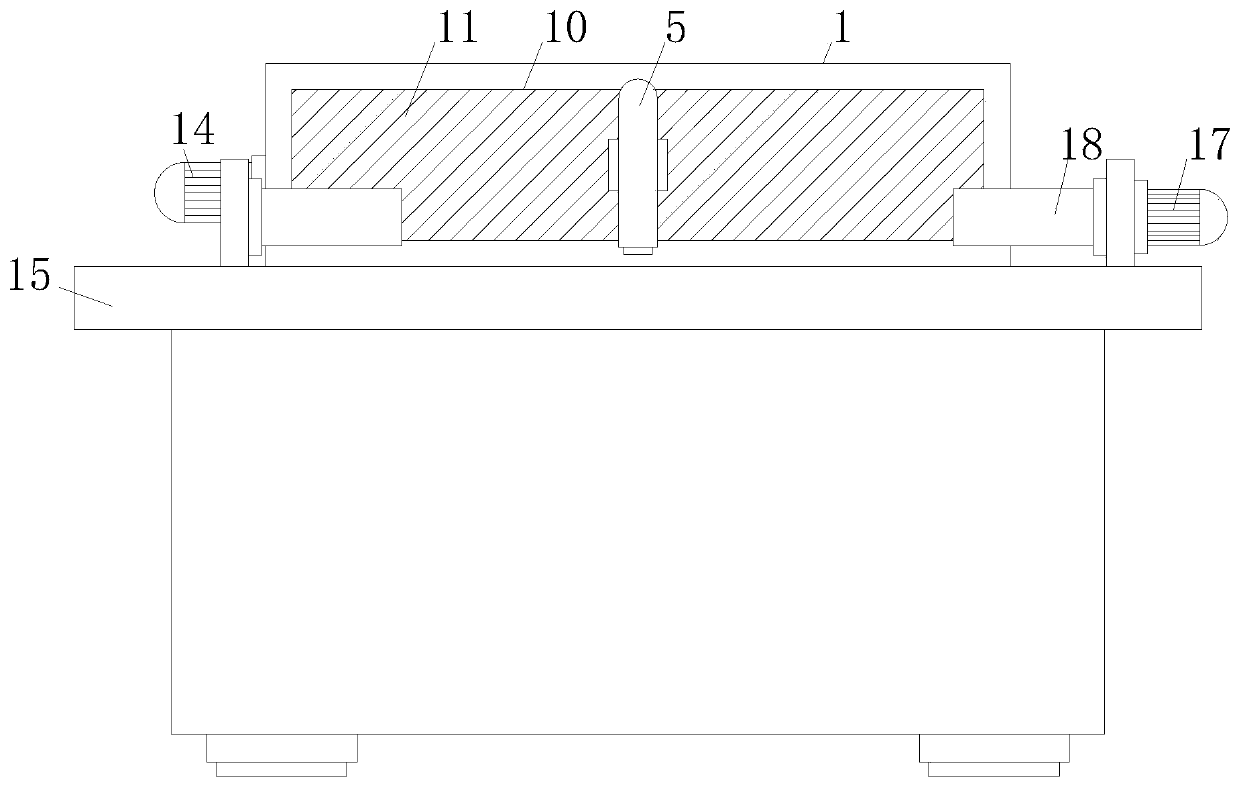

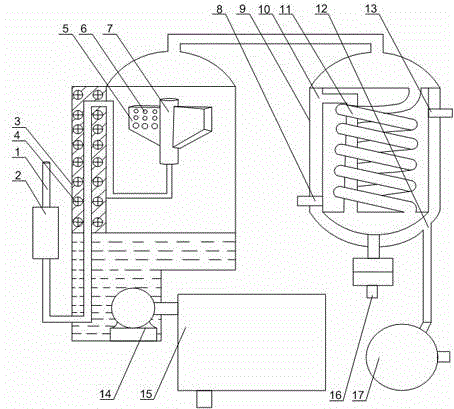

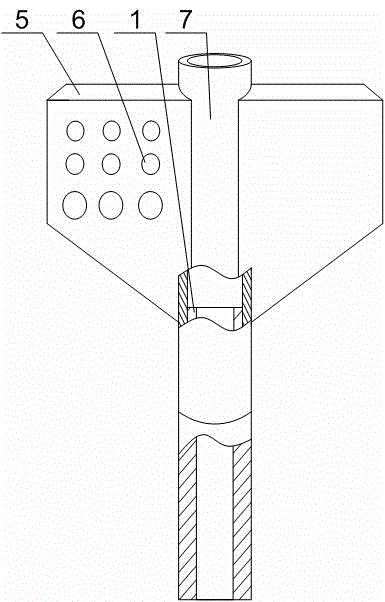

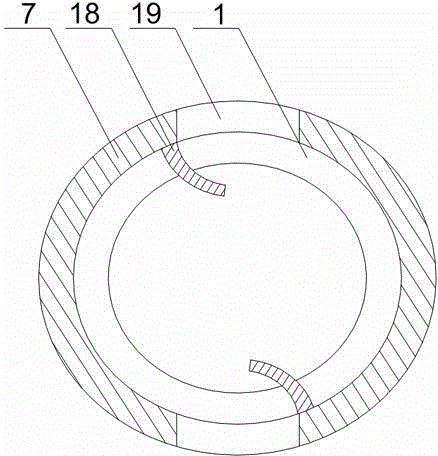

The invention relates to the technical field of welding production lines, in particular to a robot intelligent welding production line. The robot intelligent welding production line comprises a mounting box, a movable plate, a supporting plate, a connecting rod, a knocking head, a contact roller, a drive motor, a cam, a reset spring, dustproof clustered hair, a ball nut, a ball screw, a drive motor, a chip removal hopper, a rotary motor and a clamp. The movable plate is located in the mounting box, the middle position of the left side of the top of the movable plate is fixedly connected with the bottom of the supporting plate, the left end of the connecting rod is fixedly connected with the top of the right side of the knocking head, and the right end of the connecting rod stretches into the mounting box. The purpose that welding slag at the welding position is knocked away through the knocking head is achieved, thus, a manual removing manner is replaced, the whole process and automatic welding supplement each other, a manual participation working manner is reduced, the whole welding line achieves an autonomous effect, then the labor intensity is reduced, and the welding rate is increased.

Owner:中山叁迪智能设备有限公司

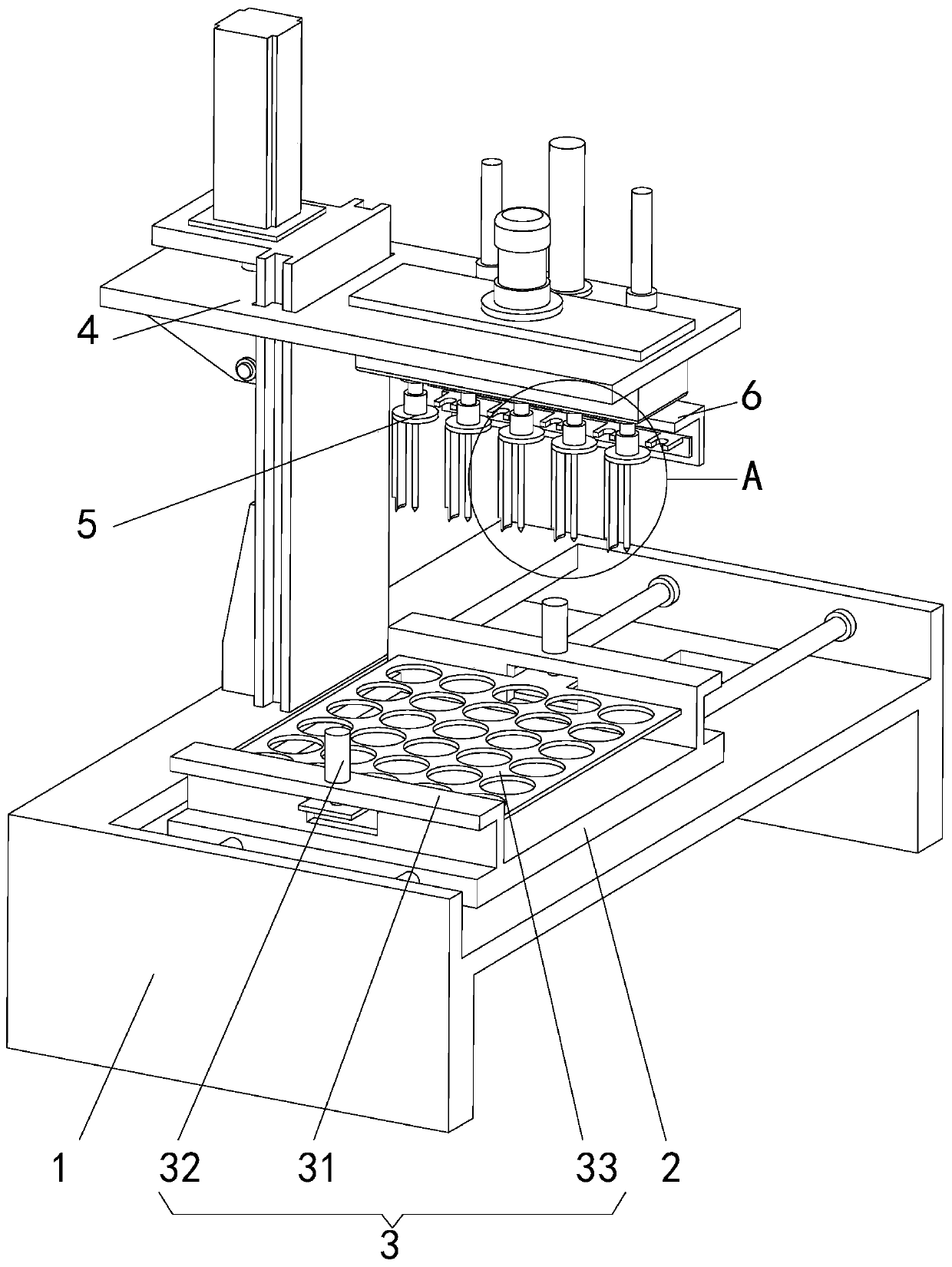

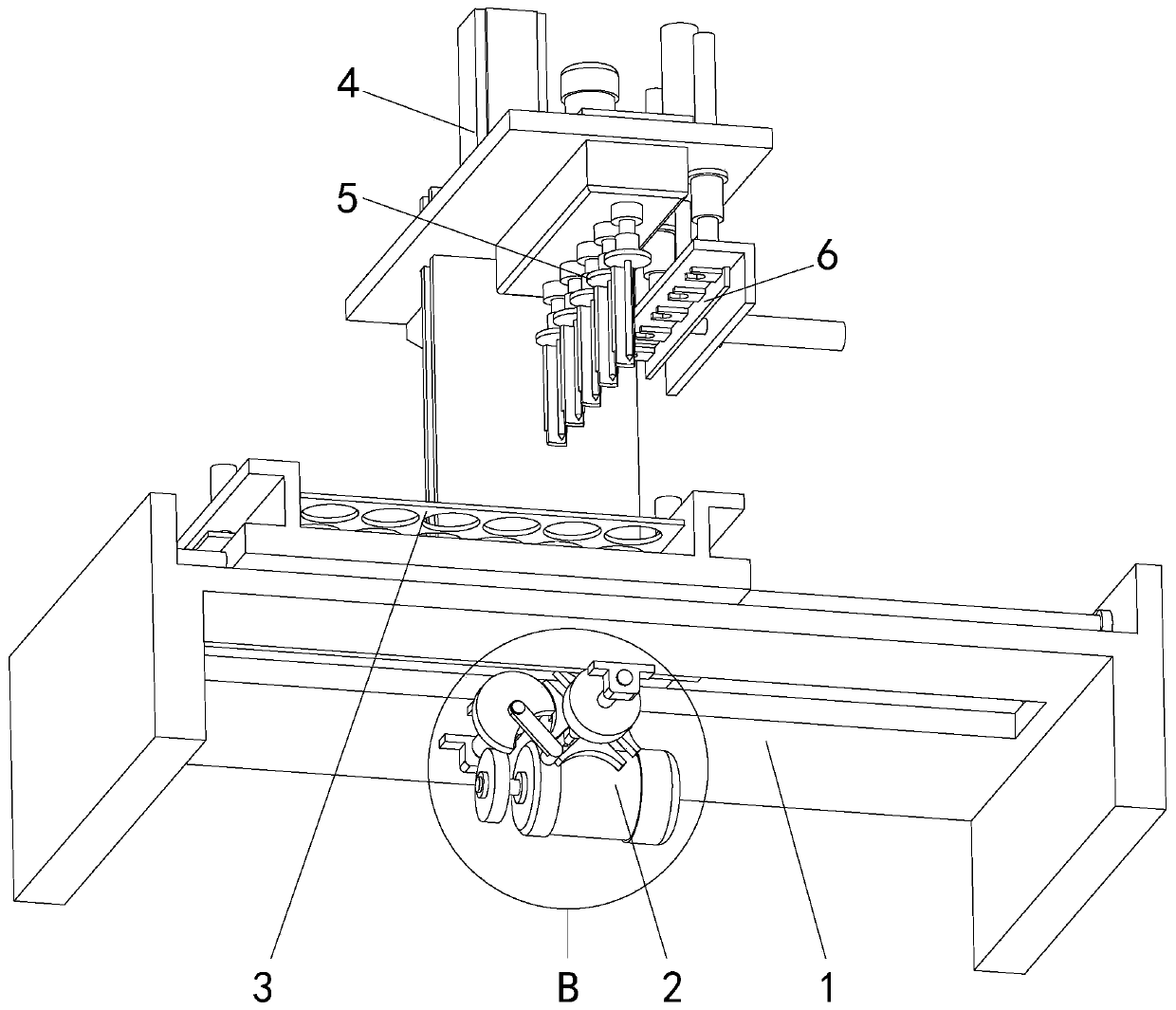

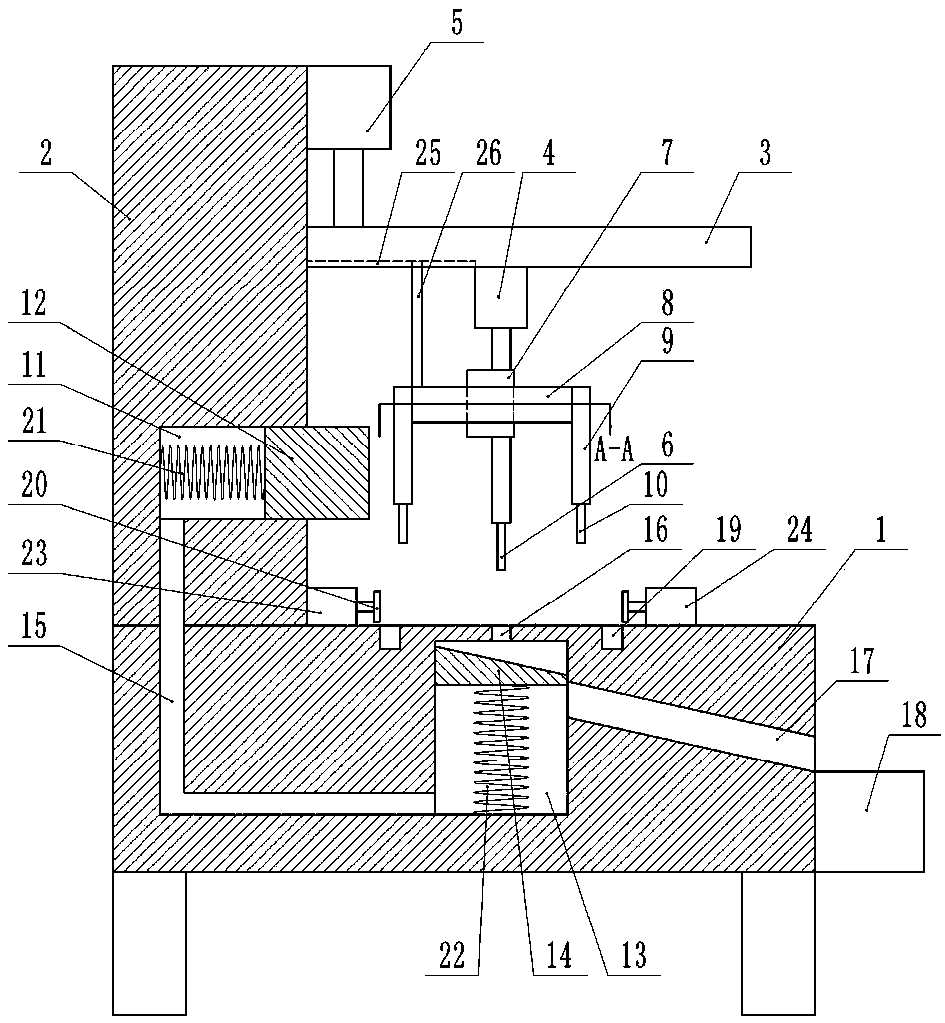

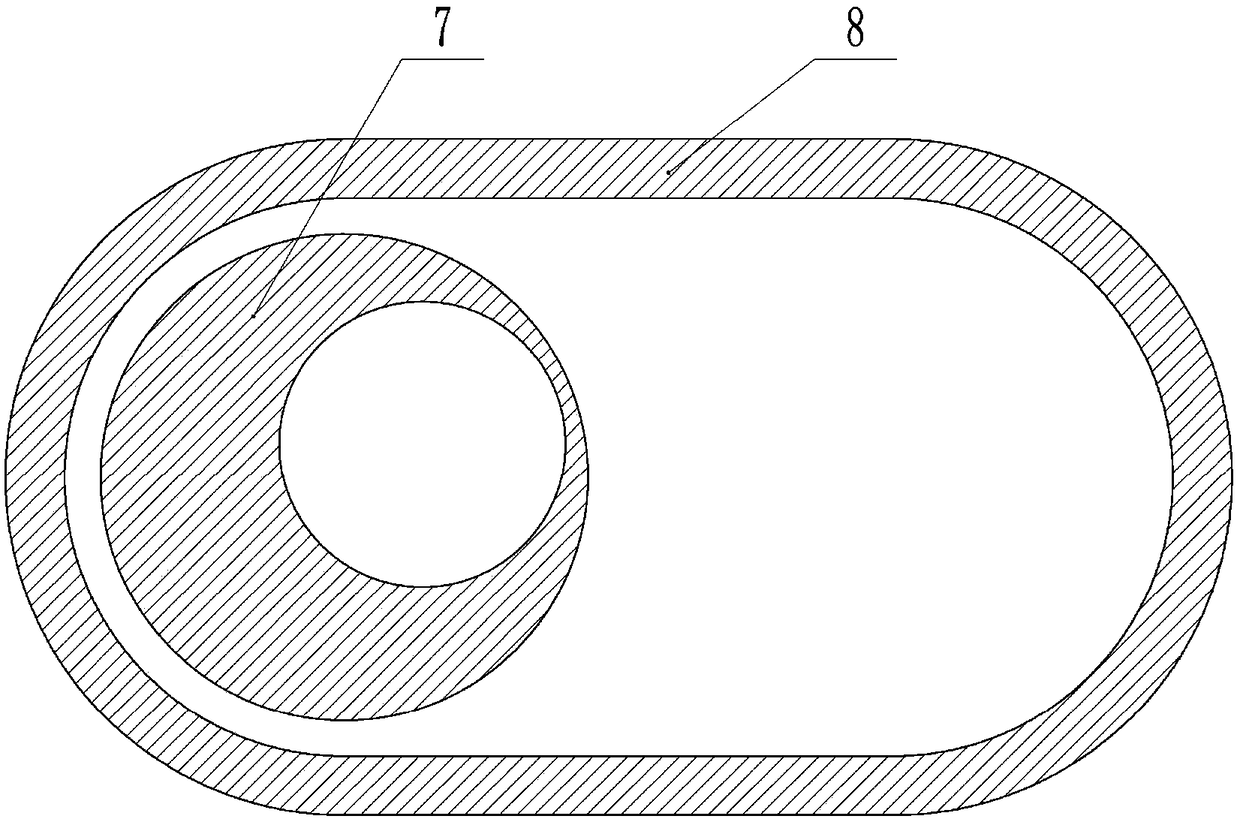

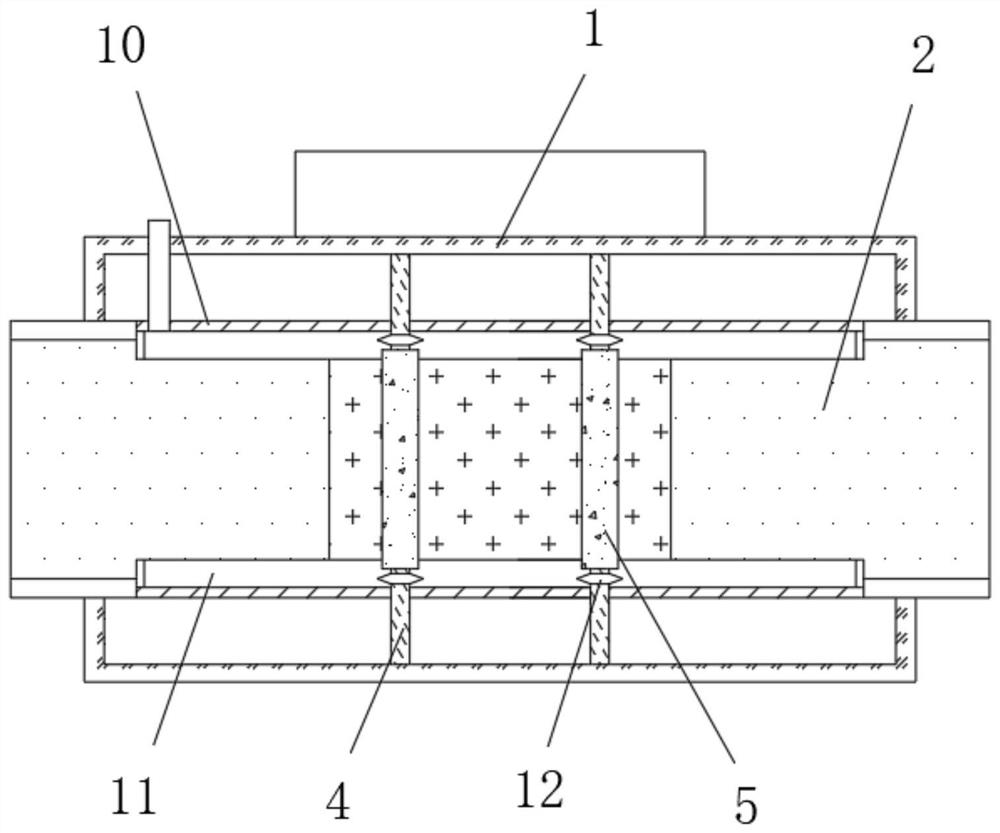

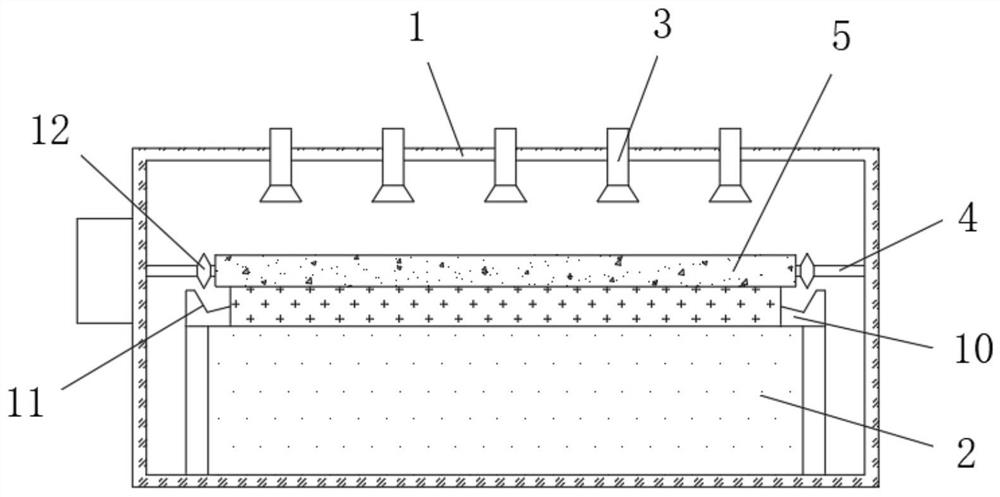

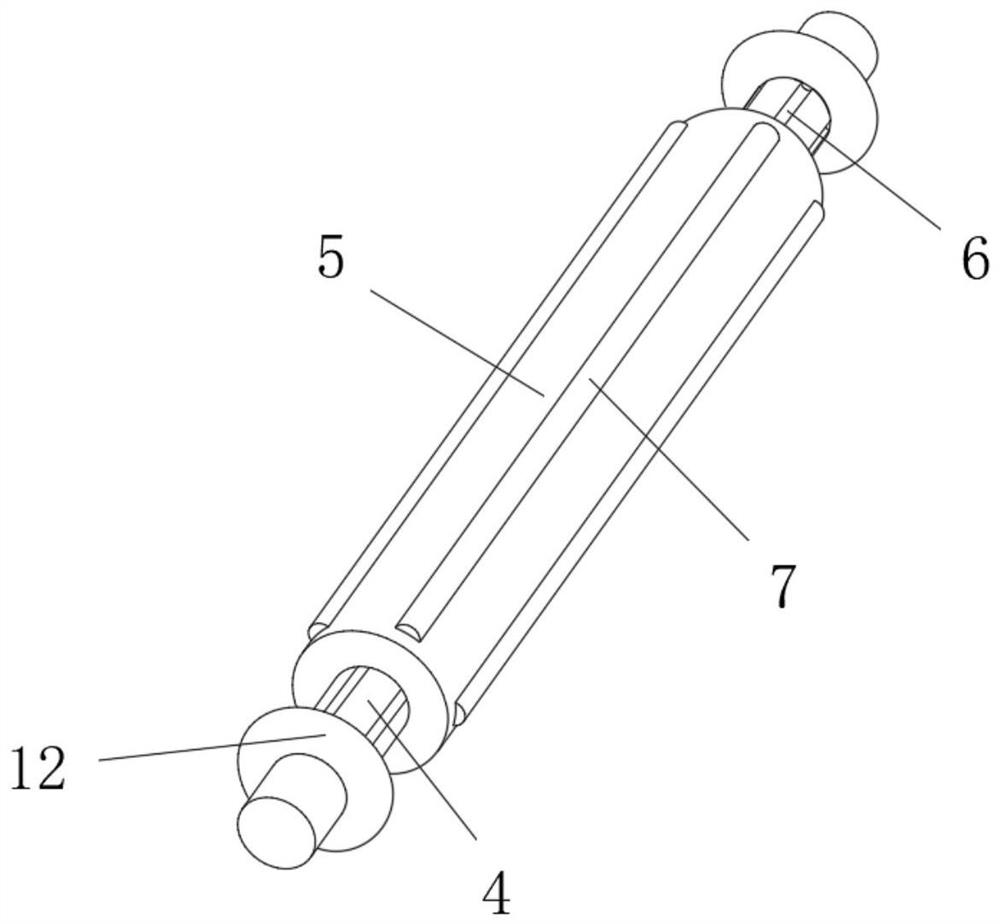

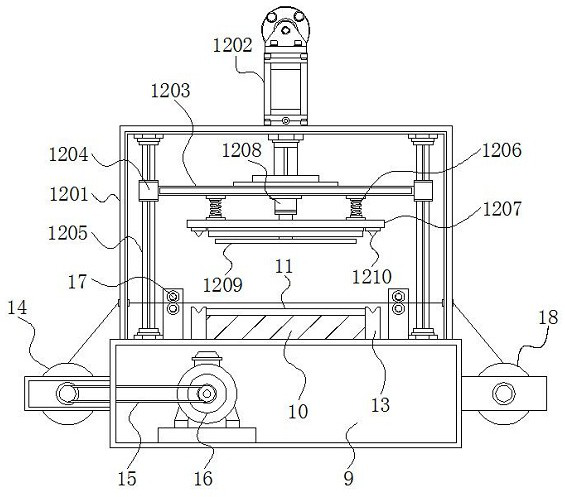

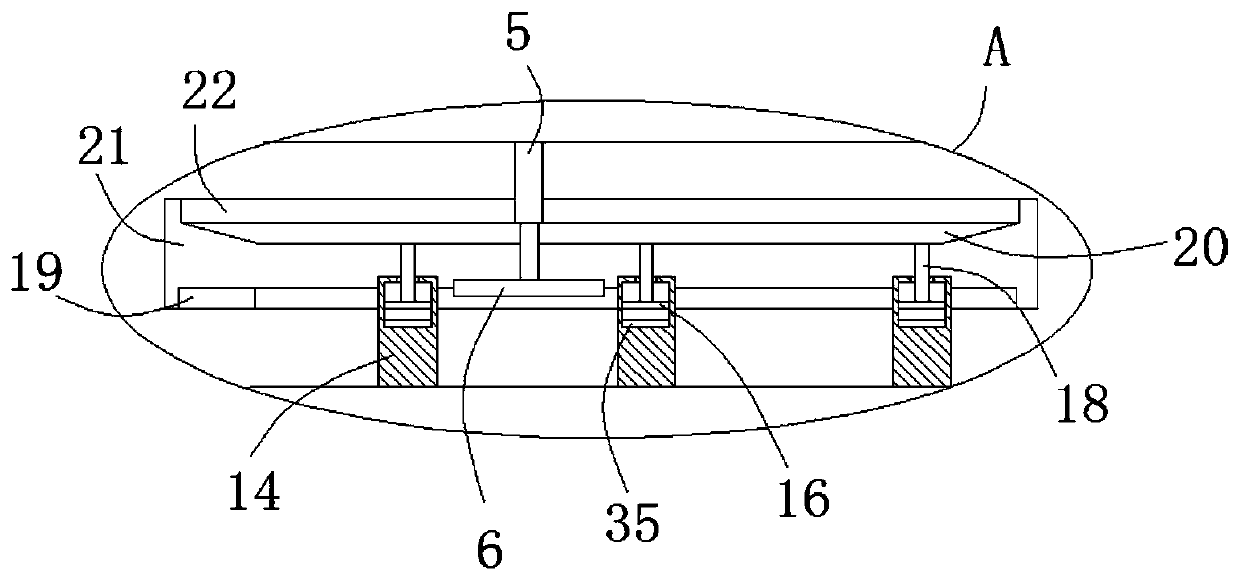

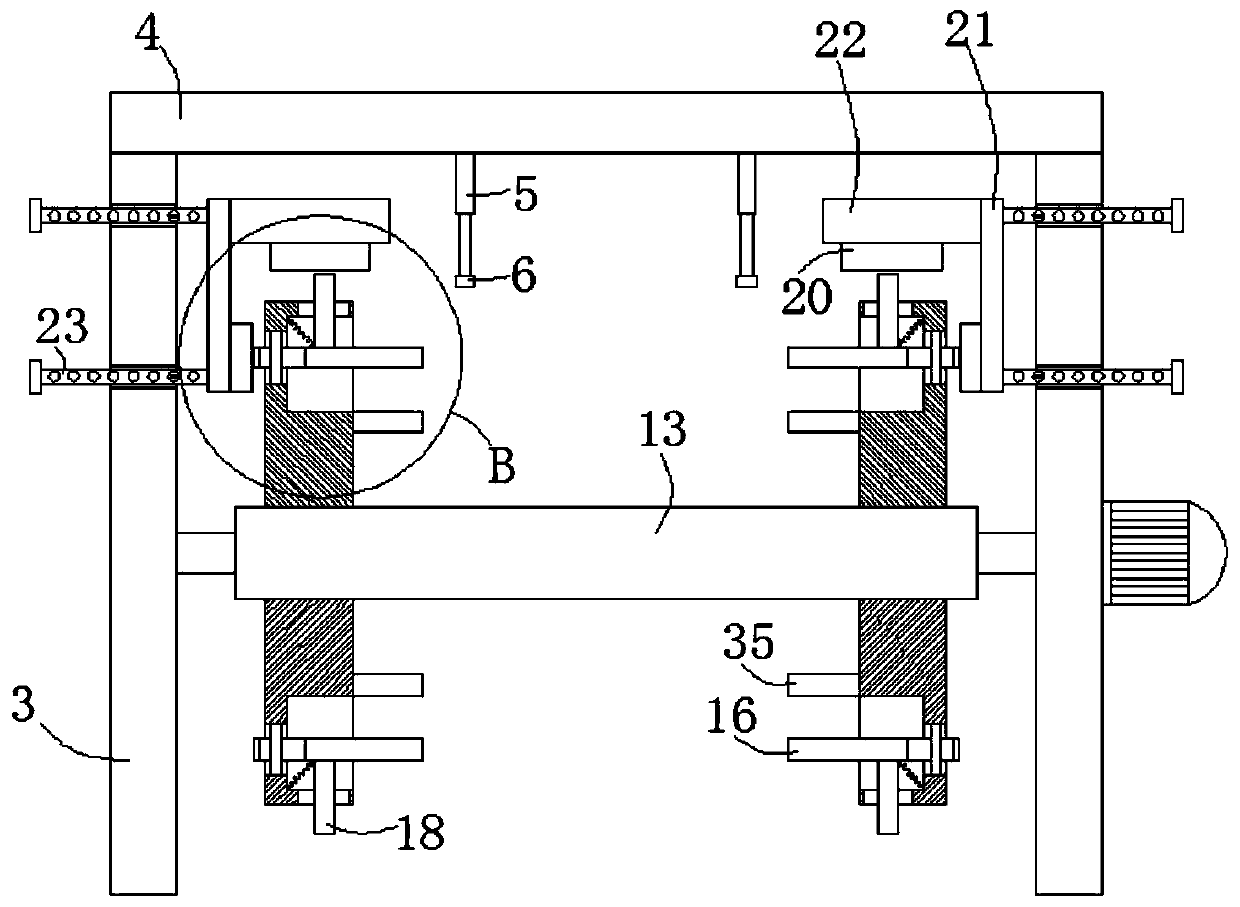

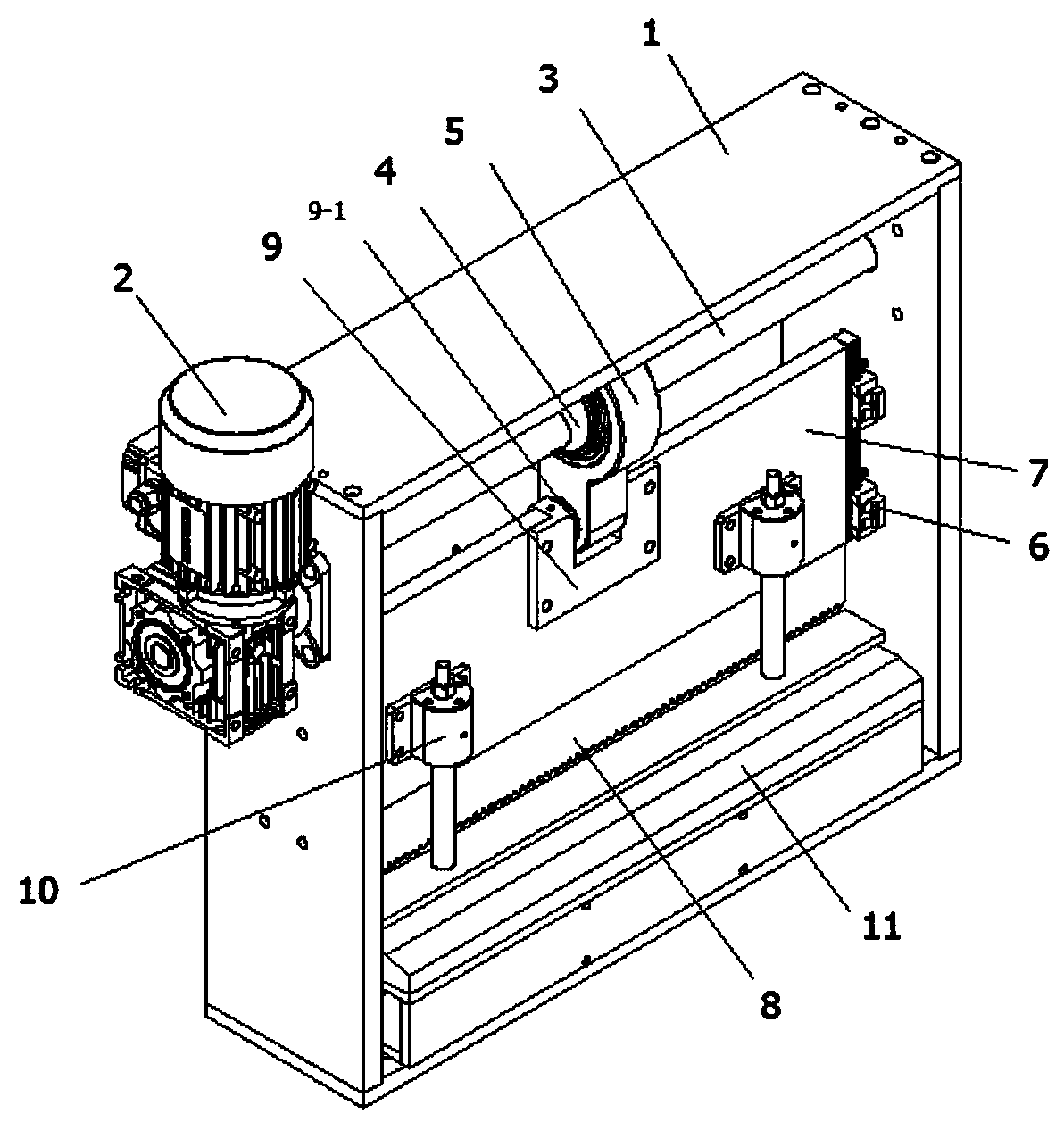

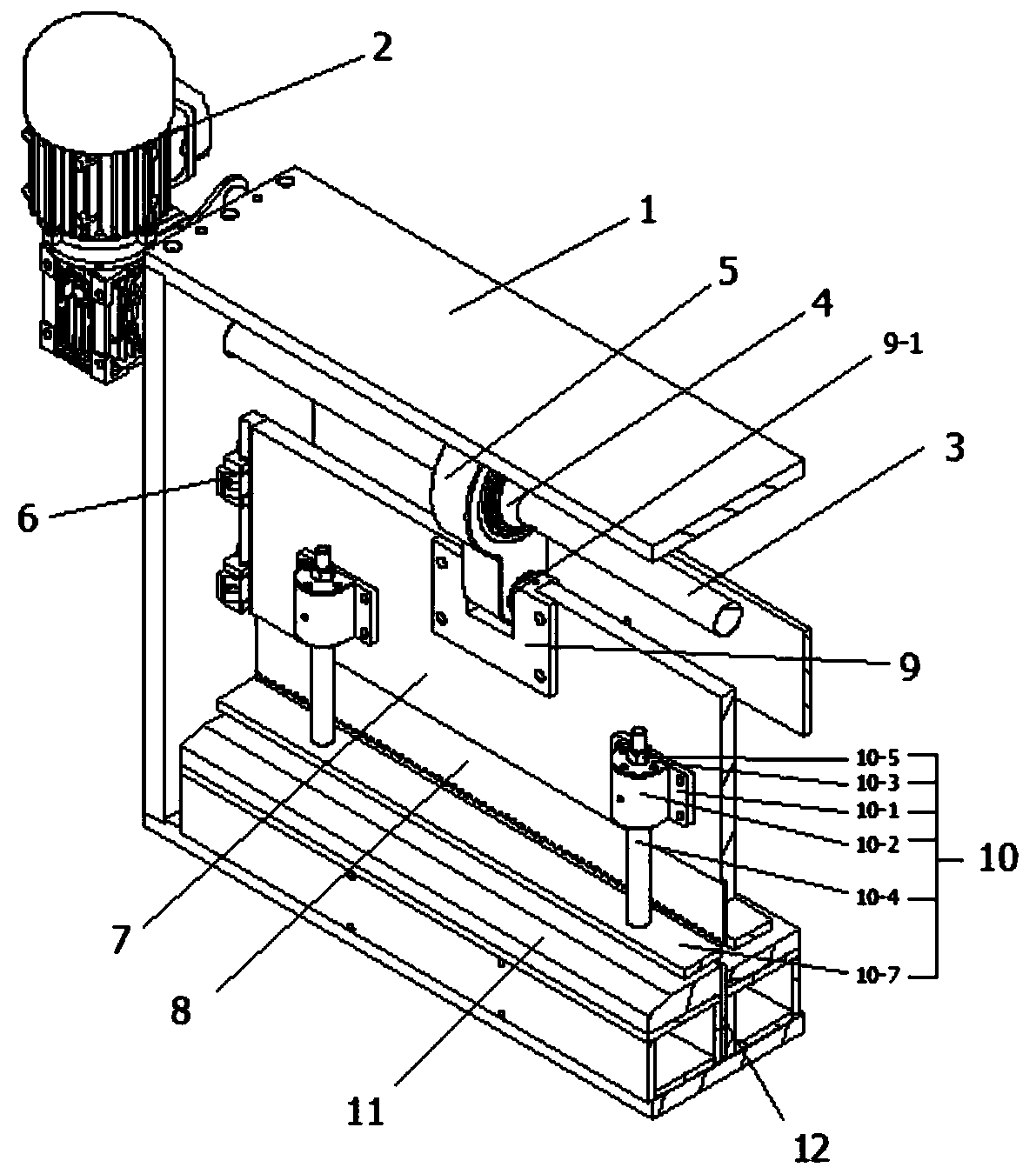

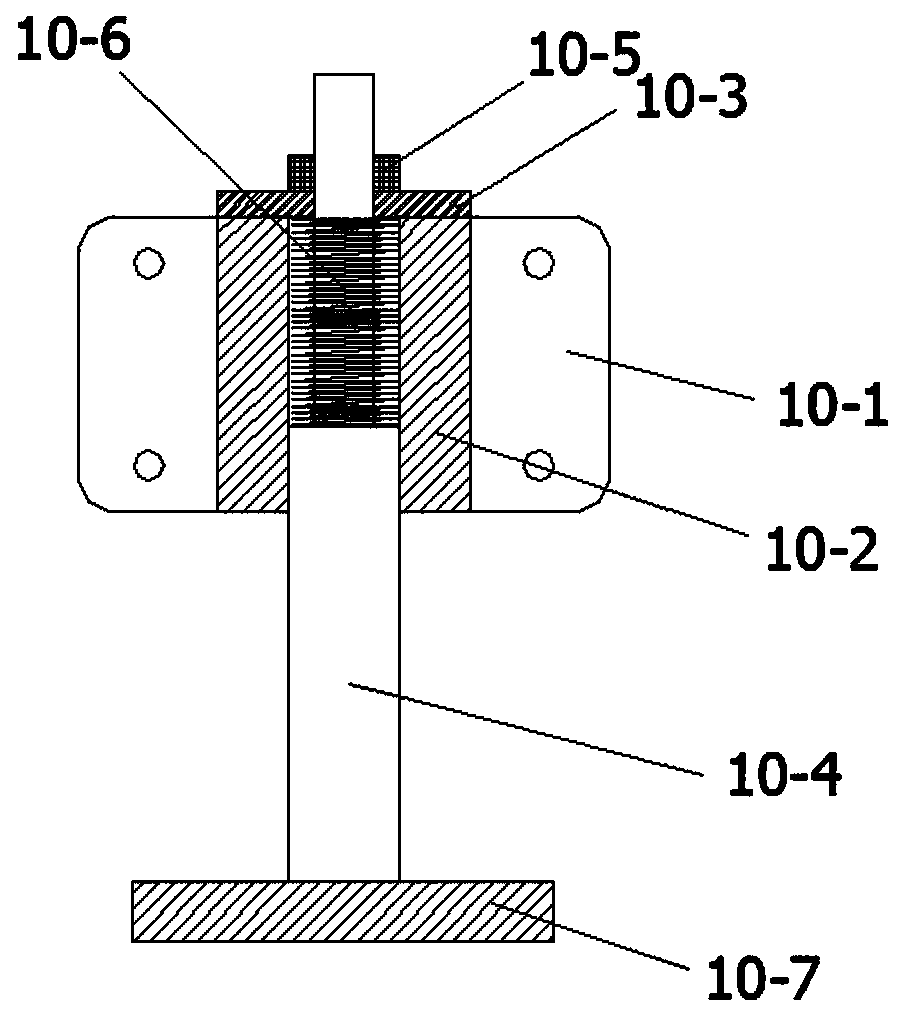

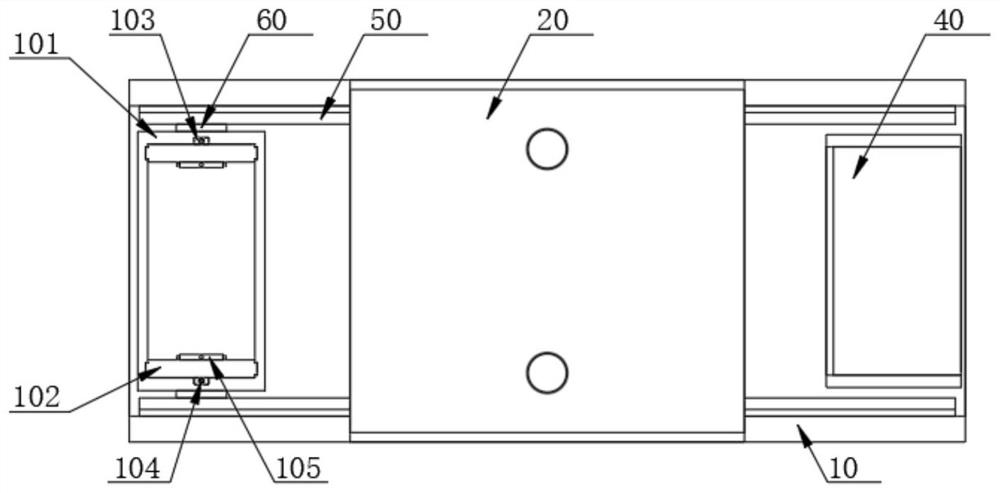

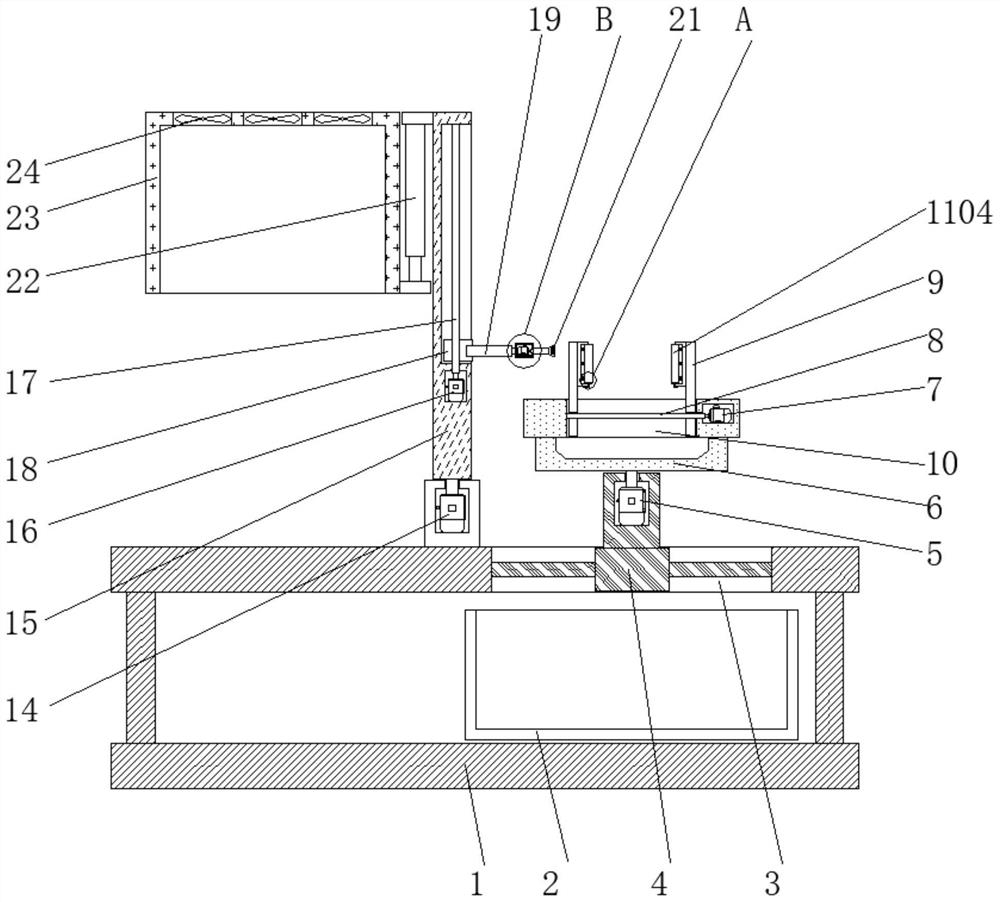

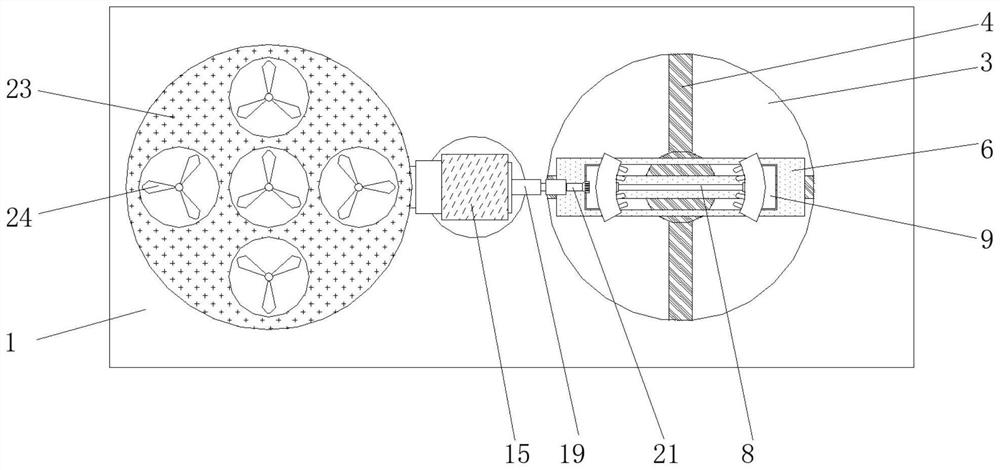

Rapid punching equipment for rigid polyurethane foam plastic plate

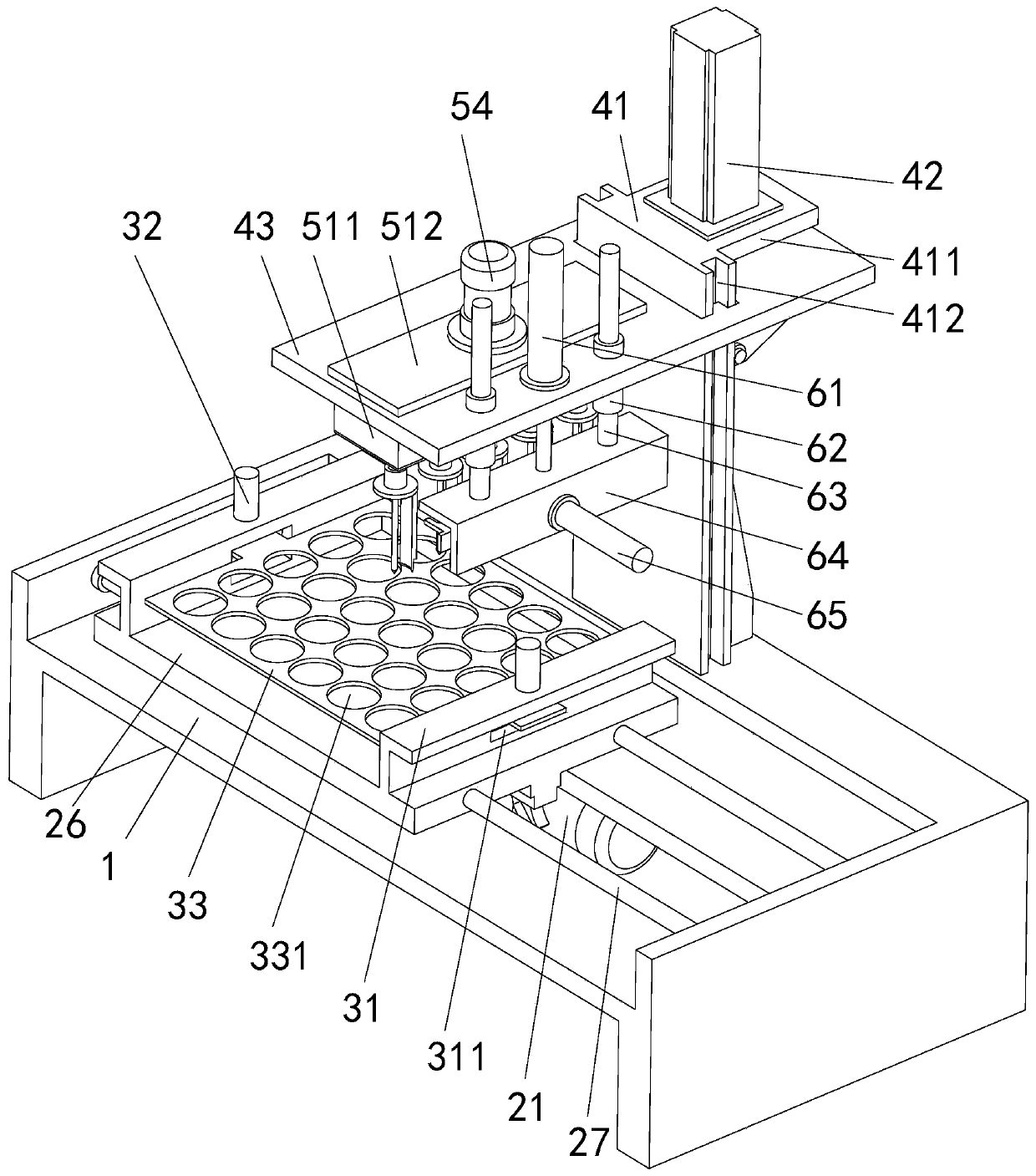

The invention relates to rapid punching equipment for a rigid polyurethane foam plastic plate. The equipment comprises a machine table, an intermittent equidistant translation mechanism which is arranged on the machine table and is used for driving a foam board to translate, a pressing mechanism which is arranged on the intermittent equidistant translation mechanism and used for pressing the foamboard, a punching lifting mechanism which is arranged on the machine table, a rotary cutting punching mechanism which is arranged on the punching lifting mechanism, and a waste removing mechanism which is arranged on the punching lifting mechanism. The intermittent equidistant translation mechanism comprises a rectangular moving platform capable of moving intermittently and equidistantly; the pressing mechanism is fixedly mounted on the upper end surface of the moving platform; the punching lifting mechanism comprises a lifting plate capable of vertically lifting; the rotary cutting punching mechanism and the waste material removing mechanism are both mounted on the lifting plate. According to the invention, the equipment provided by the invention can be used for automatically and quicklypunching the foam board, and is high in punching speed and high in efficiency.

Owner:南京幸庄科技创新产业园管理有限公司

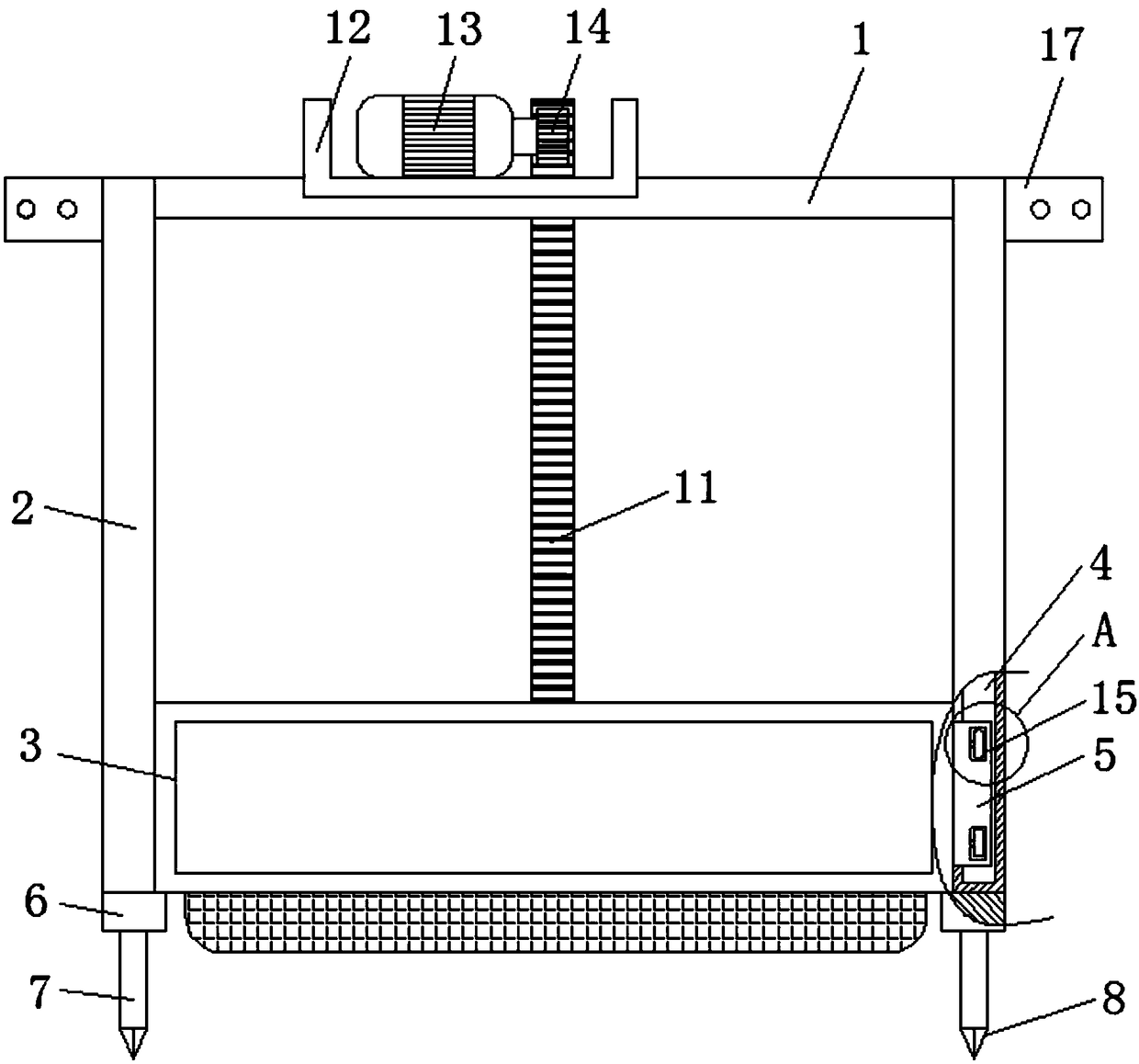

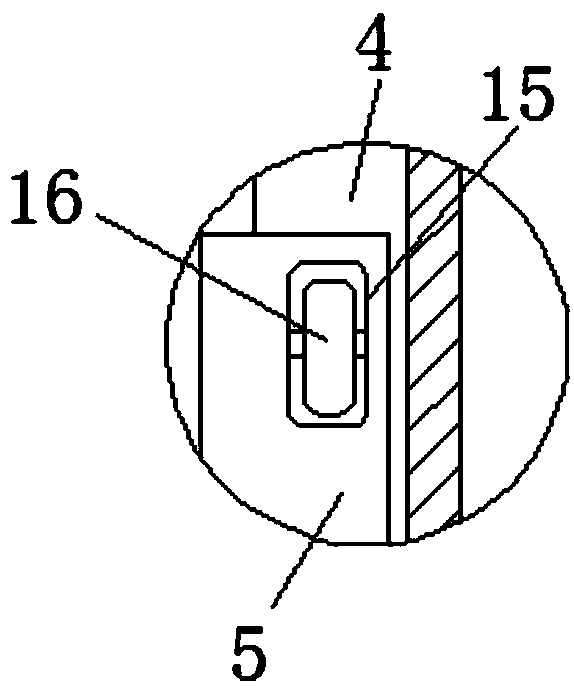

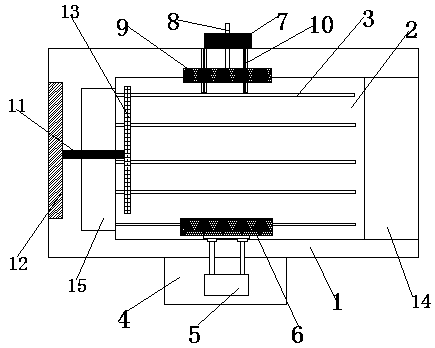

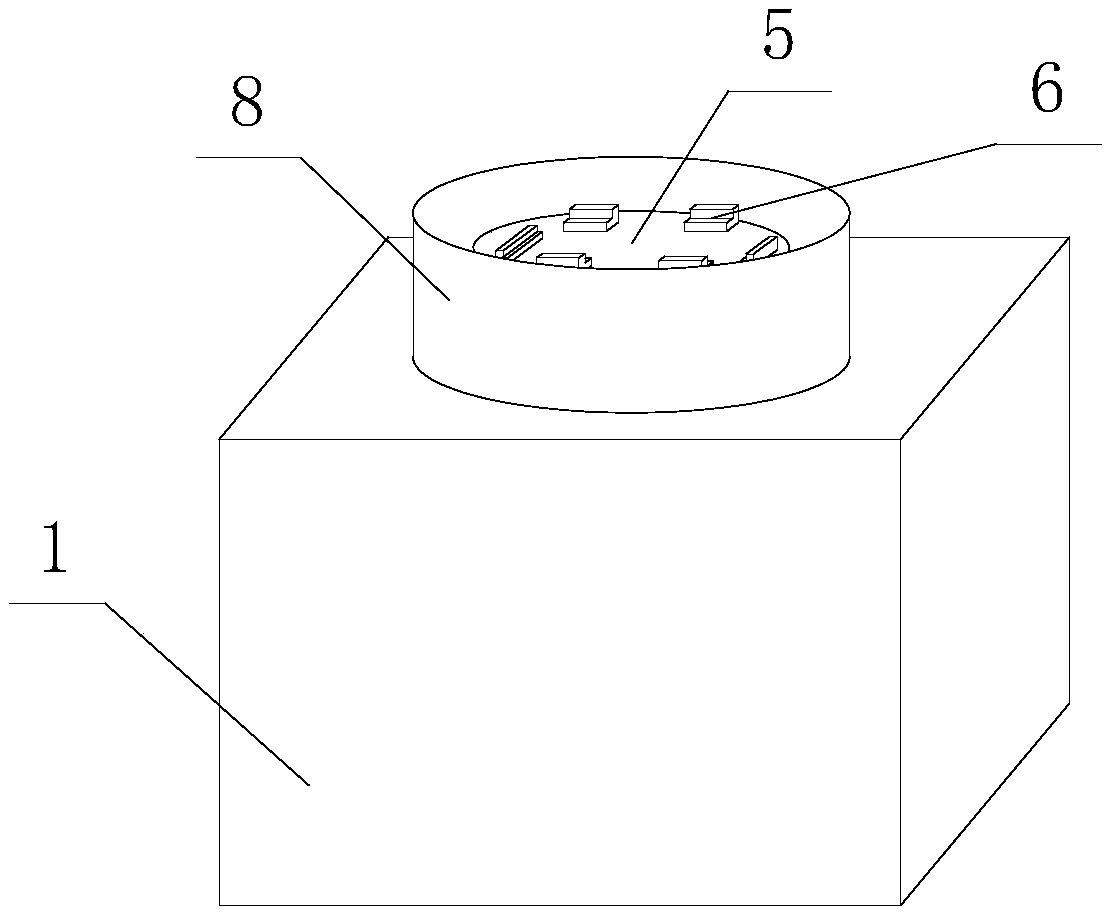

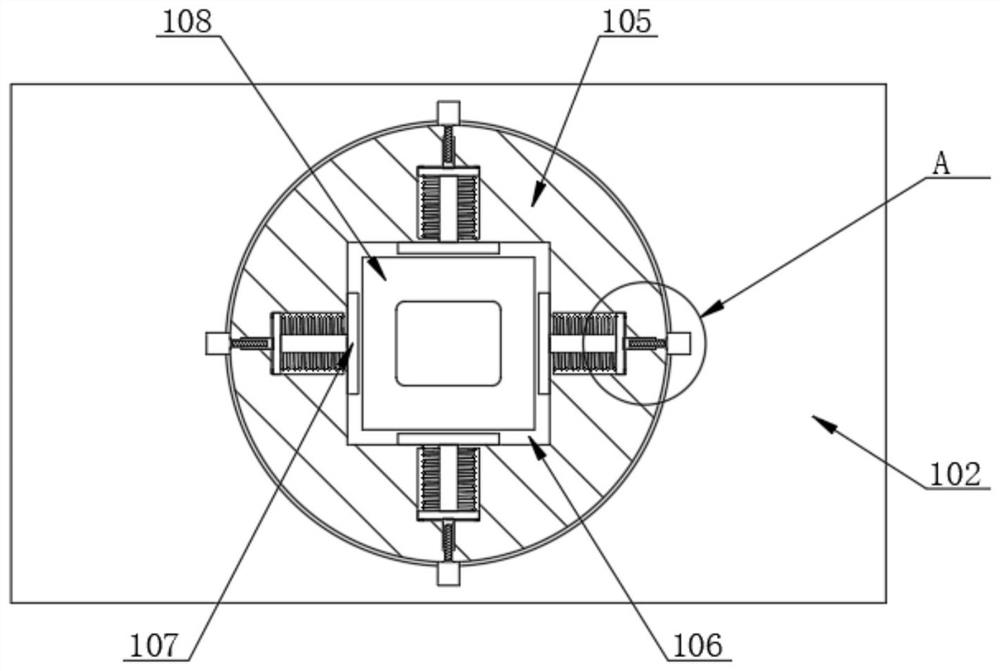

Drilling device for wood boards

PendingCN108544580AImprove processing efficiencyGuaranteed stabilityStationary drilling machinesBark-zones/chip/dust/waste removalDrill bitEngineering

The invention belongs to the technical field of wood board processing devices, and particularly discloses a drilling device for wood boards. The drilling device comprises a worktable and an auxiliaryrod, the worktable is provided with a vertical column, the column is provided with a cylinder, a beam is connected to a piston rod of the cylinder, the beam is provided with a motor, and an output shaft of the motor is provided with a drill bit. The auxiliary rod is connected to the output shaft of the motor, the auxiliary rod is provided with a support frame, vertical rods are arranged on the support frame, and brushes are connected to the vertical rods. A first sliding hole is formed in the vertical column, an ejecting block is arranged in the first sliding hole, and the worktable is provided with a through hole, a second sliding hole, a slider, a second spring, a material guiding hole and a clamping portion. The drilling device is mainly used for drilling the wood boards, and the problem that waste chip is usually left in a hole to affect subsequent splicing of the wood boards after drilling of the wood boards is completed is solved.

Owner:重庆草衣木食文化传播有限公司

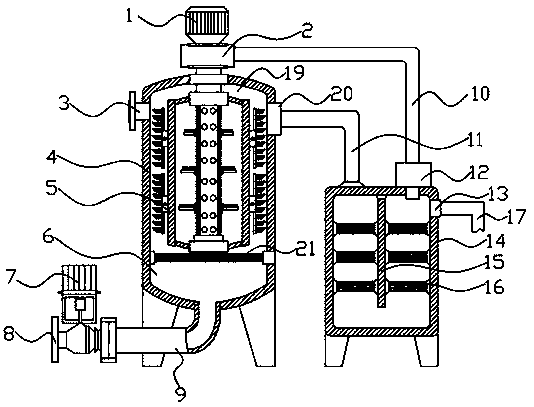

Oil filter for treating dirty oil in electrical cabinet profile bending machine

ActiveCN104587738AEasy to separateImprove adsorption capacityLiquid degasificationFiltration circuitsMagnetic filterOil filter

The invention discloses an oil filter for treating dirty oil in an electrical cabinet profile bending machine. The oil filter comprises a filter tank and an oil guide pipe, wherein the oil guide pipe penetrates through the outer wall of the filter tank and is placed at the upper end inside the filter tank; the top end of the filter tank is communicated with a condensation tank; a heating chamber is fixedly formed in the side wall of the filter tank, the oil guide pipe penetrates through the heating chamber, and a heater is mounted in the heating chamber; an oil injection column communicated with the oil guide pipe is rotationally arranged at the end part of the oil guide pipe, hollow wing plates are fixed on the two sides of the oil injection column, and a plurality of oil injection holes are formed in the opposite sides of the two wing plates; through holes communicated with the oil injection holes are formed in the oil injection column; an oil pump is fixed at the bottom of the filter tank, and the oil outlet end of the oil pump penetrates through the filter tank and is connected with a magnetic filter. Gas enters the condensation tank from the top of the filter tank and is newly fluidized under the condensation effect of the condensation tank to be convenient for centralized collection and treatment, and the purposes of improving the absorption of impurities in liquid when oil for bending is filtered and further improving the filtering efficiency of the oil for bending are further achieved.

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD

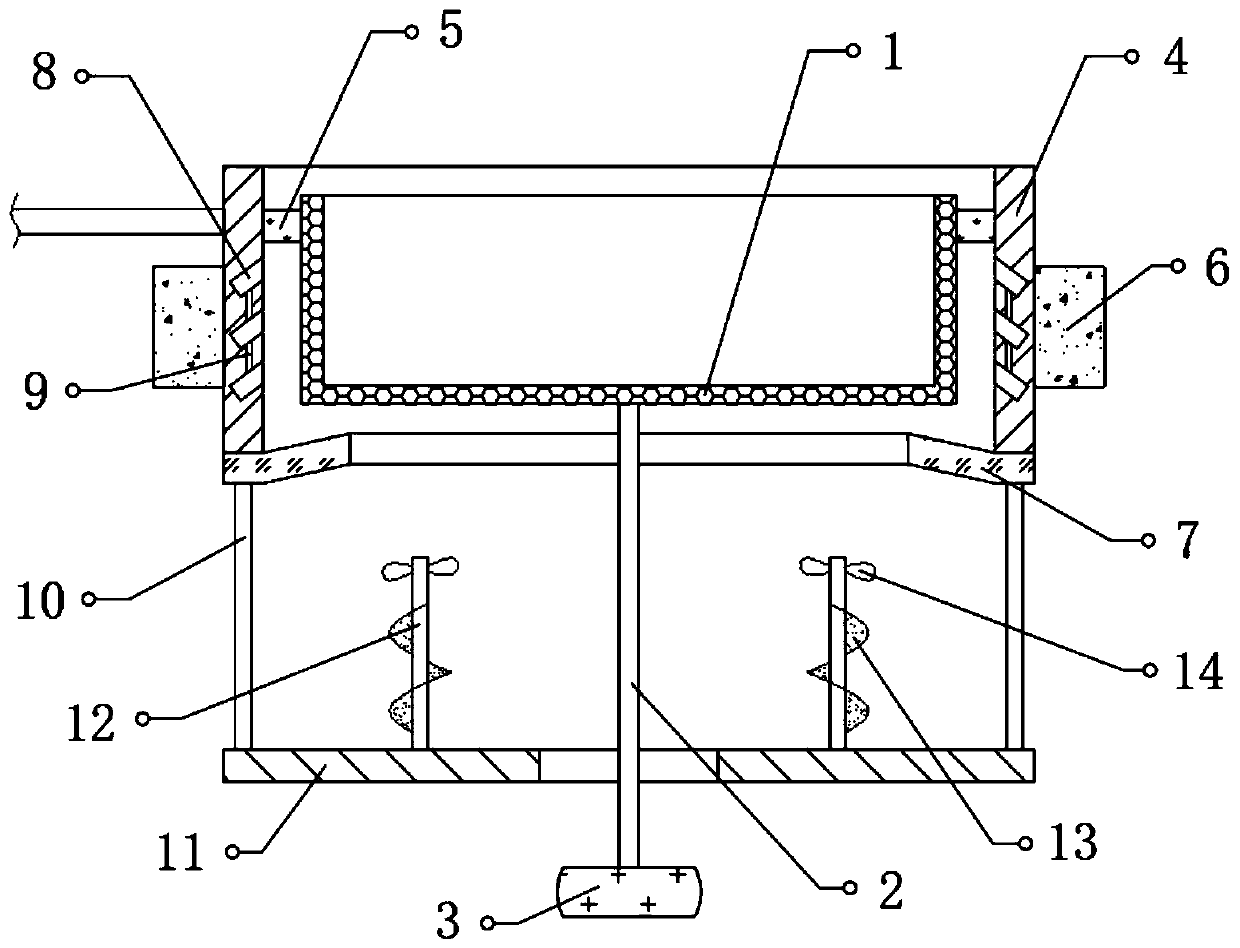

Environment-friendly riverway surface layer garbage cleaning device

The invention discloses an environment-friendly riverway surface layer garbage cleaning device. The environment-friendly riverway surface layer garbage cleaning device comprises a beam, side frames, agarbage collecting frame, a garbage collecting net and a rack. The vertical side frames are fixedly arranged at the two end portions of the beam correspondingly. The inner sides of the two side frames are set to be of a hollow structure, and sliding grooves are formed in the opposite sides of the two side frames correspondingly. The garbage collecting frame is set to be of a rectangular frame structure, and sliding plates are fixedly arranged at the two ends of the outer side of the garbage collecting frame correspondingly. The rack is fixedly arranged on the garbage collecting frame. The topend of the rack penetrates the beam and extends to the outer side of the beam. The part, close to the outer side of the rack, on the beam is fixedly provided with a motor installing frame. A motor isfixedly arranged in the motor installing frame, a gear is fixedly arranged at the end portion of an output shaft of the motor, and the gear and the rack are in meshing connection. The environment-friendly riverway surface layer garbage cleaning device is provided, and the problem that in the riverway inner intercepting process, a garbage net is likely to shake and twist, normal garbage intercepting is influenced is solved.

Owner:合肥炫升环保材料科技有限公司

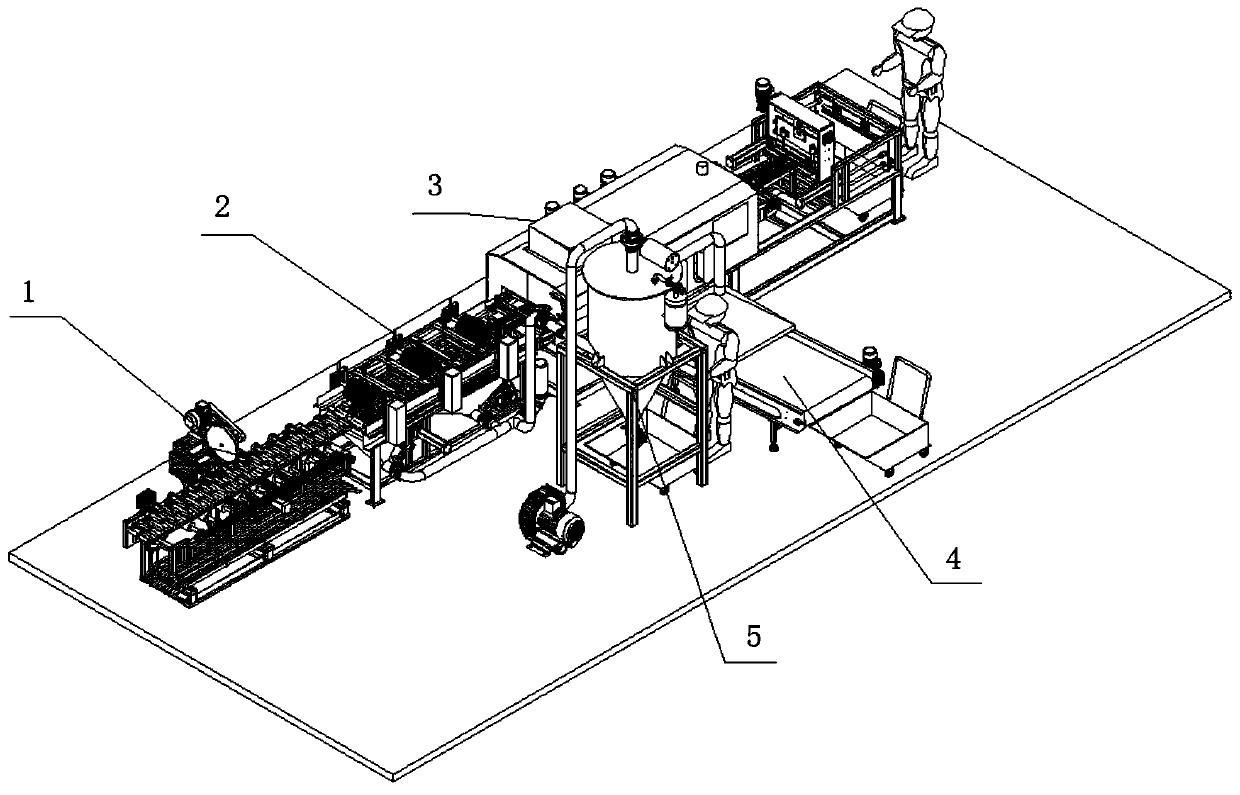

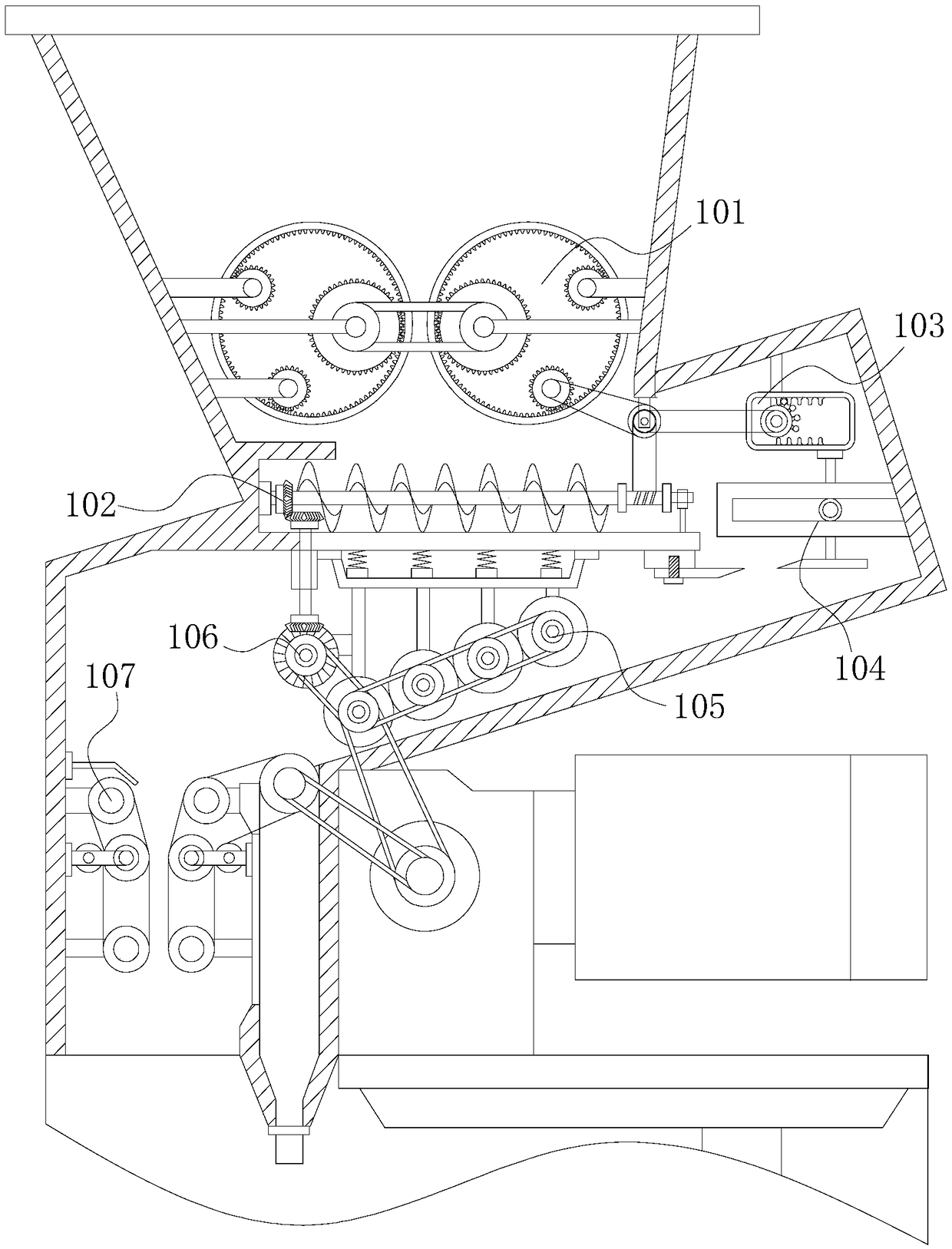

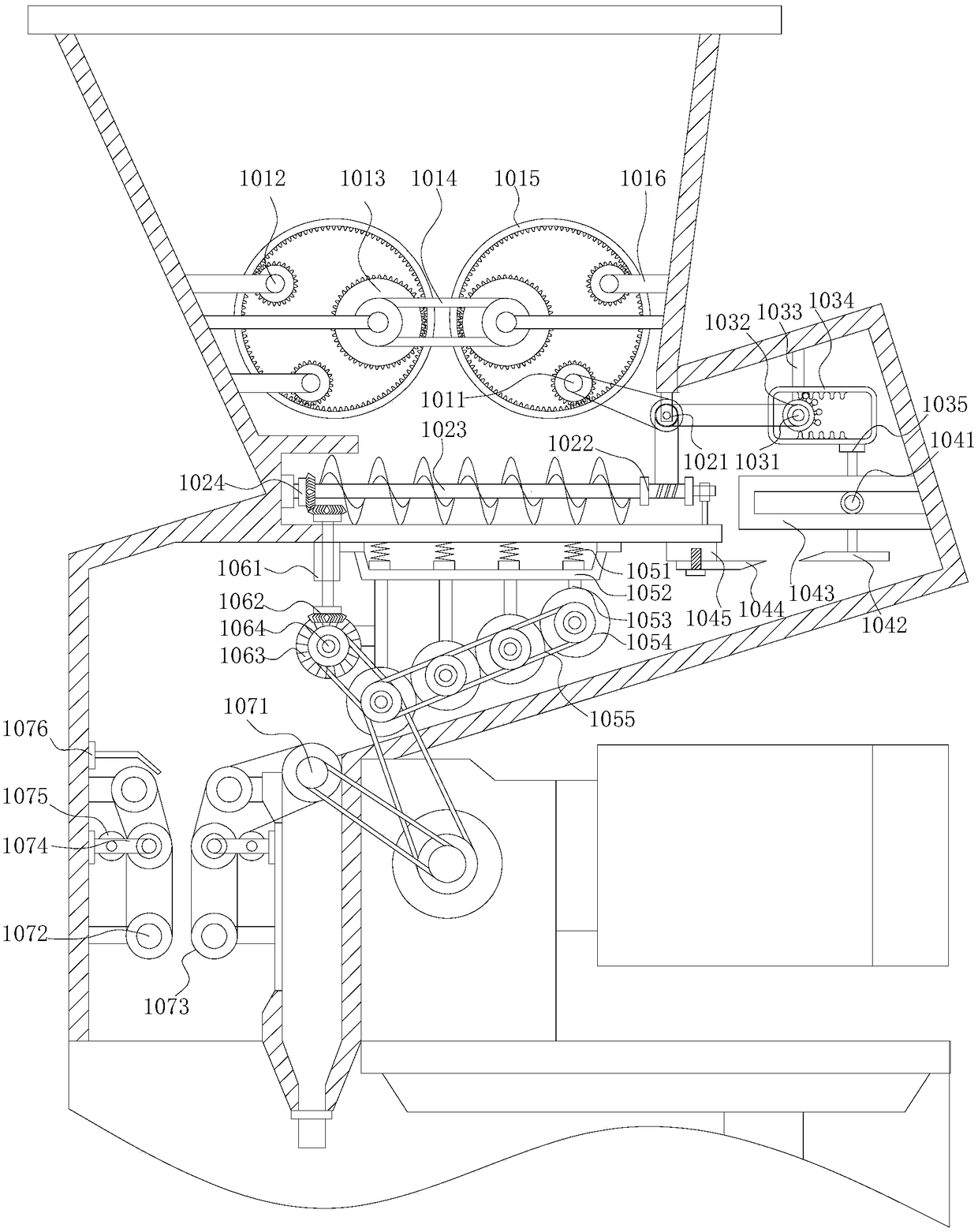

Waste rubber crawler belt material recycling production line

PendingCN110435048AImprove cutting recovery efficiencyNo displacementPlastic recyclingMetal working apparatusProduction lineSurface layer

The invention discloses a waste rubber crawler belt material recycling production line. The waste rubber crawler belt material recycling production line comprises a segmenting and cutting-off tool, asurface rough cutting tool, a surface treatment and separation device, a reclaimed material conveying structure and a vacuum recycling device; the segmenting and cutting-off tool is used for segmenting and cutting off a crawler belt; the surface rough cutting tool is used for carrying out rough cutting treatment on cut-off long-strip-shaped crawler belt surface rubber; the surface treatment and separation device is used for carrying out cutting treatment, embedded part separation, steel wire separation and steel wire shearing short and recycling on the roughly cut crawler belt remaining surface layer rubber; the reclaimed material conveying structure is used for conveying the cut surface rubber and an embedded part; and the vacuum recycling device is used for carrying out vacuum collectionand recycling on rubber particles left by the rough cutting treatment. According to the waste rubber crawler belt material recycling production line, residual rubber scraping, embedded part separation and steel wire shearing short and collection of the waste rubber crawler belt can be realized, the functions of the equipment are various, the classification and collection of all components in thewaste rubber crawler belt are effectively realized, the working synergy of all the mechanisms in the equipment is high, and the working efficiency is high.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

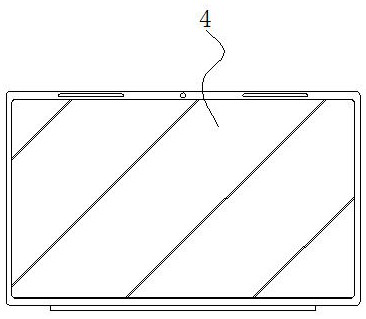

Computer electronic display screen cleaning device

InactiveCN111715575AImprove the extrusion effectImprove the use effectDrying gas arrangementsFlexible article cleaningPhysicsEngineering

The invention belongs to the technical field of computers, particularly relates to a computer electronic display screen cleaning device. The computer electronic display screen cleaning device aims tosolve the problem of poor long-time continuous cleaning effect of a computer electronic display screen in the prior art. The computer electronic display screen cleaning device comprises a cleaning box, a conveying seat extending to two sides is fixed to the inner wall of the bottom of the cleaning box, a plurality of nozzles are fixed to the middle of the inner wall of the top of the cleaning box,rotating rods are rotationally connected to the positions, located on the two sides of the nozzles, between the inner walls of the two ends of the cleaning box, and the middles of the outer walls ofthe rotating rods are sleeved with washing rollers. According to the computer electronic display screen cleaning device, liquid accumulated in the washing rollers can be guided and led out towards thetwo ends through multiple flow guiding grooves in the outer wall of each rotating rod, washing pieces connected with springs on the outer walls of the washing rollers reciprocate to improve the cleaning effect, meanwhile, the extrusion effect on the interiors of the washing rollers can be improved, and the liquid accumulated in the washing rollers can be conveniently conveyed into the flow guiding grooves to be led out, so that the use effect of the device for cleaning an electronic display screen for long time is improved.

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

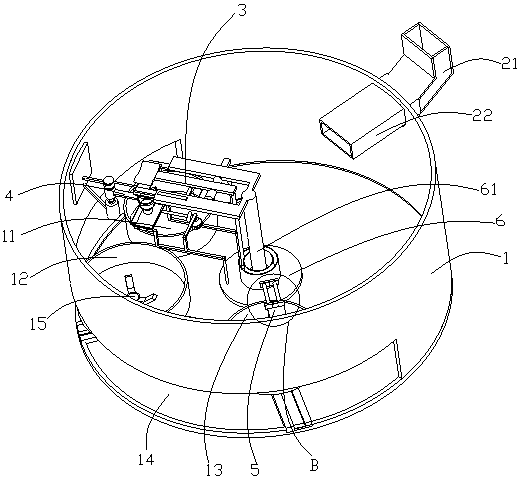

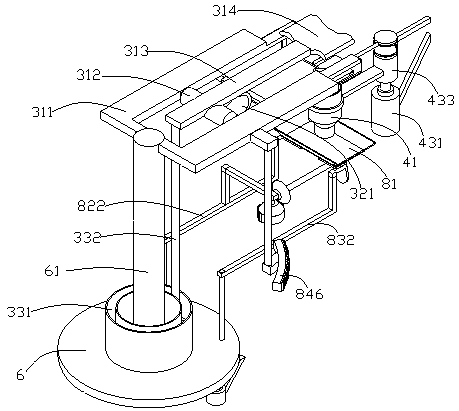

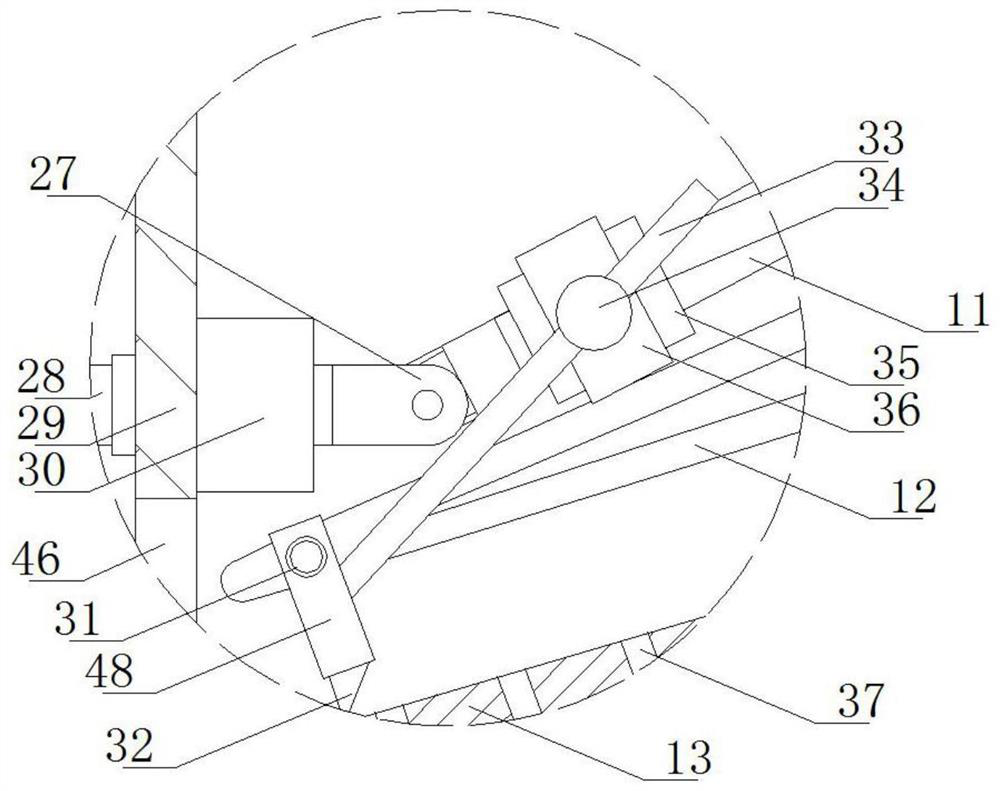

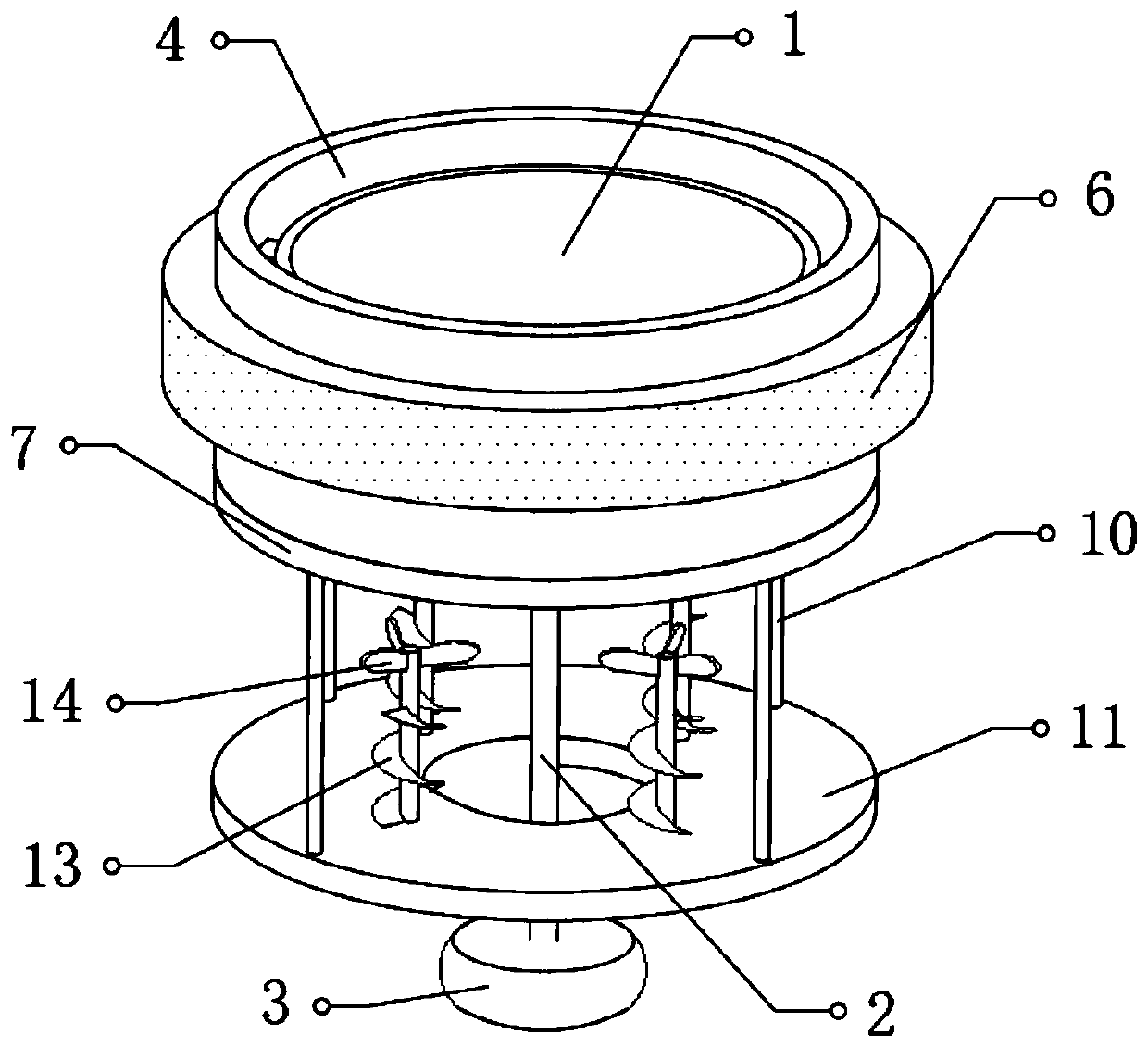

Egg white automatic separating system based on food safe processing

ActiveCN110710900ACoherent operationImprove work efficiencyKitchen equipmentAnimal scienceEngineering

The invention discloses an egg white automatic separating system based on food safe processing. The system comprises a barrel, a blanking device arranged on the barrel, a support part arranged in thebarrel, a first rotation shaft matched with the support part, a first drive device used for driving the first rotation shaft to realize intermittent rotating, an egg shell breaking device matched withthe first rotation shaft, an egg white and egg yolk separating device matched with the egg shell breaking device, and an egg shell collecting device, wherein the egg shell breaking device comprises an egg pressing assembly and an egg opening assembly matched with the egg pressing assembly, and the egg pressing assembly comprises a support rack arranged on the first rotation shaft, a rotating shaft arranged on the support rack, a support rod matched with the rotating shaft, a pressing plate arranged at one end of the support rod, and a second driving assembly used for driving the support rod to act. For the system, the operation is continuous, the manual operation is liberated, the egg shell breaking efficiency is high, and meanwhile, the sanitation of the egg shell breaking and egg whiteand egg yolk separating operation is greatly improved.

Owner:上海麦宝食品有限公司

Film laminating device with display screen cleaning function and for laminating film on computer display screen

PendingCN113247348AEasy maintenanceTo achieve the effect of flippingPackaging automatic controlSynchronous motorEngineering

The invention discloses a film laminating device with a display screen cleaning function and for laminating a film on a computer display screen, and relates to the technical field of computer display screen machining. The film laminating device comprises a base, a cleaning mechanism and a film laminating mechanism, a placement frame is arranged at the position, close to the edge, of the upper end of the base, a feeding conveying belt is arranged on the left side of the upper end of the base, and a computer display screen body is placed at the upper end of the feeding conveying belt. The computer display screen body placed in a first transfer mechanism can be clamped through clamping assemblies symmetrically distributed on the two sides of a cleaning bin, the effect that the clamping assemblies drive the computer display screen body to turn over can be achieved in cooperation with an arranged synchronous motor, dust on the surface of the computer display screen body can be cleaned through cooperation with a cleaning palm brush vertically distributed in the center of the interior of the cleaning bin, lifting and rotating of the cleaning palm brush are achieved through an air cylinder and a motor arranged at the bottom, and the effect of cleaning the dust on the surface of the computer display screen body is achieved.

Owner:深圳市凤舞科技有限公司

Marine domestic sewage filtering device

ActiveCN109574300AImprove purification effectEnsure sustainable filtrationSpecific water treatment objectivesTreatment involving filtrationEngineeringSewage

The invention discloses a marine domestic sewage filtering device. The marine domestic sewage filtering device comprises a mixing tank and a purifying tank, a filtering cabin and a discharging cabin are arranged inside the mixing tank from top to bottom, a water inlet and a water outlet which are communicated with the filtering cabin are respectively formed in a left side and a right side of the mixing tank, the water outlet is connected with the purifying tank through a connection tube a, a filtering unit is mounted in the filtering cabin and comprises a stirring shaft, the stirring shaft isinternally hollow and provided with a flow guiding channel, and communication holes are evenly formed in a sidewall of the flow guiding channel. The marine domestic sewage filtering device is capableof purifying sewage in batches, reducing water resource waste and benefiting later-period collection and treatment of a water body.

Owner:ZHEJIANG OCEAN UNIV

Novel wood cutting machine

InactiveCN108326993APrevent the risk of misalignmentImprove work efficiencyGuide fencesBark-zones/chip/dust/waste removalDrive wheelTransmission belt

The invention relates to the technical field of wood processing equipment, and discloses a novel wood cutting machine. The novel wood cutting machine comprises supporting legs. One side of each supporting leg is fixedly connected with one side of a load-bearing plate. A height adjusting device is fixedly installed in the middle of the top end of the load-bearing plate. A driving device and a driving motor are correspondingly arranged on the two sides of the height adjusting device. An output shaft of the driving motor is connected with a driven wheel through a transmission belt II in a transmitting mode. The novel wood cutting machine can cut the wood with various thickness, and is especially for cutting of wood with ultra-thickness, twice cutting forward and backward are not required, therisk of the dislocation of the twice cutting is avoided, and the cutting efficiency is improved; and at the same time, because a precise screw rod is arranged, and the pinch of a thread is 1 mm, whenthe functions of cutting and seam-taking are needed, a crank is manually adjusted, the height of a cutting piece exposed to an operating table is slowly adjusted according to the required cutting depth, so that the precise cutting data parameter is conveniently obtained, and the high-precision cutting operation is realized.

Owner:胡云康

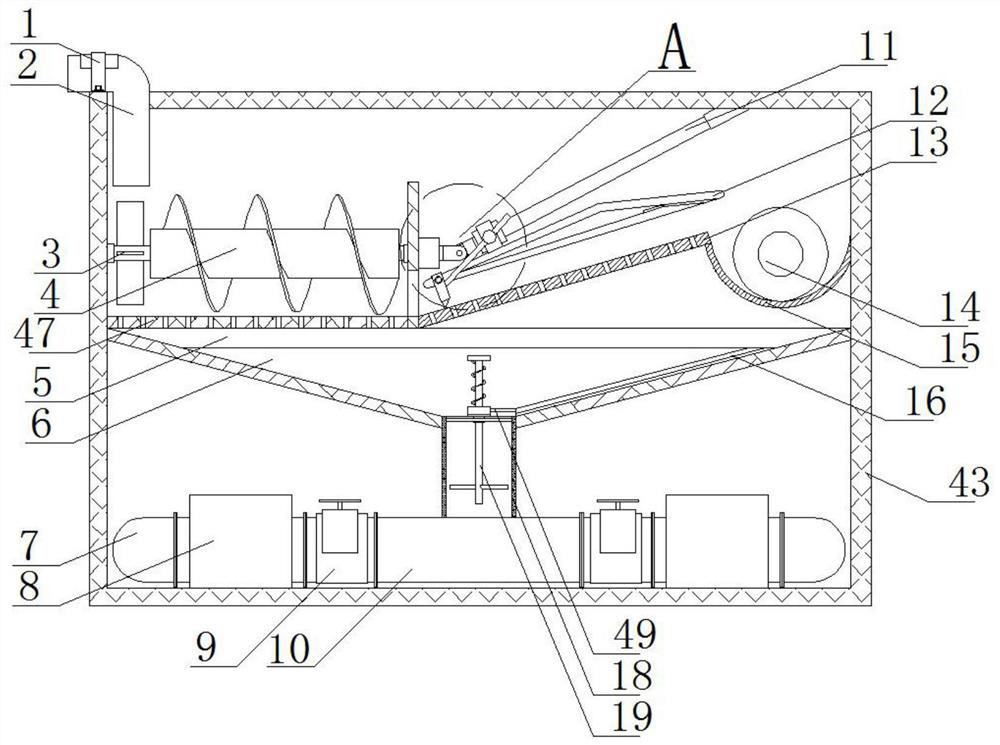

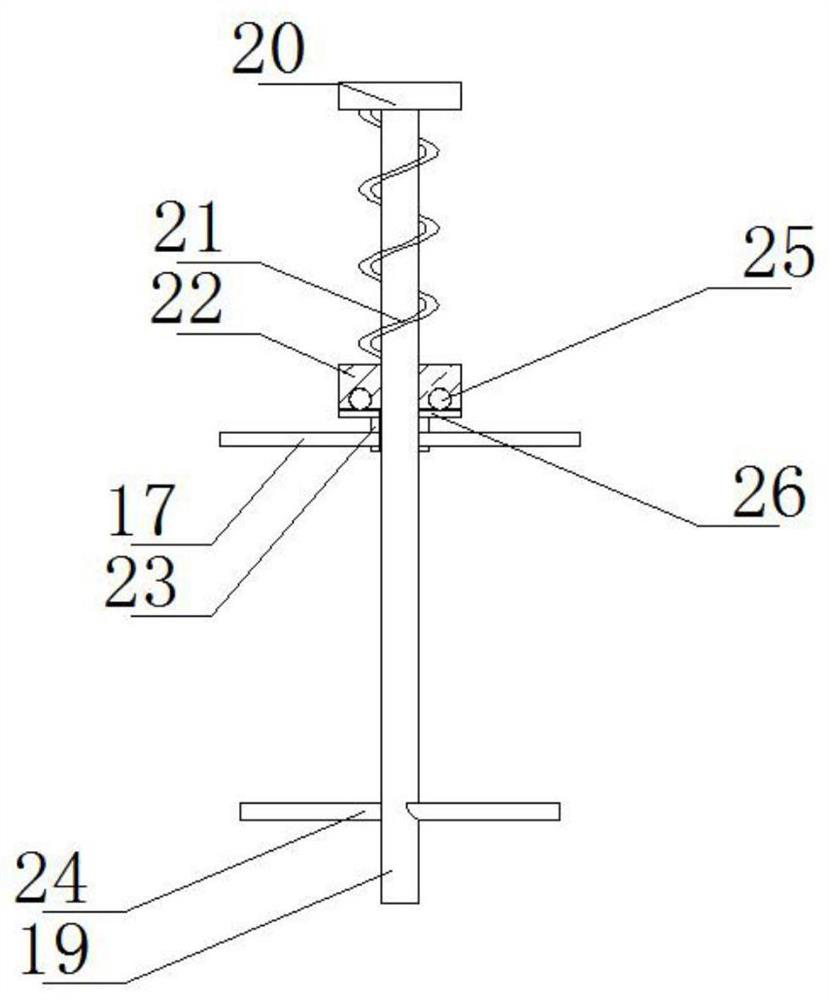

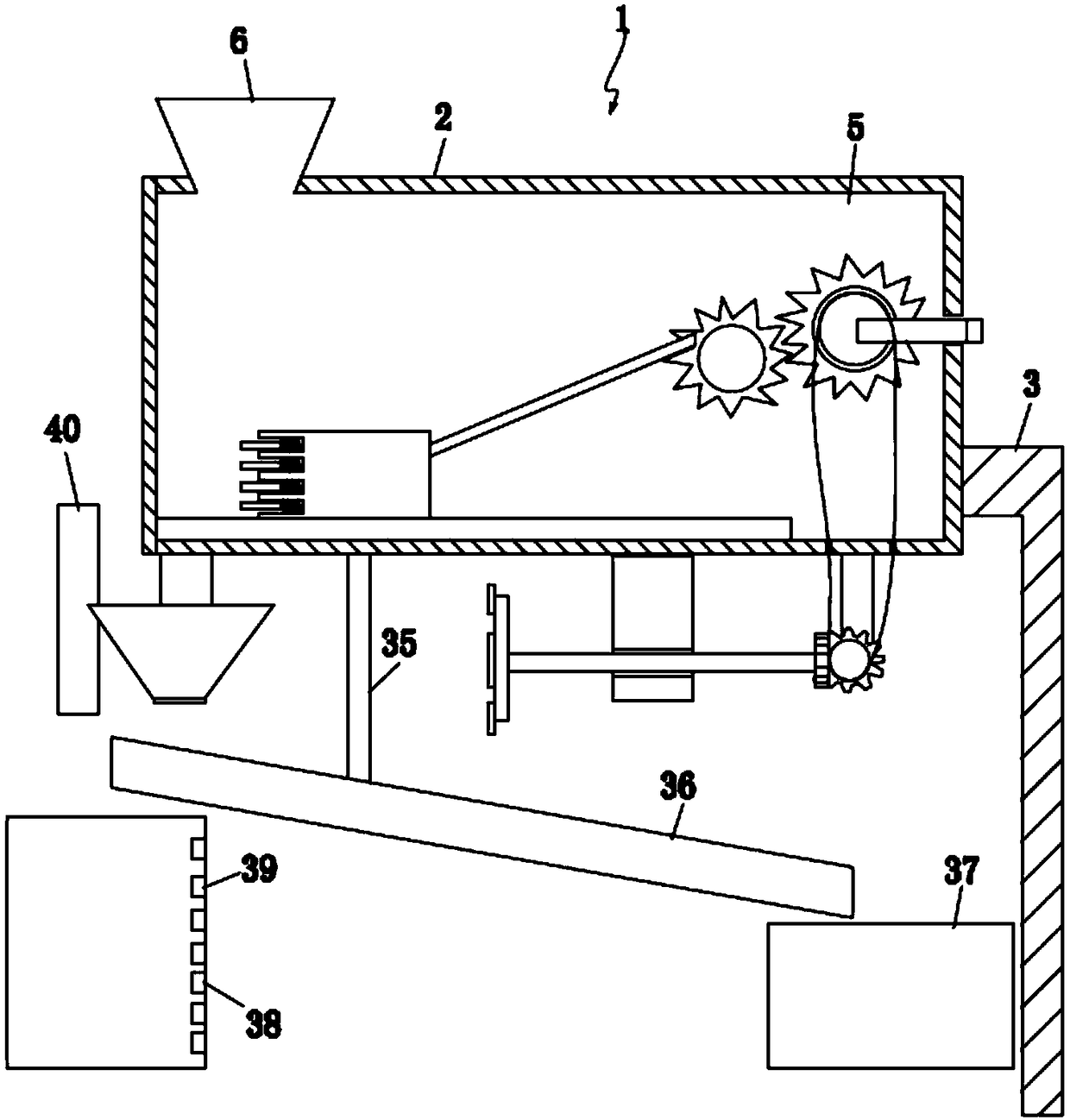

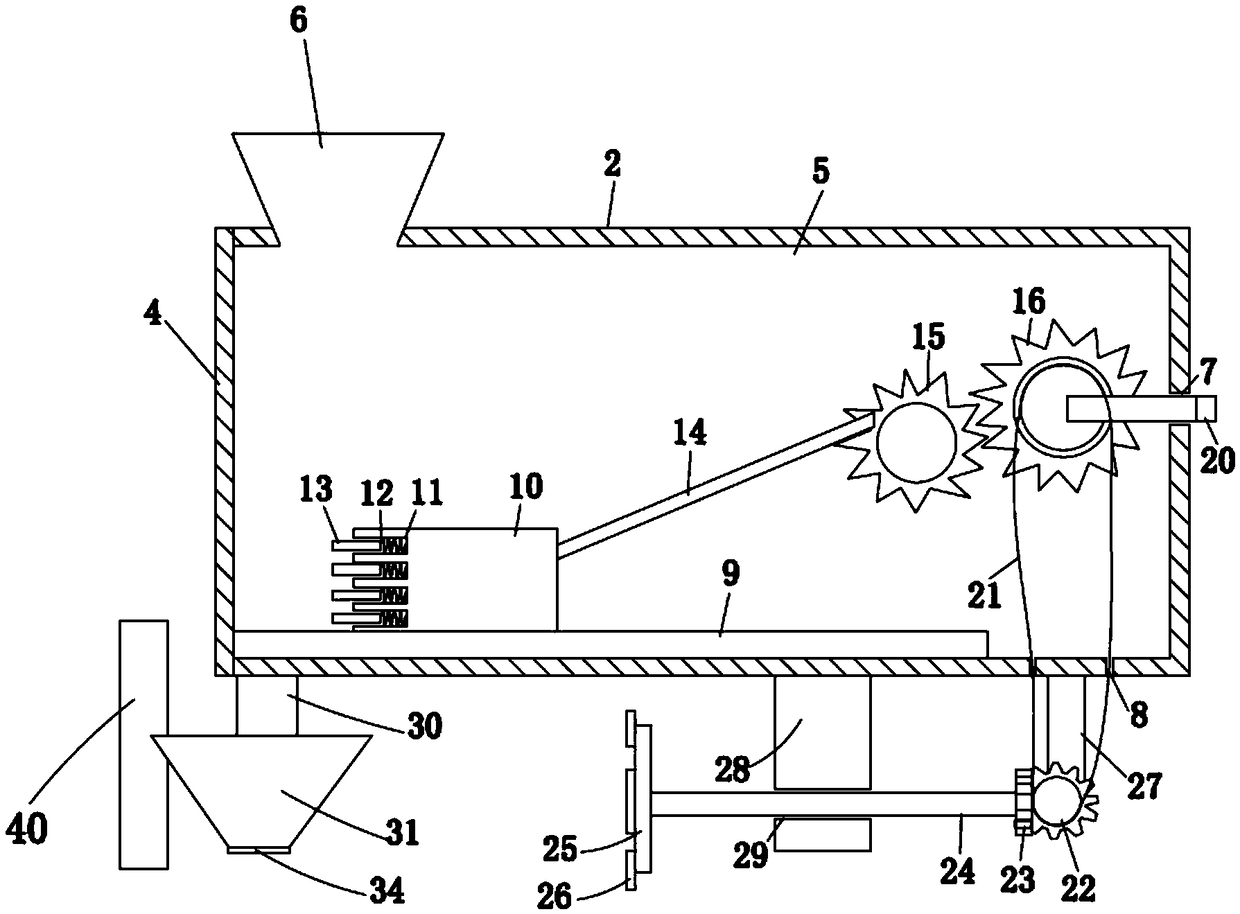

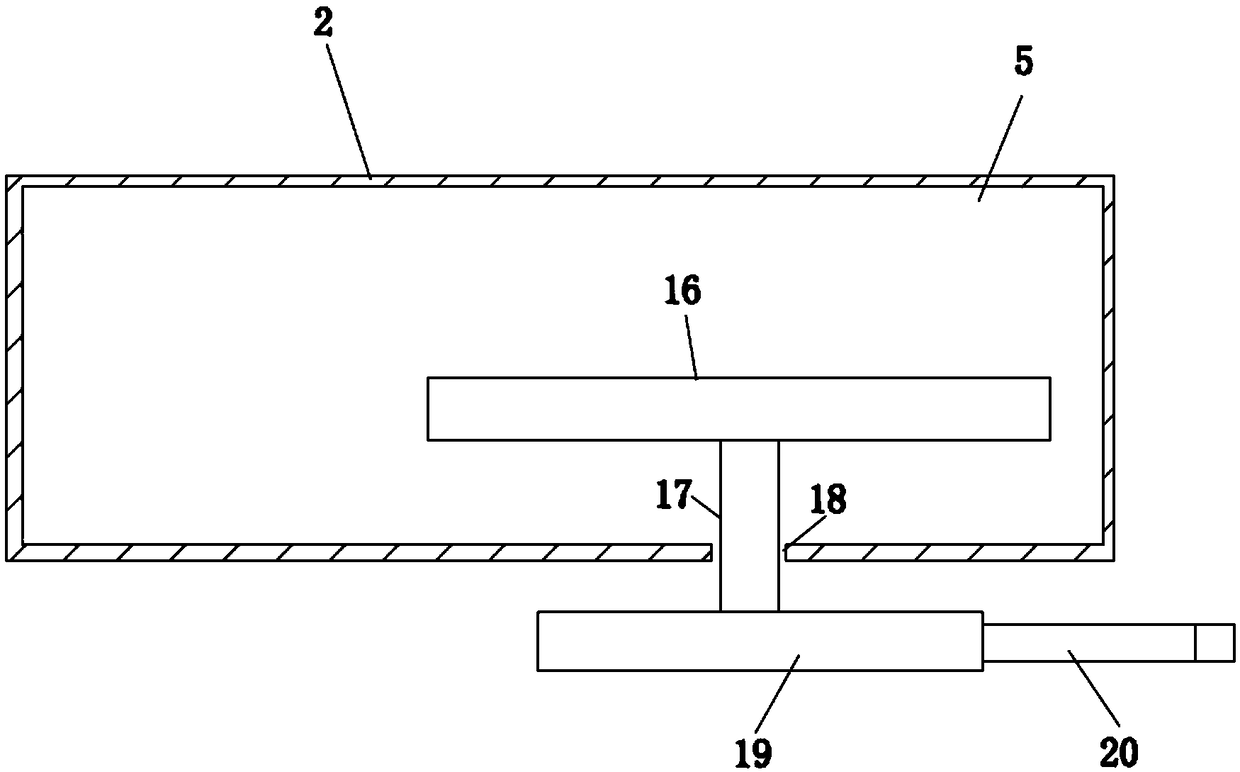

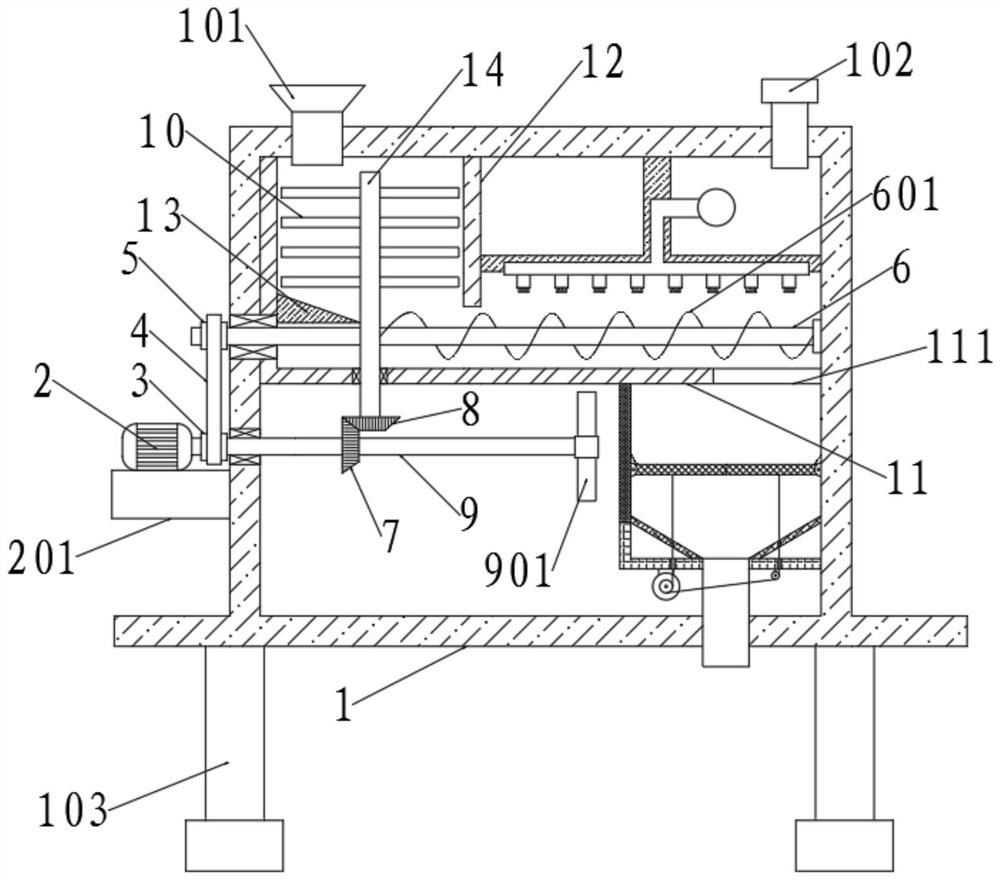

Integrated mechanical equipment for producing green and environment-friendly fertilizer

InactiveCN111514774AEasy to operateAvoid loadRotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses integrated mechanical equipment for producing a green and environment-friendly fertilizer. The equipment comprises a bottom plate, and an adjusting mechanism is arranged on thebottom plate. A mixing tank is arranged on the adjusting mechanism, a discharging port is formed in the lower end of one side of the mixing tank, a cover plate is hinged to the lower end of one sideof the mixing tank, the cover plate corresponds to the discharging port, a stirring mechanism is arranged in the mixing tank, and a feeding hopper is arranged at the upper end of the mixing tank in apenetrating mode. Four supporting rods are rotatably connected to the two sides of the bottom plate. According to the invention, workers can conveniently add corresponding ingredients and materials into two bearing boxes respectively, the accuracy of the ratio of the ingredients to the materials can be well ensured, stirring can be continuously and circularly carried out, so that continuous production is realized, the problem of non-uniform mixing caused by mixing during conveying in the past is avoided, materials and ingredients can be sufficiently and uniformly mixed, the quality of the green and environment-friendly fertilizer is guaranteed, the mixed fertilizer is convenient to collect, and the working efficiency is improved.

Owner:唐爱国

Trimming device for cotton cloth processing

ActiveCN110371742APrevent burrsGuaranteed qualitySevering textilesWebs handlingHydraulic cylinderEngineering

The invention discloses a trimming device for cotton cloth processing. The trimming device for the cotton cloth processing comprises a bottom plate, wherein a plurality of support legs are fixedly connected with the bottom of the bottom plate, two support plates are fixedly connected with the top of the bottom plate, a clamping mechanism is arranged between the two support plates, the same horizontal plate is fixedly connected with the tops of the two support plates, two hydraulic cylinders are fixedly connected with the bottom of the horizontal plate, and a cutting tool is fixedly connected with the bottoms of the hydraulic cylinders. When the trimming device for the cotton cloth processing is used, cloth is in a tensioned state when the cutting tool cuts the cloth by changing the relative position of a moving plate and a fixed plate in the process of using a belt conveyor for driving a limiting plate to move under interaction among the belt conveyor, the limiting plate, the moving plate, a vertical rod, the fixed plate, a first pressing plate and a second pressing plate, and then the circumstance that rough edges appear on the cloth is avoided, quality of the cloth is guaranteed,and convenience is provided to following processing of the cloth.

Owner:徐州兰岳企业管理服务有限公司

Machine tool table with automatic scrap cleaning function

InactiveCN107617926AAutomate cleaningAutomatic Fixed CleanupLarge fixed membersMaintainance and safety accessoriesMachine toolThreaded rod

The invention provides a machine tool table with an automatic scrap cleaning function. The machine tool table with the automatic scrap cleaning function comprises a base, wherein a working table is arranged on the base; a coolant flow guide groove is formed in the working table; an extension seat is arranged on the rear side of the base; a driving device is arranged on the extension seat and is connected with a movable pressure plate through a retractable rod; a fixing seat is arranged on the front side of the base; a threaded rod for fine adjustment is arranged on the fixing seat; the threaded rod is connected with a fixed pressure plate; two supporting blocks for supporting the fixed pressure plate are arranged on the base; a mounting seat for fixing a pushing rod is arranged at an end of the left side of the base; a push plate for cleaning scraps is arranged at a movable end of the pushing rod; a scrap transition groove with the bottom being an inclined plane is formed in the rightend of the base; and a coolant groove is formed in the base and positioned between the working table and the mounting seat. The machine tool table with the automatic scrap cleaning function is simplein structure and reasonable in design; a machined component can be fixed automatically; and meanwhile, the scraps on the working table can be cleaned automatically.

Owner:常州市金沃焊割设备有限公司

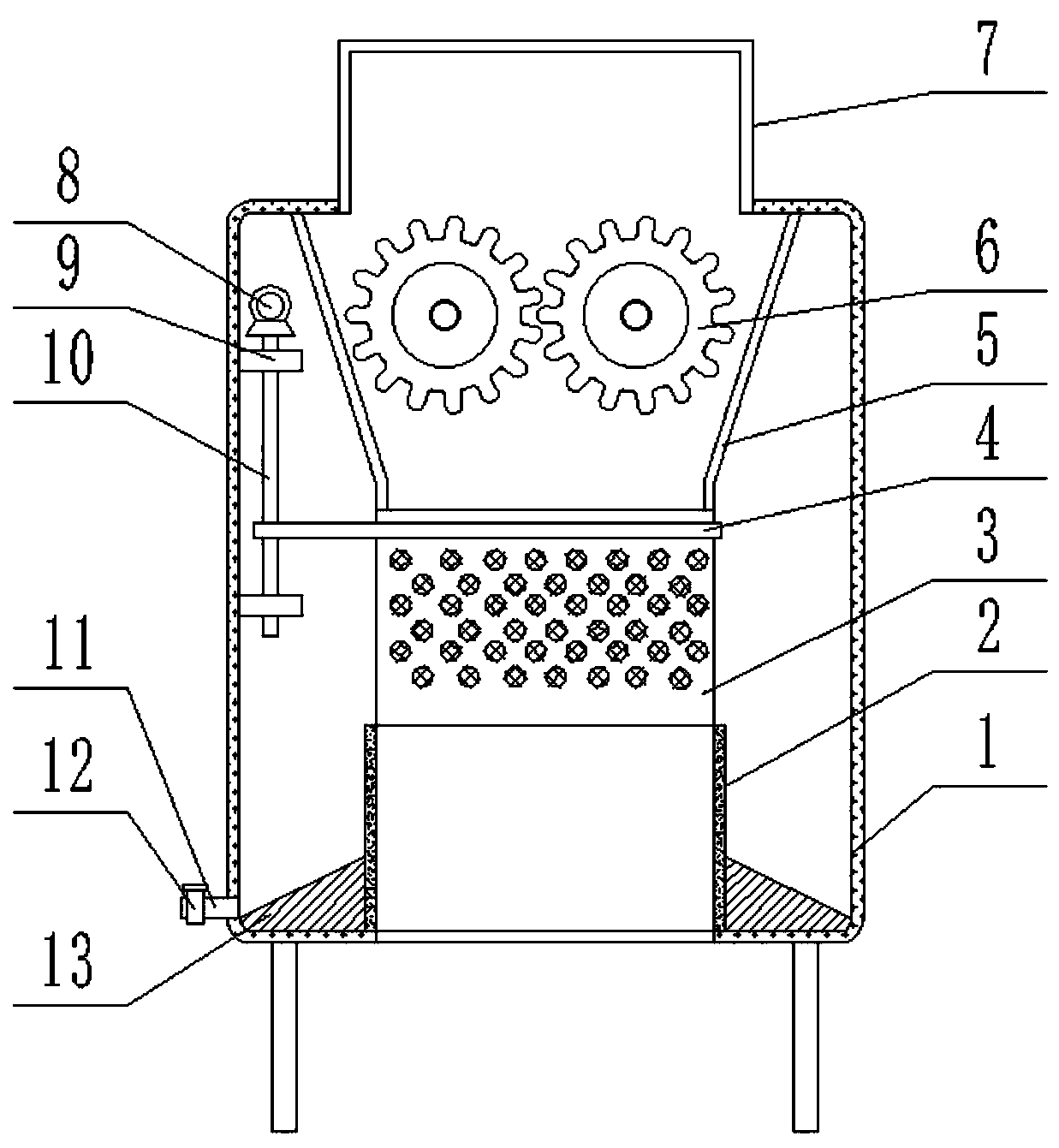

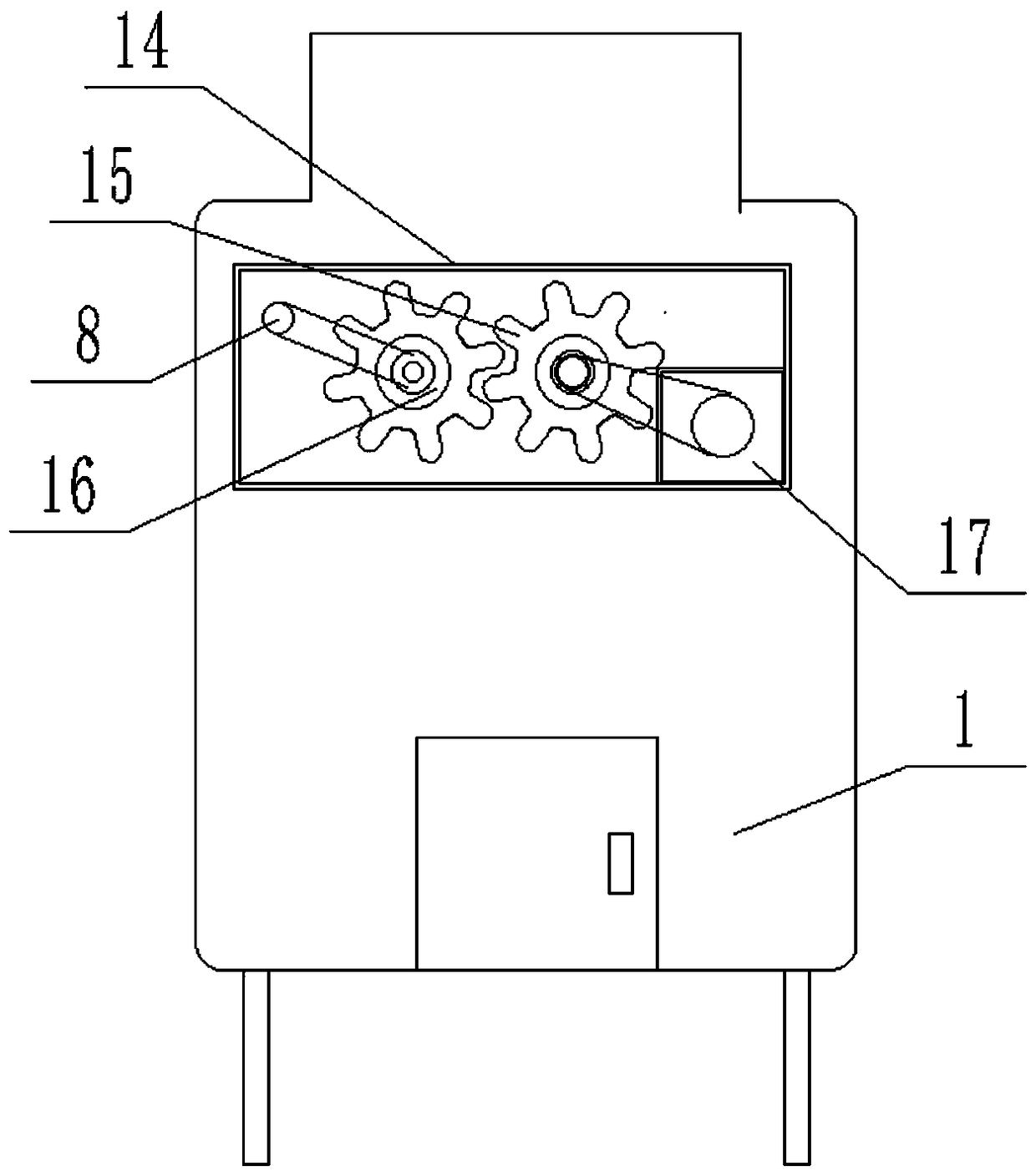

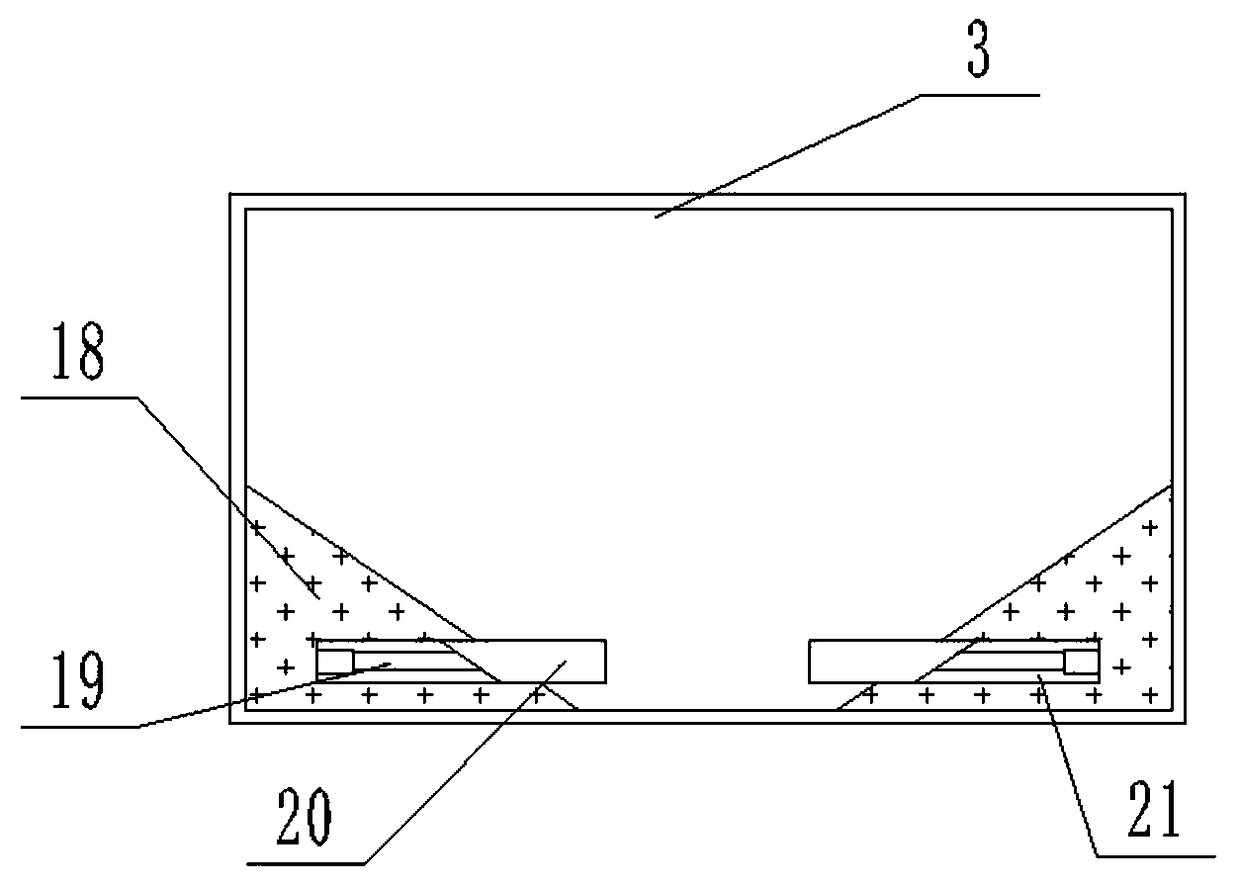

Environment-friendly solid-liquid separation device for kitchen waste

InactiveCN109277132AImprove degradation efficiencyReduce pollutionGrain treatmentsEngineeringPollution

The invention discloses an environment-friendly solid-liquid separation device for kitchen waste. The environment-friendly solid-liquid separation device comprises a box. A feeding port is formed in the outer wall of the top of the box. A feeding hopper is arranged on the inner wall of the feeding port. A limiting hopper is arranged on the inner wall of the top of the box. Two pulverizing rollersare arranged in the limiting hoper. A first annular sliding groove is formed in the outer wall of the bottom of the limiting hopper. A separation barrel is rotationally connected to the inner wall ofthe first annular sliding groove. An isolation barrel is arranged on the inner wall of the bottom of the box. A second annular sliding groove is formed in the outer wall of the top of the isolation barrel. The bottom end of the separation barrel is rotationally connected in the second annular sliding groove. A first inclined table is arranged on the inner wall of the bottom of the box. The environment-friendly solid-liquid separation device can grind and refine the kitchen waste in advance, centralized treatment is convenient, the garbage degrading efficiency is improved, pollution to the environment from the kitchen waste is reduced to the great degree, one motor is used for finishing pulverizing and separating of the kitchen waste, energy saving and environment friendliness are achieved,and the equipment cost is reduced.

Owner:文露

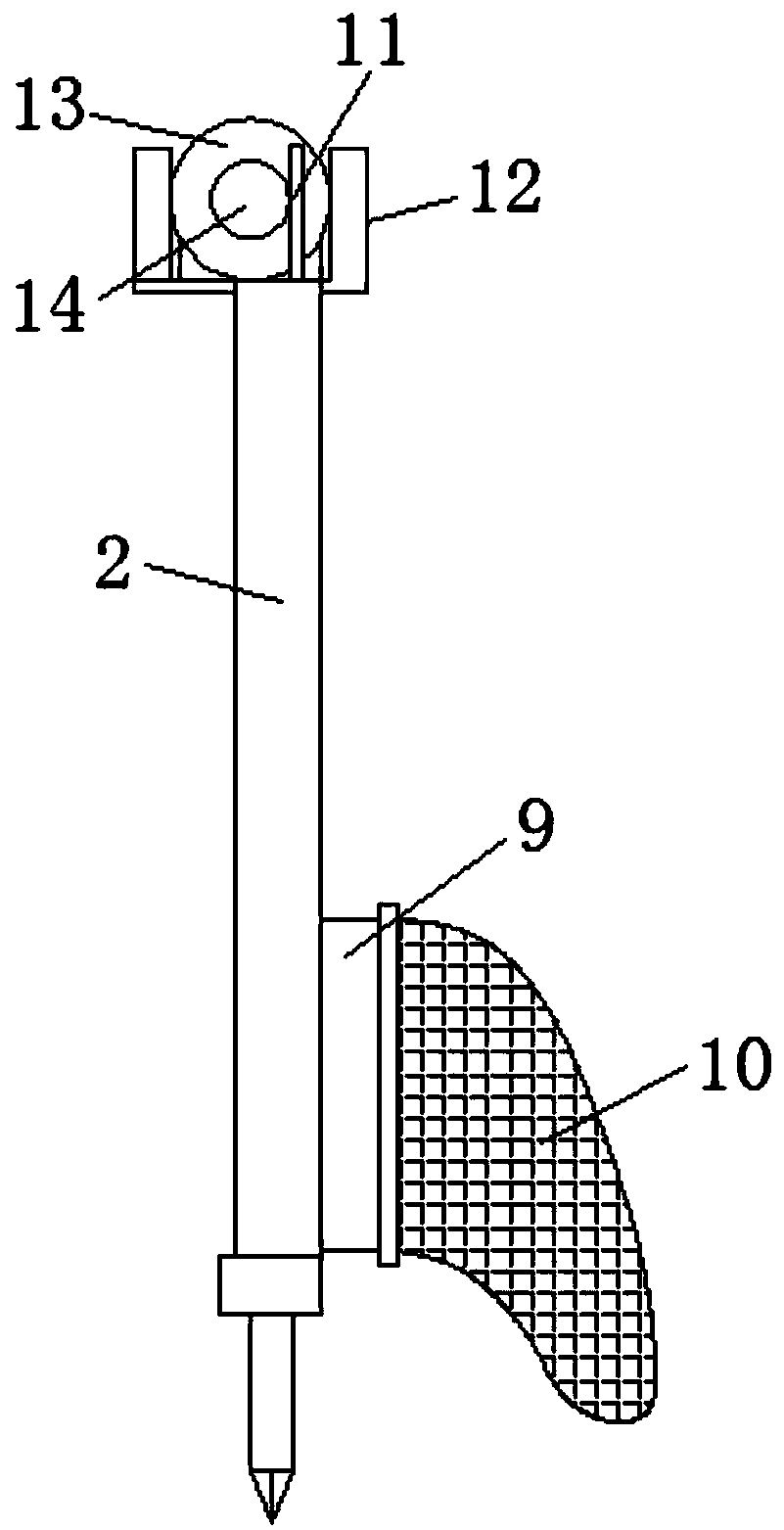

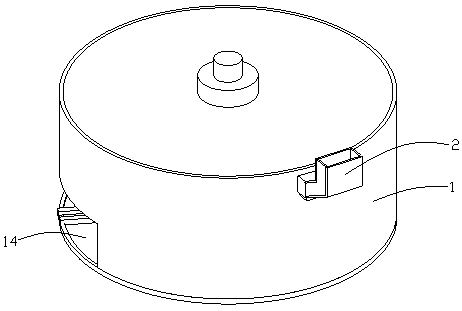

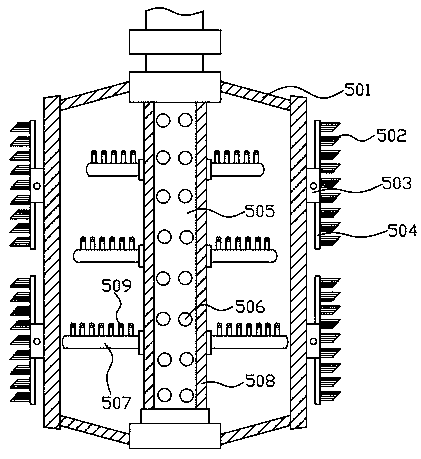

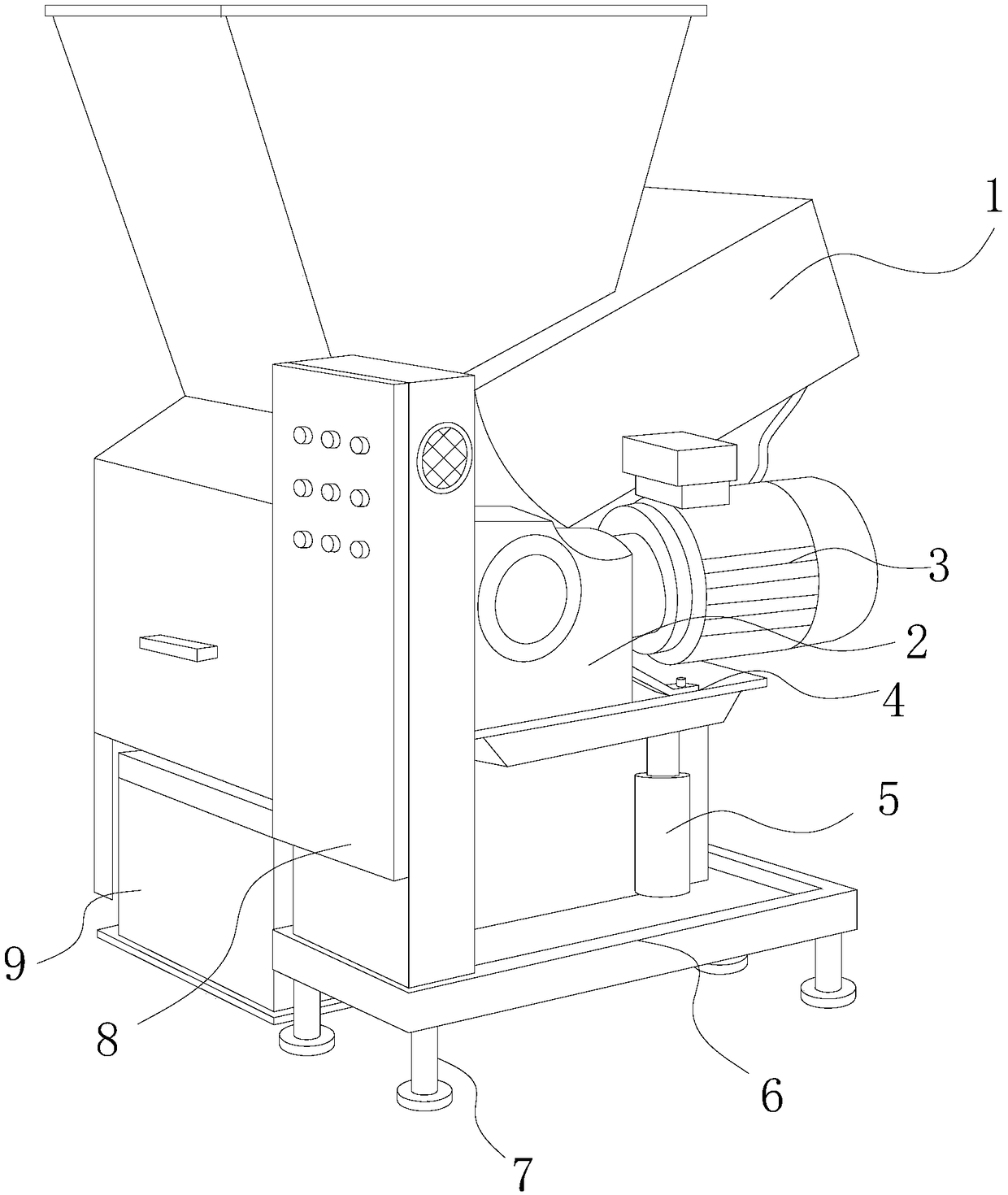

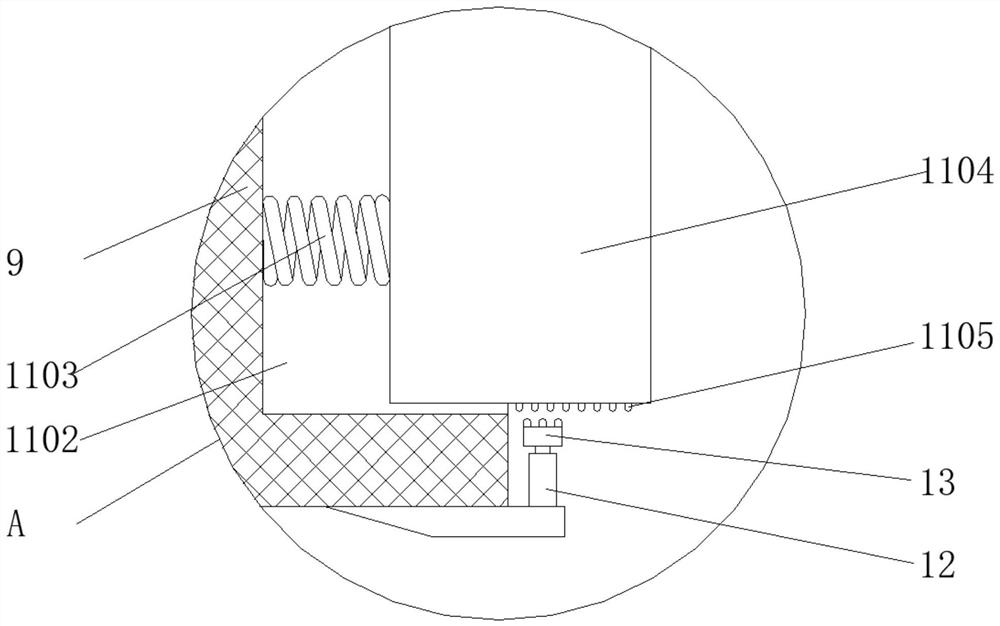

A marine litter recovering device

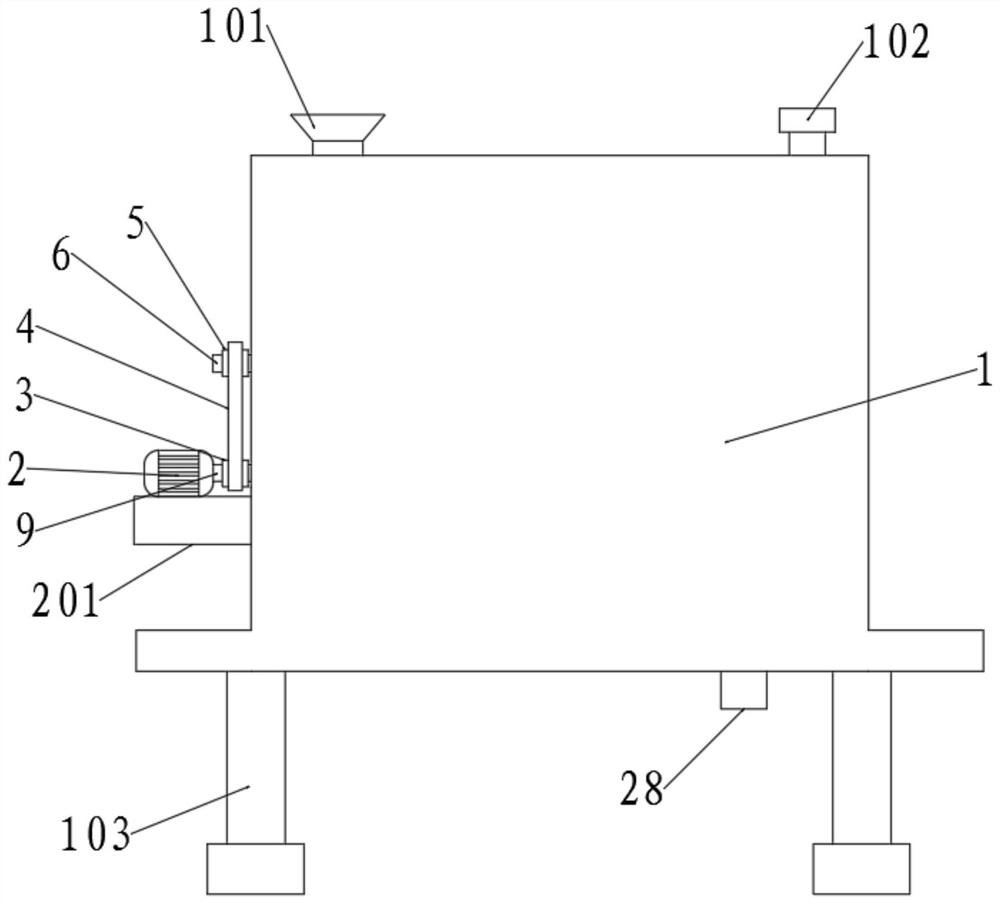

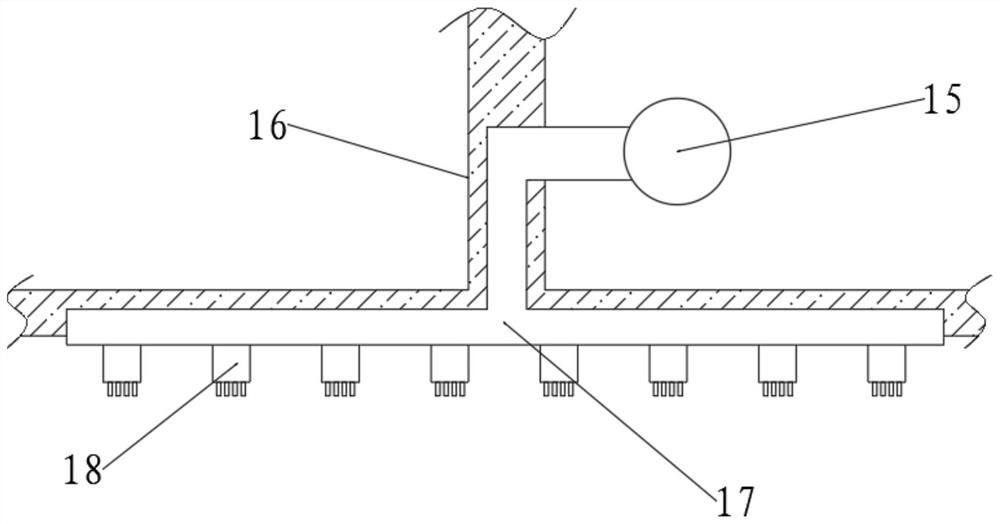

InactiveCN108746144AEasy to stackConvenient for centralized collection and processingSolid waste disposalTransportation and packagingLitterReducer

A marine litter recovering device is disclosed. The device includes a smashing tank, a reducer, a motor, a supporting base, a shock absorber, a bottom plate, adjusting feet, a control cabinet and a collection tank. The smashing tank is mounted at the rear end of the reducer, and is fixed through bolts. The bottom of the reducer is tightly attached to the top of the supporting base, and a coupler at the rear end of the reducer is mechanically connected to the main shaft of the motor. The control cabinet is perpendicularly fixed to the front end of the reducer, with a gap existing between the control cabinet and the reducer. The supporting base and the top of the bottom plate are in a clearance fit through the shock absorber in a top groove. The smashing tank of the device works in a mannerthat the reducer is driven by the motor. The transformed marine litter recovering device smashes and compresses litter, thus facilitating centralized collection and treatment and preventing further pollution.

Owner:曾丽琼

Punching device capable of conveniently punching packaging type mechanical sealing parts for pump

InactiveCN111730091AEasy to punchImprove stabilityPrecision positioning equipmentLarge fixed membersPunchingElectric machinery

The invention discloses a punching device capable of conveniently punching packaging type mechanical sealing parts for a pump. The punching device comprises a base, clamping frames and a sleeve, wherein the clamping frames are rotationally connected to the bottoms of motor boxes on the left side and the right side, the sleeve is rotationally connected to the bottom of a motor box on the rear side,the left side of a third bracket is connected with a dust collection channel through a second electric telescopic rod, a dust collector is placed on the left side of the third bracket, and the lowerside of the right side of the dust collection channel is connected with a dust collection hose through an electric telescopic column. According to the punching device capable of conveniently punchingthe packaging type mechanical sealing parts for the pump, in the process of separating fastening parts from the mechanical sealing parts, chippings left on the mechanical sealing parts can sequentially pass through the dust collection hose, the dust collection channel and a connecting pipeline to enter a waste box under the action of the dust collector, so that centralized collection and treatmentare facilitated; and the dust collection hose can move left and right and up and down, meanwhile, the mechanical sealing parts rotate, and thus comprehensive chip removal operation can be conveniently completed.

Owner:JIANGSU YITONG FLUID TECH

Domestic household-garbage crushing disposal device based on wind energy

ActiveCN107952548AConvenient for centralized collection and processingDirt cleaningGrain treatmentsTransmission beltEngineering

The invention discloses a domestic household-garbage crushing disposal device based on wind energy. The domestic household-garbage crushing disposal device comprises a placing shell and a disposal device; the placing shell is internally provided with a driving rotating shaft, fan blades, a driven rotating shaft, a transmission belt, a rotating rod, a rotating pin, a rotating sleeve, a connecting rod, a piston plate, an air inlet pipeline and an air outlet pipeline; and the disposal device is arrange at the right end of the placing shell, and the disposal device is internally provided with a crushing cavity, an odor removing cavity, a pushing rod, a rack, a feeding hopper, a crushing shaft, a cutting blade, a transmission gear, a sewage discharging pipeline and an air outlet grille. According to the domestic household-garbage crushing disposal device based on the wind energy, though wind energy transmission, better energy conservation and emission reduction effects are achieved, crushing of garbage materials is driven by the wind energy, centralized collecting is facilitated, meanwhile, circulating ventilation filtering can effectively avoid the odor in garbage from affecting the environment.

Owner:XUZHOU LIANGHAN AGRI DEV CO LTD

Municipal sewage treatment filtering device

InactiveCN113332762AImprove impact performanceAvoid siltingStationary filtering element filtersEngineeringMunicipal sewage

The invention discloses a municipal sewage treatment filtering device which comprises a box body, a partition plate is fixed to the side wall of one end in the box body, a vertical plate is fixed to the upper end of the partition plate, an inclined plate is fixed to one side of the partition plate, an arc-shaped plate is fixed to one side of the inclined plate, and the arc-shaped plate is fixedly connected with the side wall of the other end in the box body. And a discharge mechanism is arranged on the arc-shaped plate. According to the municipal sewage treatment filtering device, sewage can be well filtered, impurities in the sewage can be reduced, the subsequent sewage filtering treatment effect can be improved, the impurities in the sewage can be conveniently cleaned and collected, centralized treatment of the impurities is facilitated, meanwhile, a large number of impurities can be effectively prevented from being attached to a filtering part, cleanliness of the filtering part is guaranteed, the service life of the filter is prolonged, the filtering efficiency and quality are guaranteed, meanwhile, flow diversion can be well carried out, closing and opening can be conveniently carried out according to needs, overhauling and maintenance can be sequentially carried out under the non-stop condition, and the filtering work quality is guaranteed.

Owner:刘建华

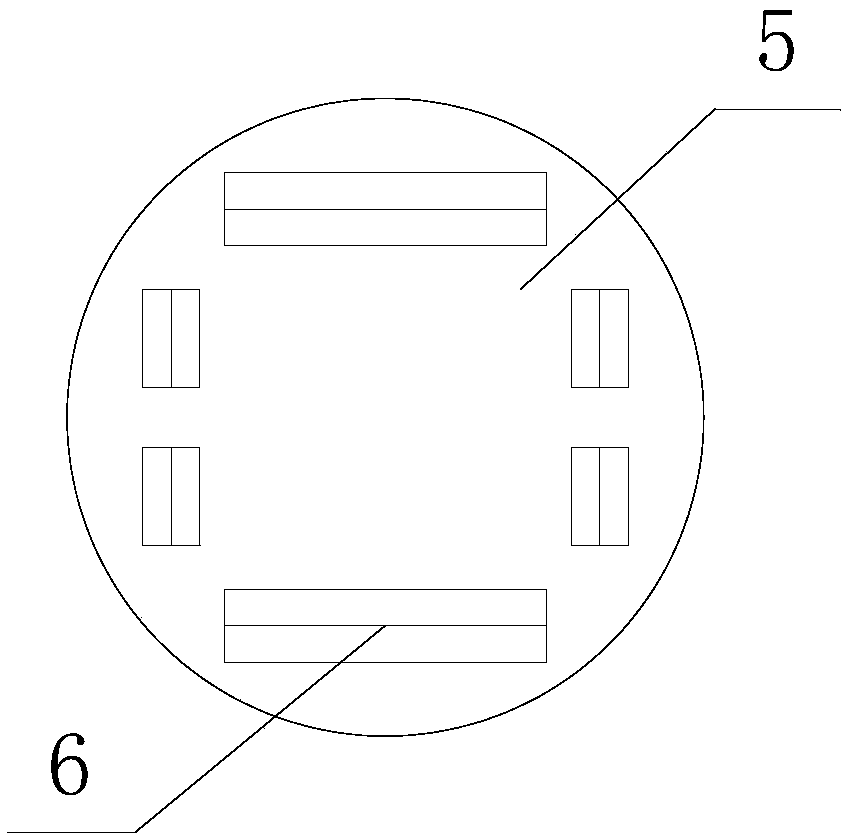

Glass spin-drying device

PendingCN109489378AQuick removalEasy to fixDrying solid materials without heatDrying gas arrangementsSpinsEngineering

The invention discloses a glass spin-drying device which comprises a workbench; a transmission mechanism is installed below the workbench; a drive motor is connected to the input end of the transmission mechanism, and a rotary shaft is connected to the output end of the transmission mechanism; one end, far away from the transmission mechanism, of the rotary shaft extends out of the surface of theworkbench; a spin-drying disc is connected to the end, far away from the transmission mechanism, of the rotary shaft; multiple clamping placement tables are distributed at the periphery of the surfaceof the spin-drying disc in a rectangular shape; the clamping placement tables distributed on the two opposite sides of a rectangle are symmetrically arranged two by two; a rectangular region enclosedby multiple clamping placement tables is matched with a glass sheet to be dried in size; each clamping placement table is in a ladder shape; a ladder of each clamping placement table is arranged awayfrom the edge of the spin-drying disc; and the external of each clamping placement table is wrapped with an antiskid damping layer. The glass spin-drying device provided by the invention is reasonable in design, can effectively improve the efficiency of removing water drops on the glass sheet, can ensure the glass sheet not to be damaged at the same time and has certain dust removal effect.

Owner:成都市澳格斯科技有限公司

Agricultural hand-cranked peanut shelling machine

InactiveCN108813652APromote energy conservation and environmental protectionEasy to operateGas current separationHuskingBlade plateAgricultural engineering

The invention discloses an agricultural hand-cranked peanut shelling machine. The machine comprises a peanut shelling machine body, a sliding rail is movably provided with a sliding block, a pluralityof spring grooves are formed in the sliding block, springs are disposed in the spring grooves, the springs are connected with shell breaking rods, the sliding block is fixedly connected with a push rod, a pinion gear is fixedly connected to one end, away from the sliding block, of the push rod, the pinion gear and the large gear are movably meshed, the large gear is connected to a main gear through a connecting rod, the main gear is connected with a first bevel gear through a connecting rope, the first bevel gear is movably meshed with a second bevel gear, a rotating rod is connected to the second bevel gear, a blade plate is fixedly connected to the rotating rod, and a plurality of blades are fixedly disposed on the blade plate. The agricultural hand-cranked peanut shelling machine is simple to operate, can perform peanut shelling and peanut shell screening simultaneously by rotating a rocker, saves manpower, requires no electricity during the whole use process, and has wide application range, environmental protection and energy saving.

Owner:台州市黄岩农欢农机机械有限公司

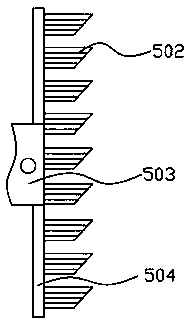

Waste rubber crawler belt steel wire cutter mechanism

PendingCN110064718AConvenient for centralized collection and processingPrevent ejectionDrive shaftWaste rubber

The invention discloses a waste rubber crawler belt steel wire cutter mechanism. The mechanism comprises a cutter frame body, a driving motor, a driving shaft, an eccentric cam, a connecting block, clamping blocks, an upper cutter rest, an upper cutter, a clamping piece, lower pressing structures, lower cutter rests and a lower cutter, the driving motor is arranged at the top end of one side of the cutter frame body, one end of the driving shaft is fixedly connected with the driving motor, the eccentric cam is eccentrically arranged with the driving shaft, the upper cutter is arranged at the bottom end of the upper cutter rest, the clamping block is fixedly connected with the cutter frame body through a fastener, the upper cutter rest is in sliding connection with the clamping block, the clamping piece is arranged at the center of the top end of the upper cutter rest, the eccentric cam is connected with the upper cutter rest through the connecting block, the lower pressing structures are arranged on the two sides of the upper cutter rest, and the lower cutter is fixedly connected with the lower cutter rest. The crawler belt wires are processed in a centralized mode, the waste collecting difficulty is reduced, the working safety of the mechanism is high, and the processing efficiency is high.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

Waste plastic processing, recycling and regenerating device

PendingCN112976415AConvenient for centralized collection and processingCrushed fullyPlastic recyclingAir dryingWater tanks

The invention relates to the technical field of waste plastic recycling, in particular to a waste plastic processing, recycling and regenerating device. According to the waste plastic processing, recycling and regenerating device provided by the invention, a motor is used for driving a first rotating shaft to rotate, the first rotating shaft drives a first-class bevel gear, a second-class bevel gear, a second rotating shaft and a smashing cutter to rotate, and waste plastic is fully smashed through the smashing cutter; the motor is used for driving a first belt wheel, a second belt wheel and a third rotating shaft to rotate, an auger is driven to guide the smashed waste plastic, a water suction pump is used for pumping cleaning liquid in a water tank, the cleaning liquid is sprayed to the surface of the smashed plastic through a spray head, and residual ash on the surface of the waste plastic is cleaned; and the motor is used for driving a fan to air-dry plastic on screens, cleaning waste liquid is discharged out of the device firstly through the screens and pipe openings, after the plastic on the screens is dried, a second motor is controlled to work, a take-up roller is driven to pull a first thin rope and a second thin rope to be pulled downwards, the two screens move downwards and are opened, the plastic falls from the pipe openings, and workers collect and treat the plastic in a centralized mode.

Owner:宁夏金曜塑业有限公司

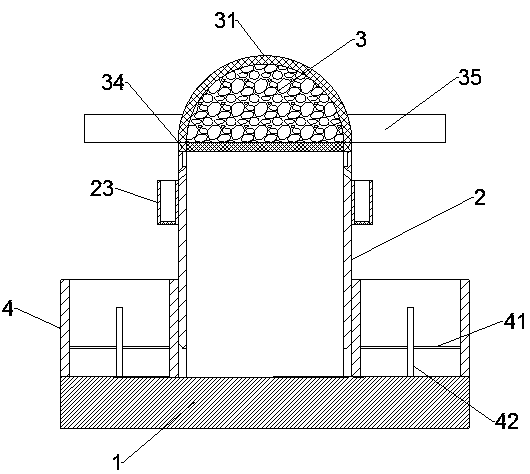

Water storage anti-blocking type road greenbelt

InactiveCN109403420AEasy to use uniformlyReduce attachmentGeneral water supply conservationSelf-acting watering devicesActivated carbonStormwater

The invention discloses a water storage anti-blocking type road greenbelt. The water storage anti-blocking type road greenbelt comprises a bottom plate, a water storage cavity, a filter head and planting cavities, wherein the planting cavities are circumferentially formed in the periphery of the water storage cavity; the water storage cavity and the planting cavities are welded and formed in the upper end of the bottom plate; the filter head is assembled and arranged at the upper end of the water storage cavity; water guide grooves are symmetrically formed in the lower parts of the two sides of the water storage cavity in a penetrating mode and penetrate through the water storage cavity and the planting cavities; floating plugs are movably arranged in the water guide grooves. According tothe water storage anti-blocking type road greenbelt, impurities are filled and adsorbed by the activated carbon when rainwater passes through the filter head, and the filtered rainwater enters the water storage cavity to be concentrated, so that unified use is facilitated; when wind exists, the wind blows fan blades to drive the filter head to rotate, so that the probability of blockage is minimized in an energy-saving and automatic mode; and water can be automatically replenished for plants planted in the planting cavities under the condition that water is stored in the water storage cavity.

Owner:丽水市正明机械科技有限公司

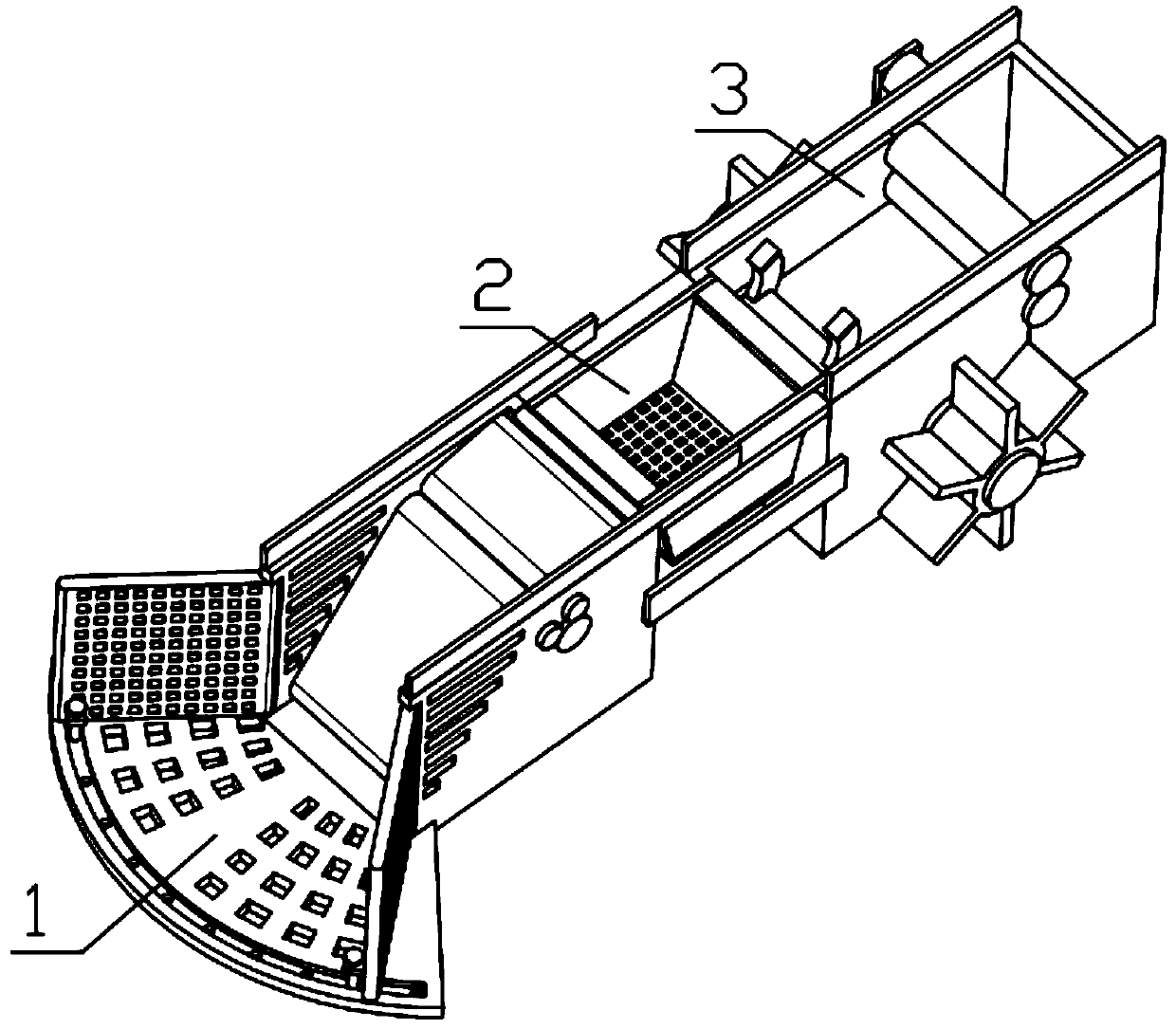

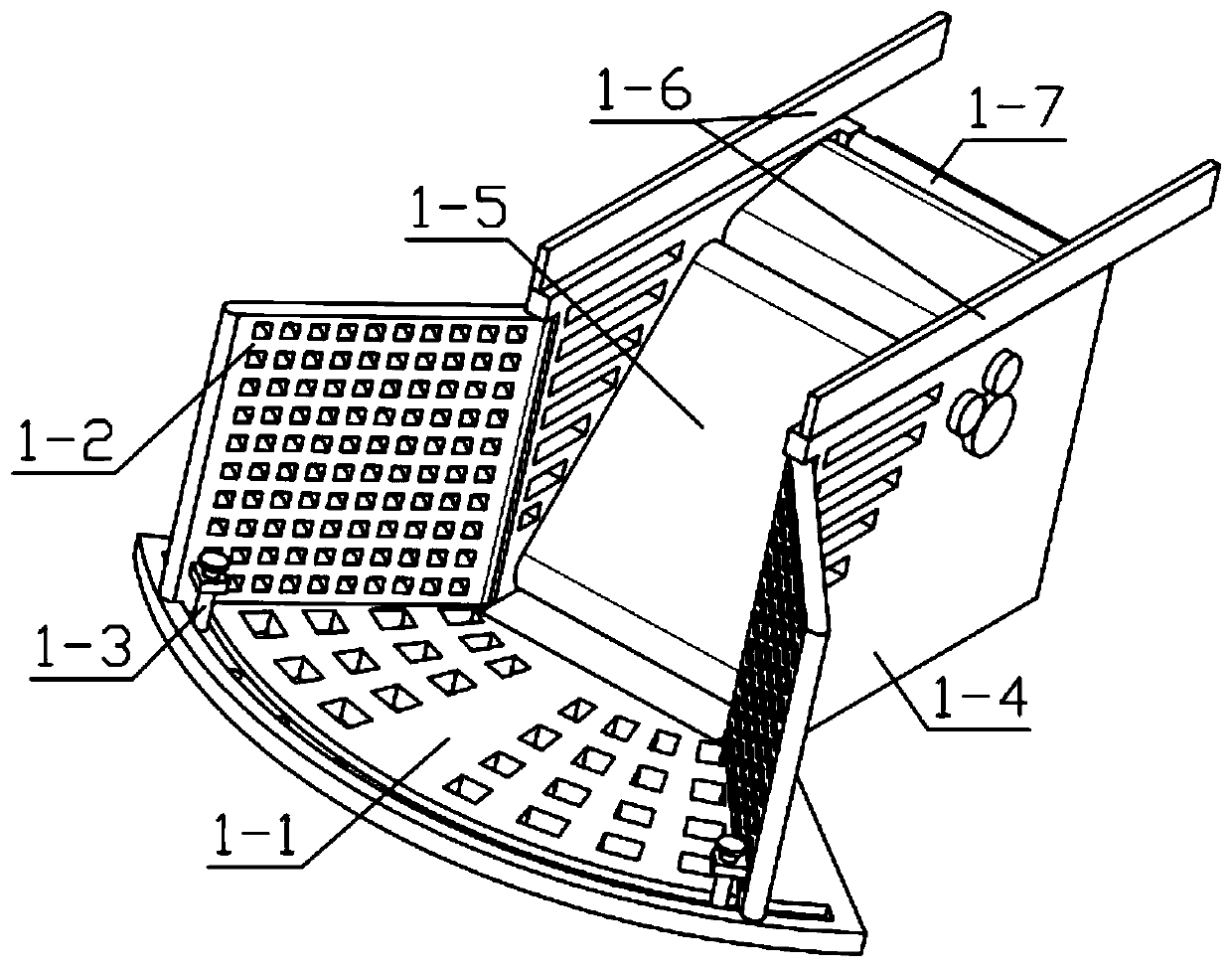

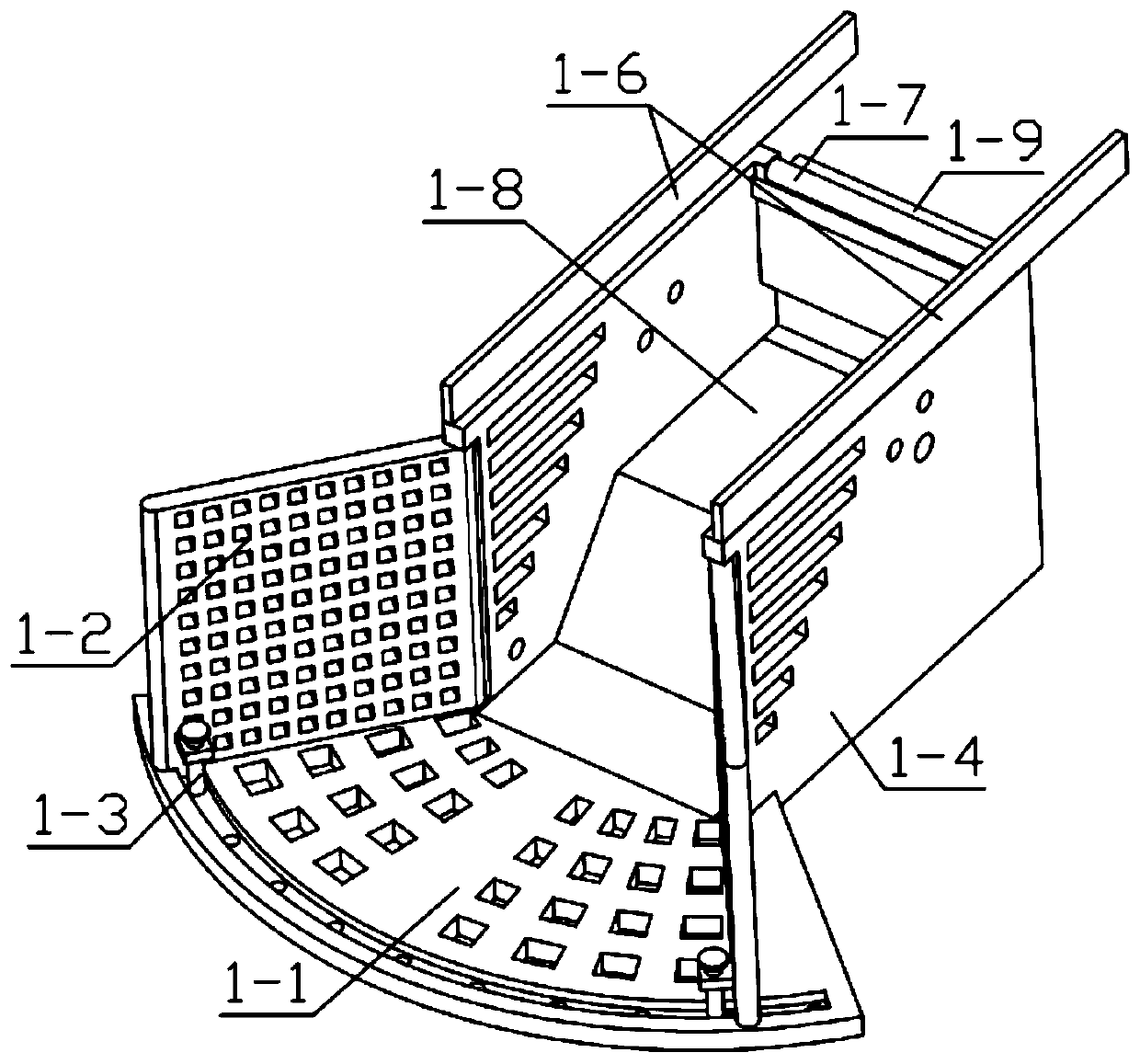

Hydraulic engineering channel cleaning device

InactiveCN111021324AWill not create a fragmented situationReduce loadWater cleaningRefuse collectionProcess engineering

The invention relates to a hydraulic engineering cleaning device, in particular to a hydraulic engineering channel cleaning device comprising a garbage collection mechanism, a draining assembly and acollection and power mechanism. According to the device, during collection of channel garbage, the garbage is not pushed to a further place, and the secondary collection of the garbage is facilitated;the collection range can be regulated through the device according to different channels, and the device has the functions of garbage collection and draining; the garbage is moved behind after draining of the garbage, and collected in a concentrated mode after being crushed; and the maximization of the storage amount is achieved, and the working efficiency of the device is improved. The garbage collection mechanism is in contact connection with the draining assembly, and the draining assembly is rotatably installed on a groove formed in the collection and power mechanism; and the garbage collection mechanism is fixedly connected with the collection and power mechanism.

Owner:宁夏众捷建设景观工程有限公司

Polishing and cleaning device for mechanical part machining and working method of polishing and cleaning device

ActiveCN114102392AGuaranteed stabilityEasy to achieve grindingGrinding carriagesGrinding drivesMechanical componentsPolishing

The invention relates to the technical field of machining, in particular to a polishing and cleaning device for mechanical part machining and a working method thereof.The polishing and cleaning device comprises a rack and a mounting frame, a fixing mechanism and a recycling mechanism are arranged in the rack, an adjusting mechanism is arranged in a fixing frame, and a polishing wheel is arranged in the fixing frame; in the process of polishing the mechanical part, two servo electric cylinders II push two movable plates to move upwards until connecting plates in the two movable plates are in contact with the bottom of a mounting frame, so that a closed cavity is formed between the mechanical part in the mounting frame and a polishing wheel; on one hand, it is guaranteed that waste chips generated in the grinding process cannot be scattered all around, it is guaranteed that metal waste chips cannot be sputtered in the grinding process, and a certain protection effect on operation safety of operators is achieved, on the other hand, the waste chips generated in the grinding process are conveniently collected and treated in a centralized mode, and the pollution degree of the grinding waste chips to the periphery of the device is reduced.

Owner:广德凯雷特机械科技有限公司

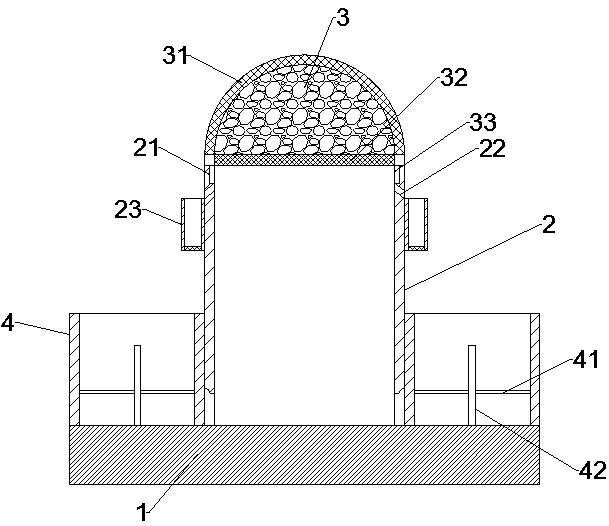

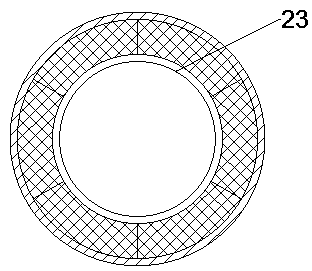

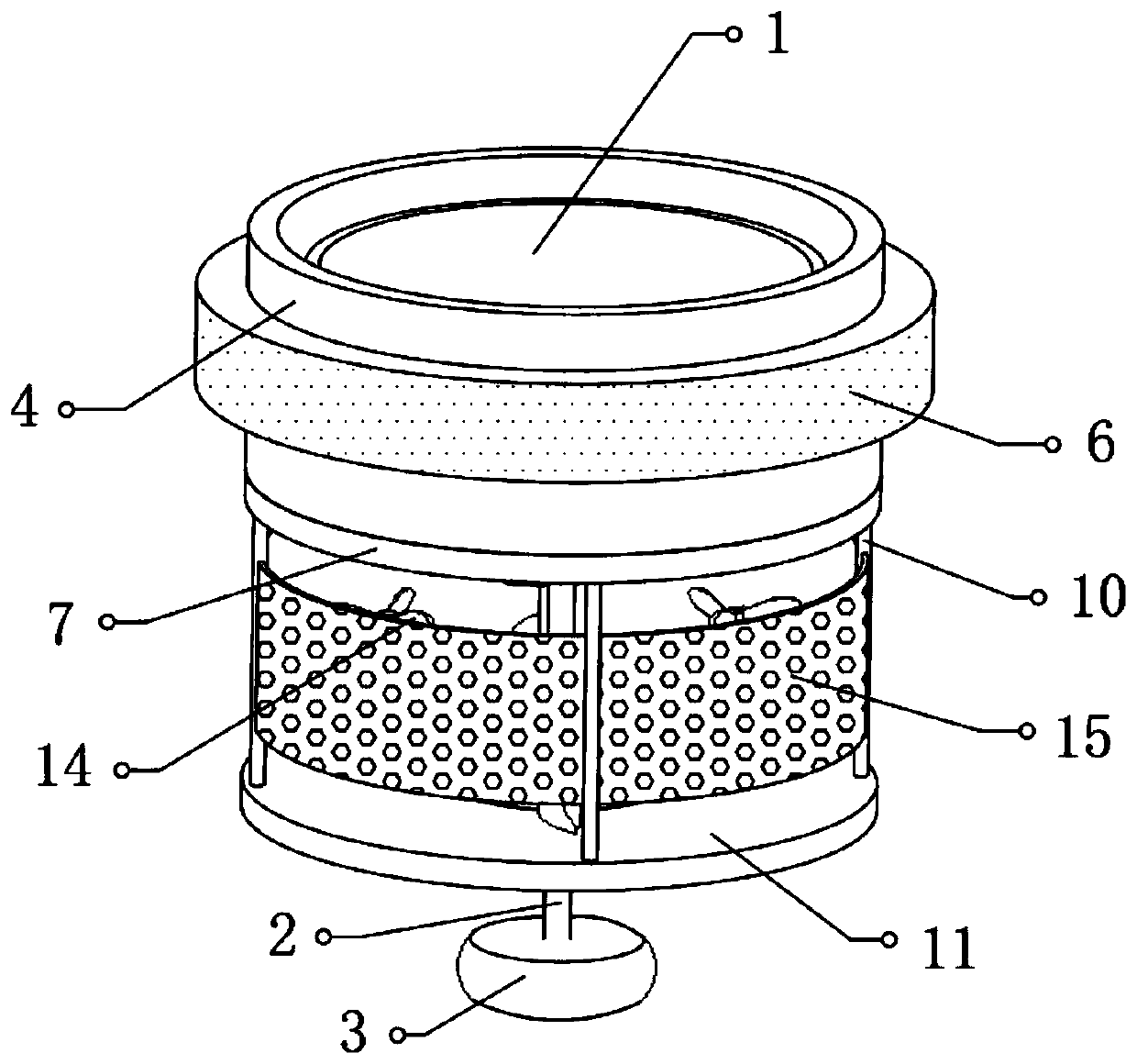

Environment-friendly alga culture device

PendingCN111480568AAvoid pollutionConvenient for centralized collection and processingClimate change adaptationCultivating equipmentsWater flowEngineering

The invention belongs to the technical field of alga culture, and particularly relates to an environment-friendly alga culture device. For the problem that broken leaves and broken parts in algae often drift away along water flow to cause water source pollution easily, the following scheme is proposed now. The environment-friendly alga culture device comprises a culture box of a net-cylinder-shaped structure; a suspension rope is fixed in the middle of the bottom of the culture box; a balancing weight is fixed at the bottom end of the suspension rope; a shielding cylinder with openings in thetop and the bottom is arranged outside the culture box; and a plurality of fixed blocks are fixed at the top end of the position between the inner wall of the shielding cylinder and the outer wall ofthe culture box. According to the alga culture device, the algae are arranged in the culture box of the net cylinder structure; the water source pollution caused by the fact that the broken leaves andthe broken parts drift away along the water flow can be avoided through plugging operation of the solid shielding cylinder; and when the algae in the culture box are collected, the shielding cylindercan be directly lifted upwards, and the broken leaves can be conveniently collected and treated in a centralized mode through a limiting piece and limiting grooves.

Owner:HUNAN UNIV OF ARTS & SCI

Ceramic box internal cleaning device

InactiveCN109692861AGood cleaning effectConvenient for centralized collection and processingHollow article cleaningHigh pressureCeramic

The invention discloses a ceramic box internal cleaning device. The device includes a rack and a workbench. A cleaning cover is arranged on the workbench. Fixed blocks are arranged on the two oppositesides of the lower part of the inside of the cleaning cover. A telescopic rod is arranged on the inner side of each fixed block. A clamping seat is arranged on the other end of each telescopic rod. An inclined waste liquid tank is arranged in the surface of the workbench. A high-pressure jet head is also arranged on the workbench. The high-pressure jet head is connected to a booster fan. A horizontally placed sliding rail is arranged on the upper part of the inside of the cleaning cover. A sliding block matching the sliding rail is arranged on the bottom of the sliding rail. A cleaning disc is connected to the bottom of the sliding block. One end of the sliding rail extends out of the cleaning cover and is connected to a lifting block. A telescopic cylinder is connected to the bottom of the lifting block. A liquid spray head is also arranged in the cleaning cover. The liquid spray head is connected to a water tank. A booster device is arranged on a water supply pipe. A waste liquid tank is arranged on the lower end of the waste liquid tank of the workbench. The ceramic box internal cleaning device can effectively clean the cavity and outer wall of the casting box, has a good cleaning effect, and facilitates the centralized collection and treatment of cleaning waste.

Owner:张元龙

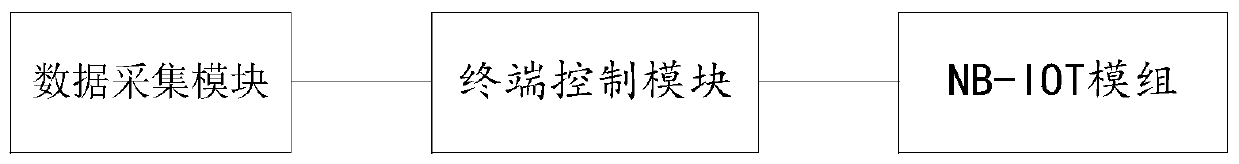

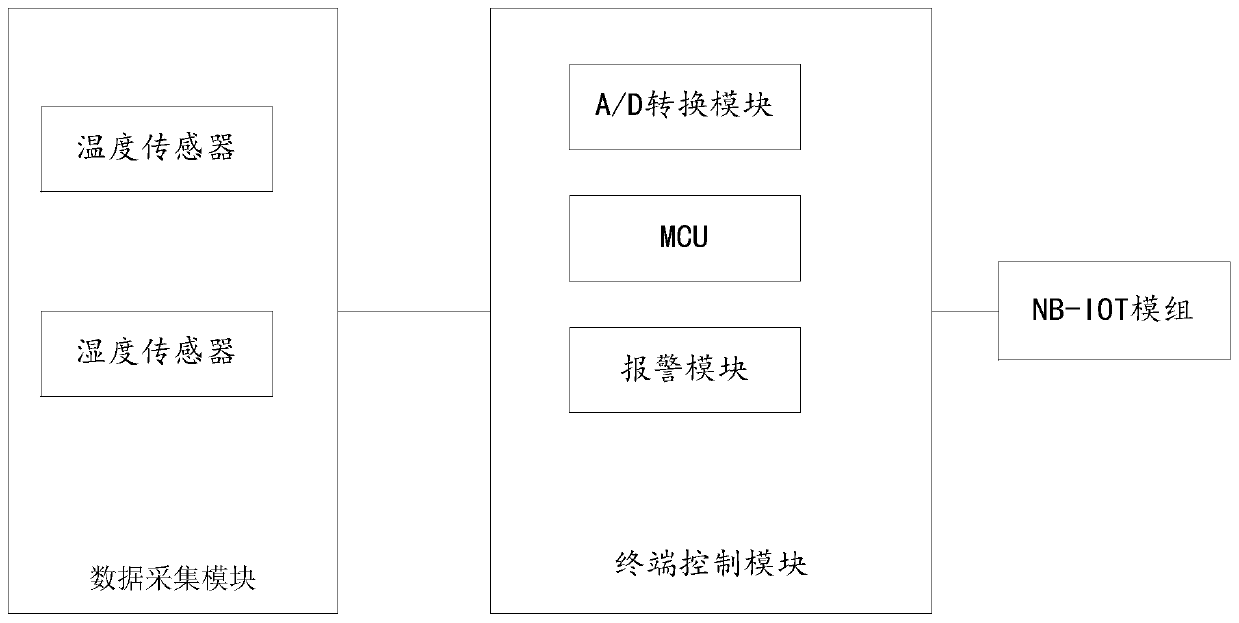

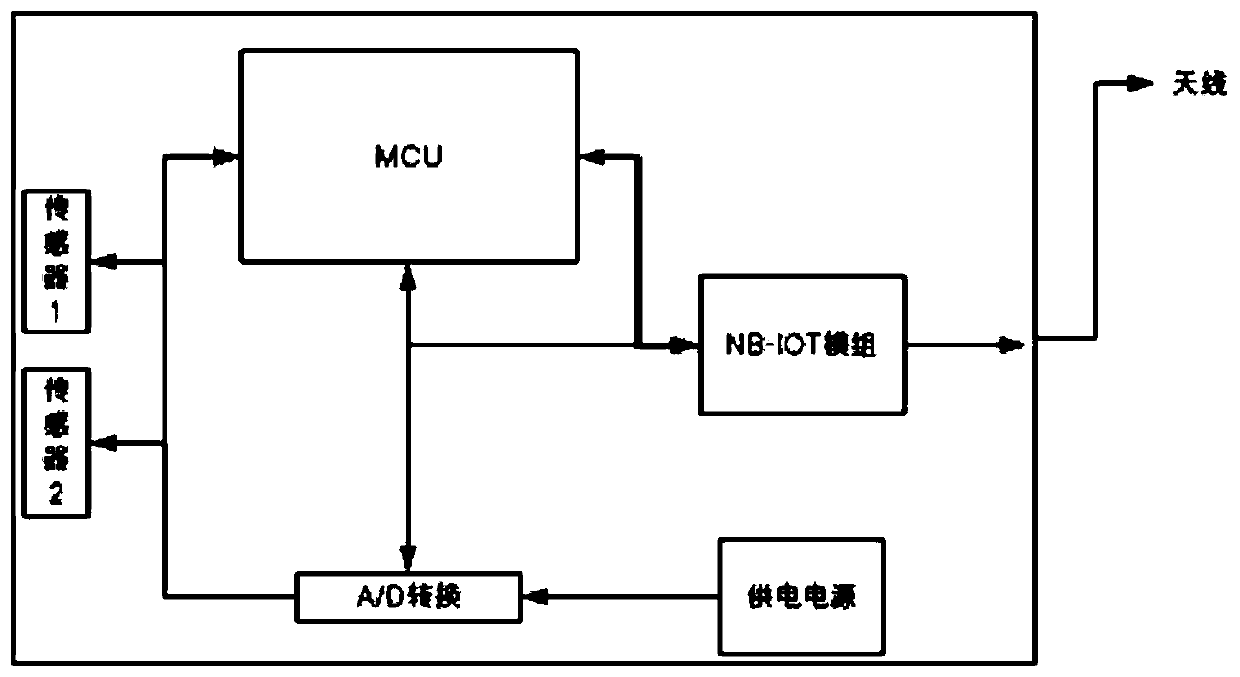

Method and system for monitoring cable joint by NB-IOT technology

InactiveCN111024261AImprove accuracyImprove the monitoring scope of online monitoringThermometer detailsElectrical testingData acquisitionData acquisition module

The invention discloses a method and system for monitoring a cable joint by an NB-IOT technology. The method comprises the steps of acquiring a temperature value and a humidity value of the cable joint based on a data acquisition module arranged on the cable joint; realizing data conversion of the temperature value and the humidity value based on an analog-to-digital conversion module on a terminal control module, and generating temperature and humidity acquisition data; and sending the temperature and humidity acquisition data to a cloud platform based on an NB-IOT module. According to the embodiment of the invention, the equipment can monitor the parameter information of the cable joint in real time, and the monitoring information is transmitted through the NB-IoT technology, so that themanpower resources and cost are greatly reduced, and the data obtaining accuracy is improved through the automatic monitoring in the equipment.

Owner:GUANGXI POWER GRID CO LIUZHOU POWER SUPPLY BUREAU

Hydraulic cylinder machining cutting equipment capable of fixing piston rods with different diameters

InactiveCN113843637AEasy to operateEasy to blow offFeeding apparatusLarge fixed membersHydraulic cylinderEngineering

The invention discloses hydraulic cylinder machining cutting equipment capable of fixing piston rods with different diameters. The hydraulic cylinder machining cutting equipment comprises a bearing table, a clamping mechanism, a first electric telescopic column, a third motor, a rotating frame and a fifth motor, a collecting box is placed at the inner bottom of the bearing table, a support is fixed in an opening, the clamping mechanism is fixed to the inner end faces of clamping plates, the rotating frame is rotationally connected to the top of the bearing table, one side of a sliding block is connected with the fifth motor through an electric telescopic rod, a second electric telescopic column is fixed to the other end face of the rotating frame, and the bottom of the second electric telescopic column is connected with a blocking cover. According to the hydraulic cylinder machining cutting equipment capable of fixing the piston rods with different diameters, and after the piston rods are vertically placed between the two clamping plates, the two clamping plates get close to each other, the piston rods are conveniently clamped and fixed, at the moment, compression springs play a role in jacking and supporting movable clamping blocks, all the movable clamping blocks are abutted against the piston rods, and therefore the piston rods with different diameters can be clamped and fixed by matching with fixed clamping blocks.

Owner:徐州山恒机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com