Ceramic box internal cleaning device

A technology for cleaning devices and boxes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor plasticity, and achieve the effect of simple structure, reasonable design and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

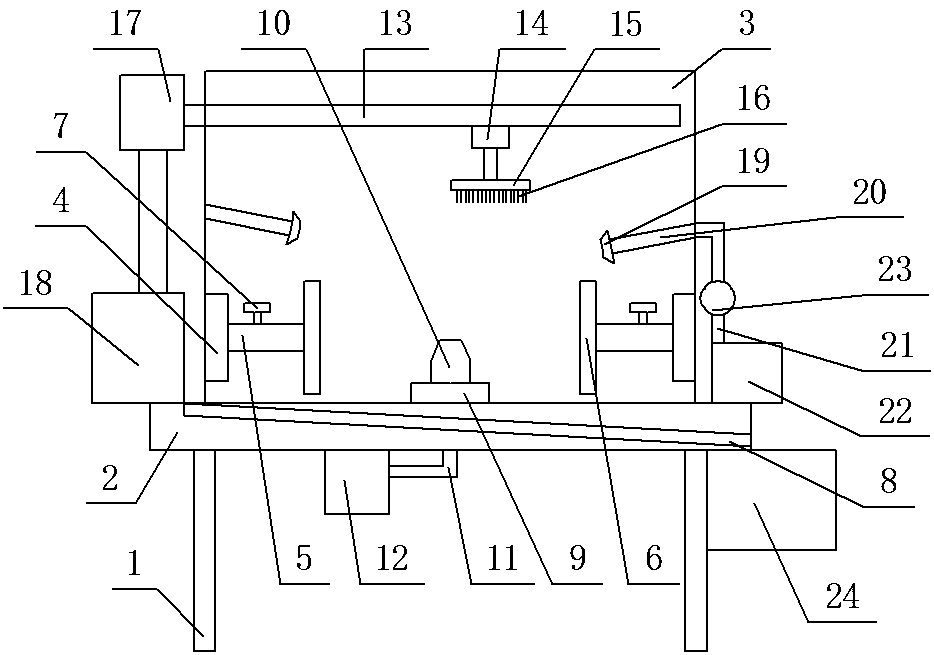

[0010] Embodiment 1: as figure 1 As shown, the present invention comprises a frame 1 and a workbench 2 is set on the frame 1, the workbench 2 is provided with a cleaning cover 3, the bottom of the cleaning cover 3 is fixedly connected with the surface of the workbench 2, and the cleaning cover 3 The opposite sides of the inner lower part are provided with fixed blocks 4, the inner side of the fixed block 4 is provided with a telescopic rod 5, and the end of the telescopic rod 5 away from the fixed block 4 is provided with a clamping seat 6, and the telescopic rod 5 is provided with a limit locking screw 7, so that There is an inclined waste liquid tank 8 on the surface of the workbench 2, and a universal seat 9 is also provided on the workbench 2. A high-pressure air jet head 10 is fixed on the universal seat 9. The central axis of the universal seat 9 is connected to the cleaning cover. The central axis of 3 coincides, and the air inlet end of the high-pressure air spray head...

Embodiment 2

[0011] Embodiment 2: Same as the above embodiment 1, wherein the water supply pipe 21 is provided with a water inlet valve, and the air supply pipe 11 is provided with an air inlet valve.

[0012] In the present invention, the casting box is placed in the middle of the workbench 2, the inner cavity of the casting box is covered on the high-pressure air spray head 10, and then the length is controlled by the telescopic rod 5, and the casting box is clamped by the oppositely arranged clamping seat 6. , after clamping, the lifting cylinder controls the height of the slide rail 13. When it reaches a suitable height, the cleaning hair 16 of the cleaning disc 15 contacts the surface of the casting, and the cleaning disc 15 rotates to drive the cleaning hair 16 to rotate on the surface of the casting box to realize cleaning of the casting surface, at the same time, the liquid spray head 19 sprays and flushes the surface of the casting box to thoroughly clean the casting surface, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com