Waste plastic processing, recycling and regenerating device

A regeneration device and waste plastic technology, applied in the field of waste plastic recycling, can solve the problems of lack of filtration and drying structure, poor recycling rate of plastic, inability to crush waste plastic, etc., and achieve the effect of convenient centralized collection and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

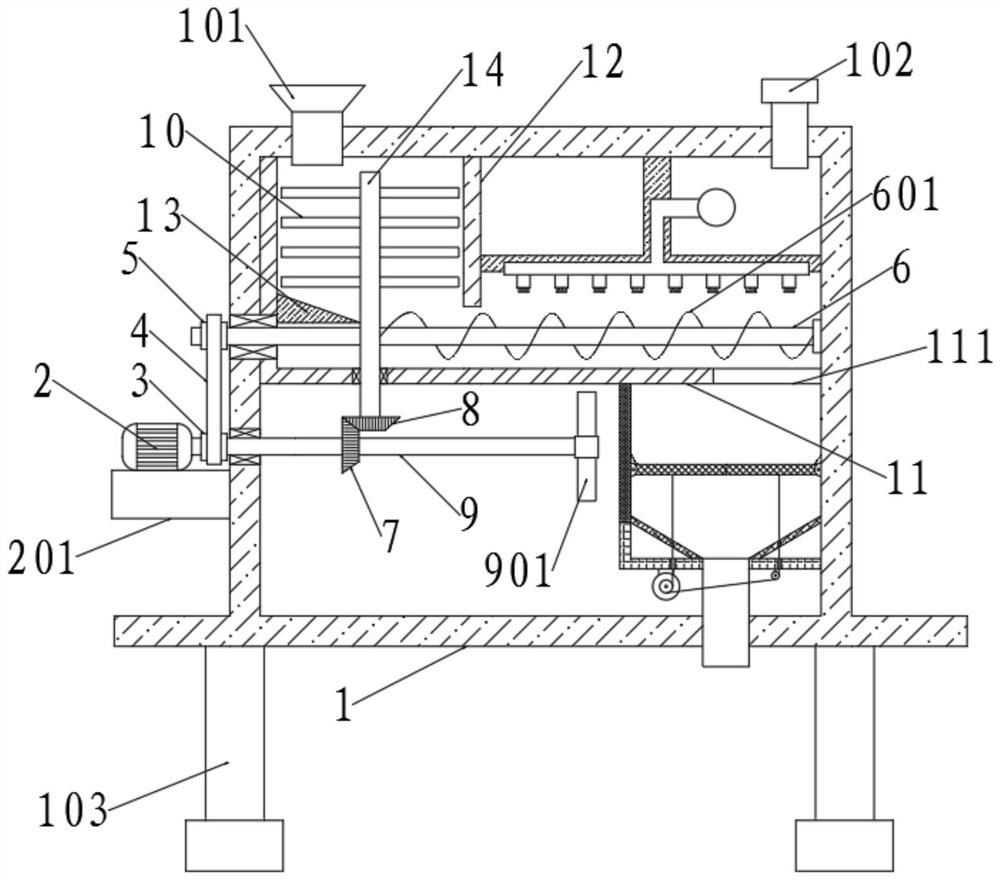

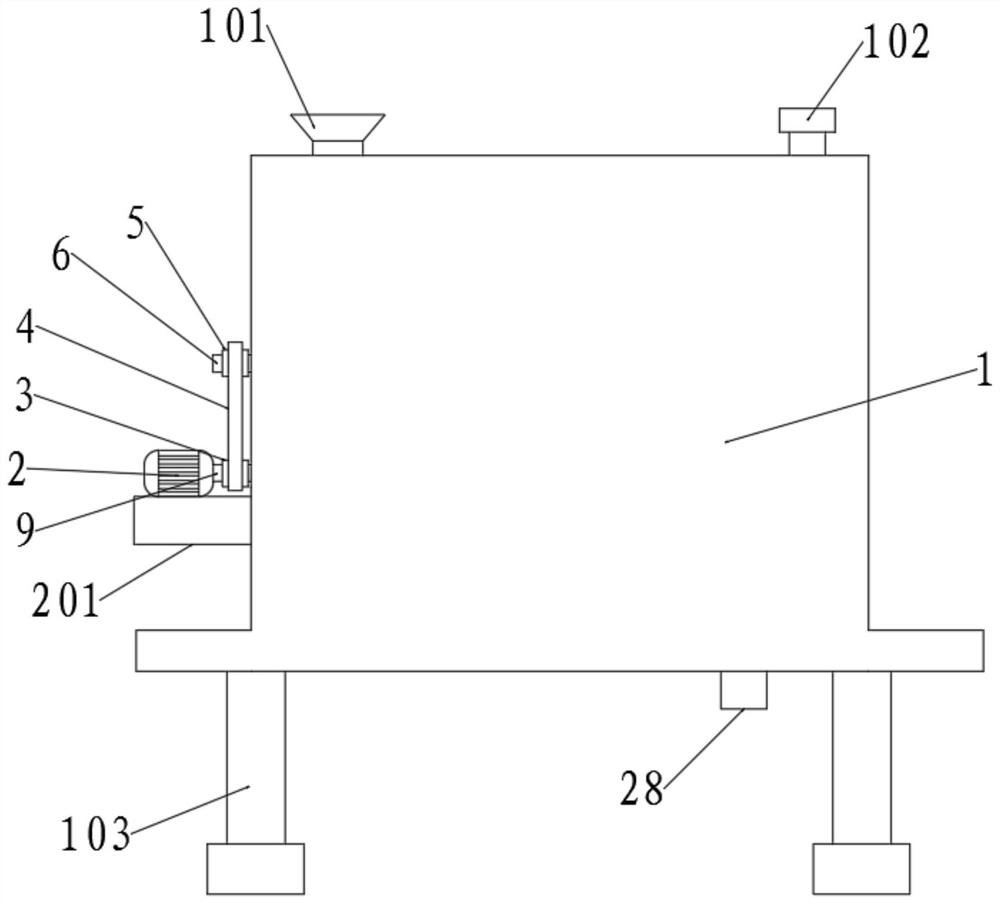

[0027] A recycling device for processing waste plastics, comprising a working box 1, outriggers 103, a first motor 2, and wind blades 9;

[0028] The bottom of the working box 1 is symmetrically connected with supporting legs 103, the left side of the top of the working box 1 is connected with a feed nozzle 101, the right side of the top is connected with a water inlet 102, the outer wall of the left end is fixedly connected with a motor seat 201, and the inside of the working box 1 is equipped with a L Type partition plate 11 and vertical baffle plate 12; Motor base 201 upper end is connected with first motor 2, and first motor 2 is connected with rotating shaft-9 to the right, is connected with belt pulley-3 on rotating shaft-9, and rotating shaft-9 is to the right Stretches into the working box 1, and is connected with a type of bevel gear 7, and the rightmost end is connected with a fan blade 901;

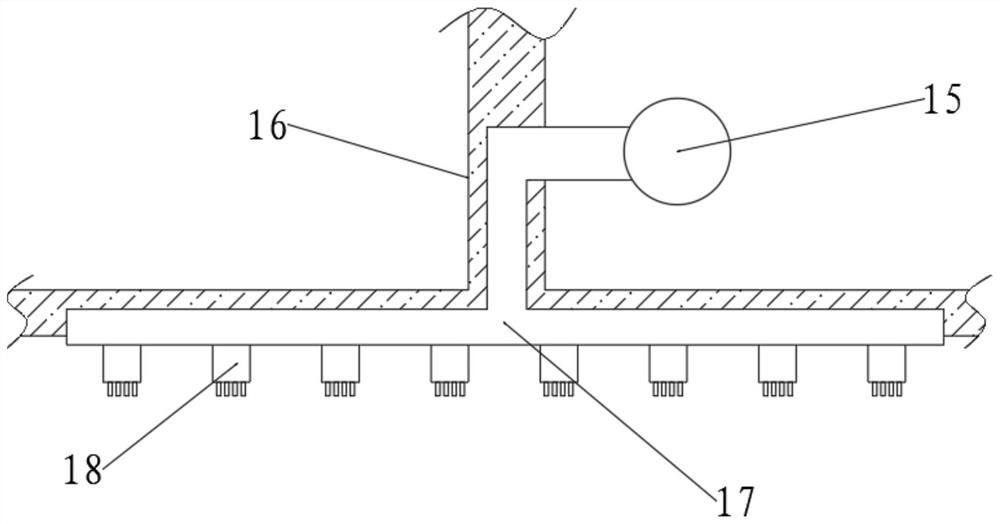

[0029] The upper end of the first-class bevel gear 7 is meshed with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com