Waste rubber crawler belt steel wire cutter mechanism

A technology for scrap rubber and cutter, applied in the field of scrap rubber crawler steel wire cutter mechanism, can solve the problems of too long tie wire and difficult collection of steel wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

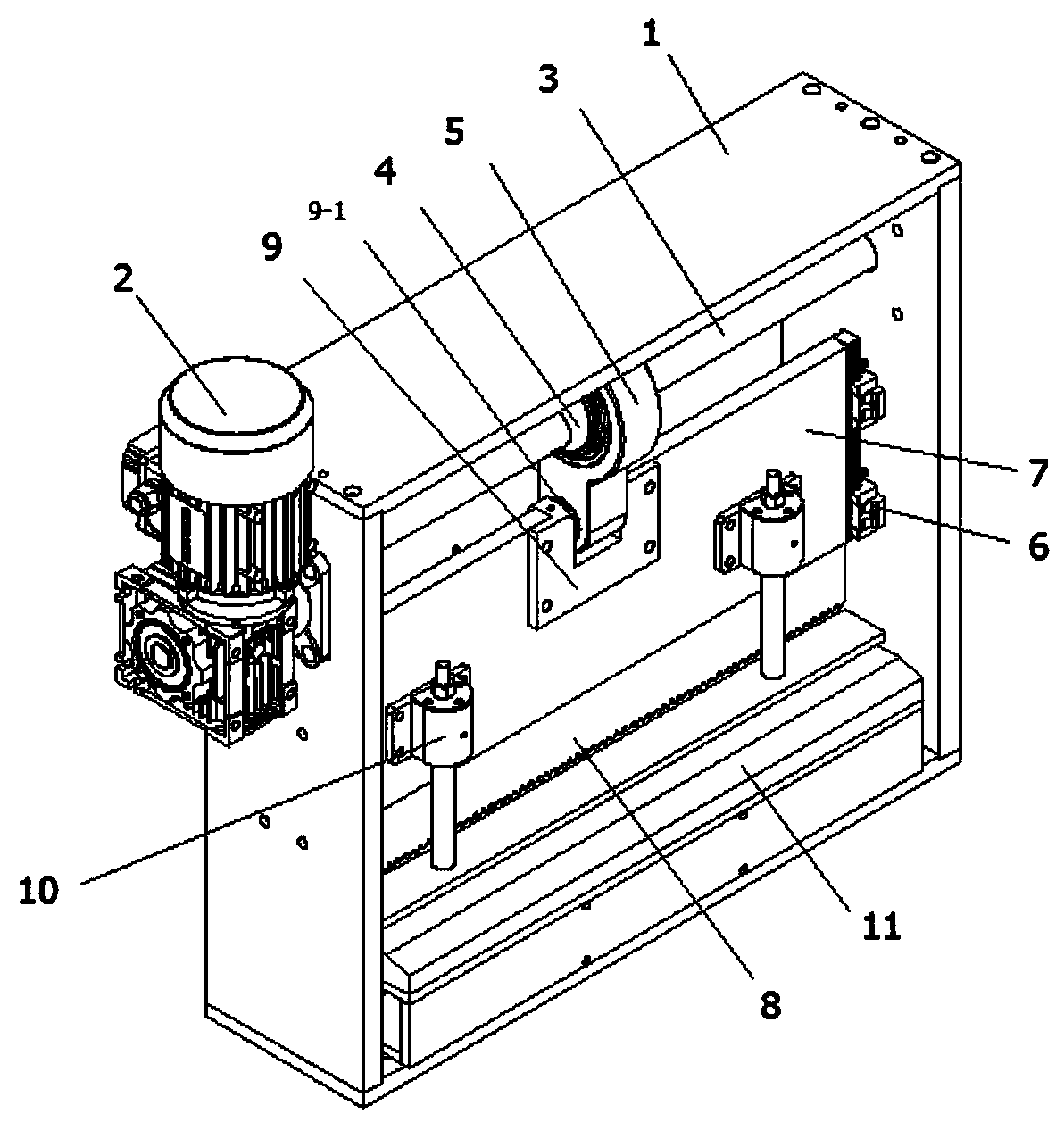

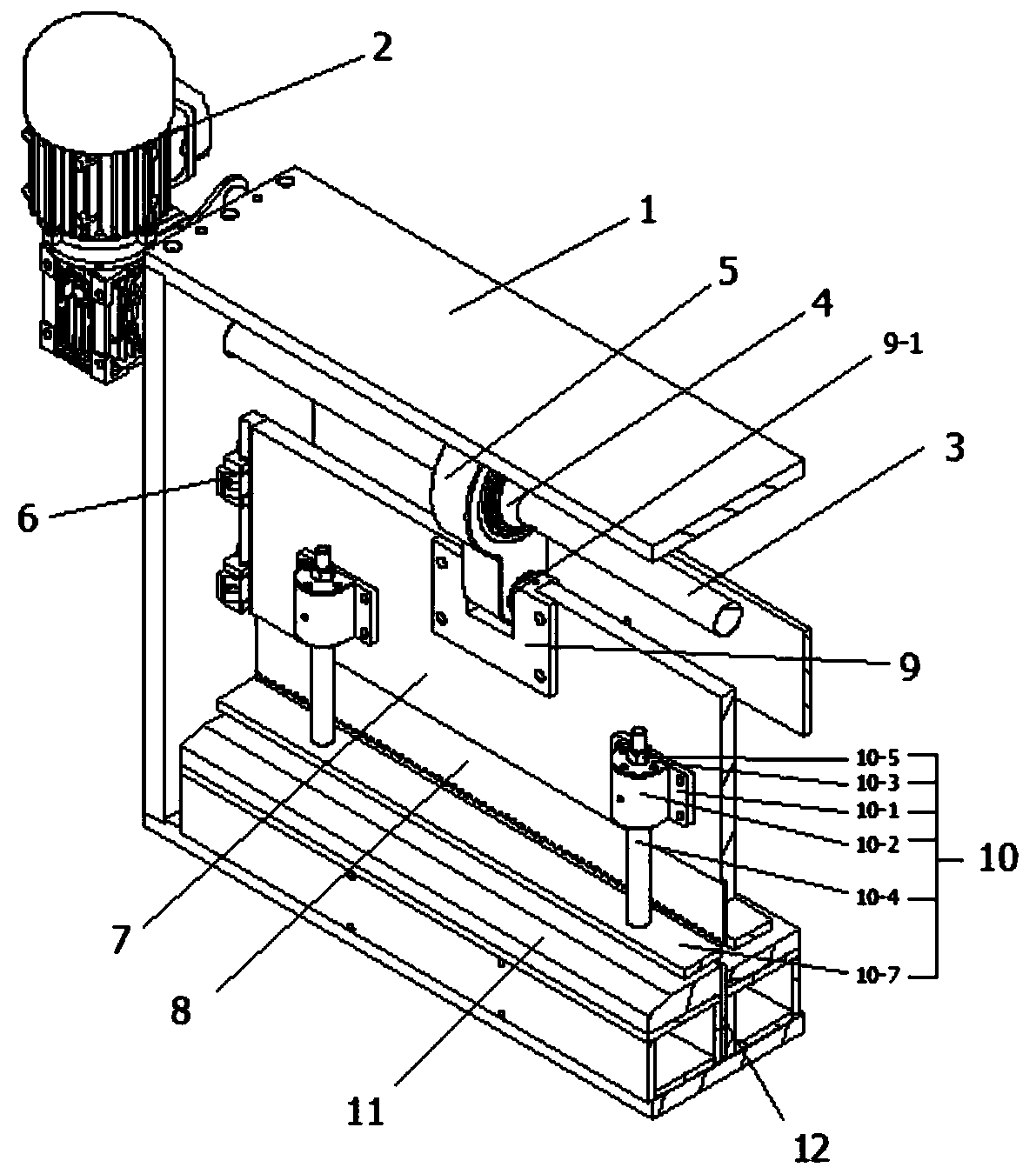

[0028] Attached Figure 1-3 It can be seen that a scrap rubber crawler wire cutter mechanism includes a cutter frame, a drive motor, a drive shaft, an eccentric cam, a connecting block, a clamping block, an upper tool holder, an upper cutter, a clamping piece, a lower pressing structure, The lower knife holder, the lower knife; the drive motor is arranged at the top end of one side of the knife frame, and the drive motor is fixedly connected to the knife frame by a fastener; the drive shaft is arranged on the At the top end of the cutter frame, both ends of the drive shaft and both sides of the cutter frame are rotated by bearings, and one end of the drive shaft extends out of the cutter frame and is fixedly connected to one end of the drive motor; The eccentric cam is arranged on the drive shaft, the eccentric cam is arranged eccentrically with the drive shaft, both sides of the eccentric cam are fixedly connected with the drive shaft; the upper cutter is arranged on the bottom...

Embodiment 2

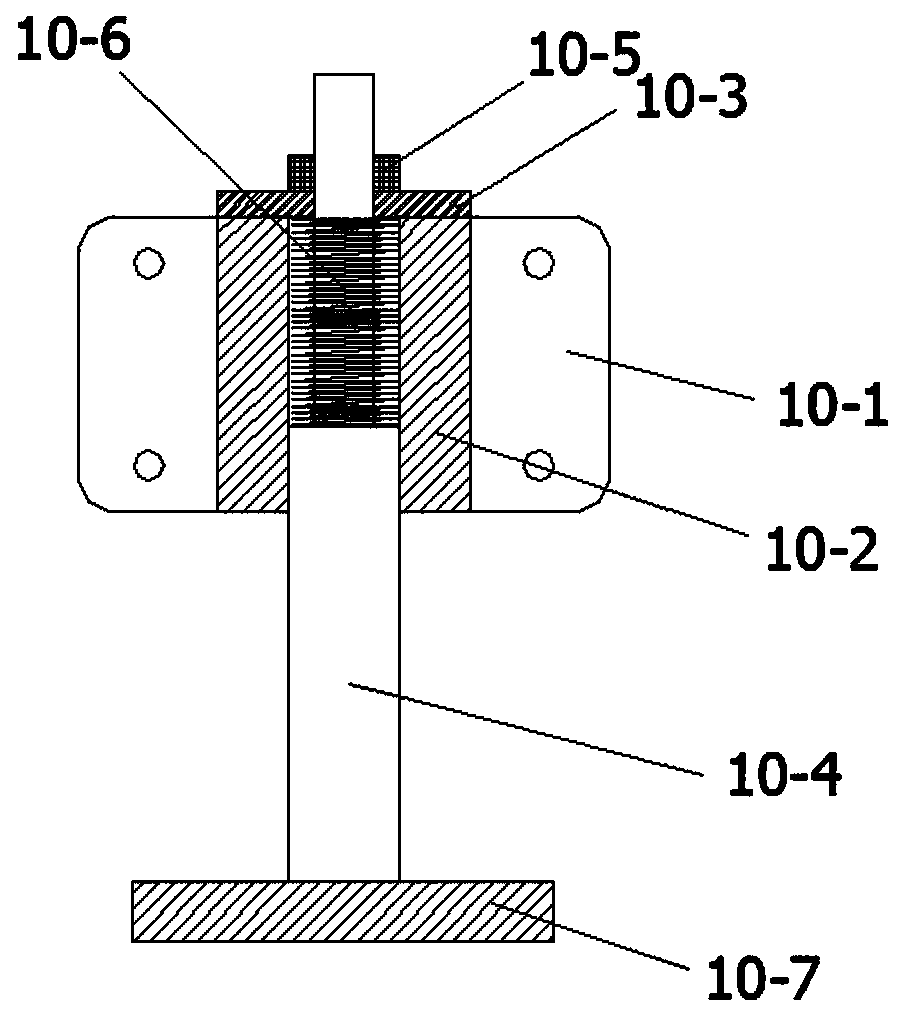

[0043] Attached Figure 4-5 It can be seen that the difference between the second embodiment and the first embodiment is the down-pressing structure. The down-pressing structure includes a fixing piece, a resisting plate, a limit cylinder, a down pressure rod, a down rod protrusion, and a limit spring. The abutment plate is arranged on one side of the fixing plate and is fixedly connected to the fixing plate; the limiting cylinder is arranged on the top surface of the fixing plate, and is fixedly connected to the abutment plate in a through arrangement; The pressing rod is arranged in the limiting cylinder; the lower pressing rod protrusion is arranged at the top end of the lower pressing rod and is fixedly connected with the lower pressing rod; the limiting spring is arranged on the outer side wall of the limiting cylinder , The top end of the limit spring is fixedly connected to the bottom surface of the lower pressing rod convex block, and the bottom end of the limit spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com