Hydrocracking method for producing chemical materials to maximum with low cost

A technology for hydrocracking and chemical raw materials, applied in the field of hydrocarbon oil cracking, can solve problems such as limiting the role of hydrocracking technology, and achieve the effects of low investment cost and operating cost, and low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

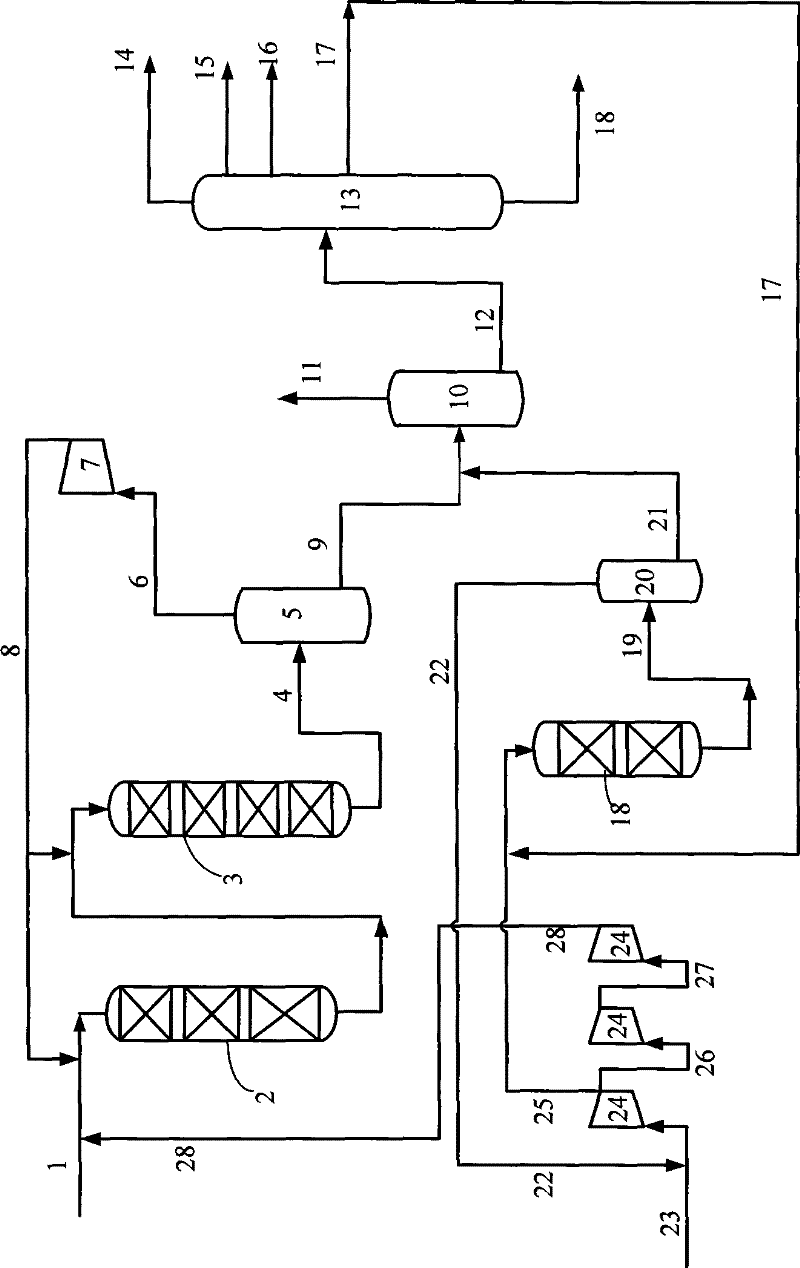

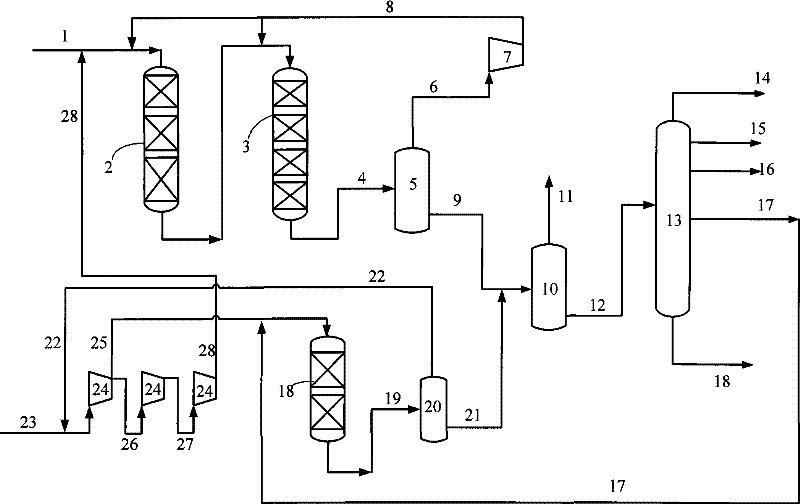

Method used

Image

Examples

Embodiment 1

[0046] Using high-sulfur and high-nitrogen heavy VGO as the raw material, the properties of the raw material are shown in Table 1. The raw material oil and hydrogen are mixed into the first reaction zone, and then contacted with the hydrofinishing catalyst and the hydrocracking catalyst in turn. After separation, the obtained hydrogen-rich gas I is compressed by a circulating hydrogen compressor and then returned to the first reaction zone, and the obtained liquid phase stream I enters a fractionation system to obtain liquefied gas, light naphtha fraction, heavy naphtha fraction, intermediate distillate and tail oil fraction; the obtained middle distillate is mixed with the hydrogen from the first-stage compression outlet of the new hydrogen compressor and enters the second reaction zone, where it is contacted with the hydrocracking catalyst to react, and the reaction product is separated from oil and gas, and the obtained rich The hydrogen gas II is returned to the inlet of th...

Embodiment 2

[0064] A hydrocracking test was carried out according to the catalyst and process flow provided by the present invention, using VGO that was heavier than that in Example 1 and had relatively poor properties as a raw material. The test results are listed in Table 7-Table 10.

[0065] As can be seen from the data in the table: the VGO raw material with poorer quality can be processed by the method provided by the present invention, and the middle distillate yield can be reduced under the conditions of one reverse inlet hydrogen partial pressure of 13.4MPa and three reverse inlet hydrogen partial pressures of 3.5MPa. Reduced to the lowest, it is 0; and the largest production is to obtain liquefied gas, light naphtha, heavy naphtha and tail oil products, and the total yield reaches 98.7% by weight.

[0066] Table 7 Example 2 Raw Oil Properties

[0067] project Density (15℃ / 15℃), g / cm3 0.9323 Sulfur content, wt% 2.990 Nitrogen content, μg / g 1300 H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com