Auxiliary agent capable of improving delayed coking liquid yield, preparation method and application thereof

A technology of delayed coking and auxiliary agent, applied in the field of oil refining additives, can solve the problems of reducing coke yield, single action mechanism and high cost of raw materials, and achieves the effects of small filling amount, simple preparation and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

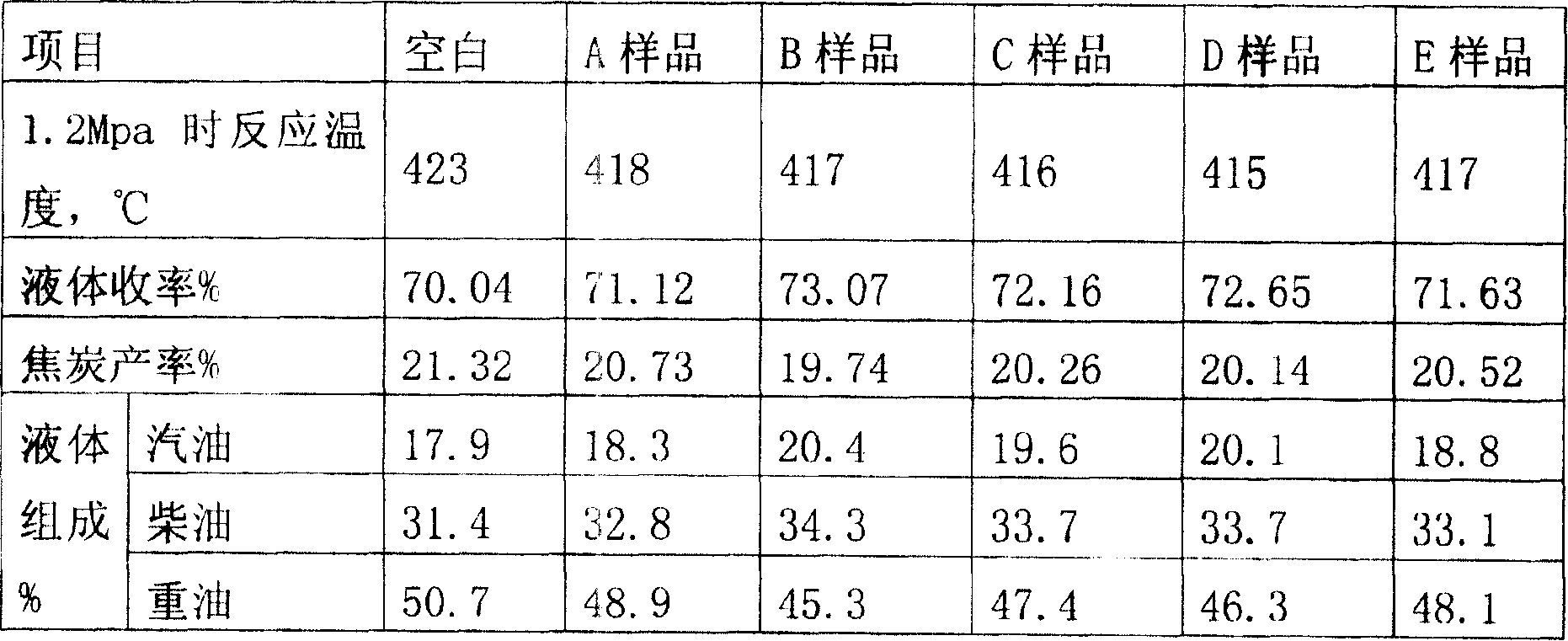

Examples

Embodiment 1

[0024] Weigh 30g butyl nitrate, 20g cetyl alcohol, 10g dimethylpolysiloxane (the kinematic viscosity is 70000mm at 40°C 2 / S), 40g of straight-run gasoline are placed in a container, stirred at normal temperature until uniformly mixed, and the liquid absorption aid A sample is obtained.

Embodiment 2

[0026] Weigh 40g n-octyl nitrate, 20g stearyl alcohol, 10g dimethylpolysiloxane (kinematic viscosity is 100000mm at 40°C 2 / S), 30g of catalytic gasoline are placed in a container, stirred at normal temperature until uniformly mixed, and the liquid absorption aid B sample is obtained.

Embodiment 3

[0028] Weigh 20g butyl nitrite, 20g eicosanol, 15g dimethylpolysiloxane (kinematic viscosity is 100000mm at 40°C 2 / S), 45g aromatic hydrocarbon solvent oil is placed in container, stirs at normal temperature until mixing evenly, obtains increasing liquid absorption agent C sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com