Patents

Literature

57results about How to "Promote cleavage reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cracking biomass pyrolytic tar catalytically using nickel-carrying carbon nano tube

InactiveCN102634355AGood thermal stability and mechanical strengthPrevent carbon deposition and deactivationBiofuelsSpecial form destructive distillationTarBiomass

The invention belongs to the field of biomass energy utilization and particularly relates to a method for cracking biomass pyrolytic tar catalytically using a nickel-carrying carbon nano tube. The method includes: obtaining nickel-based catalyst based on a carbon nano tube carrier by utilizing the carbon nano tube as a carrier and elementary-substance nickel as active component, and allowing for high-efficiency catalytic cracking of the biomass pyrolytic tar using the nickel-based catalyst, wherein the elementary-substance is in mass percentage of 0.5-30% in the composite catalyst. Specific surface area of the catalyst is enlarged greatly by utilizing the carbon nano tube as the carrier, order pore passage structure suitable for cracking reaction of macromolecule organic matters in tar is provided, and combustible gas with tar content smaller than or equal to 1% can be obtained after catalytic cracking of the biomass pyrolytic tar.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

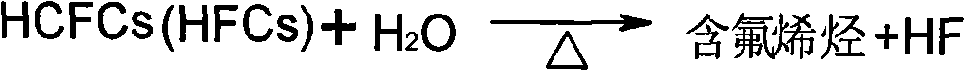

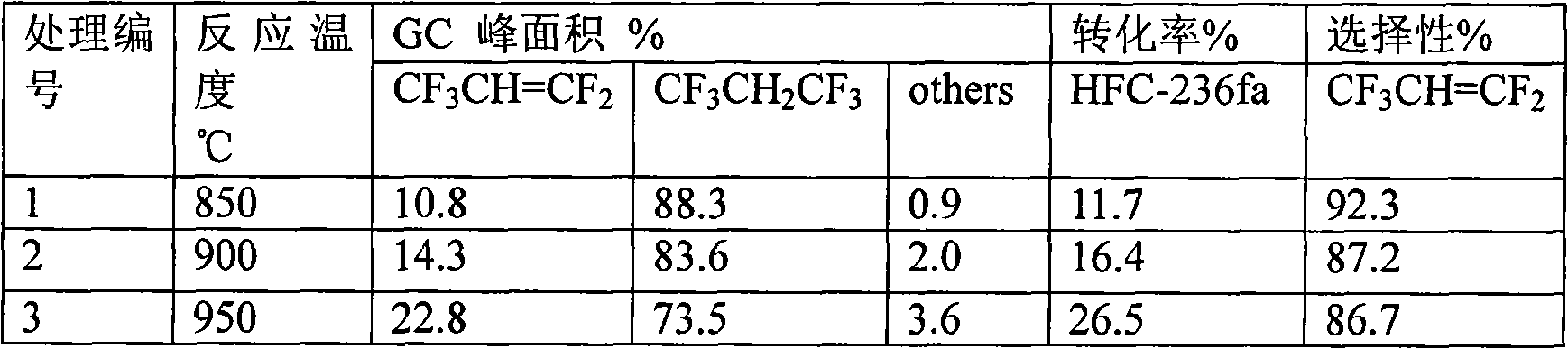

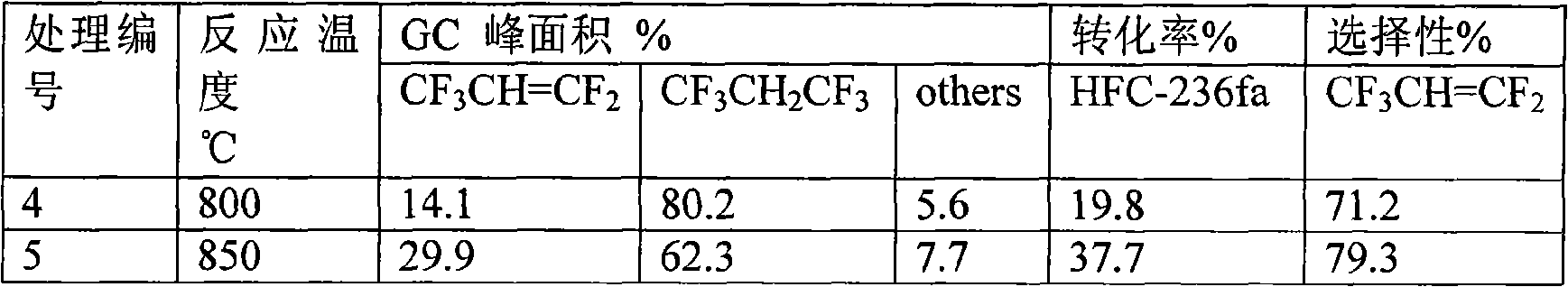

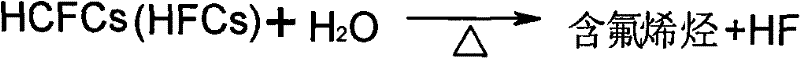

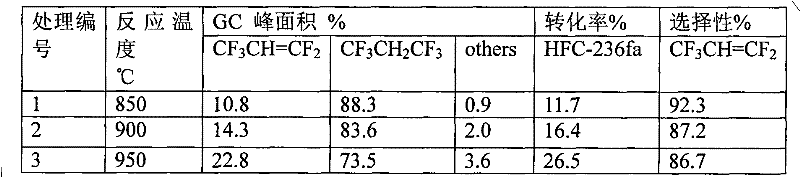

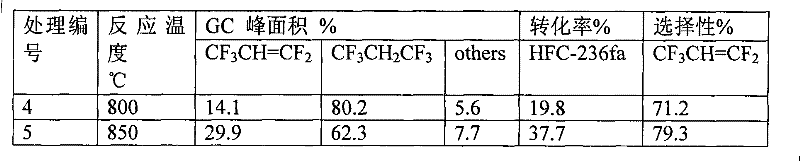

Method for preparing fluorinated alkene by high temperature wet-cracking

ActiveCN101597208AHighly corrosiveAvoid corrosionPreparation by hydrogen halide split-offHeat-exchange elementsHydrogen fluorideSal ammoniac

The invention relates to a method for preparing fluorinated alkene by high temperature wet-cracking, belonging to the field of organic synthesis. The method is characterized in that under the condition of normal pressure and the temperature of 600-1000DEG C, hydrogen fluoride alkane with the molecular formula of HnFmC3 (n +m=8, n is more than or equal to 1 and less than or equal to 8, and m is more than or equal to 2 and less than 8) is taken as raw gas to have cracking reaction in the environment of water vapor or ammonia water vapor; no catalyst is used in the method, so that the generation cost is reduced, by-products are few, the selectivity of the product is high, subsequent purification and separation are convenient, the whole technique is easy to control, and the method is very suitable for producing the fluorinated alkene in industrialization-scale.

Owner:泉州宇极新材料科技有限公司

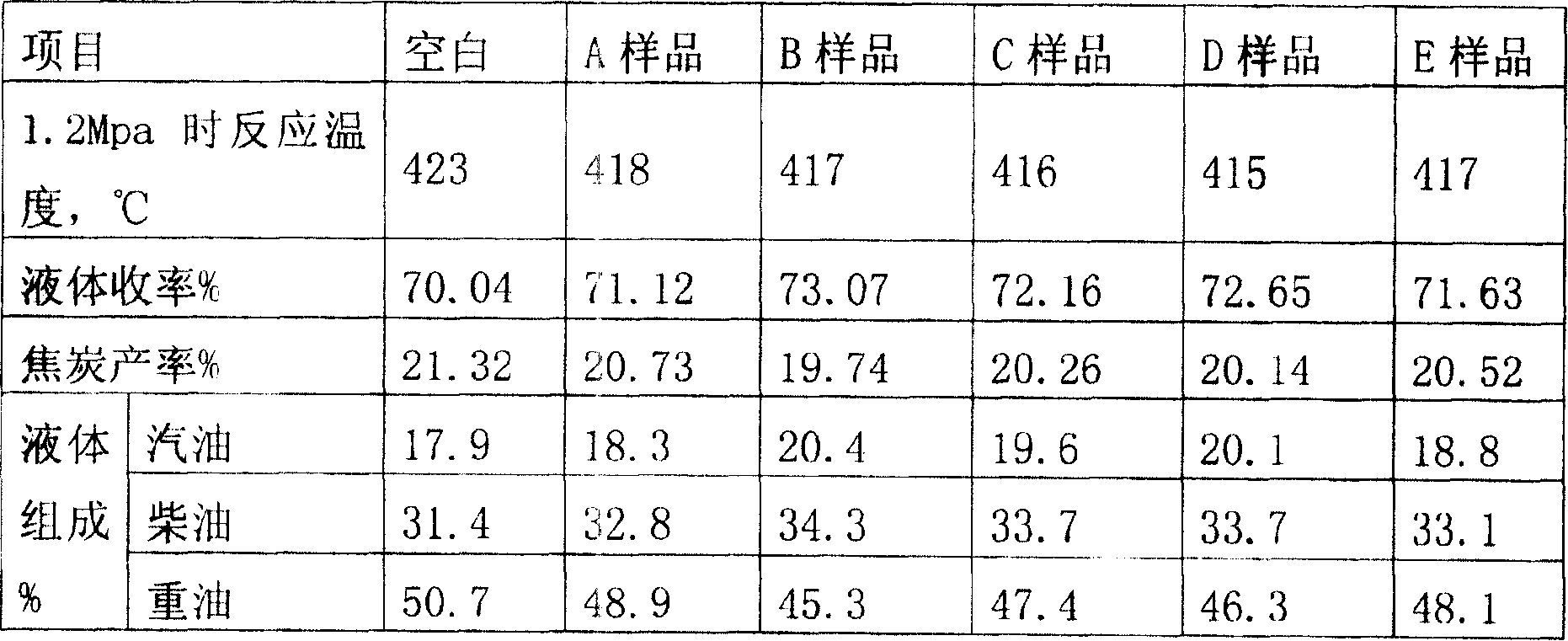

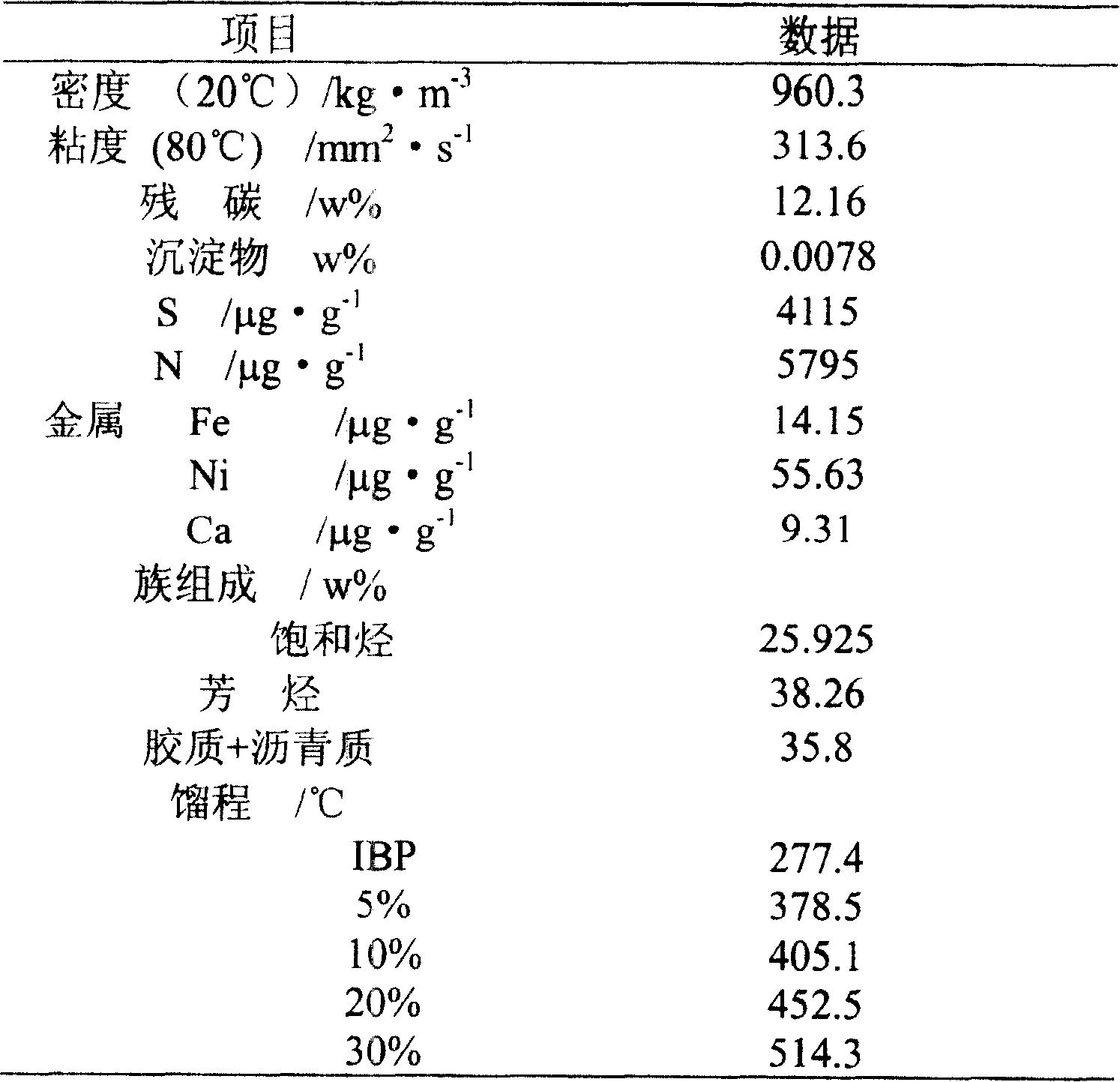

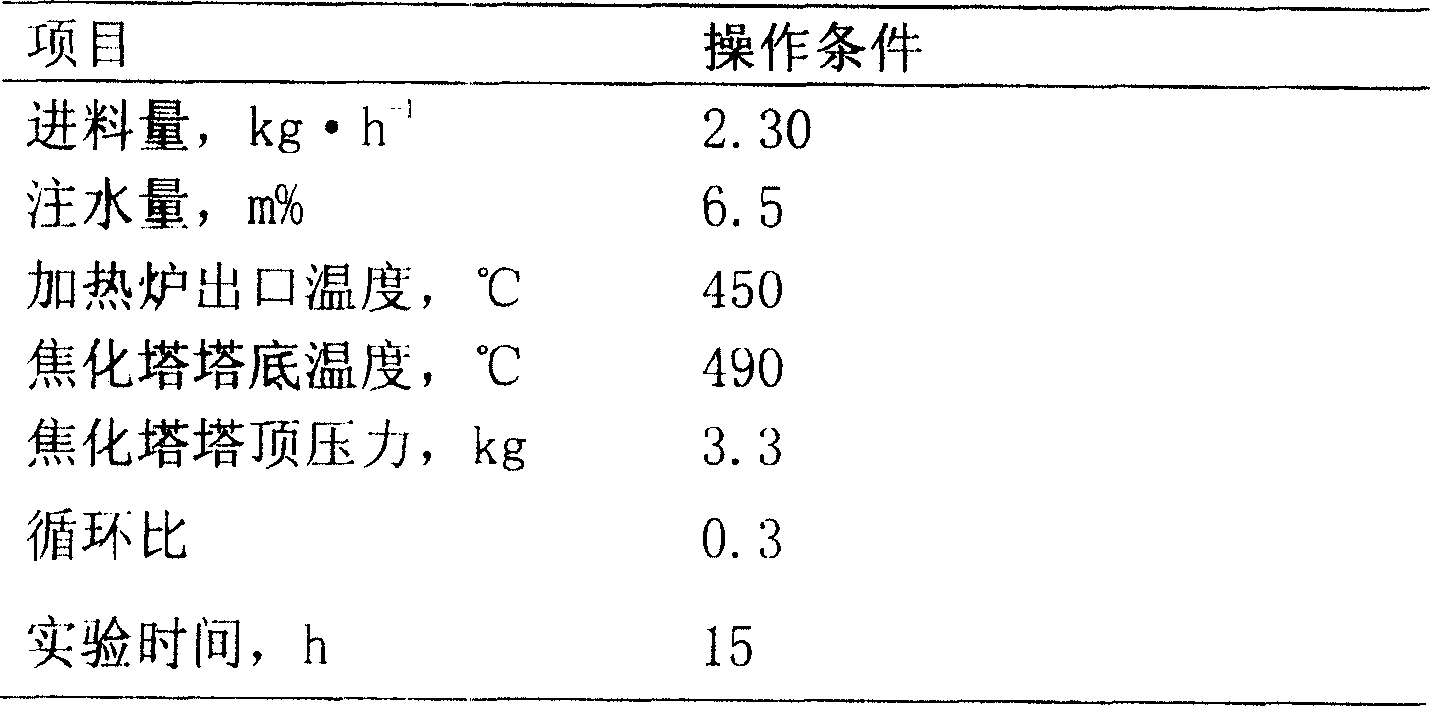

Auxiliary agent capable of improving delayed coking liquid yield, preparation method and application thereof

InactiveCN100387686CHigh yieldRaw materials are easy to getThermal non-catalytic crackingNitrateSolvent

The present invention discloses one kind of assistant for raising the yield of delayed coking liquid and its preparation process and application. The assistant consists of alkyl nitrate 20-40 wt%, fatty alcohol 10-30 wt%, dimethyl polysiloxane 10-20 wt% and solvent for the rest. The present invention can raise the yield of delayed coking liquid and reduce the yield of coke obviously.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

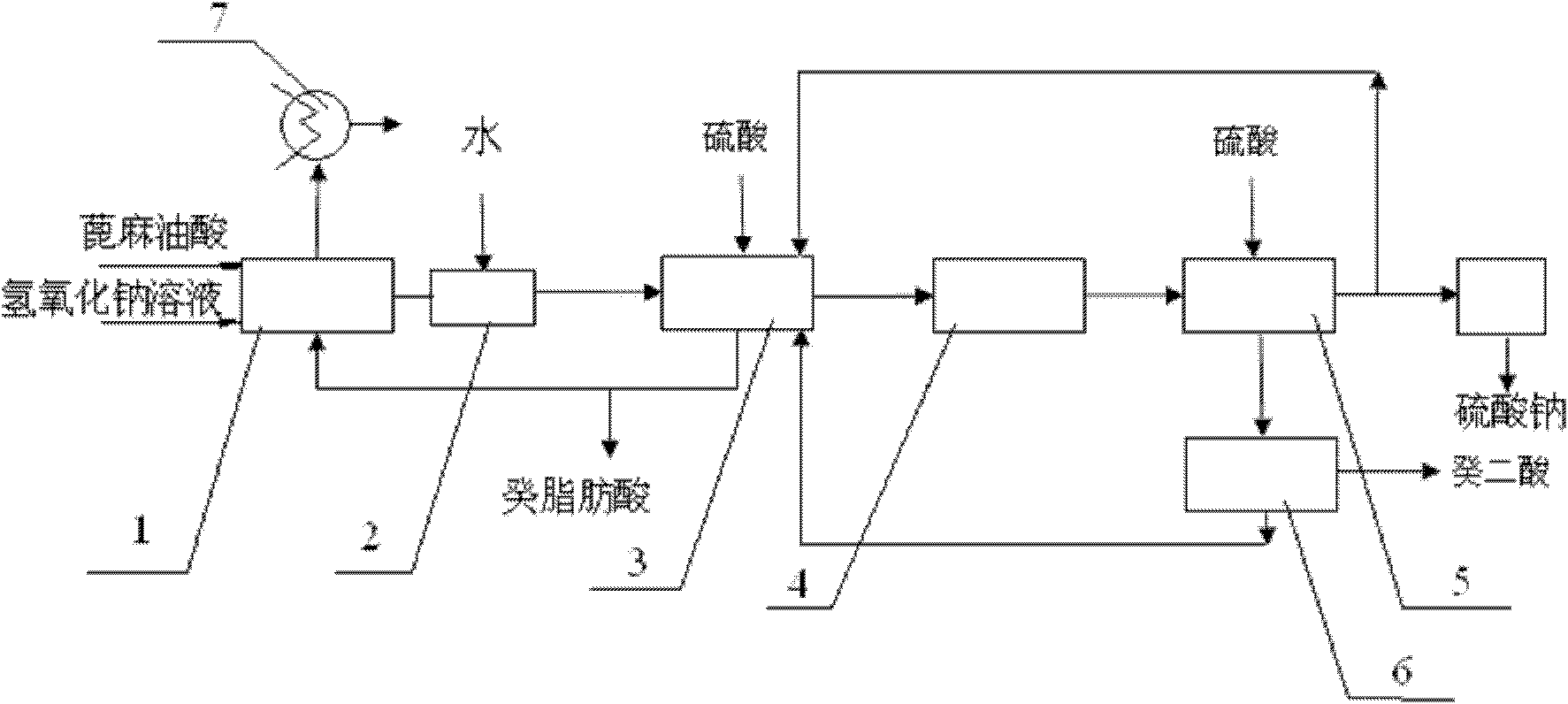

Preparation method for sebacic acid

ActiveCN102351682AEliminate pollutionSimple recycling processOrganic compound preparationCarboxylic compound preparationOctanolSebacic acid

The invention provides a preparation method for sebacic acid, which comprises the following steps: (1) adding ricinoleic acid, a diluent decanoic fatty acid and a sodium hydroxide solution in a reaction vessel for heating reaction, generating sebacic acid disodium salt, octanol, hydrogen and decanoic fatty acid sodium, (2) mixing and dissolving sebacic acid disodium salt, decanoic fatty acid, decanoic fatty acid sodium and water, placing into a neutralizing tank for neutralizing by sulfuric acid to obtain water phase of sebacic acid monosodium salt, then adding sulfuric acid into water phase, reacting and collecting the target product sebacic acid. The method of the invention reduces the difficulty of waste water treatment and the production cost which has the advantages of energy saving and consumption reduction, decanoic fatty acid is a by-product of sebacic acid production as well as a diluent which has the advantages of repeated usage and convenient recovery, no extra impurity is introduced in the production process, the product has good quality, and the major product sebacic acid, co-product octanol and by-product decanoic fatty acid have good quality.

Owner:上海华谊工程有限公司

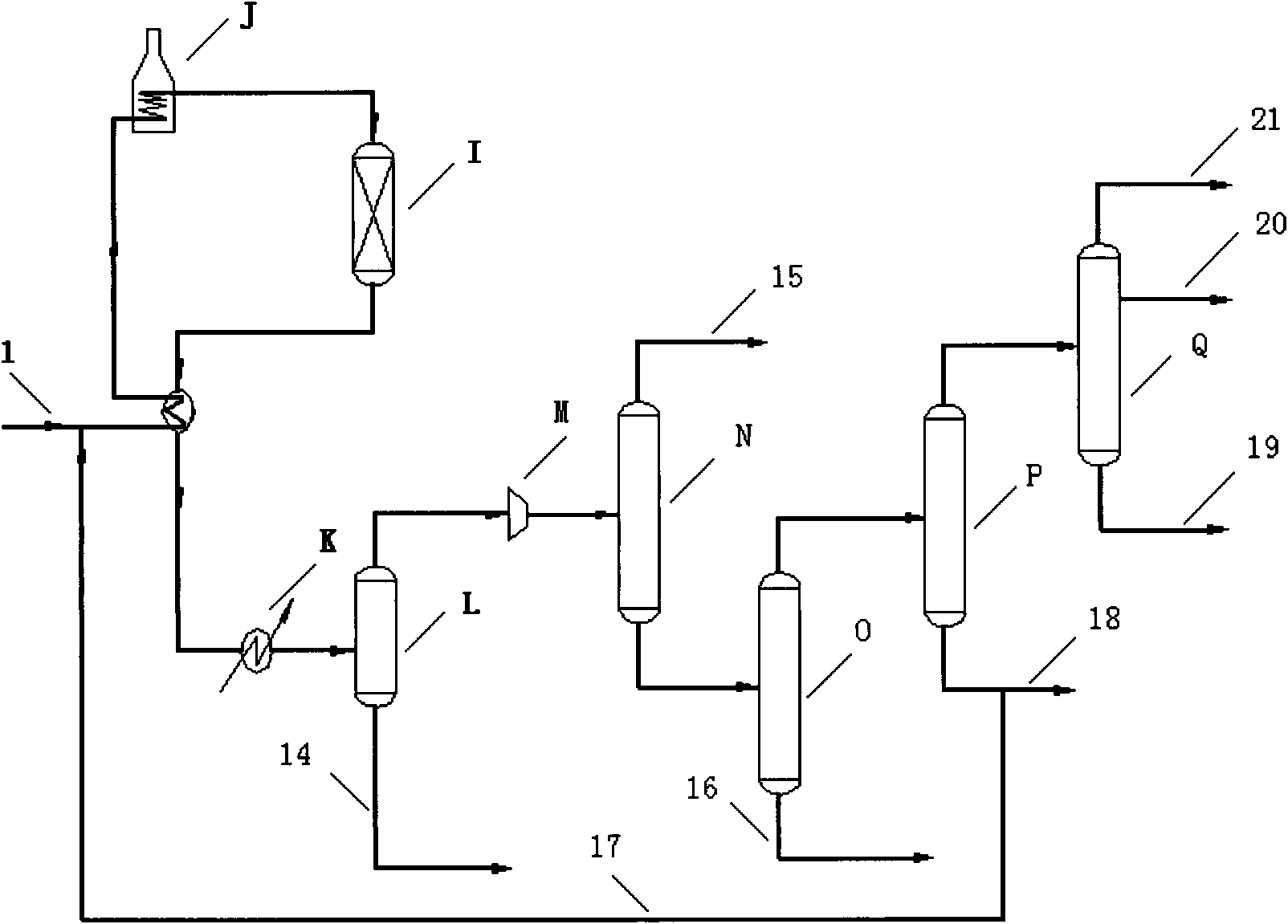

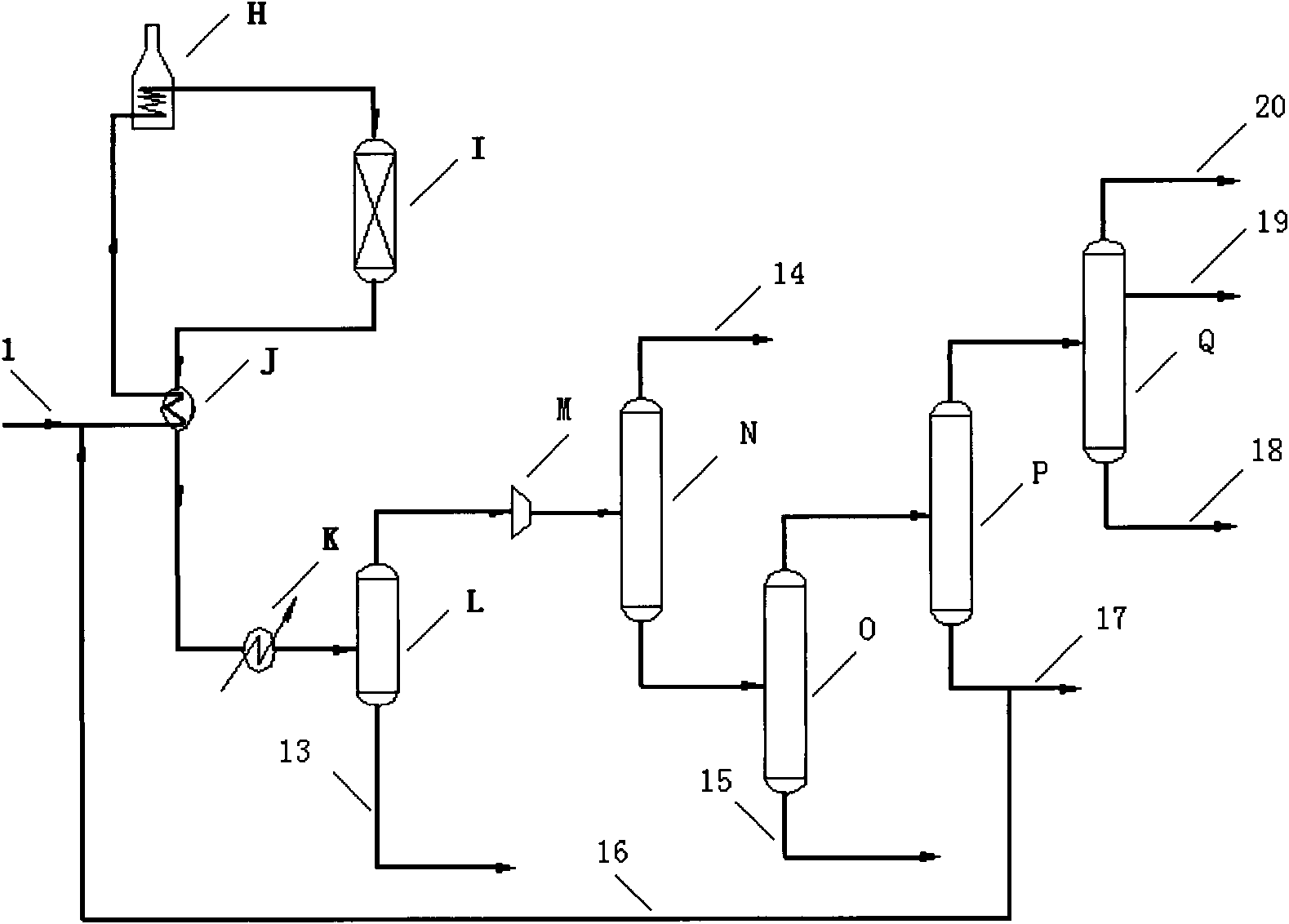

Method for preparing propylene from refinery mixed C4

InactiveCN102070390ANo reduction in olefin contentReduce olefin contentChemical industryTreatment with plural serial stages onlyButeneHigh energy

The invention discloses a method for preparing propylene from refinery mixed C4, which mainly solves the problems of low added value of the refinery mixed C4, low utilization efficiency of most of components, high energy consumption and the like existing in the prior art. According to the technical scheme, the method is realized by the following steps of: (1) allowing the refinery mixed C4 to pass through a catalytic distillation tower to isomerize butylene-1 into butylene-2, performing tower top separation to obtain light C4, and performing tower kettle separation to obtain heavy C4; (2) feeding the heavy C4 into a catalytic cracking reactor, wherein most of the butylene-2 is converted; (3) compressing a catalytic cracking reaction product and allowing the product to pass through a rectification unit to obtain a main polymer grade propylene product, a cracked gasoline byproduct, unreacted C4 and a C2<-> fraction; and (4) circulating most of the unreacted C4 and the C2<-> fraction to the catalytic cracking reactor. The method can be applied to the industrial field for producing the propylene.

Owner:王伟跃

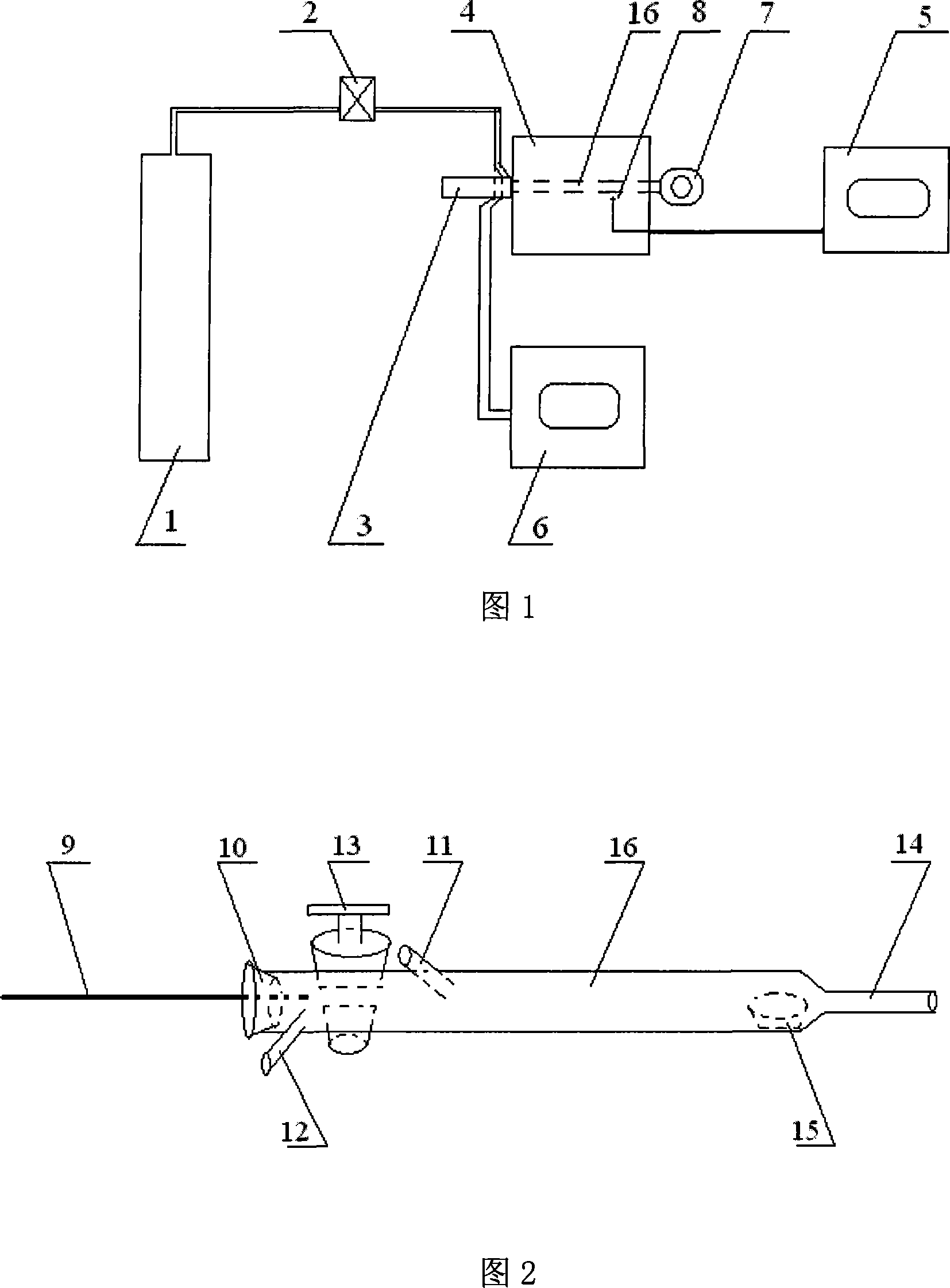

Tobacco leaf pyrolysis device

InactiveCN101187610AUniform and accurate flow rateHigh repeatabilityPreparing sample for investigationPistonCartridge heater

The utility model relates to a high temperature cracking device for tobacco leaves, which comprises a cracking quartz tube and a drum-type heater. The cracking quartz tube is arranged in the drum-type heater, a piston with a push rod is arranged on the air inletting end of the cracking quartz tube, two interfaces are arranged respectively on the cracking quartz tube, a first interface is connected with a protective air flow controller, and a second interface is connected with a vacuum circulating pump. The utility model can effectively eliminate oxygen interference in the air, and the tobacco leaves and other organics can be separated fully, which is beneficial to shorten cracking time, improve efficiency, and lower cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

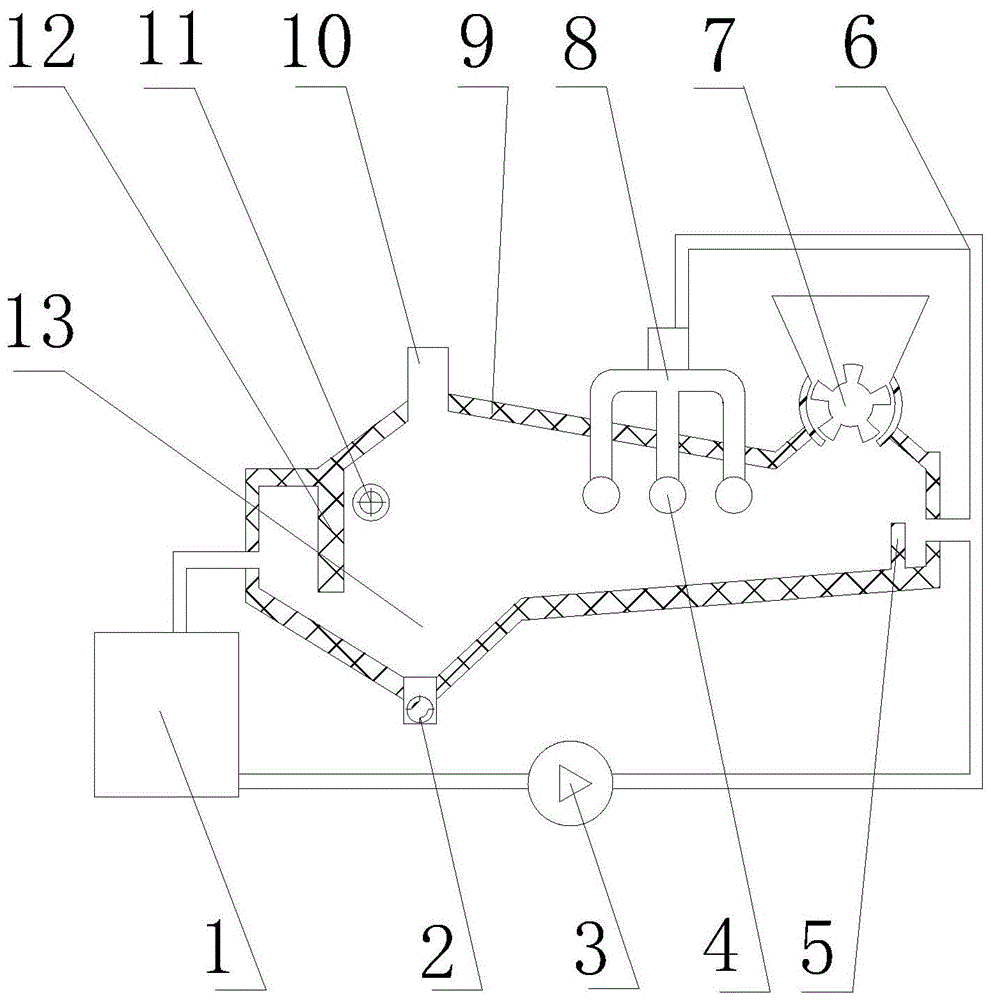

Device and technology for poly-generation of carbon, heat and electricity based on biomass gasification

PendingCN109679695ADevelop circular economyReduce dosageEnergy inputGasification processes detailsElectricityFixed bed

The invention discloses a device and a technology for poly-generation of carbon, heat and electricity based on biomass gasification. The technology comprises steps of biomass transport, biomass gasification, boiler processing, electricity generation, desulphurization and dust removal. A large-dip-angle belt is adopted to perform continuous automatic feeding for biomass transport; a composite gasification fixed bed gasification technology with combination of upper and lower suction is adopted for biomass gasification, and a byproduct is a carbonized material; steam produced by a boiler after burning of gasified gas enters a steam turbine for generating electricity and then passes through a heat exchange station for providing a heat source for heating; a scattering tower based desulphurization and dust removal integration technology is adopted for desulphurization and dust removal. The device and the technology have the advantages of being environmentally friendly and safe and realizingpoly-generation of carbon, heat and electricity.

Owner:XINDI ENERGY ENG TECH

Nickel-based tar reforming catalyst based on mesoporous zirconia carrier and preparation method thereof

InactiveCN102380387APrevent carbon deposition and deactivationGood tar catalytic conversion performanceCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveNickel oxides

The invention belongs to the field of utilization of catalyst and biomass energy and particularly relates to a nickel-based tar reforming catalyst based on a mesoporous zirconia carrier and a preparation method thereof. The nickel-based tar reforming catalyst based on a mesoporous zirconia carrier utilizes mesoporous zirconia molecular sieves as carriers and utilizes nickel oxide as an active component, and is a composite catalyst which comprises 70%-99.5% by mass of mesoporous zirconia molecular sieves and 0.5%-30% by mass of nickel oxide. Since the mesoporous zirconia molecular sieves are used as the carriers, the specific surface area of the catalyst is expanded greatly, and an order channel structure suitable for cracking reaction of macromolecular organic matter in tar is provided. By means of interaction between the mesoporous zirconia molecular sieves and the nickel oxide, reactivity of the catalyst is improved, and the catalytic reforming rate to tar can be over 99%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

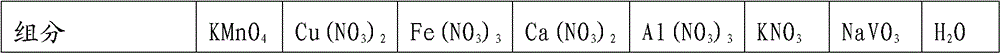

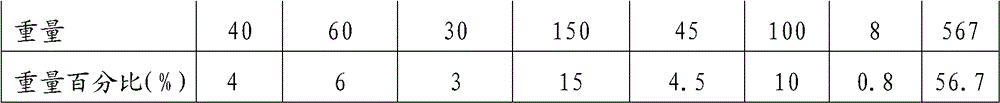

Liquid combustion-supporting sulfur-fixing coal additive and using method thereof

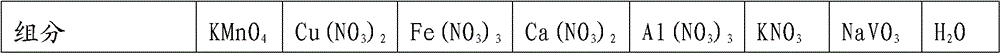

The invention discloses a liquid combustion-supporting sulfur-fixing coal additive and a using method of the additive; the liquid combustion-supporting sulfur-fixing coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 8-18% of Ca(NO3)2, 3.5-6% of Al(NO3)3, 8-18% of KNO3, 0.5-2.5% of NaVO3, and the balance of H2O. The liquid combustion-supporting sulfur-fixing coal additive provided by the invention uses water as a solvent and each component is at an ionic state, has relatively high reaction activity at a high temperature and has high combustion efficiency and an excellent sulfur fixing effect, and the sulfur fixing efficiency is more than 40%.

Owner:唐山干诚工程管理有限公司

Method for preparing xylene by shape-selective disproportionation of toluene

ActiveCN104276923AAddressing the issue of recycled hydrogen that needs to be ventedAddressing the issue of vented recycled hydrogenHydrocarbonsHydrocarbon preparationGas phaseMixed materials

The invention relates to a method for preparing xylene by shape-selective disproportionation of toluene to mainly solve the technical problem that a lot of recycle hydrogen is discharged out of a reaction system after a reaction under the hydrogen-containing reaction condition and supplemental hydrogen is greatly consumed in the prior art. The method for preparing xylene by shape-selective disproportionation of toluene comprises the following steps: reaction materials toluene and recycle hydrogen pass through a feed-in and feed-out exchanger to be heated so as to form a mixed material I; the mixed material I is heated by a heating furnace and enters a reactor, a material II obtained after a reaction enters a feed-in and feed-out heat exchanger and is cooled, and the material II enters a gas-liquid separator to be separated after being cooled; a gas phase in the upper part of the gas-liquid separator enters a gas-phase circulatory system; the recycle gas phase is mixed with supplemental hydrogen, and the mixture is recycled to the reaction system after pressurization; and a liquid phase in the lower part of the gas-liquid separator enters a subsequent liquid-phase separation system. By the technical scheme, the above problem is solved well. The method can be applied in industrial production of a shape-selective disproportionation reaction of toluene.

Owner:CHINA PETROLEUM & CHEM CORP +1

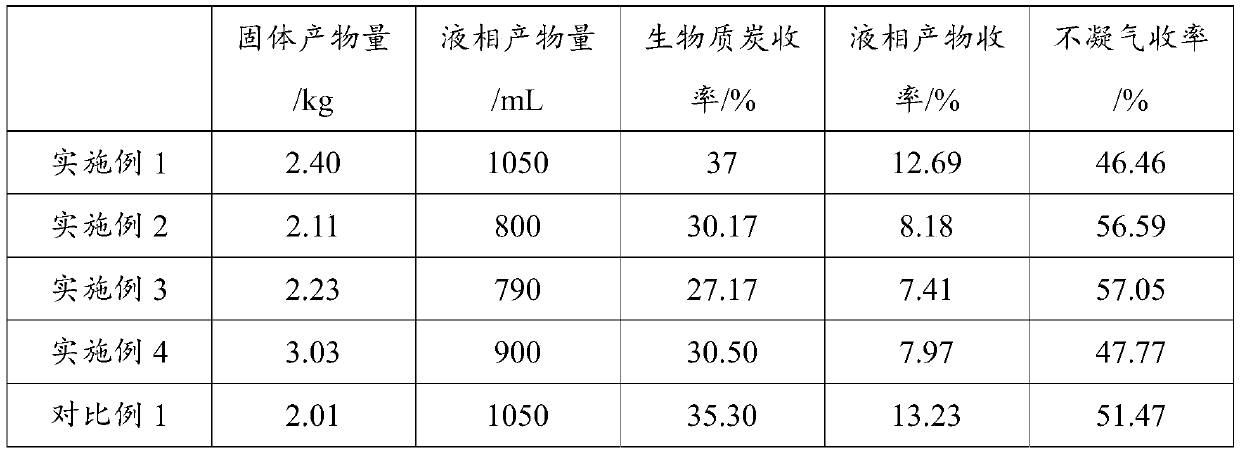

Biomass carbonization method and soil conditioner prepared by method

InactiveCN110016355AReduce the temperatureGood chemical stabilityAgriculture tools and machinesBiofuelsReaction temperatureCarbonization

The invention relates to the technical field of biomass carbonization, and discloses a biomass carbonization method and a soil conditioner prepared by the method. According to the method, straw particles and attapulgite are co-carbonized at a temperature of 250-450 DEG C, and the attapulgite has rich nano-pore structures, trace elements and other special structures, so that rich active centers areformed on the surface of the attapulgite; apparent activation energy of straw pyrolysis gas can be reduced, and continuous cracking reaction of macromolecular liquid obtained by primary pyrolysis ispromoted, so that the yield of a macromolecular liquid-phase product is reduced, and the yield of micromolecular non-condensable gas is increased. According to the method disclosed by the invention, the carbonization reaction temperature can be reduced, the oxygen content in biological oil can be reduced, and a part of wax-like substances can be obtained, so that stability of the biological oil isimproved, meanwhile, the phenomena that carbonization equipment and pipelines of the carbonization equipment are blocked and the like are avoided, and thus the service life of the equipment is prolonged.

Owner:南京三聚生物质新材料科技有限公司 +1

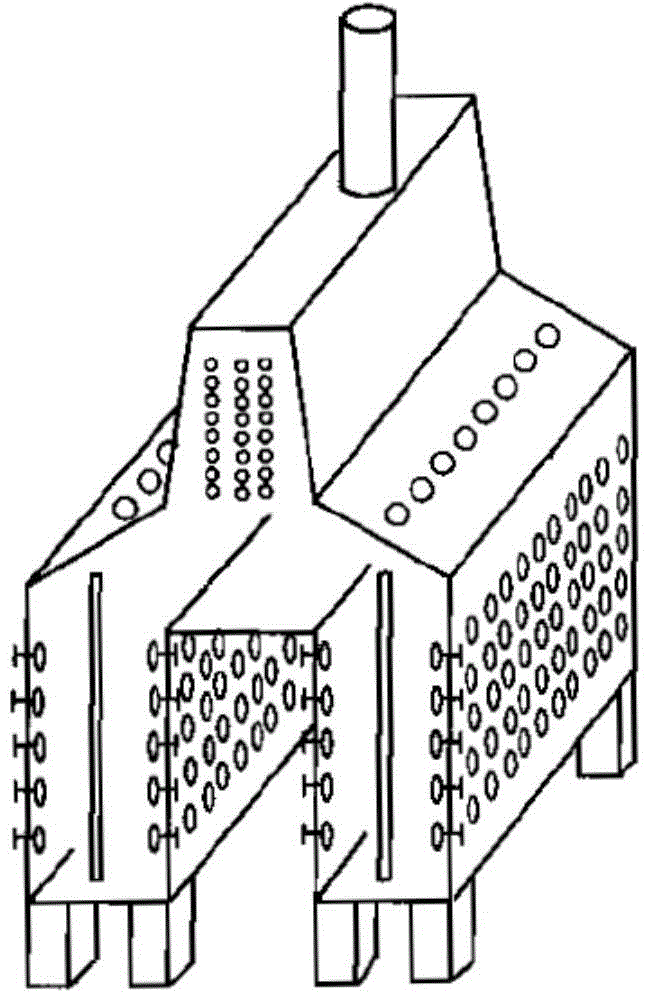

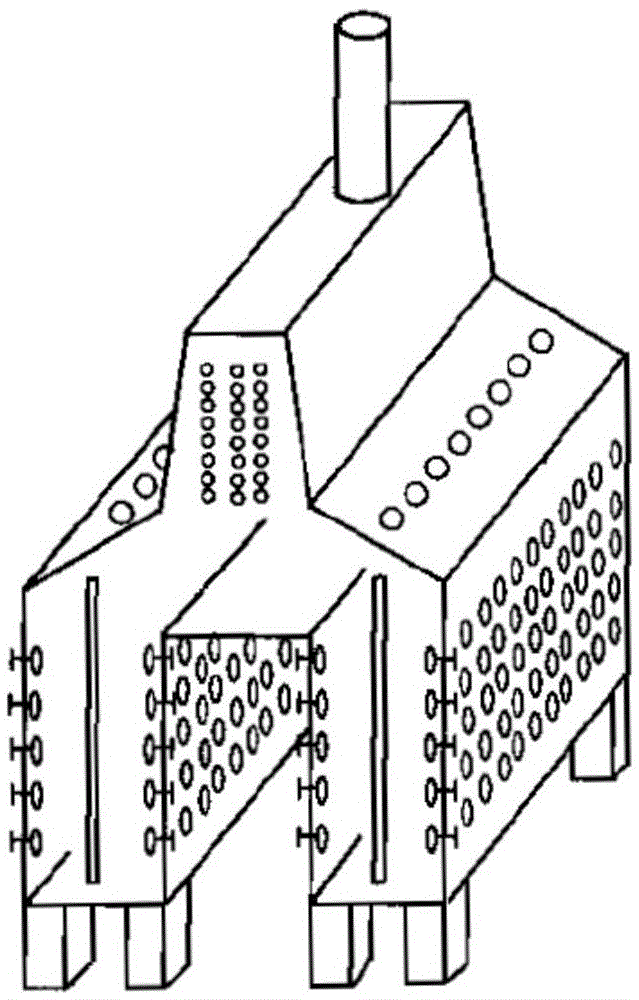

Cracking furnace

ActiveCN107974269ASimple structureSmall footprintThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingCombustorHearth

The invention discloses a cracking furnace. The cracking furnace comprises a convection section, a radiation section communicated with the convection section, a quenching boiler and a steam drum, wherein the convection section is internally provided with a convection tube bundle communicated with a feed inlet of the cracking furnace; the steam drum is arranged on the top of the convection section;the top of the convection section is provided with a fan communicated with the cracking furnace; the radiation section is internally provided with a plurality of groups of radiation tube bundles; theradiation tube bundles comprise a plurality of radiation furnace tubes; the plurality of radiation furnace tubes are arranged along the peripheries of the radiation tube bundles at intervals; the radiation furnace tubes are communicated with the convection tube bundle; the bottom and sidewall of a hearth in the radiation section are separately provided with a plurality of combustors; and the outlet ends of the radiation furnace tubes are communicated with the quenching boiler. The cracking furnace provided by the invention is simple in structure; through improvement of the arrangement mode ofthe radiation furnace tubes, difficulties in arrangement of the radiation furnace tubes can be reduced, and reaction conditions in each group of radiation furnace tubes in the cracking furnace are maximally maintained same; and the cracking furnace has the advantage of a small occupied land area under the condition of same unit production capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

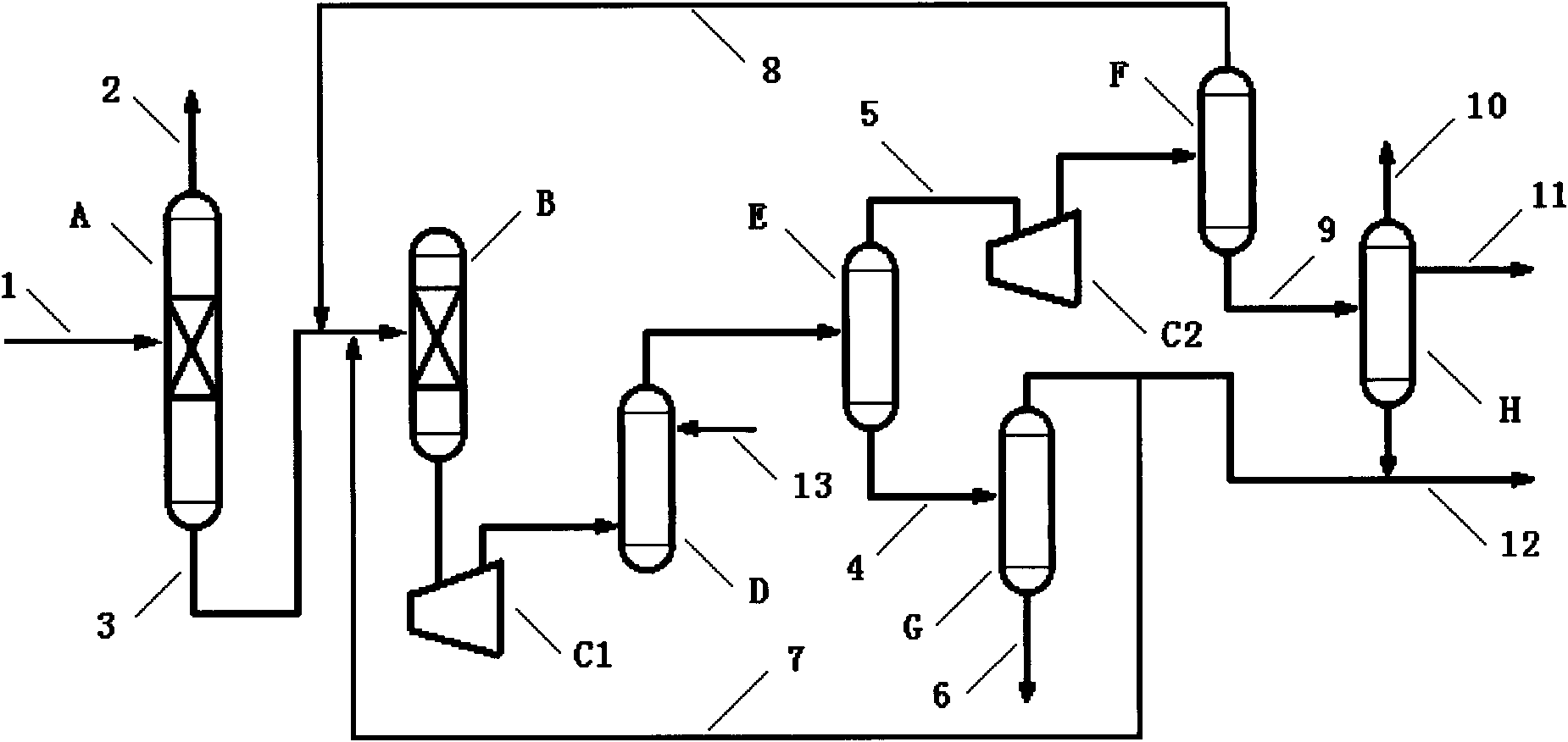

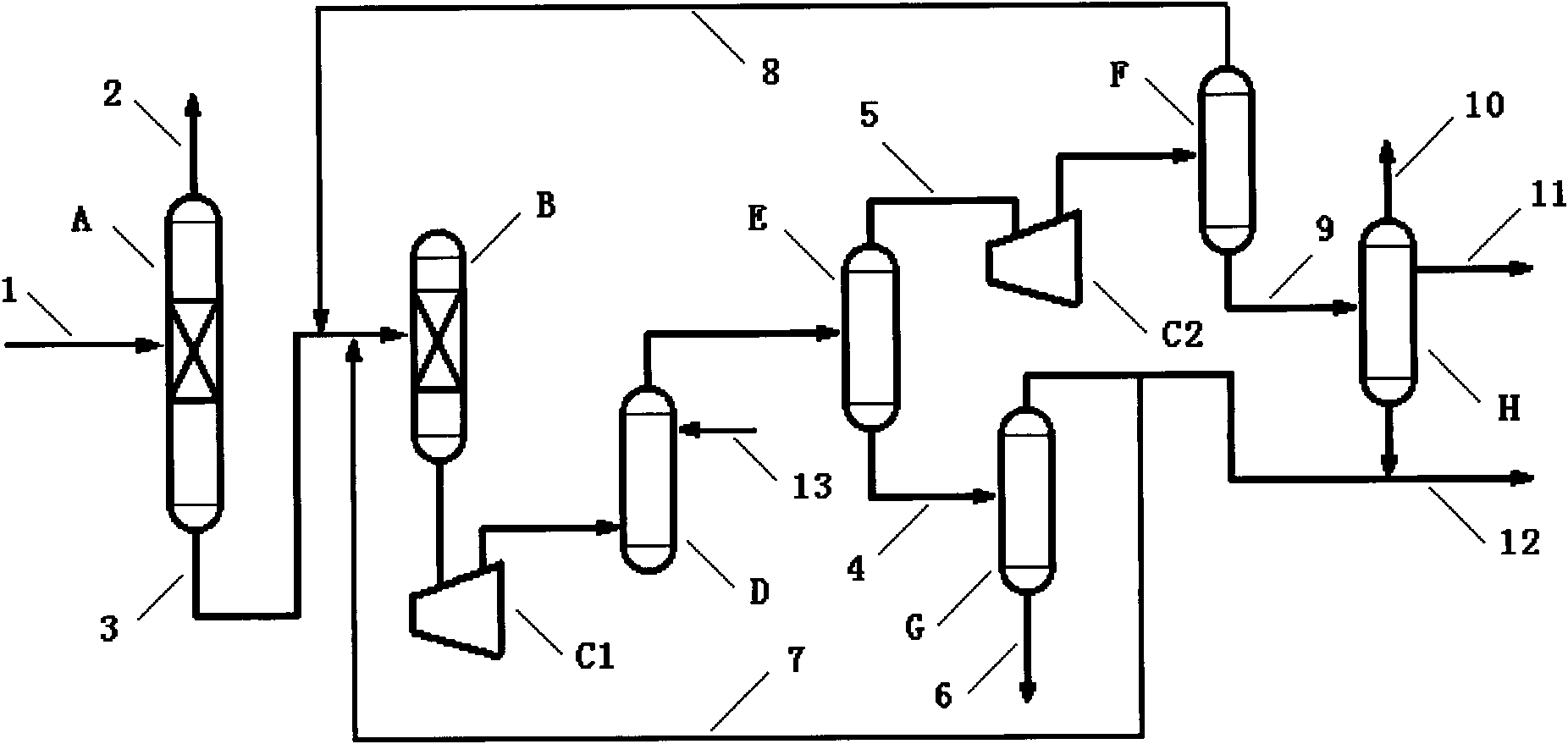

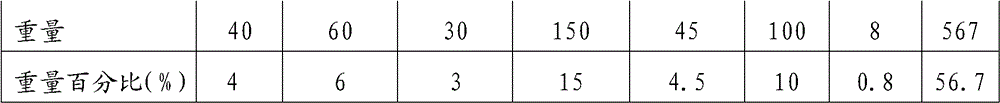

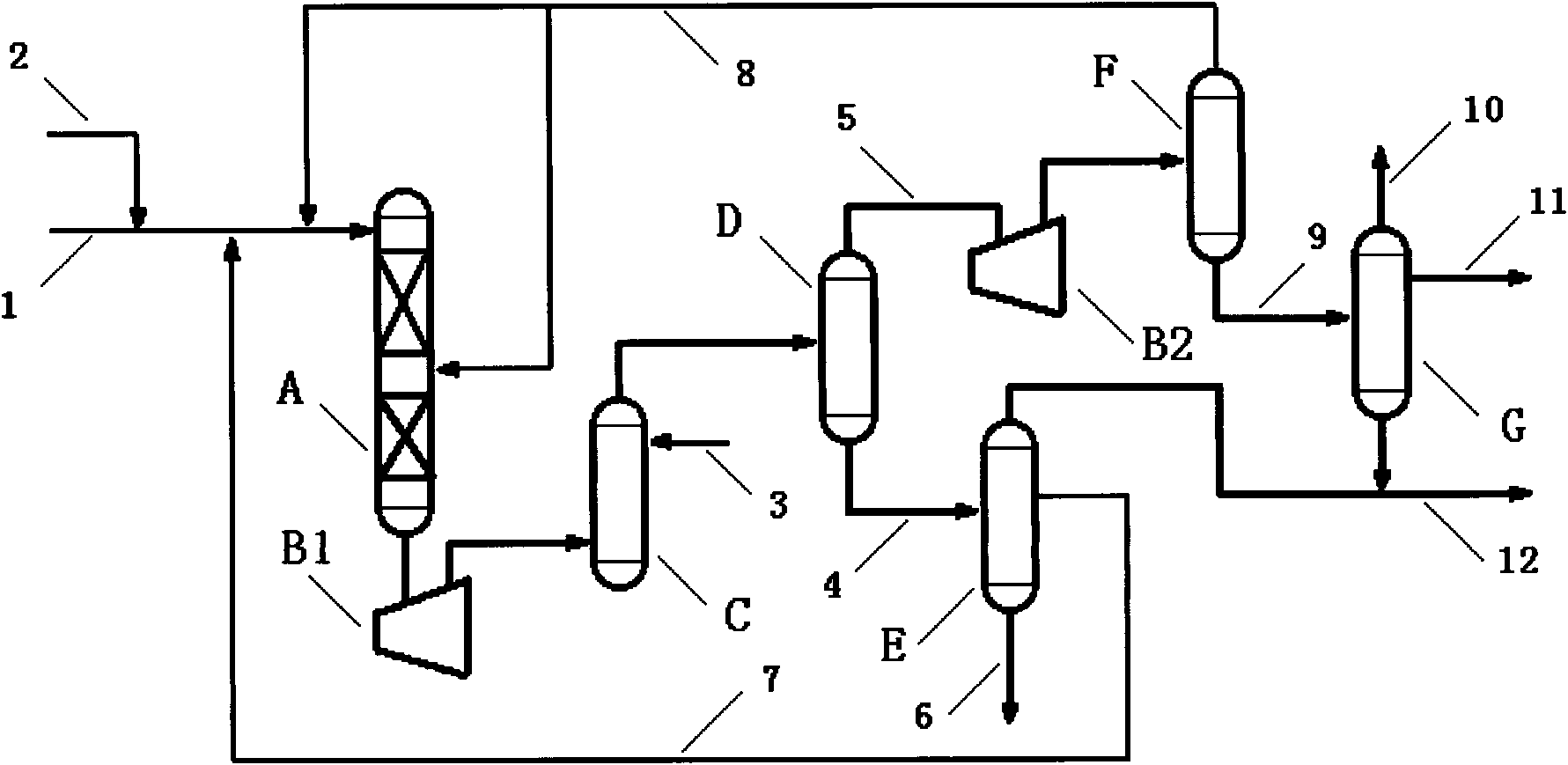

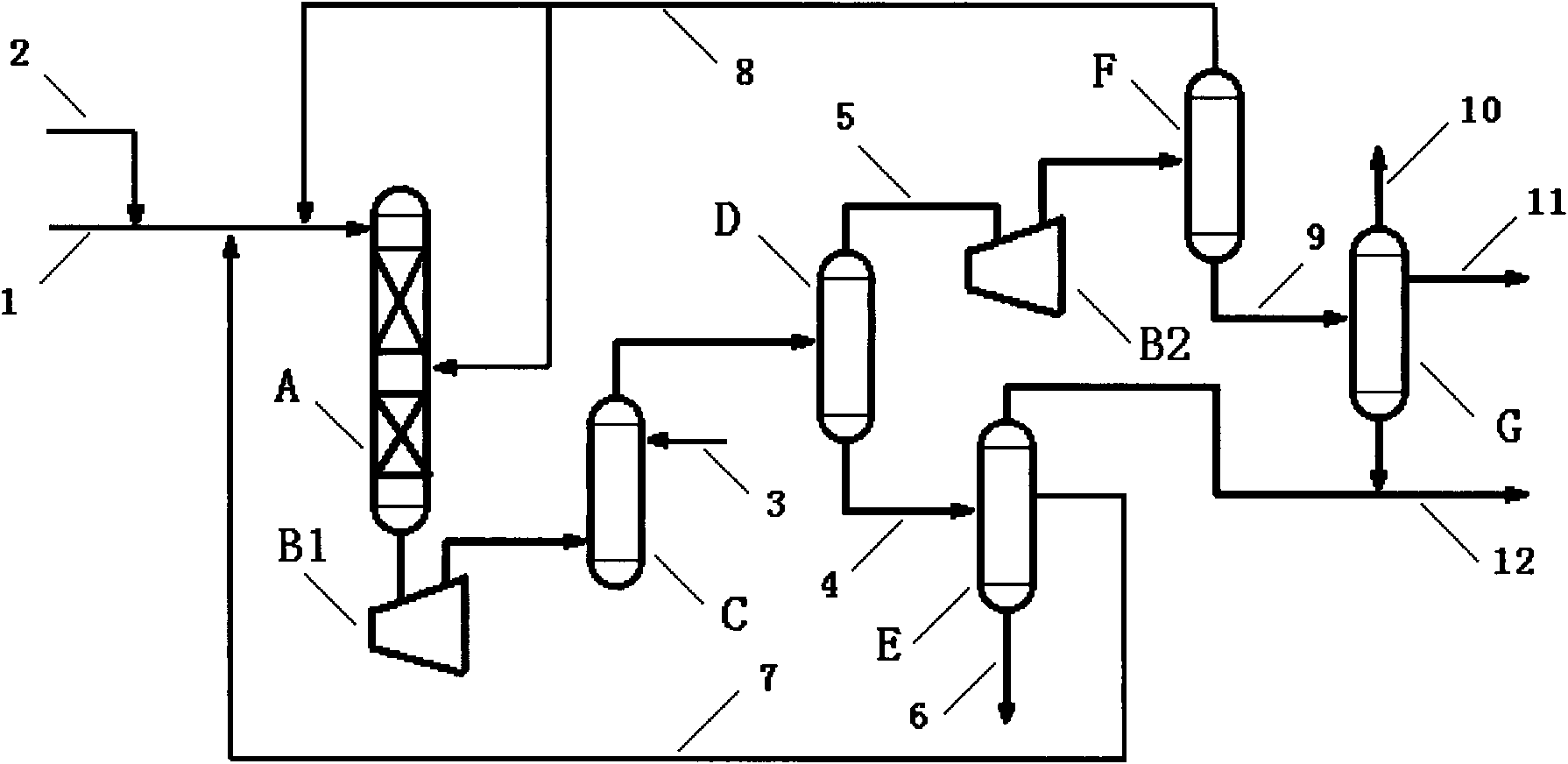

Technology for preparing propylene by utilizing by-products in refinery

InactiveCN102070389AReduce partial pressurePromote cleavage reactionHydrocarbonsHydrocarbon by hydrocarbon crackingAdditional valuesTower

The invention relates to a technology for preparing propylene by utilizing by-products in a refinery, mainly solving the problems that the chemical additional value of the by-products in the refinery in the prior art is low slightly. The invention achieves the purposes by adopting the technical scheme comprising the following steps: (1) the by-products in the refinery are mixed with butane and dry gas to obtain a mixture which enters a reactor from the top of the reactor; (2) reaction products flow out from the bottom of the reactor, and enter a tower 1 after being compressed and alkaline-cleaned; C3-fraction is obtained from the top of the tower 1, and C4+fraction is obtained from the bottom of the tower 1; (3) the C3-fraction enters a tower 2 after being compressed; C2-fraction is obtained from the top of the tower 2, and C3+fraction is obtained from the bottom of the tower 2; (4) a large amount of the C2-fraction circulates to the top of the reactor or an inlet of the second section; and the C3-fraction is rectified to obtain a polymer grade propylene product; and (5) the C4+fraction enters a tower 3; and C4 mixture is obtained from the top of the tower 3, a part of the C4 mixture extracted from the side surface circulates to the inlet at the top of the reactor, and C5+fraction is obtained from the bottom. The technology can be applied in the industrial fields of producing the propylene.

Owner:王伟跃

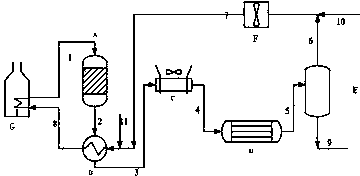

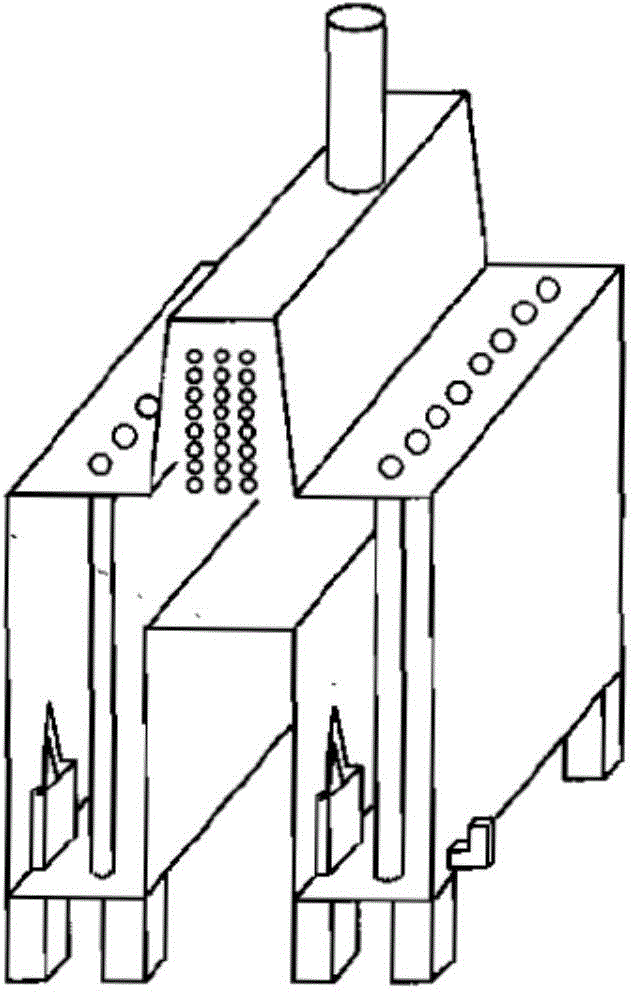

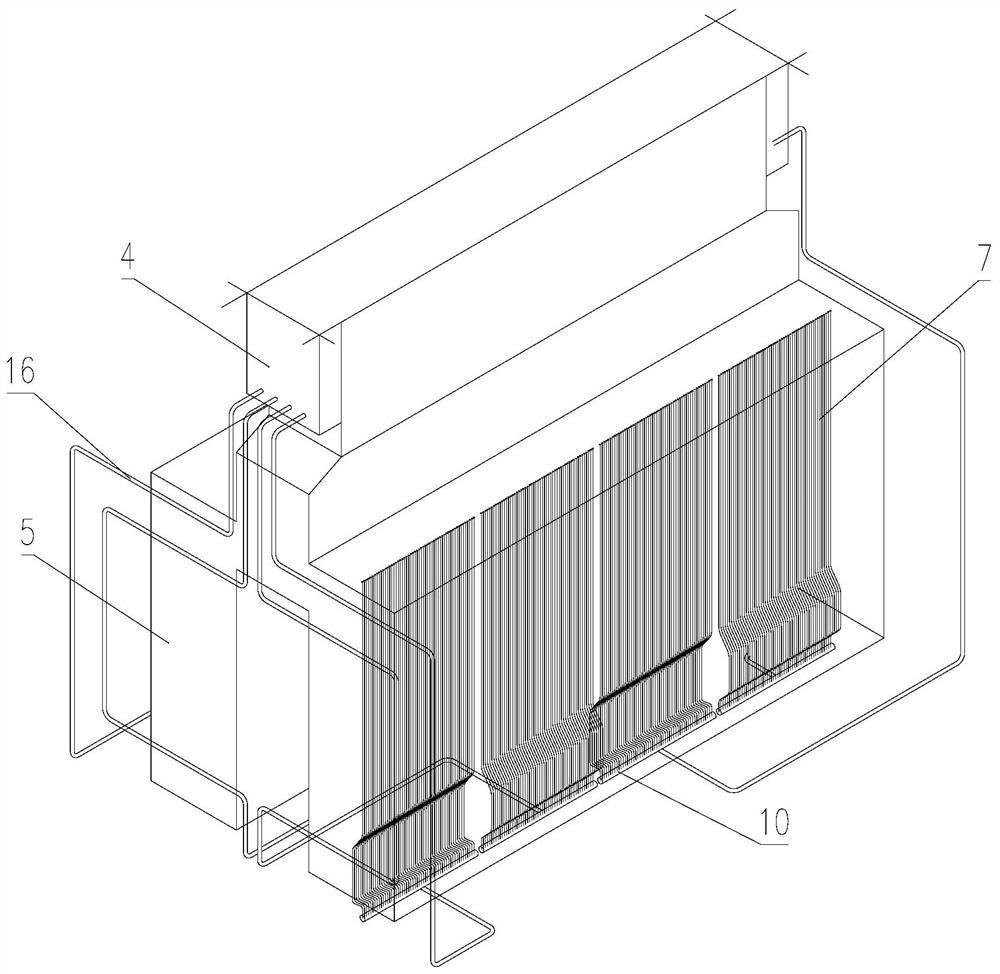

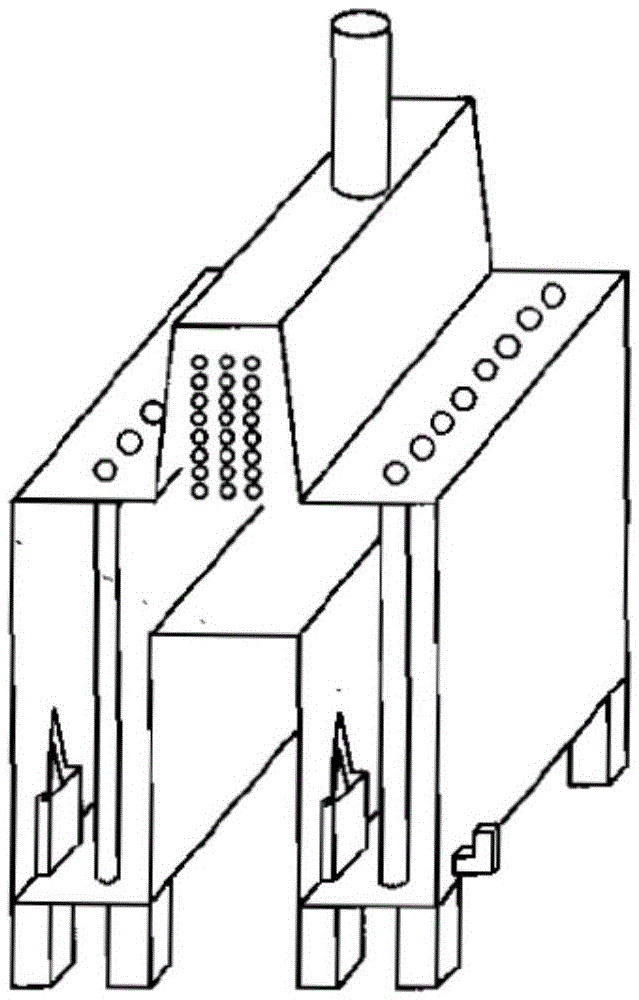

Ethylene cracking furnace of double-section heat supply structure

ActiveCN104560114AReduce the amount usedReduce equipment investment costs and operation and maintenance costsThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingQuenchingEngineering

The invention provides an ethylene cracking furnace of a double-section heat supply structure. The ethylene cracking furnace comprises a radiation section (1), a convection section (5), a radiation coiled tube (4), a quenching boiler (6), a high-pressure steam pocket (7) and a draft fan (8), wherein the quenching boiler (6) is connected with the radiation coiled tube (4); the draft fan (8) is connected with the top of the convection section (5); and the high-pressure steam pocket (7) is connected with the quenching boiler (6). The ethylene cracking furnace is of the double-section combined heat supply structure that the radiation section (1) is internally provided with an upper heat supply section and a lower heat supply section. By adopting the ethylene cracking furnace of the double-section heat supply structure, the arrangement of a combustor and the design of a combustion tube line arrangement are simplified, the flame inside a hearth is prevented from coiling to touch furnace tubes, interference of flame is also prevented, uniform distribution of heat in the height direction inside the hearth in the radiation section is maintained, and meanwhile the emission of NOx is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

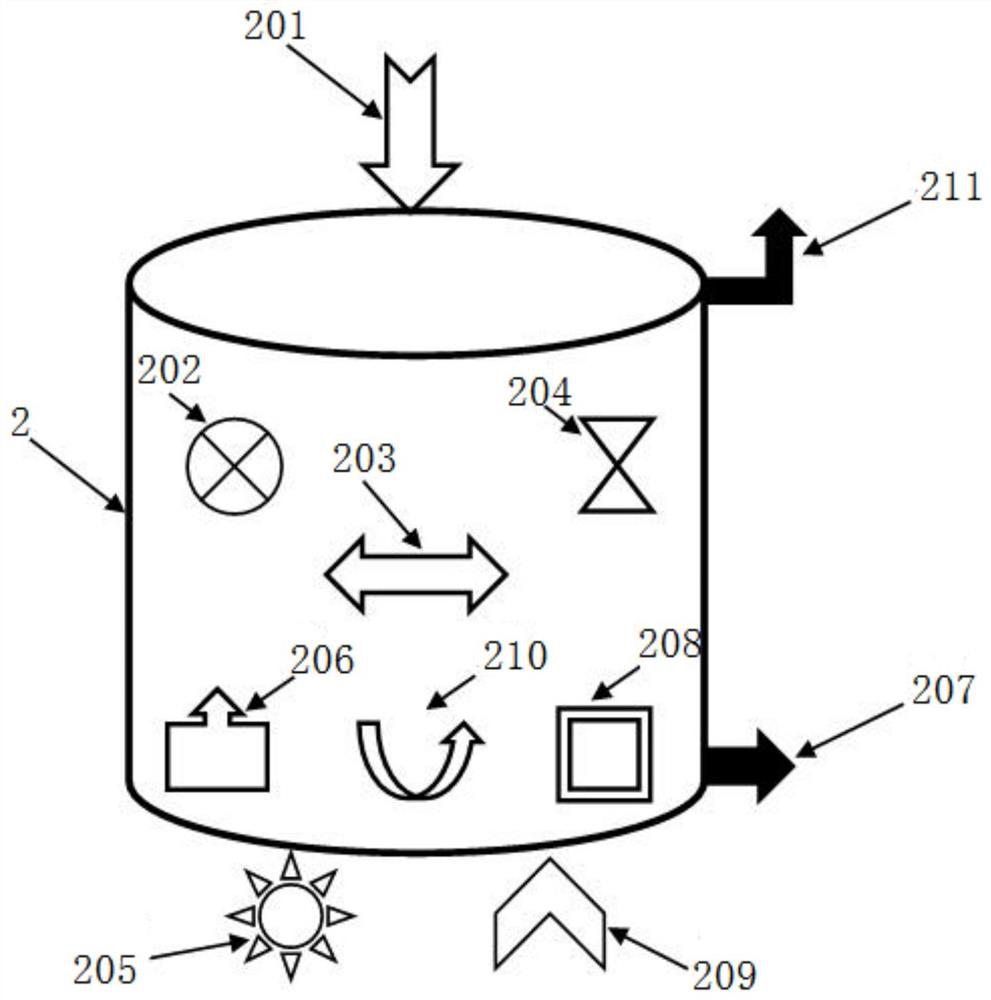

A waste plastic molten salt pyrolysis device

InactiveCN105385468BPromote cleavage reactionIncrease chance of repeated exposureLiquid hydrocarbon mixture productionHydrocarbon oils treatmentMolten saltPlastic waste

Owner:CHINA GASOLINEEUM TECH & DEV CORP

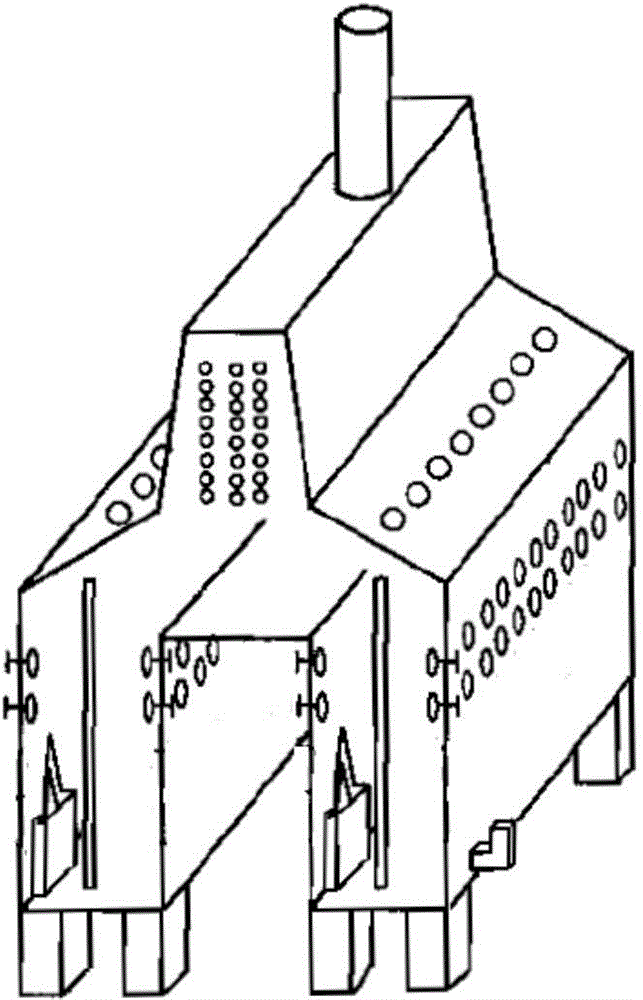

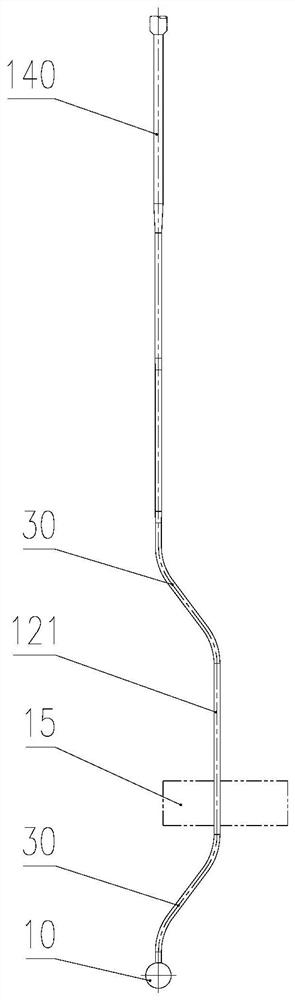

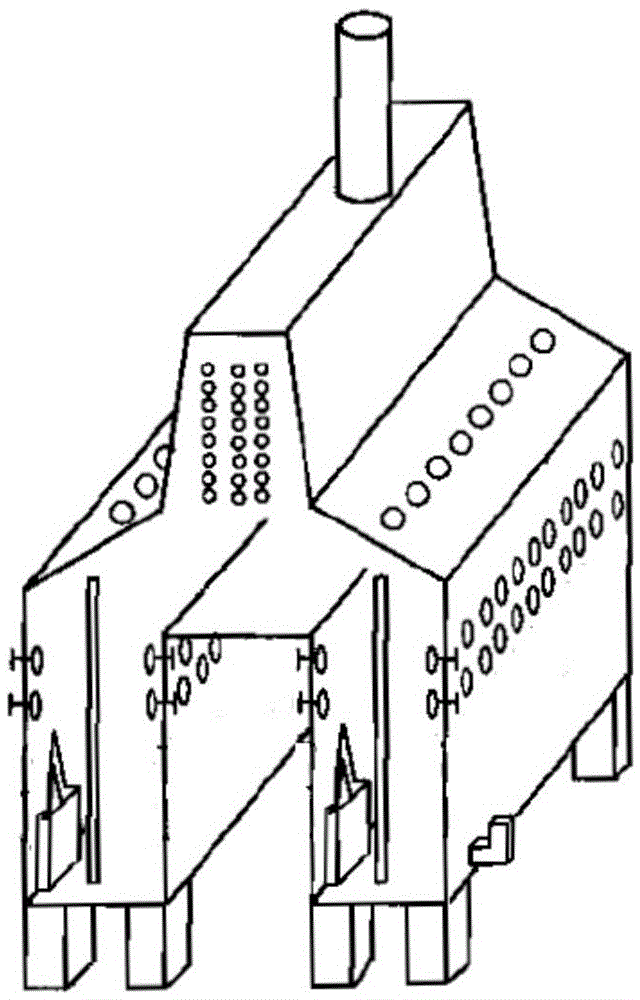

An ethylene cracking furnace

ActiveCN109486506BGood for absorbing thermal expansionSolve the blockageThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingThermal dilatationThermodynamics

The invention belongs to a petrochemical industry, and provides an ethylene cracking furnace which comprises a high-pressure drum, a convection section, a radiation section, a quenching boiler and a combustor. Single-pass radiation furnace pipes are arranged in the radiation section and comprise inlet section straight pipes and bending pipe connectors, each bending pipe connector comprises two S-shaped bending pipes and an inlet straight pipe positioned between the two S-shaped bending pipes, a plurality of radiation furnace pipes form a large group, a plurality of large groups are arranged inthe radiation section, all radiation furnace pipes in each large group are connected with a shared collecting tube through the bending pipe connectors, outlet section straight pipes of the radiationfurnace pipes in each large group are vertically arranged relative to the bottom of the combustor, the convection section is connected with the collecting tube through a crossover pipe, and the crossover pipe is of a stereoscopic II-type structure distributed along the length, width and height directions of a furnace body of the radiation section. A distributed mode of the crossover pipe can ensure that a line of the crossover pipe has sufficient flexibility to absorb thermal expansion of the furnace pipes, so that bending of the furnace pipes is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

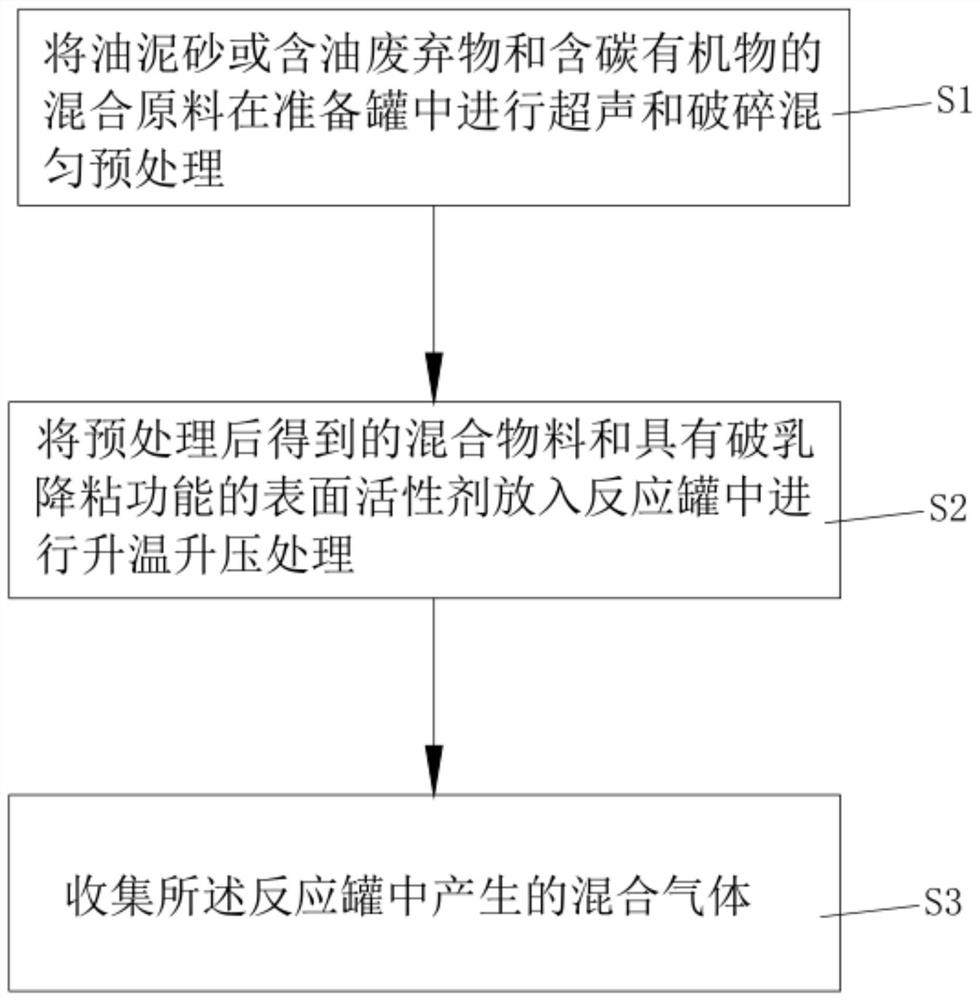

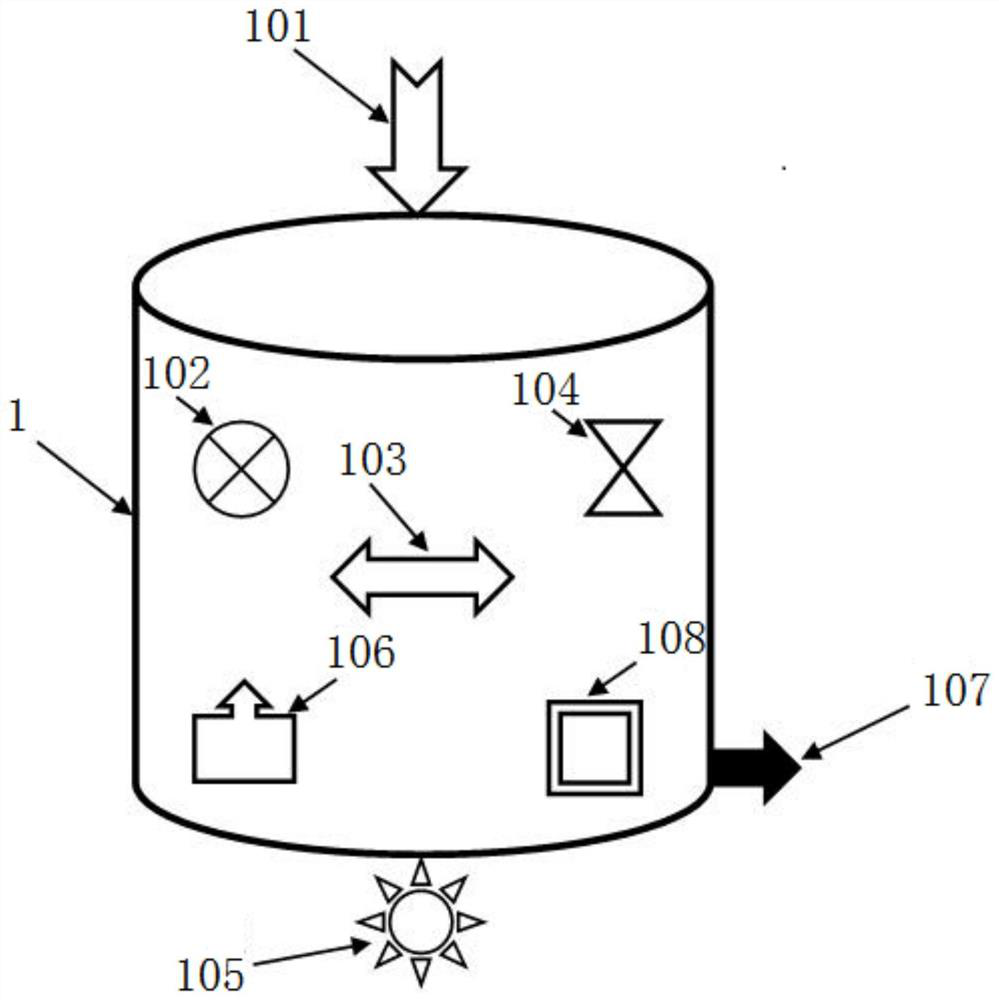

Catalytic treatment process and system for converting hazardous waste oil-containing silt into solid waste

ActiveCN113443799AReduce oil contentPromote cleavage reactionWater treatment compoundsSludge treatment by pyrolysisActive agentMixed materials

The invention discloses a catalytic treatment process and system for converting hazardous waste oil-containing silt into solid waste. The treatment process comprises the following steps: S1, carrying out ultrasonic and crushing uniform mixing pretreatment on mixed raw materials of oil-containing silt and carbonaceous organic matter in a preparation tank; S2, putting a mixed material obtained after pretreatment and a surfactant with demulsification and viscosity reduction functions into a reaction tank, and carrying out heating and pressurizing treatment; and S3, collecting the mixed gas generated in the reaction tank. According to the catalytic treatment process for the oil-containing silt, a low-temperature hydrothermal carbonization pyrolysis and surfactant combined method is adopted, the oil-containing silt and a carbon-containing organic matter are used as main raw materials, and the oil-containing silt is subjected to structural transformation, activation and promotion of a cracking reaction with relatively high activation energy through physical, chemical and engineering means; and the oil content of the oil-containing silt can be efficiently reduced, so that the treated oil silt reaches the national harmless emission standard, and zero emission of the whole production process is realized.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Combustion-supporting coal additive and application method thereof

The invention discloses a combustion-supporting coal additive and an application method thereof. The coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 1.5-6% of Zn(NO3)2, 6-14% of KNO3, 5-10% of NaNO3, 0.5-1.5% of NaVO3 and the balance of H2O. The combustion-supporting coal additive disclosed by the invention uses water as a solvent, and the components are in an ionic state, so the combustion-supporting coal additive has high reaction activity; the combination of the components in the additive can promote the decarburization and cracking reactions of the coal as well as the sufficient combustion of volatile compounds and fixed carbon, enhance the combustion efficiency of the coal, and save the coal by 4-10%.

Owner:国家电投集团协鑫滨海发电有限公司

An ethylene cracking furnace with a double-stage heating structure

ActiveCN104560114BLarge heating loadReduce usageThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingCombustorEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

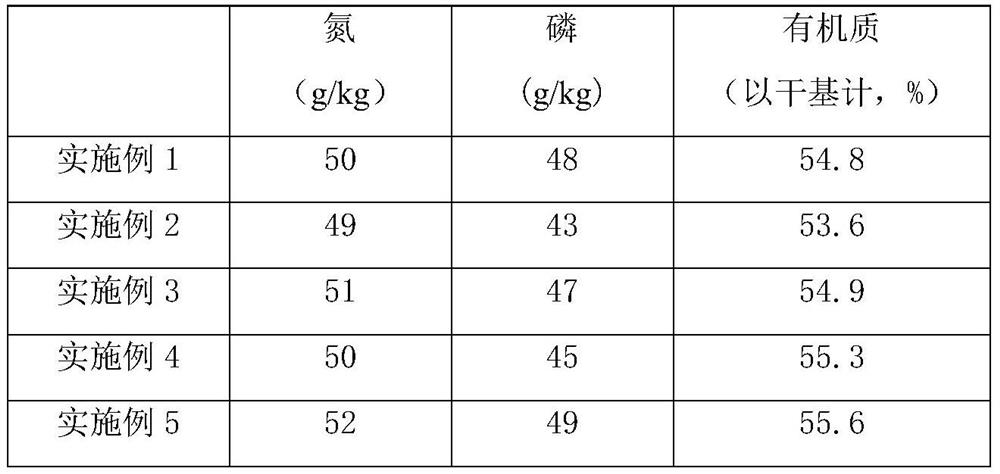

Nitrogen and phosphorus retention composting method of municipal domestic sludge

InactiveCN112723941AReduce churnImprove filtration efficiencyBio-organic fraction processingExcrement fertilisersMicrobial agentSludge

The invention provides a nitrogen and phosphorus retention composting method of municipal domestic sludge, which belongs to the technical field of sludge treatment, and comprises the following steps: adding auxiliary materials, saccharomycetes and a stabilizer into municipal domestic sludge, composting, monitoring the temperature of the compost during composting, carrying out temperature-controlled fermentation, controlling the temperature of the first stage of composting to be within 40 DEG C, and adding a protective agent to assist fermentation, in the second stage of composting, the temperature is controlled to be within 50 DEG C, and exogenous microbial inoculants are used for auxiliary fermentation. According to the method, a step-by-step fermentation method is adopted, the combined action of the stabilizer, the protective agent, the exogenous microbial agent and the like is utilized, the effects of nitrogen fixation and phosphorus fixation are achieved, nitrogen and phosphorus loss is reduced, the fertilizer fermentation efficiency is improved, and a new direction is provided for sludge treatment.

Owner:SCI RES ACADEMY OF GUANGXI ENVIRONMENTAL PROTECTION

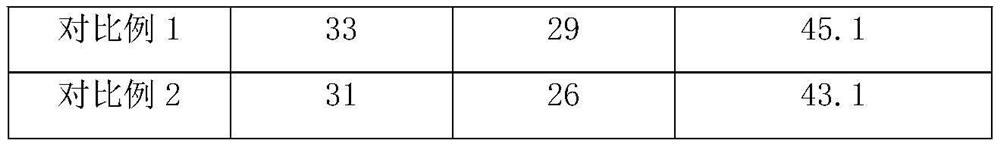

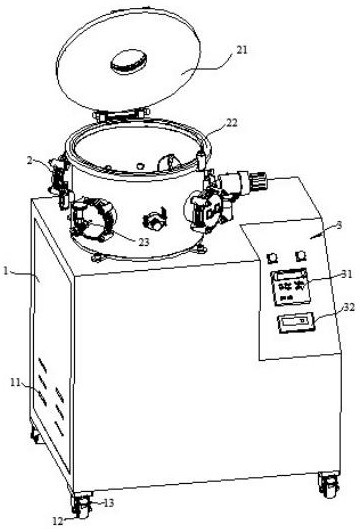

Vacuumizing equipment for polyethylene wax powder

PendingCN113663634APromote cleavage reactionReduce consumptionProcess control/regulationProductsThermodynamicsPumping vacuum

The invention relates to vacuumizing equipment for polyethylene wax powder. Thevacuumizing equipmentcomprises a working cabinet and a reaction kettle, wherein the reaction kettle is fixed at the upper end of the working cabinet, and is suitable for storing materials, the working cabinet is hollow, a vacuum device is fixed in the working cabinet, and is communicated with the reaction kettle, a control platform is arranged on one side of the working cabinet, and the control platform can control the vacuum device to pump away air in the reaction kettle. According to the present invention, the structure is simple, the vacuum device communicated with the reaction kettle is arranged in the work cabinet, the vacuum device can pump away the air in the reaction kettle so as to form the negative pressure in the reaction kettle, and the negative pressure in the reaction kettle can easily increase the cracking reaction of the material in the reaction kettle, such that the reaction time is substantially reduced, the production efficiency is improved, and the energy consumption is reduced.

Owner:扬州科博新材料有限公司

Oleic acid modified magnetorheological fluid recycling-treating method

InactiveCN105931793AAccelerated settlementEliminate stickingMagnetic liquidsMagnetorheological fluidCarrier fluid

The invention discloses an oleic acid modified magnetorheological fluid recycling-treating method, belonging to the field of magnetic waste fluid recycling and treatment. A recycling-treating agent used by the method comprises the following components by mass percent: 2-4% of dodecanol polyoxyethylene ether, 35-45% of sodium hypochlorite, 2-4% of dichloro[(1,2,5,6-eta)-cycloocta-1,5-diene]ruthenium and residual water. According to the method disclosed by the invention, by employing the sodium hypochlorite to remove oleic acid via oxidative cracking in the magnetorheological fluid, the surfactant is lost in the magnetorheological fluid, and the cohesive action between main dispersed particles and carrier fluid in the magnetorheological fluid is eliminated; and thus, the main dispersed particles can be quickly settled under the action of its own gravity, and the main dispersed particles and the carrier fluid are separated, thereby providing a foundation for subsequent recycling of the magnetorheological fluid. The method has the advantages of being simple in components, easy in preparation and low in cost, and simultaneously being simple in reaction conditions and good in treatment effect when the magnetorheological fluid is treated.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

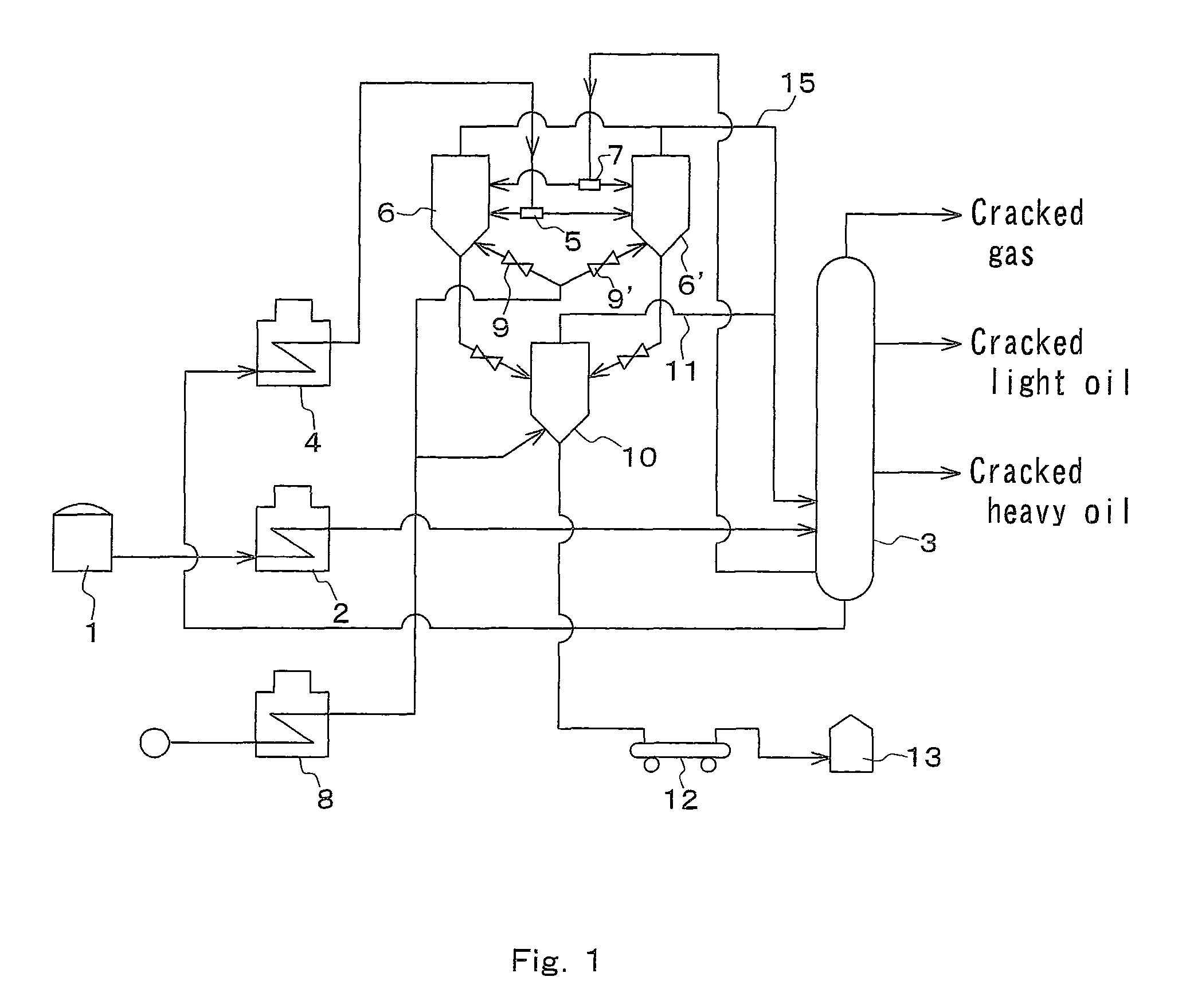

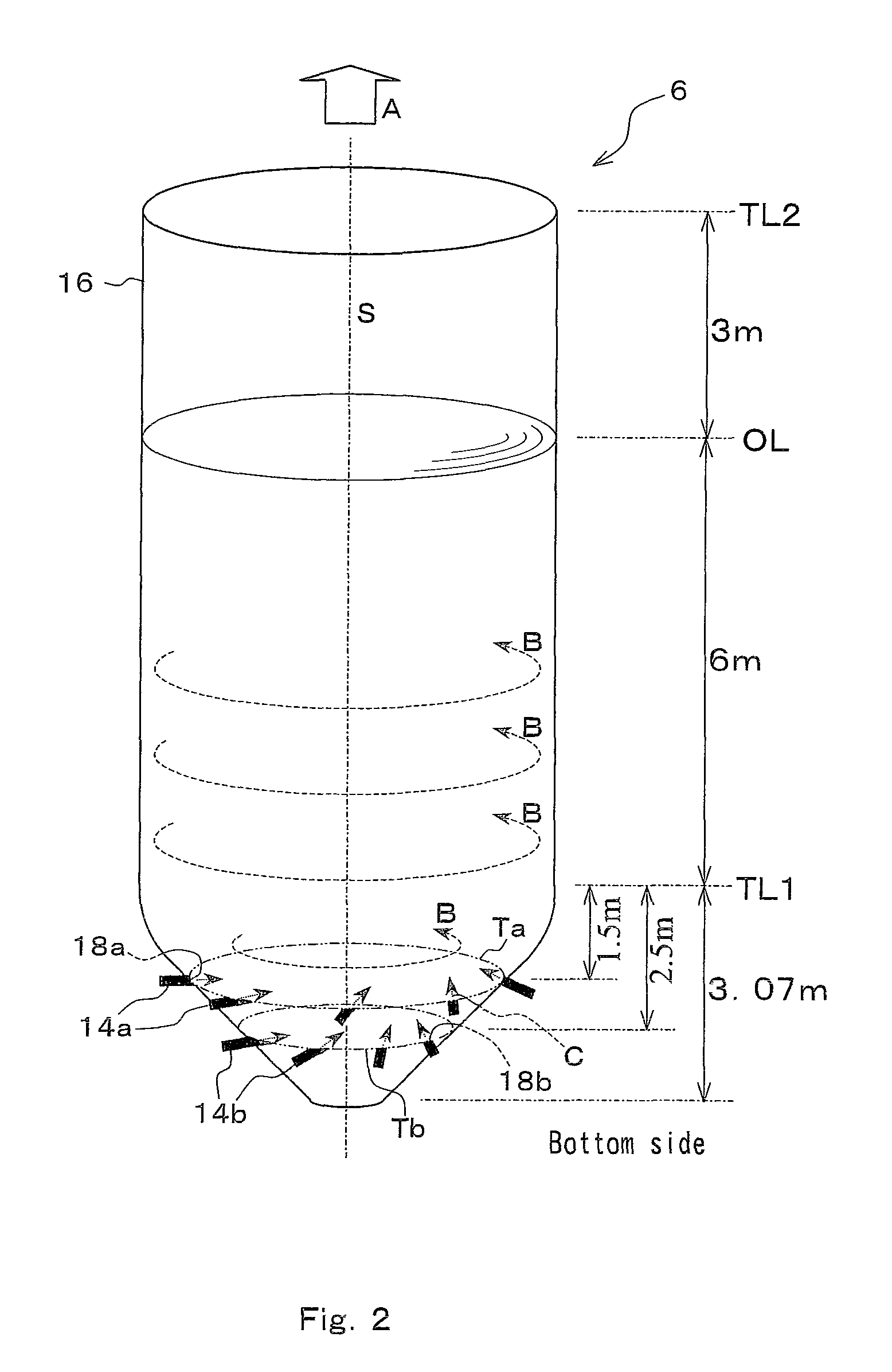

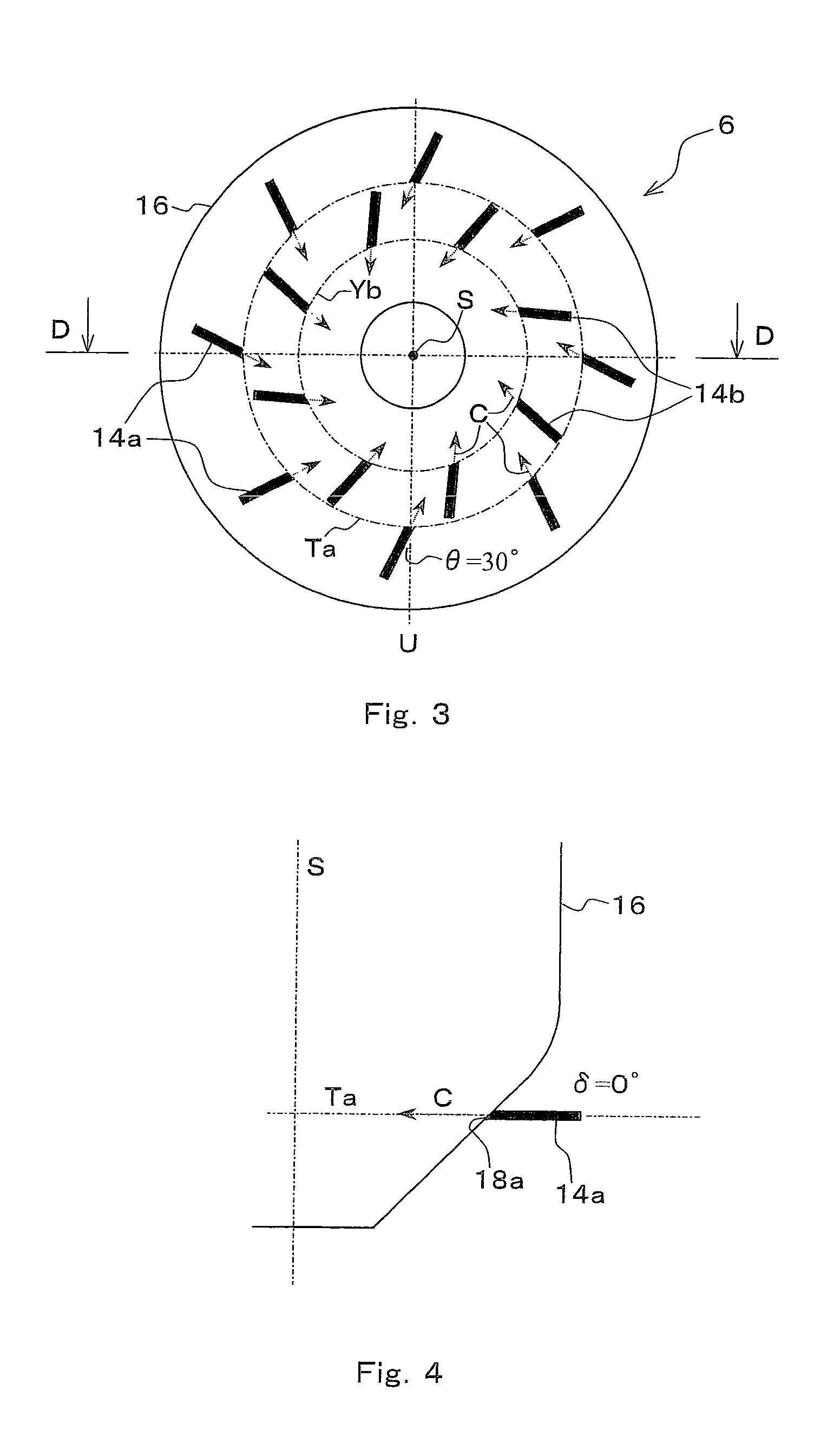

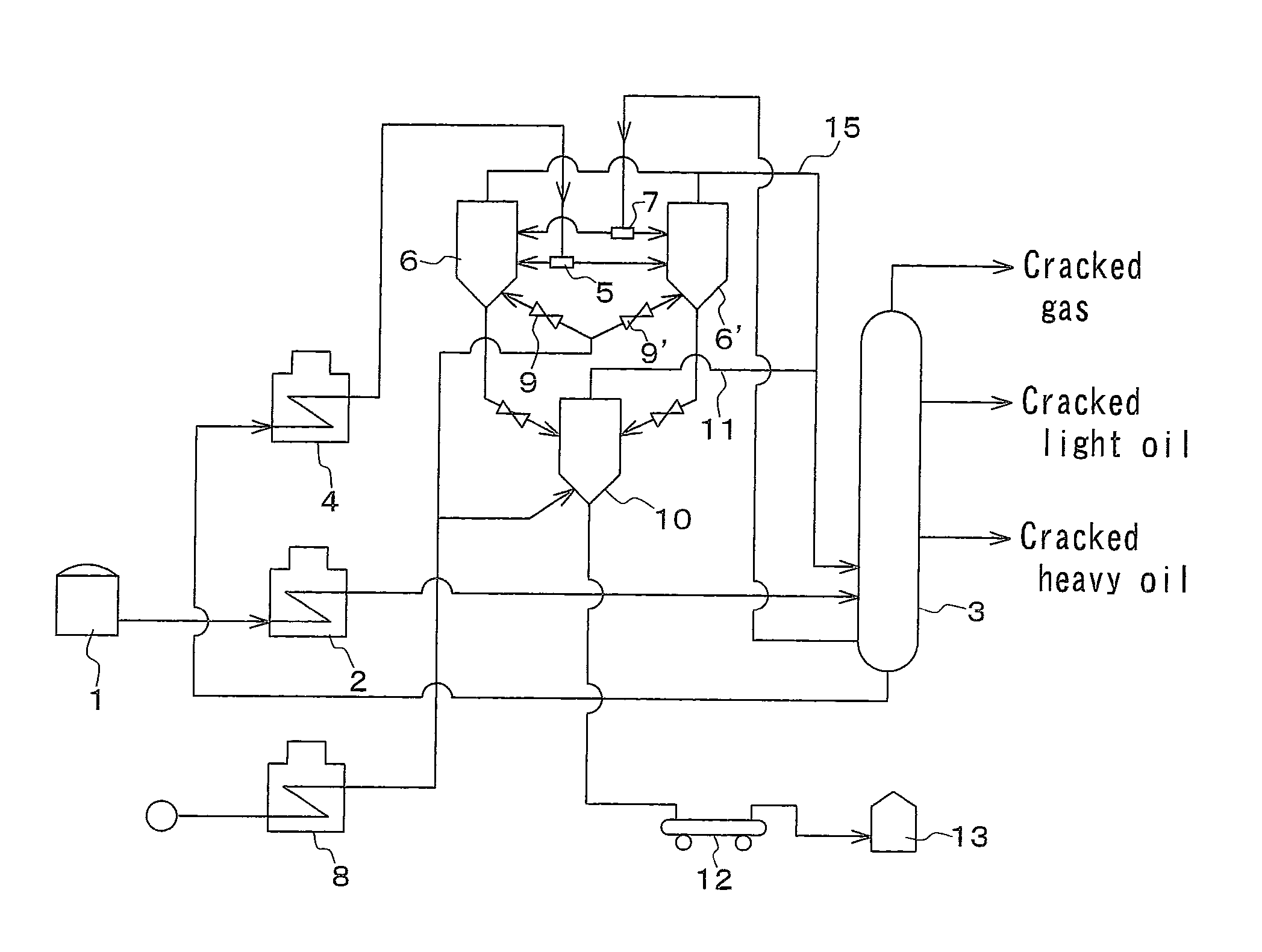

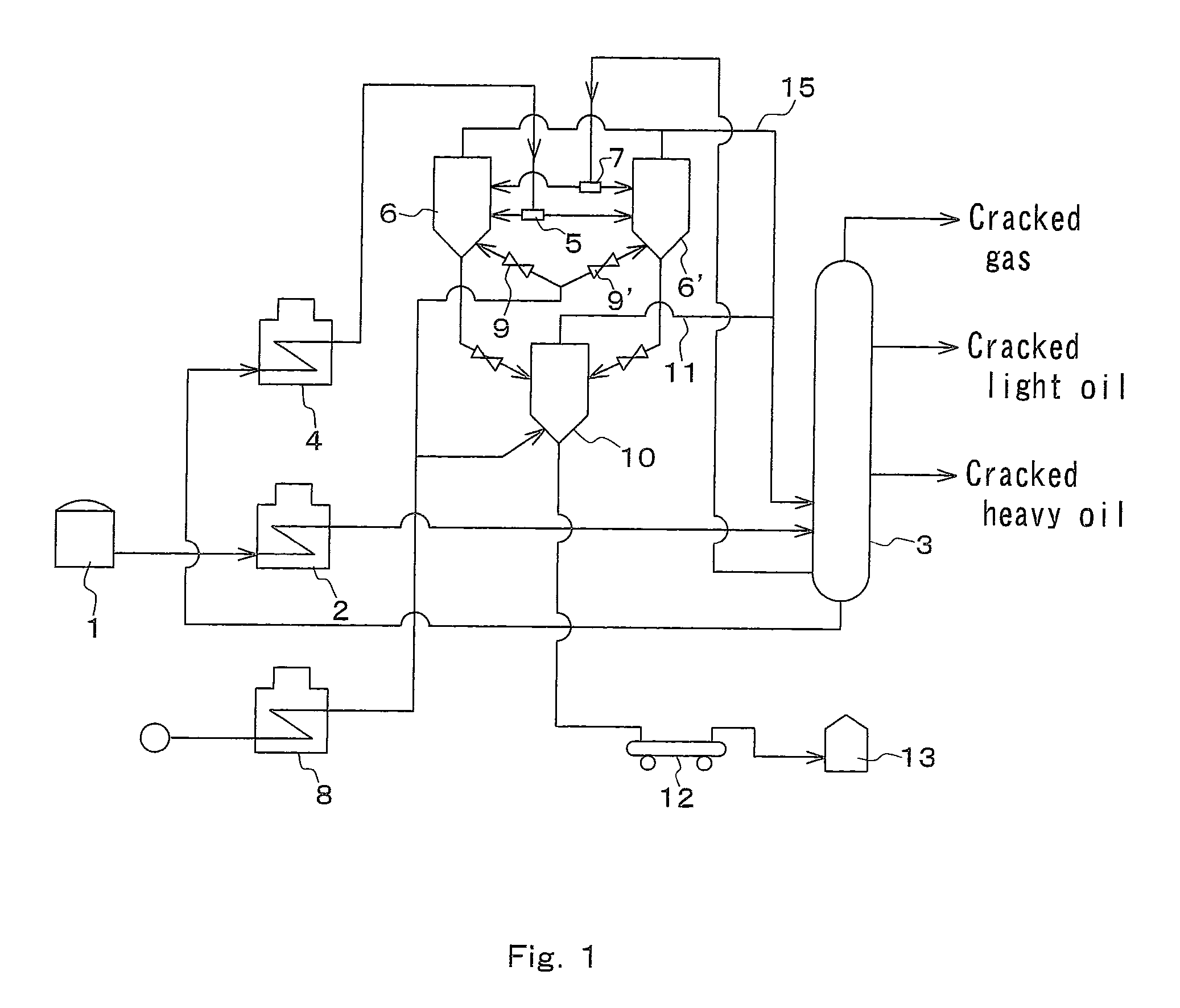

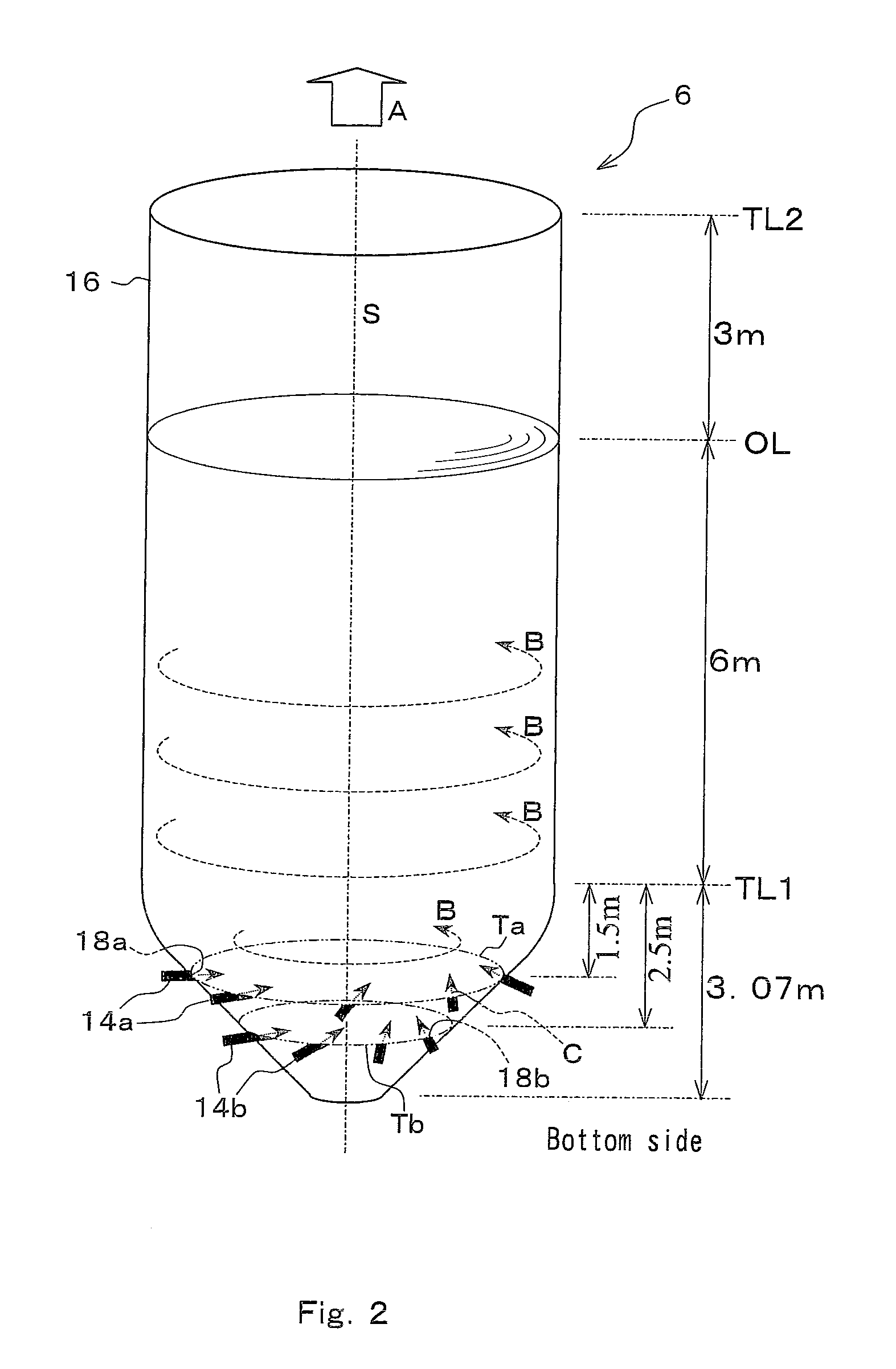

Process, reactor and facility for thermally cracking heavy petroleum oil

InactiveUS8262903B2Promote cleavage reactionUniform productThermal non-catalytic crackingHydrocarbon oil cracking processSuperheated steamRotational flow

Owner:CHIYODA CORP +1

A liquid combustion-supporting sulfur-fixed coal additive and its application method

The invention discloses a liquid combustion-supporting sulfur-fixing coal additive and a using method of the additive; the liquid combustion-supporting sulfur-fixing coal additive comprises the following components in percentage by weight: 3-7.5% of KMnO4, 3-8% of Cu(NO3)2, 2-7.5% of Fe(NO3)3, 8-18% of Ca(NO3)2, 3.5-6% of Al(NO3)3, 8-18% of KNO3, 0.5-2.5% of NaVO3, and the balance of H2O. The liquid combustion-supporting sulfur-fixing coal additive provided by the invention uses water as a solvent and each component is at an ionic state, has relatively high reaction activity at a high temperature and has high combustion efficiency and an excellent sulfur fixing effect, and the sulfur fixing efficiency is more than 40%.

Owner:唐山干诚工程管理有限公司

Method for preparing fluorinated alkene by high temperature wet-cracking

ActiveCN101597208BHighly corrosiveAvoid corrosionPreparation by hydrogen halide split-offHeat-exchange elementsHydrogen fluorideAlkane

The invention relates to a method for preparing fluorinated alkene by high temperature wet-cracking, belonging to the field of organic synthesis. The method is characterized in that under the condition of normal pressure and the temperature of 600-1000DEG C, hydrogen fluoride alkane with the molecular formula of HnFmC3 (n +m=8, n is more than or equal to 1 and less than or equal to 8, and m is more than or equal to 2 and less than 8) is taken as raw gas to have cracking reaction in the environment of water vapor or ammonia water vapor; no catalyst is used in the method, so that the generation cost is reduced, by-products are few, the selectivity of the product is high, subsequent purification and separation are convenient, the whole technique is easy to control, and the method is very suitable for producing the fluorinated alkene in industrialization-scale.

Owner:泉州宇极新材料科技有限公司

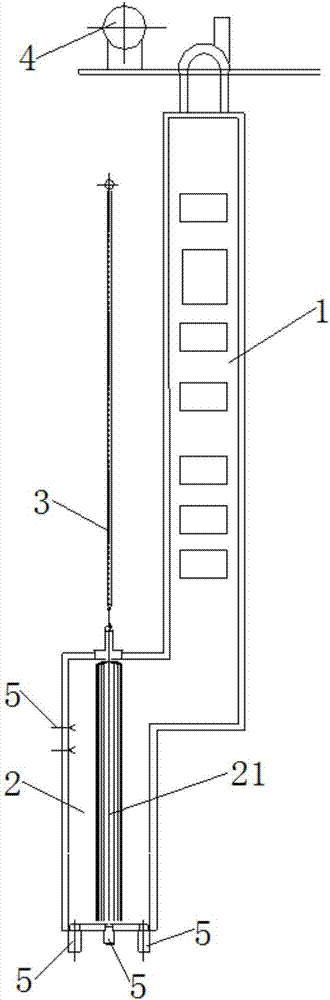

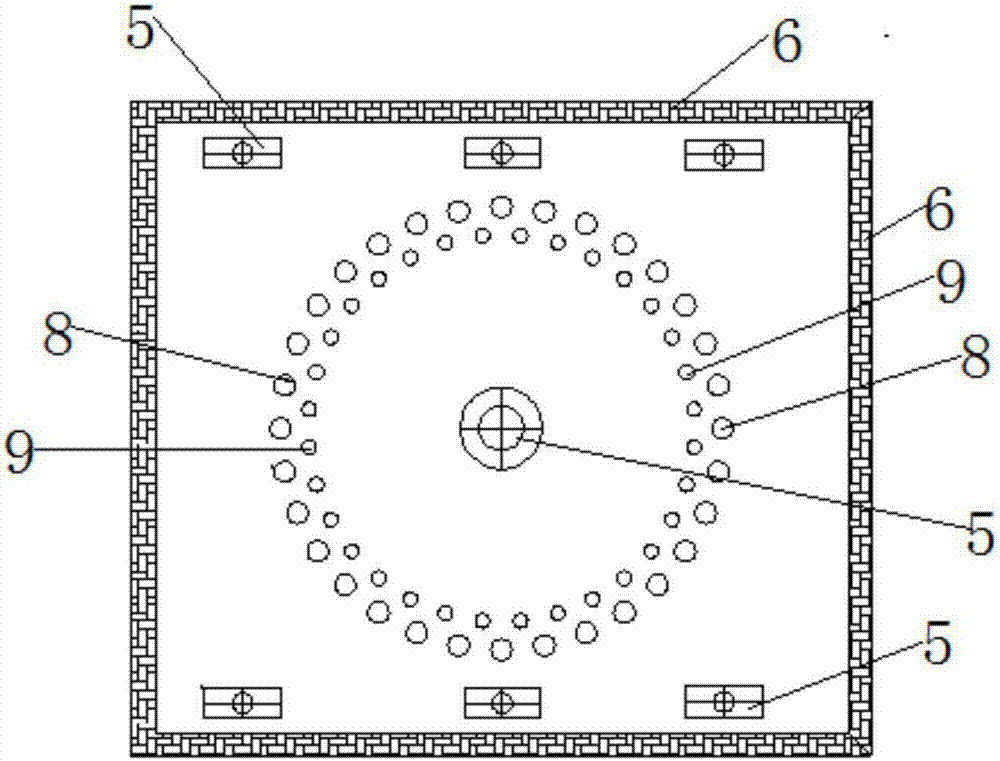

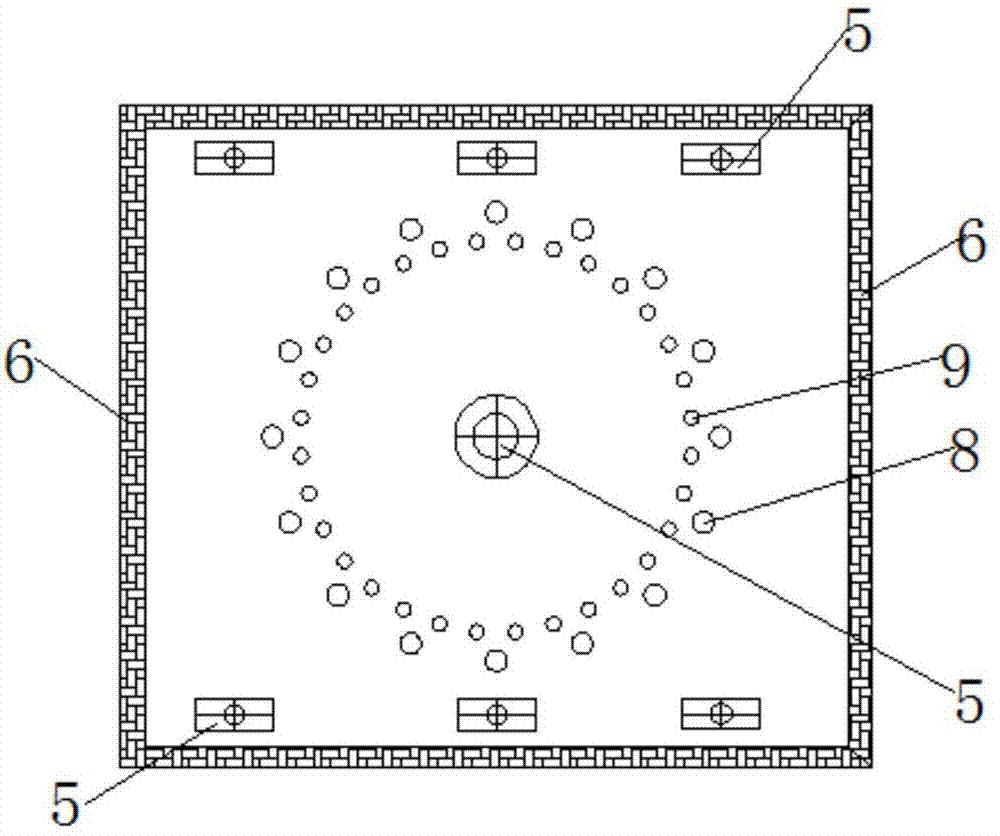

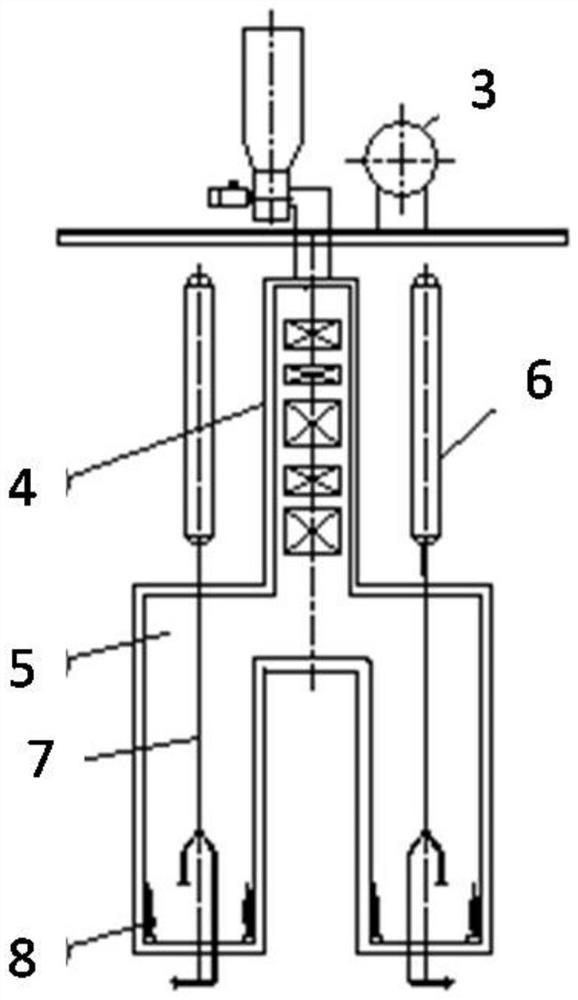

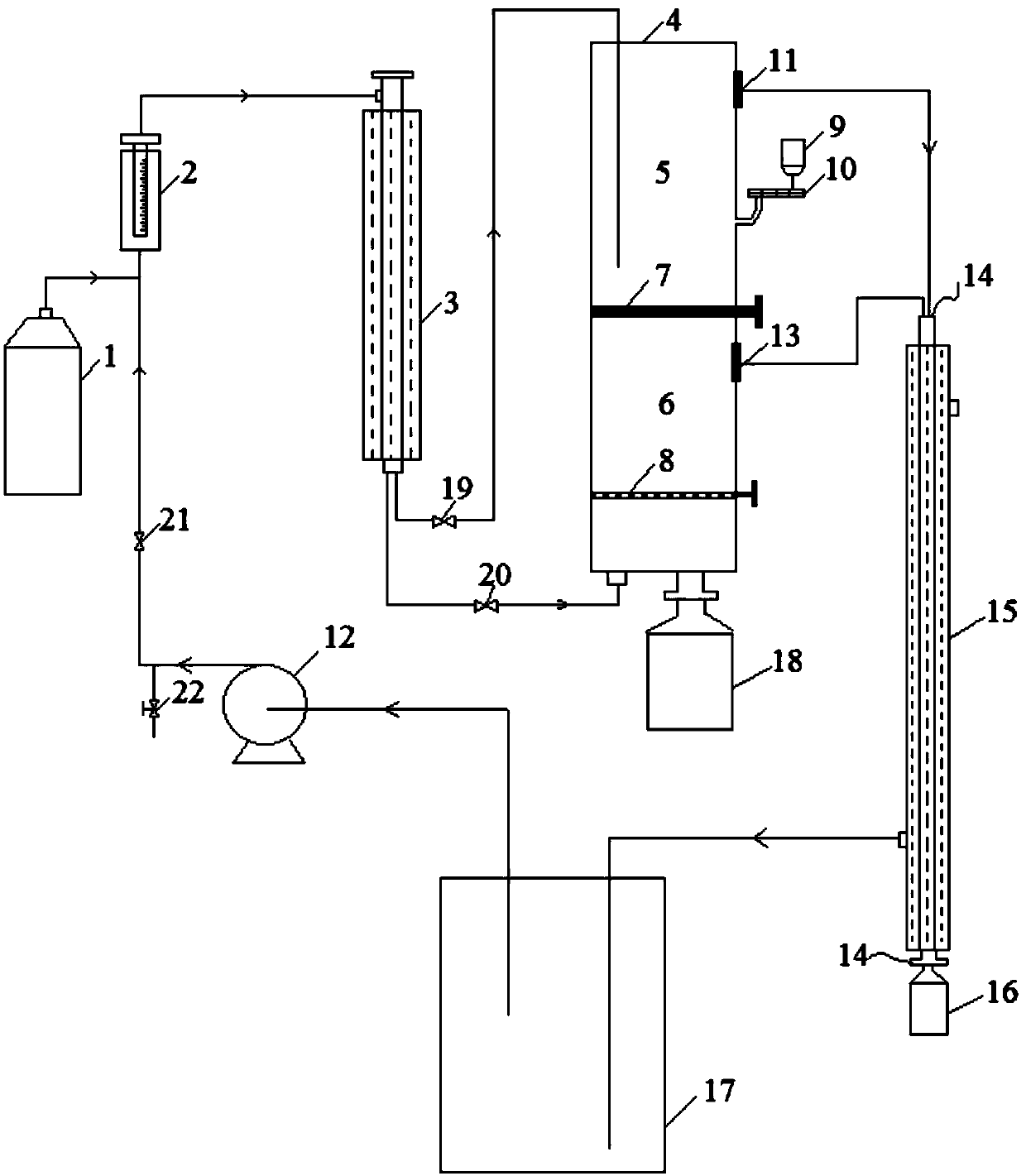

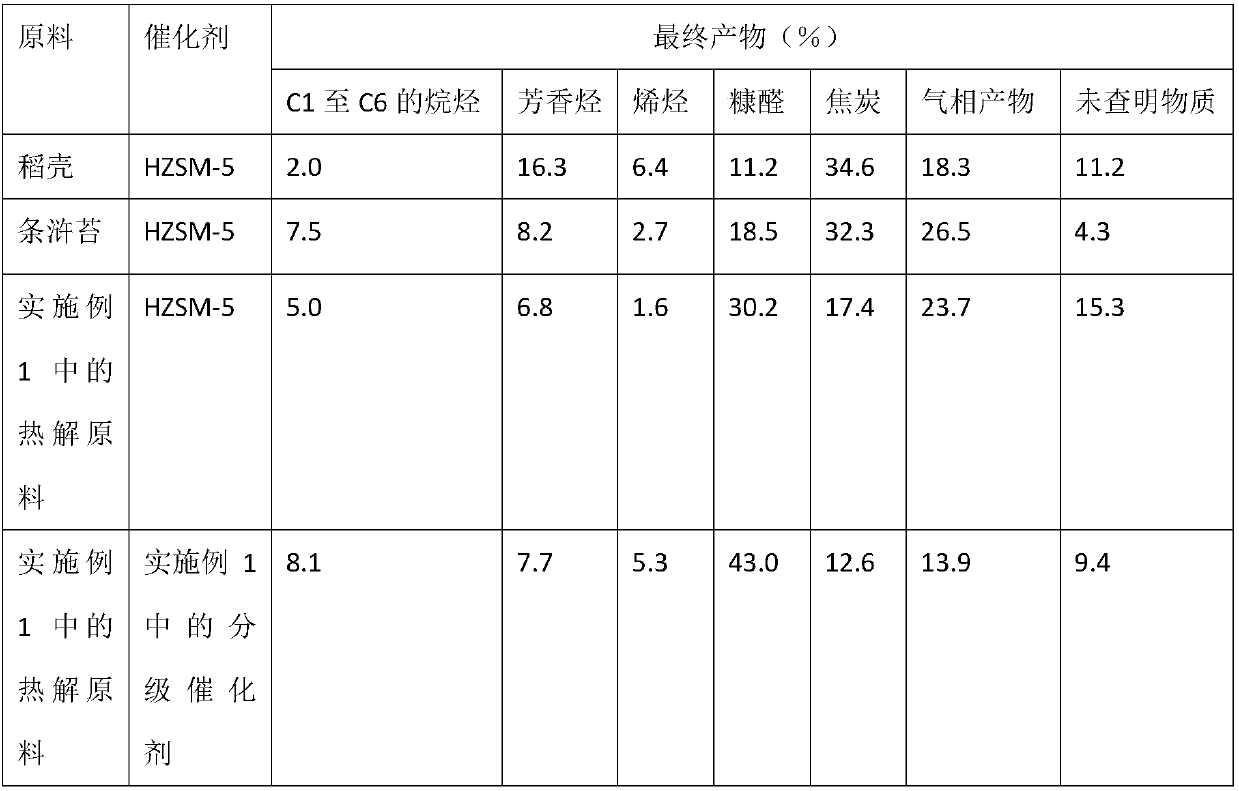

A kind of equipment and method for producing oil by staged cocatalytic pyrolysis of agricultural and forestry waste and seaweed

InactiveCN107083253BHigh yieldEffective quality improvementBiofuelsEnergy inputCarbon depositLow oxygen

The invention belongs to the field of the biological energy utilization, and provides a device and a method for preparing oil by co-catalytically pyrolyzing forestry and agricultural wastes and algae in a sectional manner. The method comprises the following steps: mixing algae powder and forestry and agricultural waste powder to form a raw material, soaking HZSM-5 powder in a precursor solution containing gallium, and then soaking in a precursor salt solution containing nickel or silicon to obtain a composite catalyst; enabling carrier gas to enter from top of a heating section I; conveying the raw material to the heating section I by virtue of a spiral conveyor, enabling a non-condensed gas to rise to a projection section of the heating section I, placing the catalyst on a catalyst cushion layer of the projection section, after the pyrolysis is finished, turning an insert plate for 180 degrees, enabling the low-temperature product to fall into a heating section II, and enabling the carrier gas to enter from the bottom of the heating section II. A projection section at an outlet of the heating section II is provided with a cushion layer of self-made composite catalyst. The reaction residual coke is collected into a collection tank by virtue of an overturning stainless steel carrier net, and volatile components are collected into a liquid collector after being condensed. The low-oxygen high-quality biological oil is generated by utilizing the process, so that the conversion efficiency can be increased, and the carbon deposit deactivation of a molecular sieve can be effectively reduced.

Owner:JIANGSU UNIV

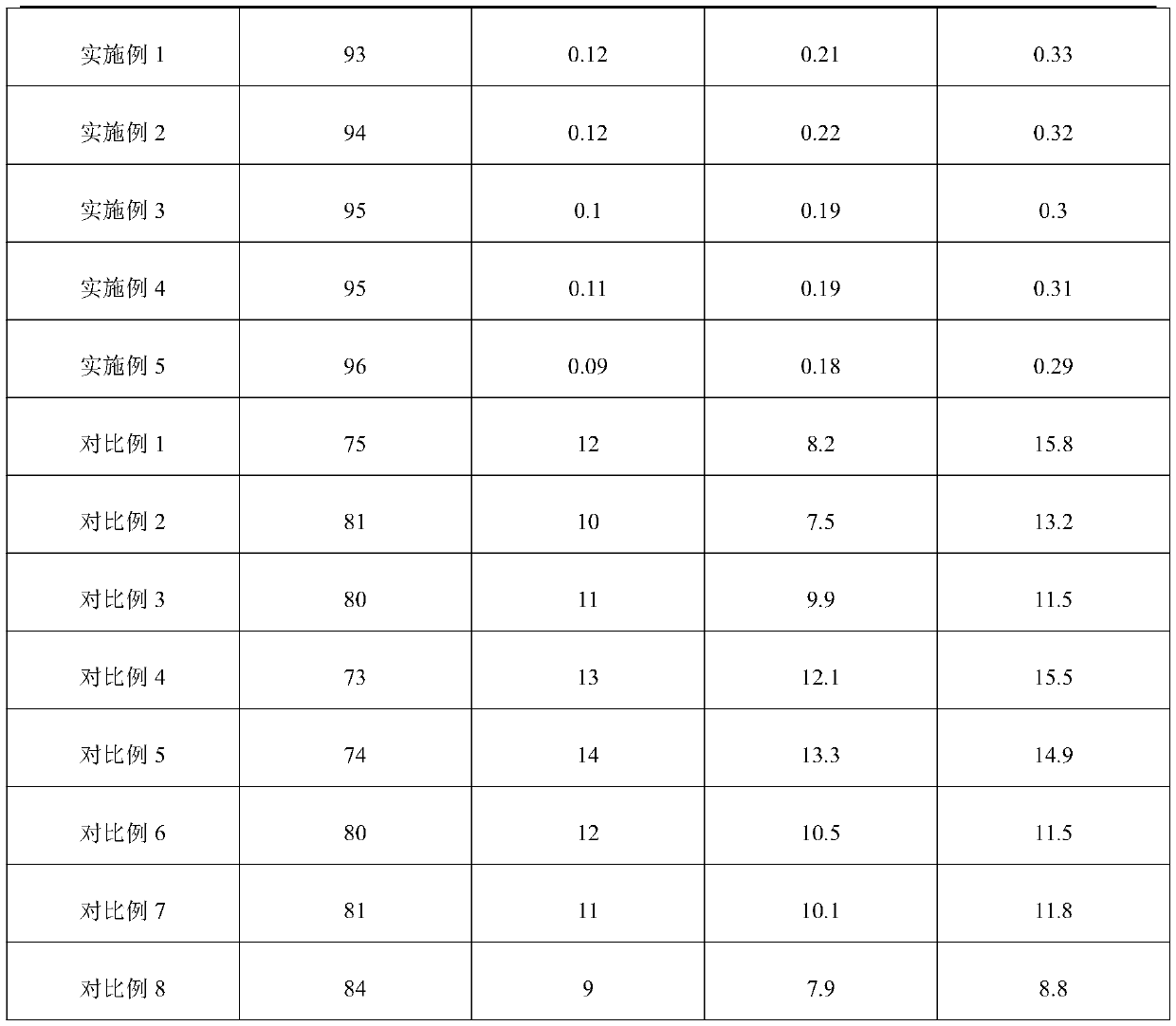

Agriculture and forestry biomass gasification power generation method

ActiveCN109880655ATake advantage ofImprove the utilization rate of combustion heat valueCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsTarBiomass combustion

The invention provides an agriculture and forestry biomass gasification power generation method, which mainly comprises three steps of agriculture and forestry biomass preprocessing, gasification andcatalytic cracking to generate burning gas, and power generation by burning gas, wherein the step of agriculture and forestry biomass preprocessing is characterized in that agriculture and forestry biomasses are smashed and dried to obtain a raw material of a specific particle size range so as to be favorable for fully utilizing the biomasses in subsequent steps of gasification, catalytic crackingand the like, the use ratio of a biomass combustion calorific value is improved, the generation of acid substances, including tar, oxysulfide, oxynitride and the like, can be reduced, and environmentpollution caused by emission can be reduced without additional processing.

Owner:袁英江

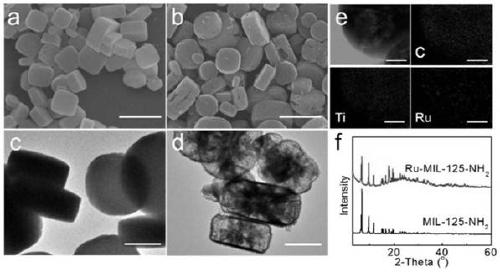

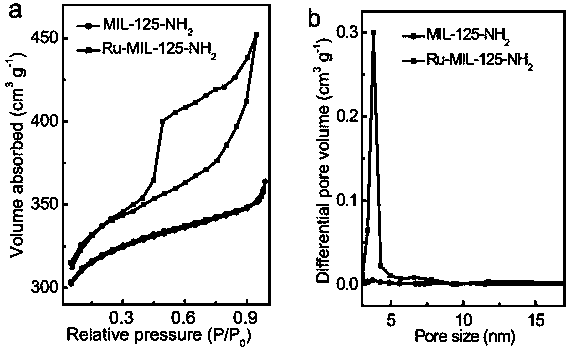

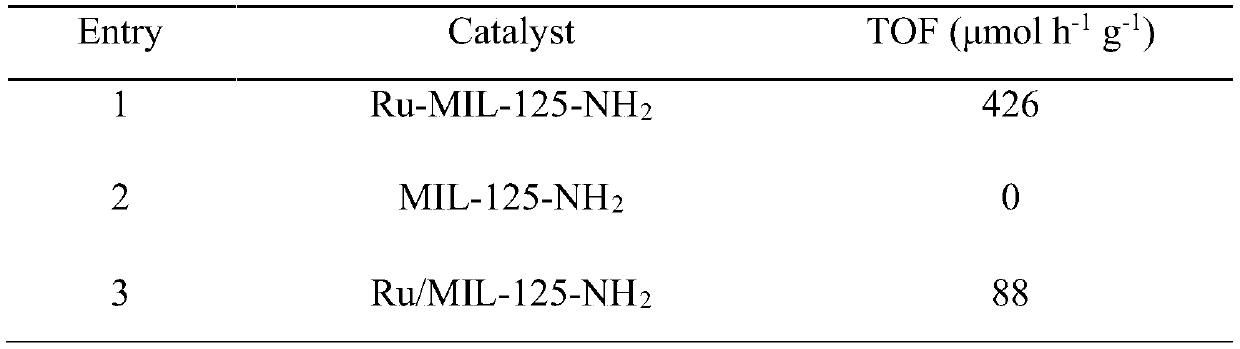

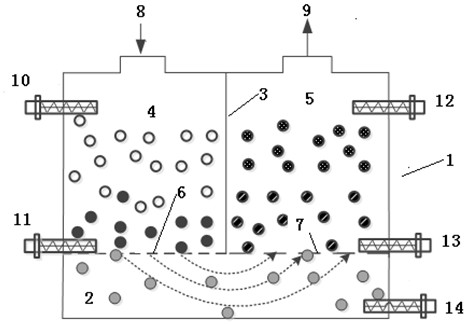

Mesoporous Ru-MIL-125-NH2 catalyst prepared from supercutical fluid

ActiveCN110183677AImprove permeabilityChange contentOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionPhotocatalytic water splittingPolymer science

The invention discloses a mesoporous Ru-MIL-125-NH2 catalyst prepared from a supercutical fluid. The mesoporous Ru-MIL-125-NH2 material is prepared by putting prepared MIL-125-NH2 and RuCl3*xH2O intomethanol according to a feeding ratio, uniformly stirring and mixing the components at the room temperature, introducing carbon dioxide of certain pressure, and conducting a reaction for 5 hours at 200 DEG C; cooling the mixture to the room temperature, removing the carbon dioxide in the reaction kettle in a pressure release mode, washing the obtained precipitate with N,N-dimethyl formamide (DMF)and methanol, putting the product obtained through centrifugation into a vacuum drying tank, removing residual DMF and methanol, and by conducting drying for 24 hours at a drying temperature of 80 DEGC, so as to obtain the mesoporous Ru-MIL-125-NH2 catalyst material. The material has good catalysis activity upon photocatalytic water splitting.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Biomass gasification processor and biomass gasification method

ActiveCN112048343AHigh integration of reaction systemSimple processGasification processes detailsFixed-bed gasificationProcess engineeringFlue gas

The invention discloses a biomass gasification processor and a biomass gasification method. The biomass gasification processor comprises a shell, the shell comprises a reaction zone and an ash storagezone, the reaction zone is divided into a biomass pyrolysis zone and a tar conversion zone by a partition plate, the biomass pyrolysis zone is communicated with the tar conversion zone through the ash storage zone, a gas inlet is formed in the top of the biomass pyrolysis zone, and a gas outlet is formed in the top of the tar conversion zone. The biomass gasification method comprises the steps that biomass raw materials enter the gasification processor and react in the biomass pyrolysis zone, and high-temperature flue gas and biological semi-coke are obtained after reaction; and high-temperature flue gas enters the tar conversion zone after passing through the ash storage zone and is in contact with a filler filled in the tar conversion zone for reaction. According to the biomass gasification processor and the biomass gasification method, the tar and dust content of fuel gas can be reduced, and the gasification efficiency of raw materials can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process, reactor and facility for thermally cracking heavy petroleum oil

InactiveUS20100000909A1Promote cleavage reactionUniform productThermal non-catalytic crackingHydrocarbon oil cracking processEngineeringProduct gas

The suppression of coke adherence in a reaction vessel and cracked gas pipelines at the outlet of the reaction vessel and the prevention of plugging are designed by improving the dispersion of superheated steam inside the reaction vessel to preferable conditions, and pitch having more uniform and higher quality can be produced.A cracking process in which superheated steam is directly contacted with the heavy petroleum oil by blowing the superheated steam into the reaction vessel to be thermally cracked to oil fractions and pitch, wherein the superheated steam is blown into the reaction vessel from the bottom portion thereof so that the superheated steam generates rotational flow around the central axis of the shell of the reaction vessel.

Owner:CHIYODA CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com