An ethylene cracking furnace

An ethylene cracking furnace and cracking furnace technology, applied in the directions of cracking, hydrocarbon cracking to hydrocarbon production, non-catalytic thermal cracking, etc. The effect of improving the yield of olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings. Although the preferred embodiments of the present invention are shown in the drawings, it should be understood that the present invention can be implemented in various forms and should not be limited by the embodiments set forth herein. The present invention will be described in further detail below in conjunction with the accompanying drawings:

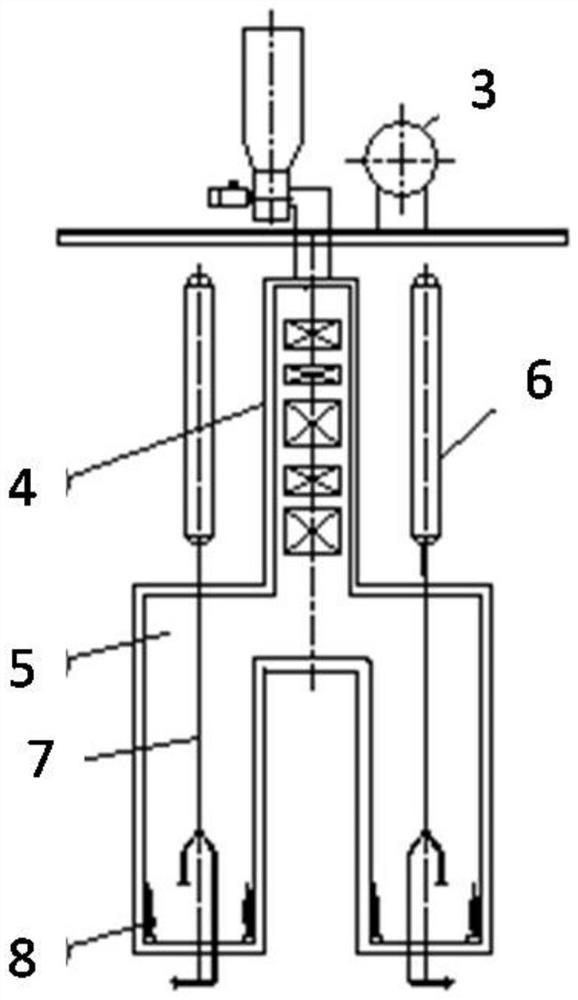

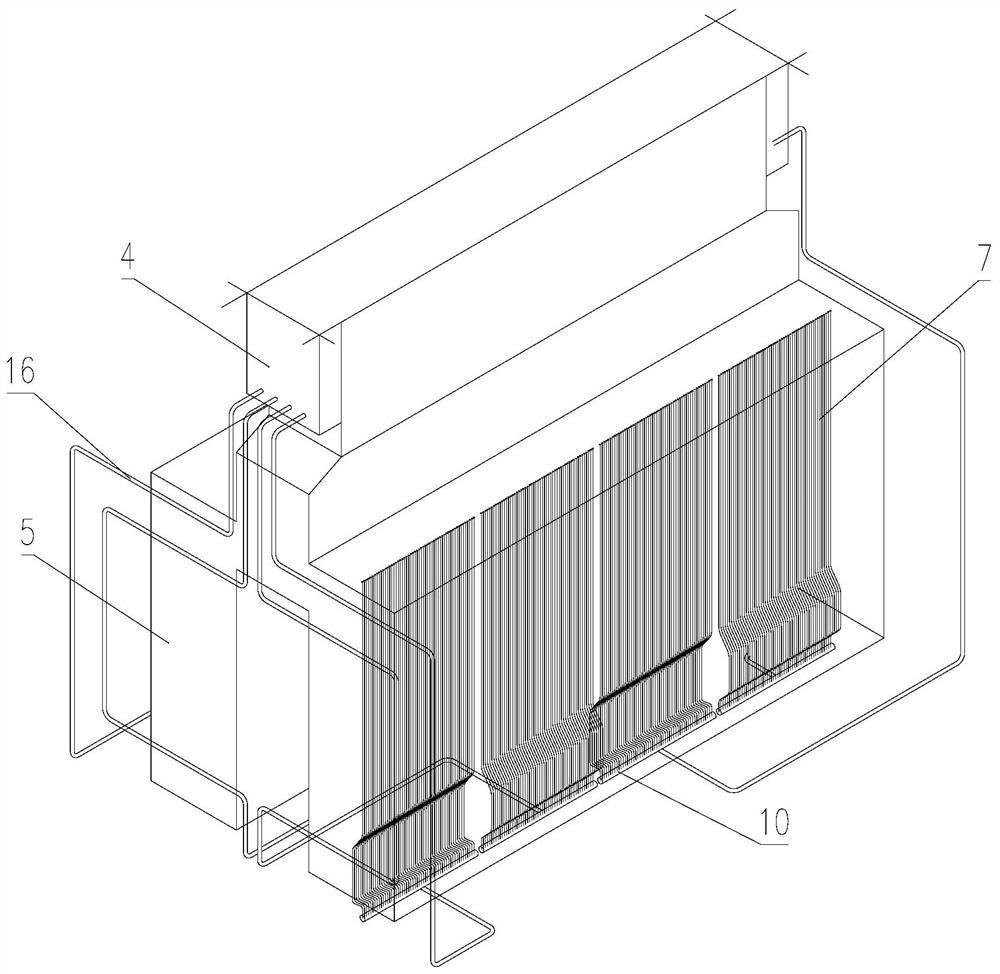

[0041] Such as figure 1 As shown, an ethylene cracking furnace includes: a high-pressure steam drum 3, a convection section 4, a radiant section 5, a quenching boiler 6 and a burner 8;

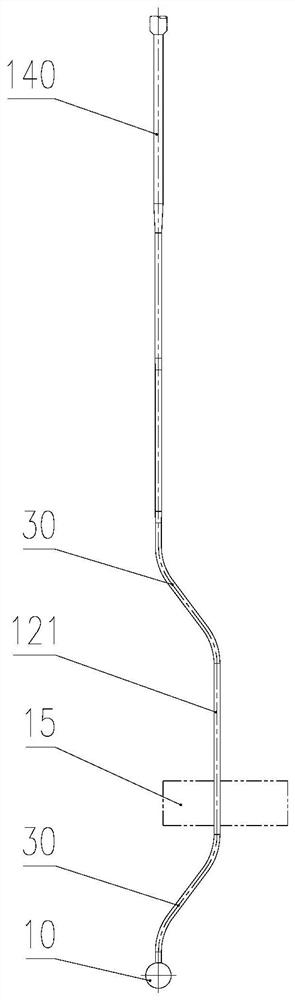

[0042] A single-pass radiant furnace tube 7 is arranged in the radiant section 5, such as figure 2 As shown, the radiant furnace tube 7 includes an outlet section straight pipe 140 and an elbow connecting piece, the elbow connecting piece is composed of two S-shaped elbow pipes 30 and an inlet straight pipe 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com