Liquid combustion-supporting sulfur-fixing coal additive and using method thereof

A technology of coal-fired additives and additives, applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of reduced sulfur fixation efficiency, corrosion of combustion equipment, and insignificant combustion-supporting effect of coal-fired additives, and achieve good combustion-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The components of the combustion-supporting sulfur-fixing coal-burning additive and the weight percent of each component are (total weight is 1000g):

[0027] components

QUR 4

Cu(NO 3 ) 2

Fe(NO 3 ) 3

Ca(NO 3 ) 2

Al(NO 3 ) 3

KNO 3

NaVO 3

h 2 o

weight

30

55

50

180

35

150

15

485

weight percentage (%)

3

5.5

5

18

3.5

15

1.5

48.5

[0028] The steps of using the combustion-supporting sulfur-fixing coal-burning additive are as follows:

[0029] a. Mix the combustion-supporting, sulfur-fixing and coal-burning additives in the above ratio, stir, and heat to 60°C;

[0030] b. After cooling, the combustion-supporting solid-sulfur coal-burning additive mixture is injected into the furnace by compressed air, and the pressure of the compressed air is 0.5MPa.

[0031] The amount of combustion-supporting s...

Embodiment 2

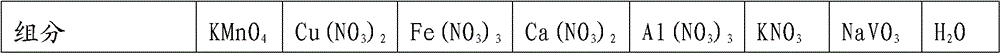

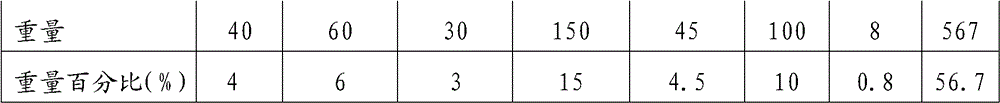

[0035] The components of the combustion-supporting sulfur-fixing coal-burning additive and the weight percent of each component are (total weight is 1000g):

[0036] components

KMnO 4

Cu(NO 3 ) 2

Fe(NO 3 ) 3

Ca(NO 3 ) 2

Al(NO 3 ) 3

KNO 3

NaVO 3

h 2 o

weight

50

80

20

140

40

80

25

565

weight percentage (%)

5

8

2

14

4

8

2.5

56.5

[0037] The steps of using the combustion-supporting sulfur-fixing coal-burning additive are as follows:

[0038] a. Mix the combustion-supporting, sulfur-fixing and coal-burning additives in the above ratio, stir, and heat to 40°C;

[0039] b. After cooling, the combustion-supporting solid-sulfur coal-burning additive mixture is injected into the furnace by compressed air, and the pressure of the compressed air is 0.6MPa.

[0040] The combustion-supporting sulfur-fixing coal...

Embodiment 3

[0044] The components of the combustion-supporting sulfur-fixing coal-burning additive and the weight percent of each component are (total weight is 1000g):

[0045] components

QUR 4

Cu(NO 3 ) 2

Fe(NO 3 ) 3

Ca(NO 3 ) 2

Al(NO 3 ) 3

KNO 3

NaVO 3

h 2 o

weight

60

50

40

120

50

180

5

495

weight percentage (%)

6

5

4

12

5

18

0.5

49.5

[0046] The steps of using the combustion-supporting sulfur-fixing coal-burning additive are as follows:

[0047] a. Mix the combustion-supporting, sulfur-fixing and coal-burning additives in the above ratio, stir, and heat to 50°C;

[0048] b. After cooling, the combustion-supporting solid-sulfur coal-burning additive mixture is injected into the furnace by compressed air, and the pressure of the compressed air is 0.3MPa.

[0049] Preferably, the injection mode of the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com