Method for preparing xylene by shape-selective disproportionation of toluene

A technology of p-xylene and toluene, which is applied in the field of toluene shape-selective disproportionation to p-xylene, can solve the problem of replenishing hydrogen consumption and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

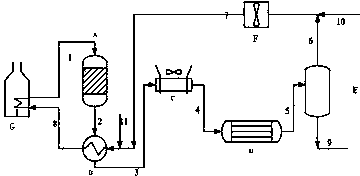

Image

Examples

Embodiment 1

[0026] In this process embodiment, it is assumed that the conversion rate of toluene is 30%, and the supplementary hydrogen contains 92% hydrogen. The following embodiments are the same.

[0027] The reaction aromatics feed containing 99% toluene and the circulating hydrogen containing 90.5% are exchanged through the inlet and outlet materials, and then fed through the heating furnace. The materials enter the reactor containing ZSM-5 molecular sieve catalysts. Then after air cooling, the material is water cooled and the temperature is 25°C, and it enters the gas-liquid separator for separation. The circulating gas phase contains 89% hydrogen, and the circulating hydrogen is not exhausted. The compression cycle is returned to the reaction system, and the liquid phase enters the subsequent liquid phase separation system.

[0028]

Embodiment 2

[0030] The reaction aromatics feed containing 80% toluene and the circulating hydrogen containing 86.0% are exchanged through the inlet and outlet materials, and then fed through the heating furnace. The materials enter the reactor containing the ZSM-11 molecular sieve catalyst. Then the material is air-cooled and then water-cooled at a temperature of 50°C. It enters the gas-liquid separator for separation. The circulating gas phase contains 81.0% hydrogen, and the circulating hydrogen is not exhausted. The compression cycle is returned to the reaction system, and the liquid phase enters the subsequent liquid phase separation system.

[0031]

Embodiment 3

[0033] The reaction aromatics feed containing 70% toluene and the circulating hydrogen containing 88.0% are exchanged through the inlet and outlet materials and then fed into the heating furnace. The materials enter the reactor containing ZSM-5 molecular sieve catalysts. Then after air cooling, the material is water cooled and the temperature is 10°C, and it enters the gas-liquid separator for separation. The circulating gas phase contains 86.0% hydrogen, and the circulating hydrogen is not exhausted. The compression cycle is returned to the reaction system, and the liquid phase enters the subsequent liquid phase separation system.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com