Method for producing xylene by shape-selective disproportionation of toluene

A technology of p-xylene and toluene, which is applied in the field of toluene shape-selective disproportionation to p-xylene, can solve the problem of replenishing hydrogen consumption and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

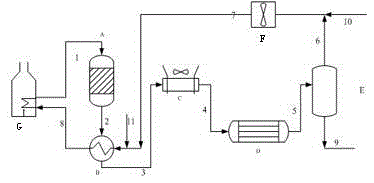

Image

Examples

Embodiment 1

[0025] In this process embodiment, it is assumed that the conversion rate of toluene is 30%, and the supplementary hydrogen contains 92% hydrogen. The following embodiments are the same.

[0026] The reaction aromatics feed containing 99% toluene and the circulating hydrogen containing 90.5% are exchanged through the inlet and outlet materials, and then fed through the heating furnace. The materials enter the reactor containing ZSM-5 molecular sieve catalysts. Then after air cooling, the material is water cooled and the temperature is 25°C, and it enters the gas-liquid separator for separation. The circulating gas phase contains 89% hydrogen, and the circulating hydrogen is not exhausted. The compression cycle is returned to the reaction system, and the liquid phase enters the subsequent liquid phase separation system.

Embodiment 2

[0028] The reaction aromatics feed containing 80% toluene and the circulating hydrogen containing 86.0% are exchanged through the inlet and outlet materials, and then fed through the heating furnace. The materials enter the reactor containing the ZSM-11 molecular sieve catalyst. Then the material is air-cooled and then water-cooled at a temperature of 50°C. It enters the gas-liquid separator for separation. The circulating gas phase contains 81.0% hydrogen, and the circulating hydrogen is not exhausted. The compression cycle is returned to the reaction system, and the liquid phase enters the subsequent liquid phase separation system.

Embodiment 3

[0030] The reaction aromatics feed containing 70% toluene and the circulating hydrogen containing 88.0% are exchanged through the inlet and outlet materials and then fed into the heating furnace. The materials enter the reactor containing ZSM-5 molecular sieve catalysts. Then after air cooling, the material is water cooled and the temperature is 10°C, and it enters the gas-liquid separator for separation. The circulating gas phase contains 86.0% hydrogen, and the circulating hydrogen is not exhausted. The compression cycle is returned to the reaction system, and the liquid phase enters the subsequent liquid phase separation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com