Tobacco leaf pyrolysis device

A high-temperature pyrolysis and tobacco leaf technology, which is applied in the preparation of test samples, etc., can solve the problems that the shielding gas is difficult to control the flow rate uniformly, and the oxygen interference in the air cannot be completely eliminated, so as to achieve low cost, short cracking time, and reduce secondary pollution. The effect of secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment is intended to illustrate the present invention rather than to further limit the present invention, and the present invention can be implemented in any mode described in the summary of the present invention.

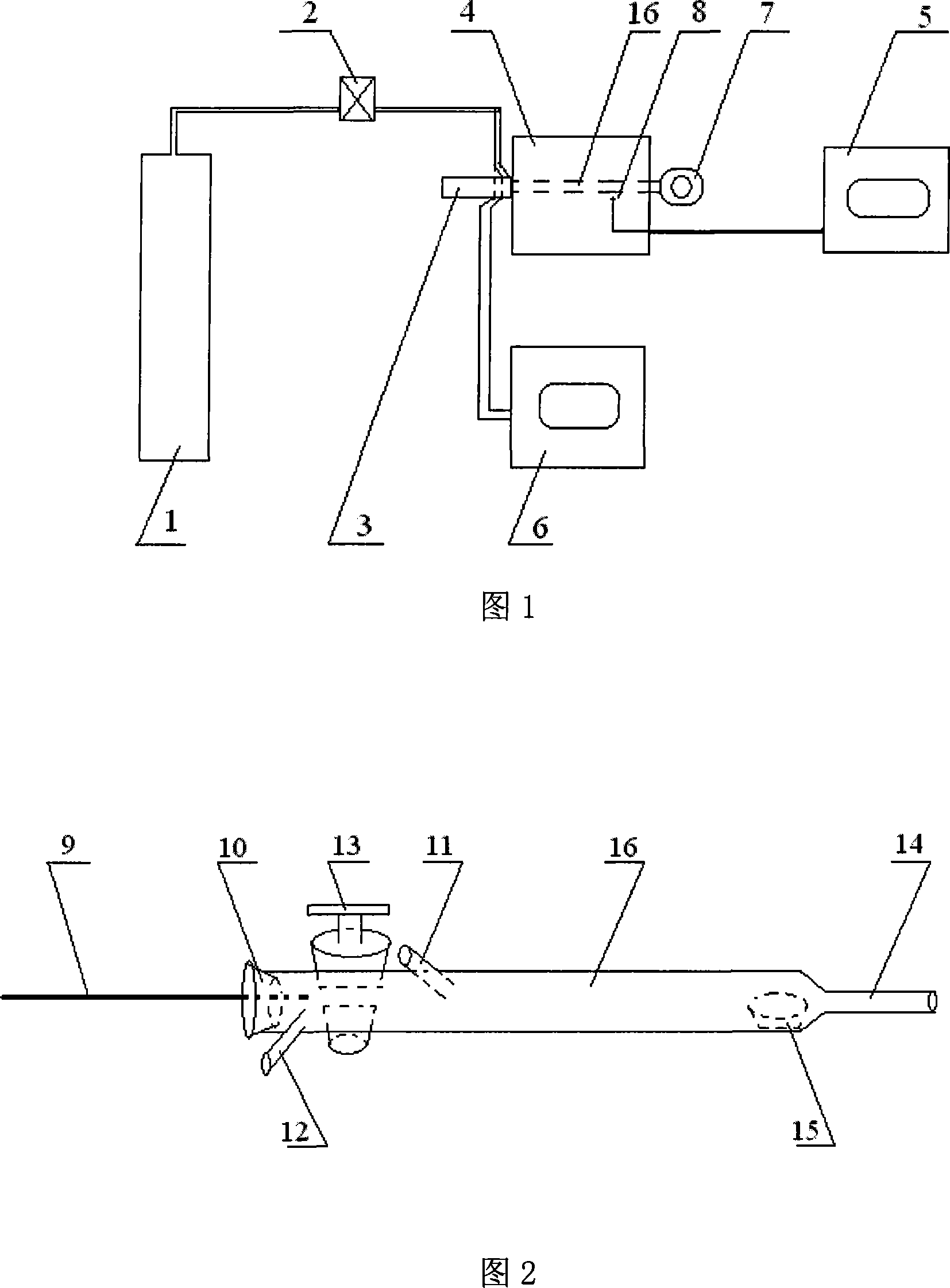

[0026] Referring to Fig. 1, shown in Fig. 2, present embodiment comprises cracking quartz tube 16, cartridge heater 4, and cracking quartz tube 16 is placed in the cartridge heater 4, and pyrolysis quartz tube inlet end 3 is provided with a push rod 9 The rubber piston 10, the pyrolysis quartz tube 16 is also provided with two interfaces respectively, the first interface 11 is connected with the digital display gas flow controller 2 with a protective valve, and the second interface 12 is connected with the vacuum circulating water pump 6 connect.

[0027] A piston switch 13 is arranged between the two interfaces, and the second interface 12 connected with the vacuum circulating water pump 6 is located on the side of the piston 10 with the push rod....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com