A waste plastic molten salt pyrolysis device

A technology of cracking device and waste plastics, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the treatment of hydrocarbon oil, etc., can solve the problems of uneven heating, unfavorable heat transfer process, small contact surface, etc. Enhance the effect of mixing uniform heat exchange and increasing the heat exchange surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. In the figures, identical elements are indicated with similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale. Also, some well-known parts may not be shown.

[0024] The invention can be embodied in various forms, some examples of which are described below.

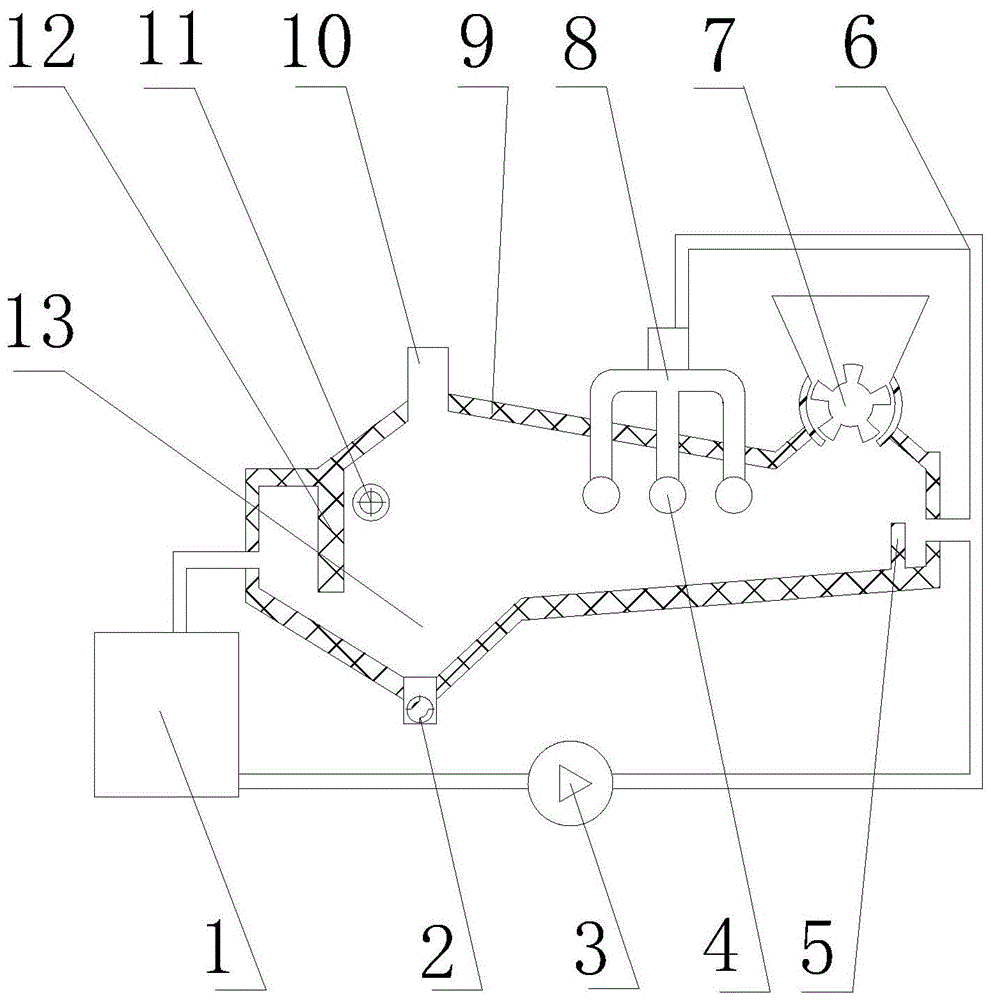

[0025] figure 1 A schematic diagram of the structure of the waste plastic molten salt pyrolysis device of the present invention is shown. The molten salt cracking device for waste plastics includes a cracking furnace, a molten salt furnace 1 , a molten salt pump 3 , a feeder 7 , a salt delivery pipe 6 and a distributor 8 .

[0026] figure 1 Among them, the cracking furnace has an upper wall 9 and a lower wall, the left end of the cracking furnace is a molten salt outlet, and the right end of the cracking furnace is a molten salt inlet. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com