Mesoporous Ru-MIL-125-NH2 catalyst prepared from supercutical fluid

A ru-mil-125-nh2, supercritical fluid technology, applied in the field of materials, can solve the problem of small pore size and achieve the effect of improving reactivity and visible light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The high mesoporous Ru-MIL-125-NH of the present embodiment 2 The synthesis method is as follows:

[0033] Synthesis of highly mesoporous Ru-MIL-125-NH 2 The metal salt precursor used is RuCl 3 ·xH 2 O, MOFs material is MIL-125-NH 2 .

[0034] MIL-125-NH 2 with RuCl 3 ·xH 2 O was added to the reaction kettle according to the mass ratio of 100:5, stirred at room temperature until uniformly mixed, then filled with carbon dioxide at a certain pressure (5.58MPa), reacted for 5 hours at a reaction temperature of 200°C, and cooled to room temperature , remove the carbon dioxide in the reactor by pressure relief, centrifuge to obtain a solid precipitate, wash the obtained precipitate with DMF and methanol, and then place it in a vacuum drying oven to remove the remaining solvent molecules, the drying temperature is 80 ° C, Ru-MIL-125-NH was obtained after drying for 12 hours 2 .

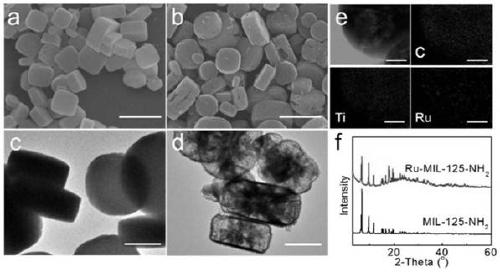

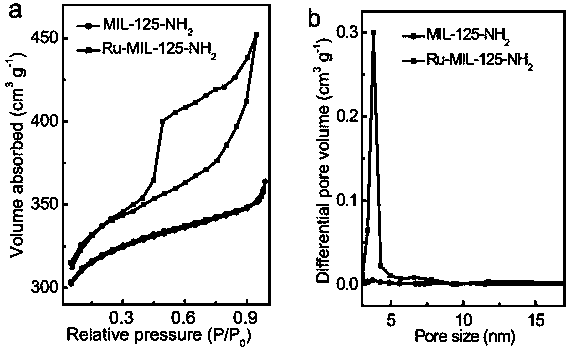

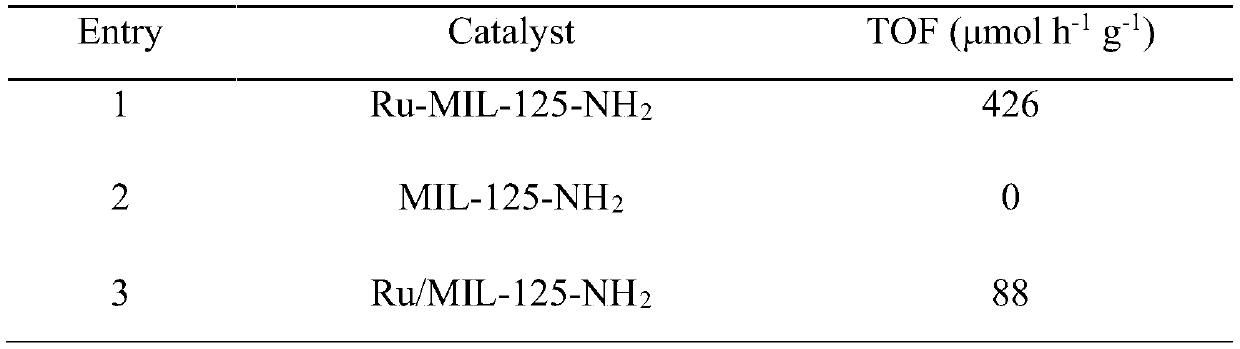

[0035] MIL-125-NH 2 And the obtained high mesoporous Ru-MIL-125-NH of this embodiment ...

Embodiment 2

[0039] Mesoporous Ru-MIL-125-NH of the present embodiment 2 The synthesis method is as follows:

[0040] Synthesis of Mesoporous Ru-MIL-125-NH 2 The metal salt precursor used is RuCl3 ·xH 2 O, MOFs material is MIL-125-NH 2 .

[0041] MIL-125-NH 2 with RuCl 3 ·xH 2 O is added to the reaction kettle according to the mass ratio of 100:5, stirred at room temperature until uniformly mixed, then filled with carbon dioxide at a certain pressure (5.58MPa), and reacted for 1 hour at a reaction temperature of 200°C, then cooled to room temperature , remove the carbon dioxide in the reactor by pressure relief, centrifuge to obtain a solid precipitate, wash the obtained precipitate with DMF and methanol, and then place it in a vacuum drying oven to remove the remaining solvent molecules, the drying temperature is 80 ° C, Ru-MIL-125-NH was obtained after drying for 12 hours 2 .

[0042] The resulting Ru-MIL-125-NH 2 Scanning, transmission electron microscopy, X-ray diffraction (X...

Embodiment 4

[0044] Mesoporous Ru-MIL-125-NH of the present embodiment 2 The synthesis method is as follows:

[0045] Synthesis of Mesoporous Ru-MIL-125-NH 2 The metal salt precursor used is RuCl 3 ·xH 2 O, MOFs material is MIL-125-NH 2 .

[0046] MIL-125-NH 2 with RuCl 3 ·xH 2 O was added to the reaction kettle according to the mass ratio of 100:5, stirred at room temperature until uniformly mixed, then filled with carbon dioxide at a certain pressure (5.58MPa), reacted for 3 hours at a reaction temperature of 200°C, and cooled to room temperature , remove the carbon dioxide in the reactor by pressure relief, centrifuge to obtain a solid precipitate, wash the obtained precipitate with DMF and methanol, and then place it in a vacuum drying oven to remove the remaining solvent molecules, the drying temperature is 80 ° C, Ru-MIL-125-NH was obtained after drying for 12 hours 2 .

[0047] The resulting Ru-MIL-125-NH 2 Scanning, transmission electron microscopy, X-ray diffraction (XR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com