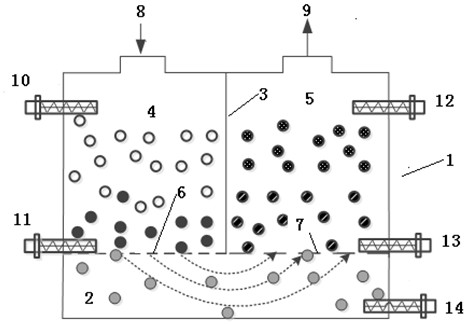

Biomass gasification processor and biomass gasification method

A biomass and processor technology, applied in the field of biomass gasification equipment and biomass treatment, can solve the problems of complex series process and large heat loss, achieve high integration of reaction system, less energy dissipation, and simplify process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Adopt above-mentioned biomass gasification processor, select forestry residue fir as raw material, device feeding material is fir pulverized material after forming and processing granular material, is columnar particle, length is 20mm, section diameter 10mm, water content 4wt%, heat The value is 18.67 MJ / kg. The fir pellets are pushed and filled in the biomass pyrolysis zone by the screw feeder, and the solid product bio-semi-coke after the reaction is used as the filler in the tar conversion zone and loaded in the tar conversion zone by the screw feeder. When the airtightness of the reactor is good, nitrogen enters from the gas inlet, and the displaced air in the reactor is discharged from the gas outlet, and the gas inlet is closed after 3 to 5 minutes of replacement. During the reaction process, a slight negative pressure operation is adopted, and the vacuum degree in the reactor is maintained between 400 and 600 Pa. The reaction temperature in the biomass pyrolysis...

Embodiment 2

[0047] Adopt above-mentioned biomass gasification processor, select forestry residue larch as raw material, device feeding material is larch pulverized material after forming and processing granular material, is columnar particle, length 30mm, section diameter 10mm, moisture content 10wt%, The heat value is 18.63MJ / kg. The larch pellets are pushed and filled in the biomass pyrolysis zone by a screw feeder. The filling in the tar conversion zone includes two layers, wherein the biomass semi-coke is used as the first filling layer, and the bio-semi-coke with a potassium carbonate loading of 10wt% Coke as a second fill layer. When the airtightness of the reactor is good, nitrogen enters from the gas inlet, and the replaced air in the reactor is discharged from the gas outlet, and the gas inlet is closed after 3 to 5 minutes of replacement. During the reaction process, a slight negative pressure operation is adopted, and the vacuum degree in the reactor is maintained between 400 ...

Embodiment 3

[0049] Using the above-mentioned biomass gasification processor, select the forestry residue sylvestris sylvestris sylvestris as raw material, and the device feeds the sylvestris sylvestris sylvestris crushed material after molding and processing, which is columnar particles with a length of 15mm, a cross-sectional diameter of 12mm, and a water content of 6wt. %, calorific value is 18.42MJ / kg. Pine sylvestris granules are pushed and filled in the biomass pyrolysis zone by a screw feeder. Biomass semi-coke and dolomite are mechanically mixed according to a mass ratio of 10:1 as the first filling layer. The nickel oxide loading is 5wt%. Semi-focus as a second fill layer. When the airtightness of the reactor is good, nitrogen enters from the gas inlet, and the replaced air in the reactor is discharged from the gas outlet, and the gas inlet is closed after 3 to 5 minutes of replacement. During the reaction process, a slight negative pressure operation is adopted, and the vacuum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com