Vacuumizing equipment for polyethylene wax powder

A technology of vacuum equipment and polyethylene wax powder, which is applied in mechanical equipment, the method of chemically changing substances by using atmospheric pressure, pyrolysis reaction, etc., can solve the problems that are not suitable for use in the laboratory environment, and achieve simple structure, Reduce reaction time and increase the effect of cleavage reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

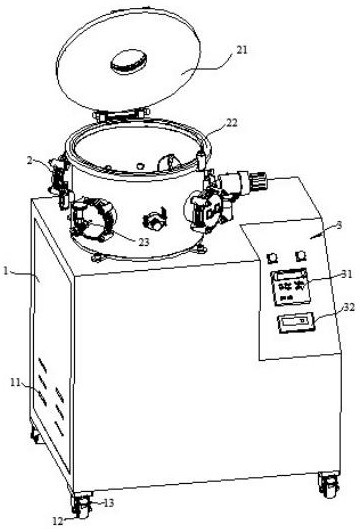

[0028] Such as figure 1 As shown, a kind of vacuum equipment for polyethylene wax powder of the present invention comprises: working cabinet and reactor 2, and described reactor 2 is fixed on the upper end of described working cabinet, and described reactor 2 is suitable for depositing material, The inside of the work cabinet is hollow, and a vacuum device 1 work cabinet is fixed inside the work cabinet; 10, the vacuum device 1 work cabinet; 10 communicates with the reaction kettle 2, and a control platform is arranged on one side of the work cabinet 3, wherein the control platform 3 can control the working cabinet of the vacuum device 1; 10 takes away the air inside the reactor 2; the present invention has a simple structure, and is connected to the reactor 2 by setting 10, through the vacuum device 1 work cabinet; 10 can take away the air in the reactor 2 so as to form the negative pressure in the reactor 2, and the negative pressure of the reactor 2 contributes to Increasi...

Embodiment 2

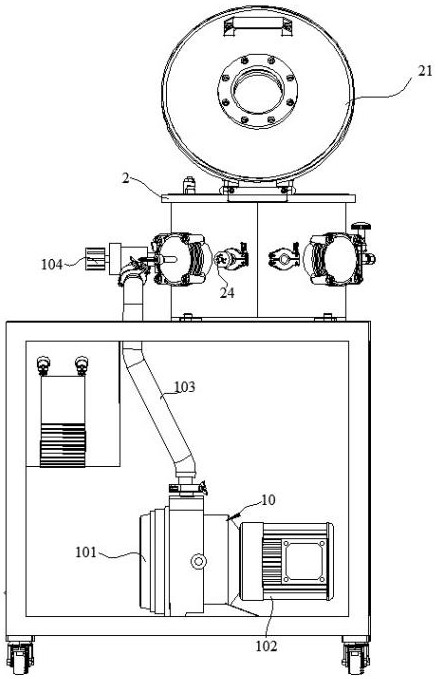

[0030] Such as figure 1 and figure 2 As shown, a kind of vacuum equipment for polyethylene wax powder of the present invention comprises: working cabinet and reactor 2, and described reactor 2 is fixed on the upper end of described working cabinet, and described reactor 2 is suitable for depositing material, The inside of the work cabinet is hollow, and a vacuum device 1 work cabinet is fixed inside the work cabinet; 10, the vacuum device 1 work cabinet; 10 communicates with the reaction kettle 2, and a control platform is arranged on one side of the work cabinet 3, wherein the control platform 3 can control the working cabinet of the vacuum device 1; 10 takes away the air inside the reactor 2; the present invention has a simple structure, and is connected to the reactor 2 by setting 10, through the vacuum device 1 work cabinet; 10 can take away the air in the reactor 2 so as to form the negative pressure in the reactor 2, and the negative pressure of the reactor 2 contribut...

Embodiment 3

[0033] Such as figure 1 and figure 2 As shown, a kind of vacuum equipment for polyethylene wax powder of the present invention comprises: working cabinet and reactor 2, and described reactor 2 is fixed on the upper end of described working cabinet, and described reactor 2 is suitable for depositing material, The inside of the work cabinet is hollow, and a vacuum device 1 work cabinet is fixed inside the work cabinet; 10, the vacuum device 1 work cabinet; 10 communicates with the reaction kettle 2, and a control platform is arranged on one side of the work cabinet 3, wherein the control platform 3 can control the working cabinet of the vacuum device 1; 10 takes away the air inside the reactor 2; the present invention has a simple structure, and is connected to the reactor 2 by setting 10, through the vacuum device 1 work cabinet; 10 can take away the air in the reactor 2 so as to form the negative pressure in the reactor 2, and the negative pressure of the reactor 2 contribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com