Preparation method for sebacic acid

A technology of sebacic acid and sulfuric acid, which is used in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high toxicity of diluents, high production costs, affecting the implementation of industrialization, etc., to eliminate environmental problems. Contamination issues, lower production costs, the effect of simplifying the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

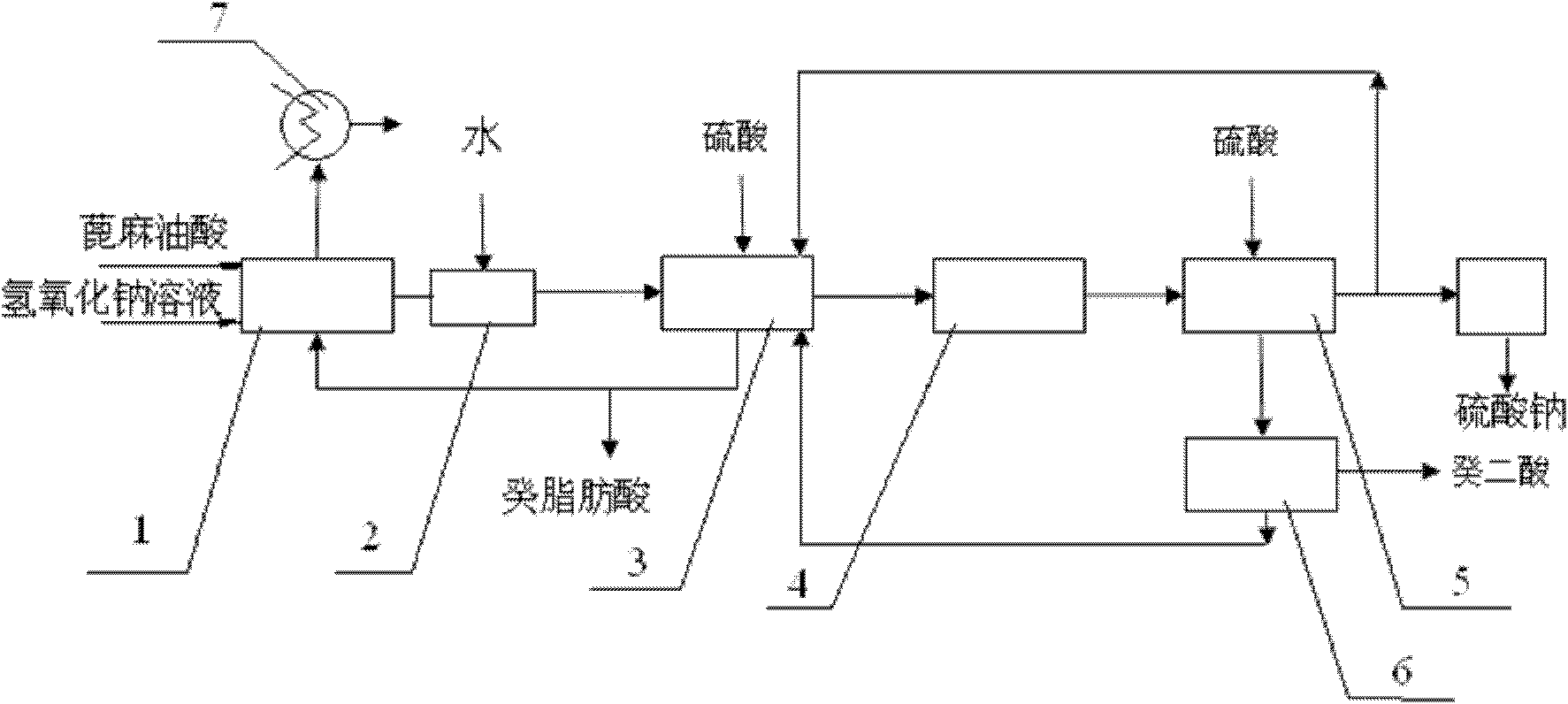

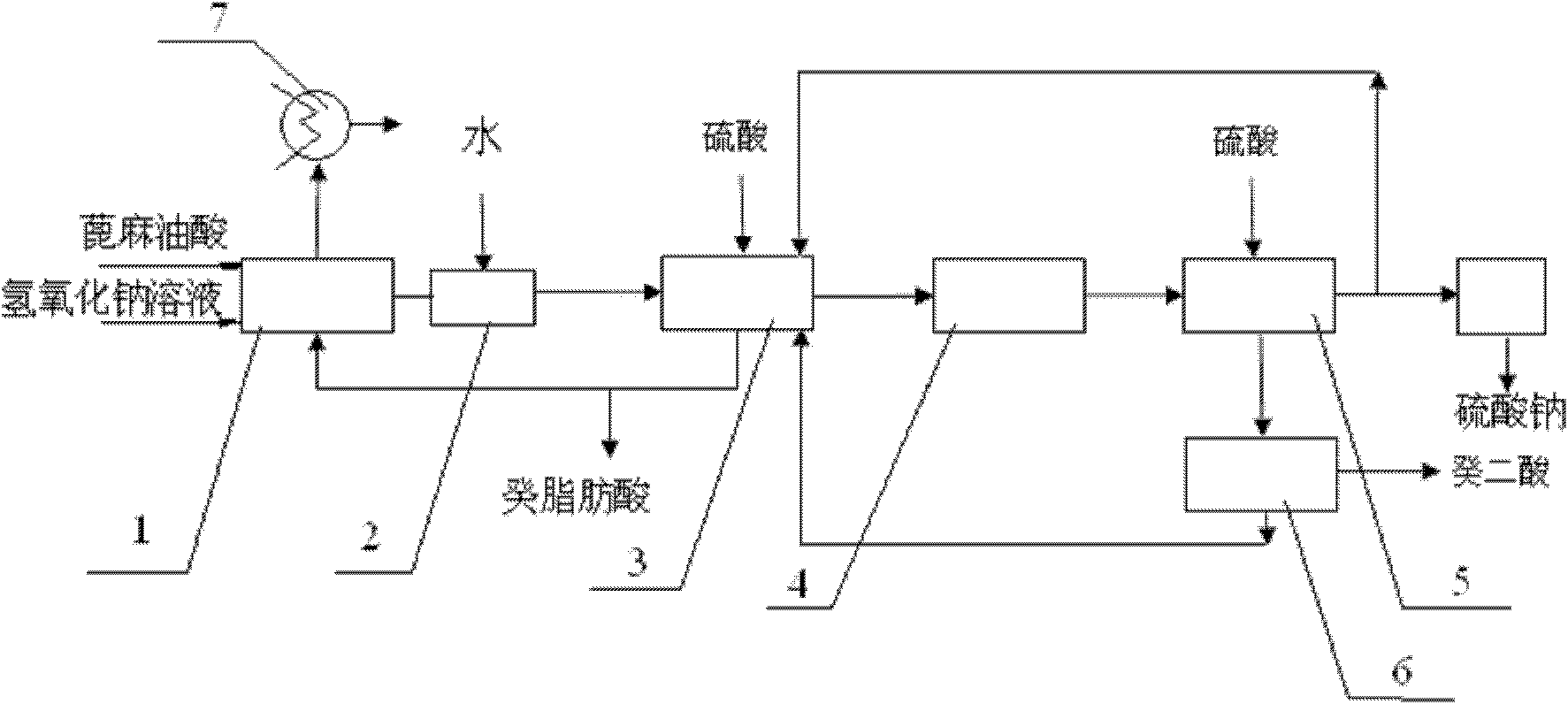

[0049] use figure 1 process.

[0050] (1) 0.5 kg of ricinoleic acid, 0.025 kg of capric acid and 0.55 kg of sodium hydroxide solution with a mass concentration of 45% were added to the reactor, stirred, heated to 340° C., and the reaction time was 4 hours, and the ricinoleic acid was cracked to generate Disodium sebacate, sec-octanol, hydrogen, and sodium capric acid;

[0051] The mass ratio of ricinoleic acid, capric acid and sodium hydroxide solution is 1: 0.05: 1.1;

[0052] Disodium sebacic acid and sodium capric acid enter the liquefaction tank;

[0053] (2) Sebacic acid double sodium salt, decanoic acid sodium cracking material are miscible with water in the liquefaction tank, and the water temperature is controlled at 80 ℃ and then beaten into the neutralization tank, and the sulfuric acid neutralizing material liquid with a mass concentration of 93% is adjusted To pH = 6.5, an oily phase of decanoic acid, and an aqueous phase containing monosodium sebacic acid were ...

Embodiment 2

[0064] use figure 1 process.

[0065] (1) 0.5 kg of ricinoleic acid, capric acid and mass concentration of 50% sodium hydroxide solution are added to the reaction kettle, stirred, heated to 260°C, and the reaction time is 5 hours, and the ricinoleic acid is cracked to generate sebacic acid bis Sodium salt, 2-octyl alcohol, hydrogen gas and sodium capric fatty acid;

[0066] The mass ratio of ricinoleic acid, capric acid and sodium hydroxide solution is 1: 0.02: 1.1;

[0067] Disodium sebacic acid and sodium capric acid enter the liquefaction tank 2;

[0068] (2) disodium sebacic acid, sodium capric acid are miscible with water in the liquefaction tank, and the temperature is controlled at 90°C, then they are beaten into the neutralization tank, and the sulfuric acid neutralizing feed solution with a mass concentration of 50% is to pH= 6.5. Obtain the oil phase decanoic acid and the water phase containing sebacic acid monosodium salt, and then collect the target product seba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com