Ethylene cracking furnace of double-section heat supply structure

A technology of ethylene cracking furnace and furnace wall, which is applied in the direction of non-catalytic thermal cracking, cracking, hydrocarbon cracking and hydrocarbon production, etc., which can solve the unfavorable requirements of energy saving, emission reduction and operation automation, increase the risk of overheating of the outer wall of the furnace, and long-term installation Stable and safe operation and other issues, to eliminate the bottom overheating problem, reduce equipment investment costs and operation and maintenance costs, save the effect of external space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

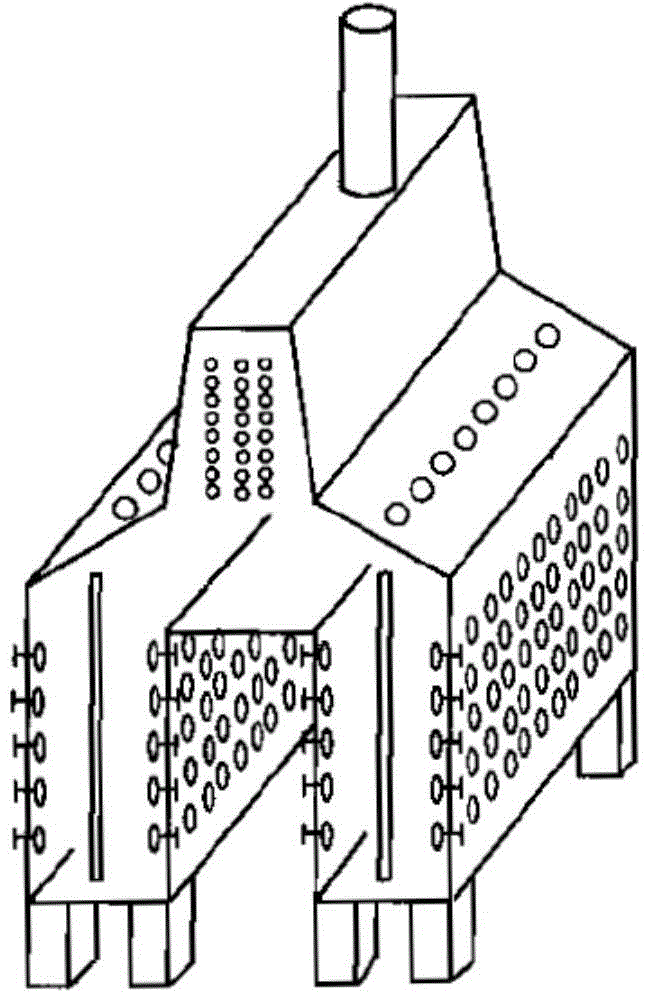

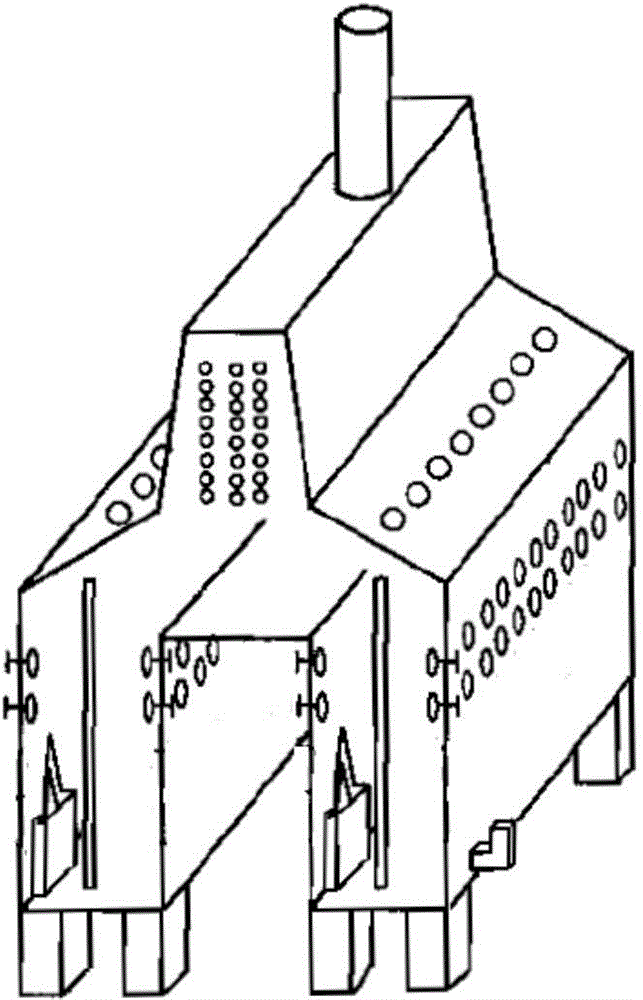

[0066] Such as Figure 4 , 6 , shown in 9, a kind of ethylene cracking furnace of two-stage heating structure, it comprises radiation section 1, convection section 5, radiation coil 4, quenching boiler 6, high-pressure steam drum 7, induced draft fan 8, described quenching boiler 6 Connected to the radiant coil 4, the induced draft fan 8 is connected to the top of the convection section 5, and the high-pressure steam drum 7 is connected to the quench boiler 6, characterized in that:

[0067] The ethylene cracking furnace adopts a two-stage joint heating structure of the upper heating section and the lower heating section in the radiant section 1;

[0068] The heating equipment installed in the upper heating section is the upper burner 3, and the heating equipment installed in the lower heating section is the lower burner 2. Both the upper burner 3 and the lower burner 2 are oriented in the flame direction. The burner at the top of the radiant section 1;

[0069] The side fu...

Embodiment 2

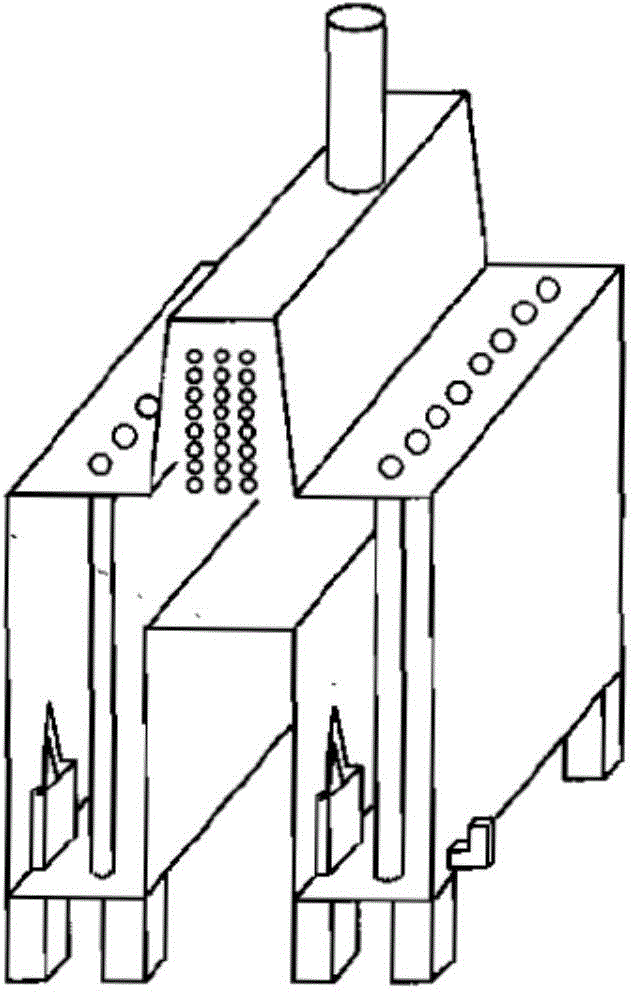

[0084] Such as Figure 5 , 7 , shown in 10, a kind of ethylene cracking furnace of two-stage heating structure, it comprises radiation section 1, convection section 5, radiation coil 4, quenching boiler 6, high-pressure steam drum 7, induced draft fan 8, described quenching boiler 6 Connected to the radiant coil 4, the induced draft fan 8 is connected to the top of the convection section 5, and the high-pressure steam drum 7 is connected to the quench boiler 6, characterized in that:

[0085] The ethylene cracking furnace adopts a two-stage joint heating structure of the upper heating section and the lower heating section in the radiant section 1;

[0086] The heating equipment installed in the upper heating section is the upper burner 3, and the heating equipment installed in the lower heating section is the lower burner 2. Both the upper burner 3 and the lower burner 2 are oriented in the flame direction. The burner at the top of the radiant section 1;

[0087] The side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com