Method for actively lubricating reduction gearbox

A reduction box, active technology, applied in gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve problems such as inability to meet lubrication requirements, poor splash lubrication effect, and limited splash oil. The effect of reducing design difficulty, increasing lifespan, improving reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

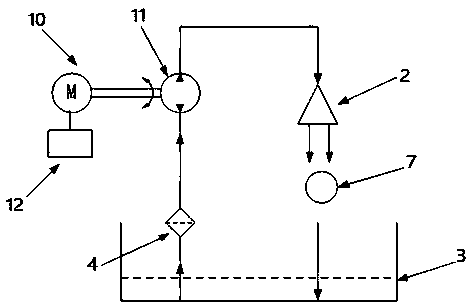

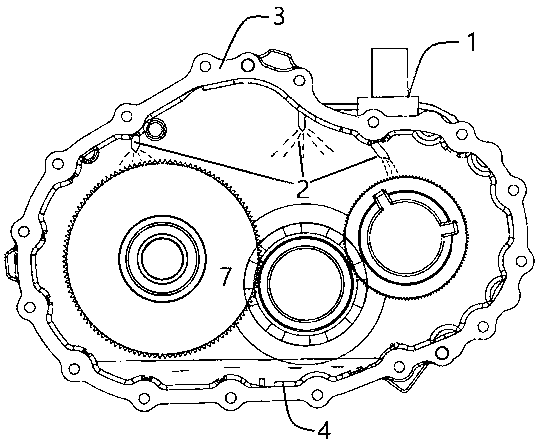

[0030] like figure 1 and 3 As shown, this embodiment provides an active lubrication method for a gearbox, based on the electronic oil pump 1, the electronic oil pump 1 includes a motor 10, a gear pump 11 and a controller 12, the motor 10 is connected to the gear pump 11, and the controller 12 is connected to the motor 10 and the controller 12. The CAN bus of the automobile is connected separately, and the controller 12 obtains the speed of the drive motor through the CAN bus, and controls the speed of the motor 10, and the motor 10 controls the gear pump 11 to spray oil through the fuel injector 2 connected to the gear pump 11; the gear pump 11 can be an external gear The gear pump can also be an internal gear pump, which is an external gear pump in this embodiment; the motor 10 can be a brushed motor or a brushless motor.

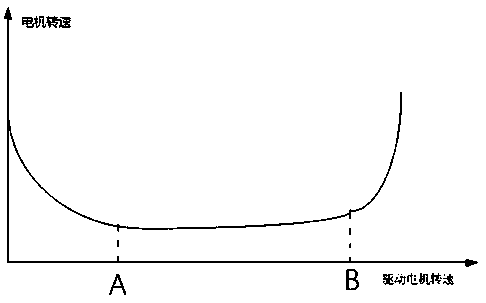

[0031] When the controller 12 detects that the rotational speed of the driving motor is less than the set threshold-A, the controller 12 controls the rot...

Embodiment 2

[0044] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that in order to ensure the fuel injection quantity of the fuel injector 2, this embodiment provides another structure of the fuel injector. The structure of the fuel injector 2 includes a wedge-shaped housing, and An oil inlet 23 , an oil injection pipe 24 and an oil outlet 25 with a rectangular cross-section are arranged on the wedge-shaped housing. The oil injection pipe 24 bifurcates to both sides in the wedge-shaped housing to form two oil outlets 250 and 251 .

[0045] In this embodiment, through the two oil outlets 250 and 251, lubricating oil is sprayed out from the two oil outlets 250 and 251 with rectangular cross-sections in an umbrella shape, which can be used for large-area lubrication.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com