High performance type three-dimensional cell

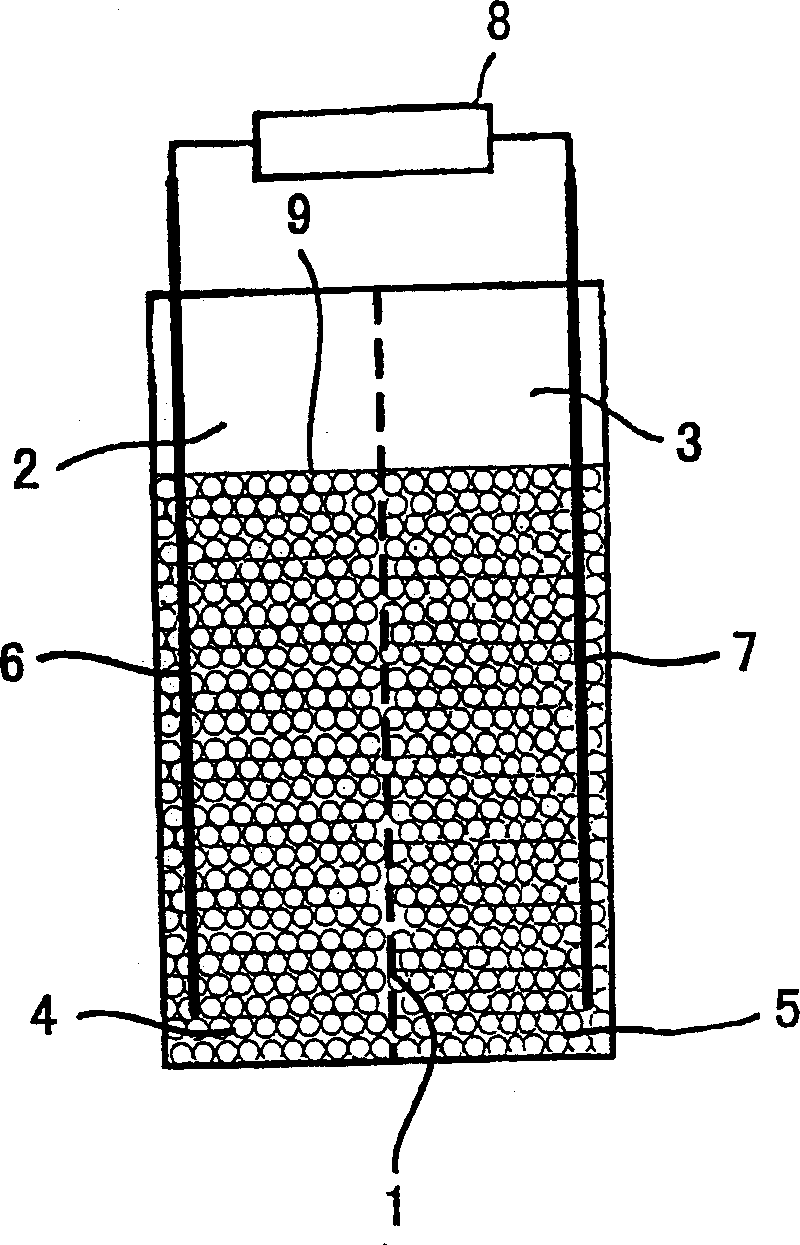

A high-output, battery technology, applied in the direction of large flat batteries/batteries, nickel storage batteries, primary batteries, etc., can solve problems such as increased resistance, increased production time, and reduced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

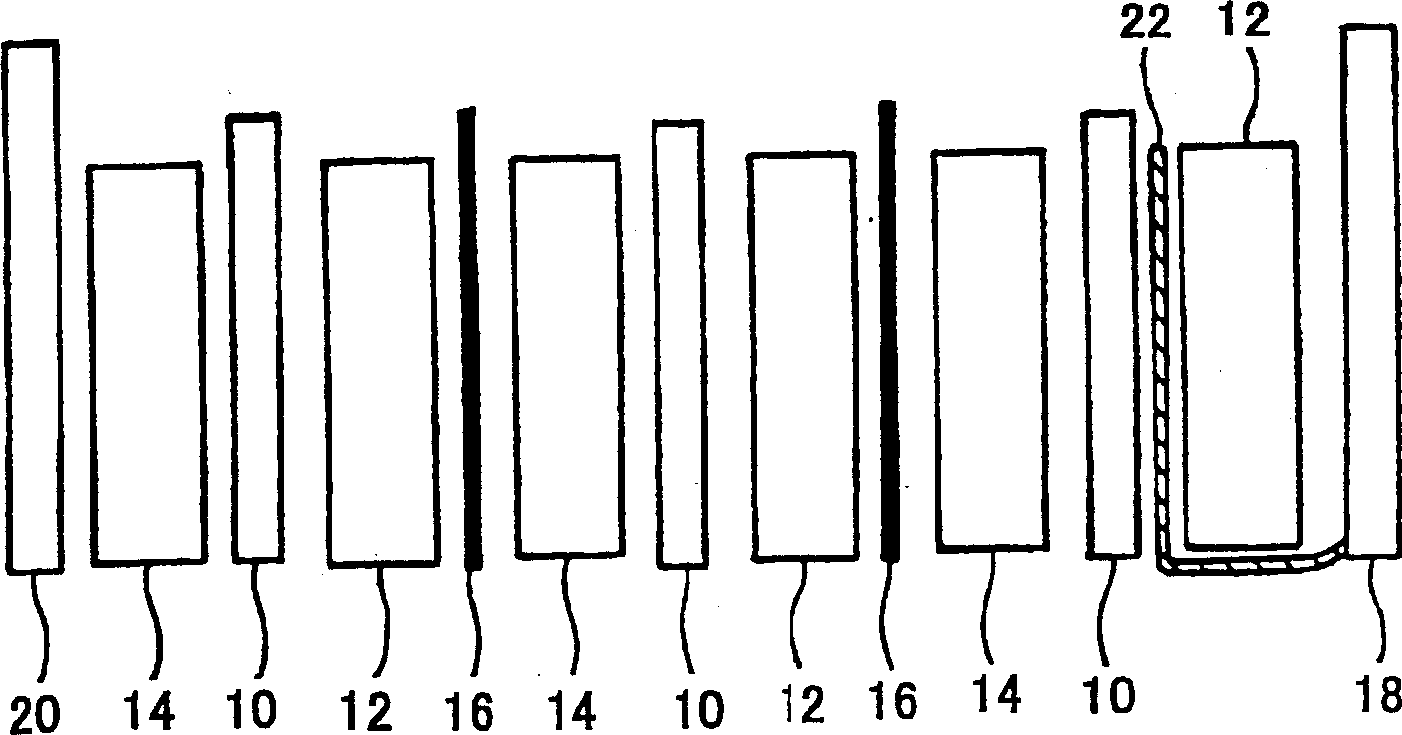

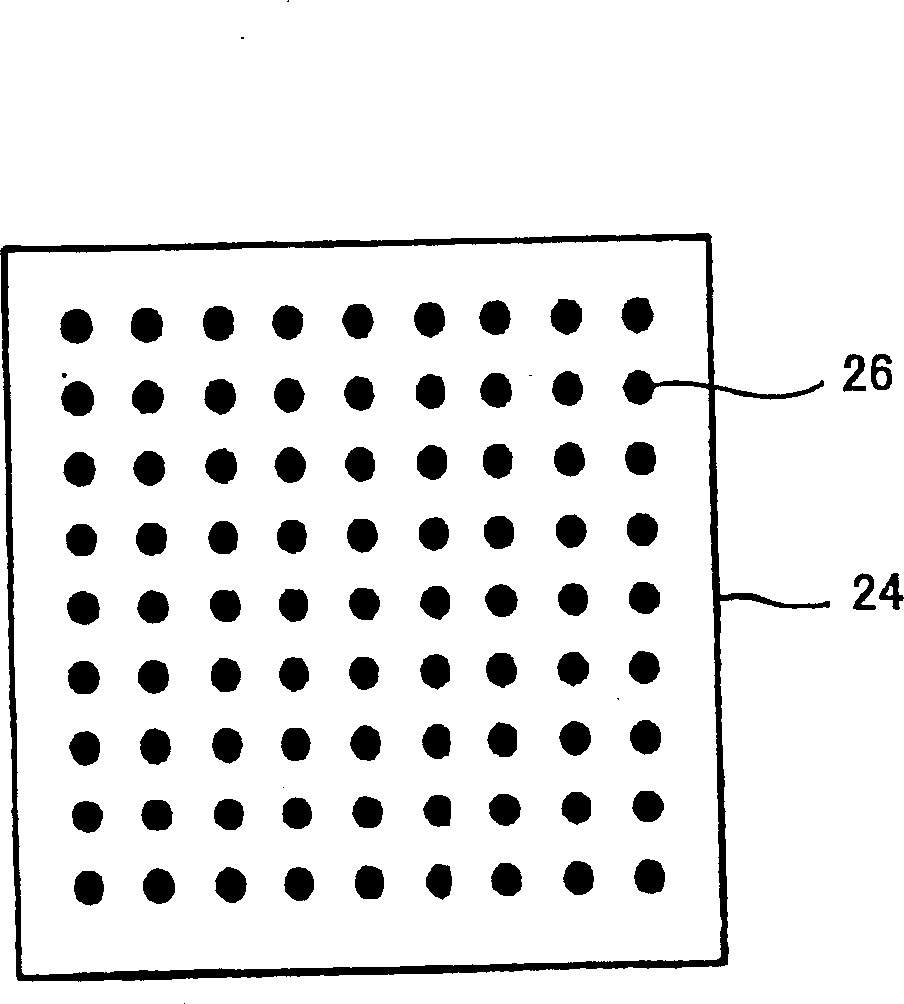

Embodiment 1

[0136] Put 150 grams of granular graphite (acetylene carbon black) into a Henschel mixer with a volume of 10 liters, and stir at a speed of 1000 rpm for about 3 minutes to fully disperse the granular graphite. Further, 1000 g of nickel hydroxide powder and 100 g of carbon fiber (trade name "DONER-247") were added thereto, and stirred at 1000 rpm for about 3 minutes. Further, 150 g of ethylene-vinyl acetate copolymer was added thereto, and stirring and mixing were carried out for 10 minutes at a temperature above the softening temperature and below 130° C. A separation layer (nylon non-woven fabric) is pre-laid on the bottom of the frame with a cross-sectional size of 100mm×100mm, and then the nickel hydroxide mixture is filled thereon. Press molding is performed by applying a pressure of 0.1 MPa while heating from above, and the temperature is lowered in this state to harden the resin. The molded object is taken out from the mold to obtain an electrode material in which the a...

Embodiment 2

[0138] The nickel hydroxide powder was mixed and stirred with the conductive filler and the resin in the same manner as in Example 1 to obtain a nickel hydroxide mixture. A separation layer (nylon non-woven fabric) is pre-laid on the bottom of the frame with a cross-sectional size of 100mm×100mm, and then the nickel hydroxide mixture is filled thereon. The resin is hardened by cooling in the mold without applying pressure. The molded product was taken out from the mold to obtain an electrode material in which the active material and the separator were integrally molded.

Embodiment 3

[0140]The nickel hydroxide powder was mixed and stirred with the conductive filler and the resin in the same manner as in Example 1 to obtain a nickel hydroxide mixture. A current collector (nickel plate) is laid in advance on the bottom of a frame with a cross-sectional size of 100mm×100mm, and then the nickel hydroxide mixture is filled thereon. Press molding is performed by applying a pressure of 0.1 MPa while heating from above, and the temperature is lowered in this state to harden the resin. The molded product was taken out from the mold to obtain an electrode material in which the active material and the current collector were integrally molded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com