Multi-working-condition heat storage type electric boiler

A multi-working-condition, electric boiler technology, applied in heat storage equipment, heat exchanger types, heat storage heaters, etc., can solve the problems of difficult process control, large water storage tanks, increased civil construction costs, etc., and achieve a simple control method. Practical, simple and reliable method, and the effect of saving heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in detail through examples and accompanying drawings. But these examples are not limitations on the scope of protection of the present invention, and all changes within the scope of the basic idea of the technical solution of the present invention or substantially equivalent to the technical solution of the present invention are within the scope of protection of the present invention.

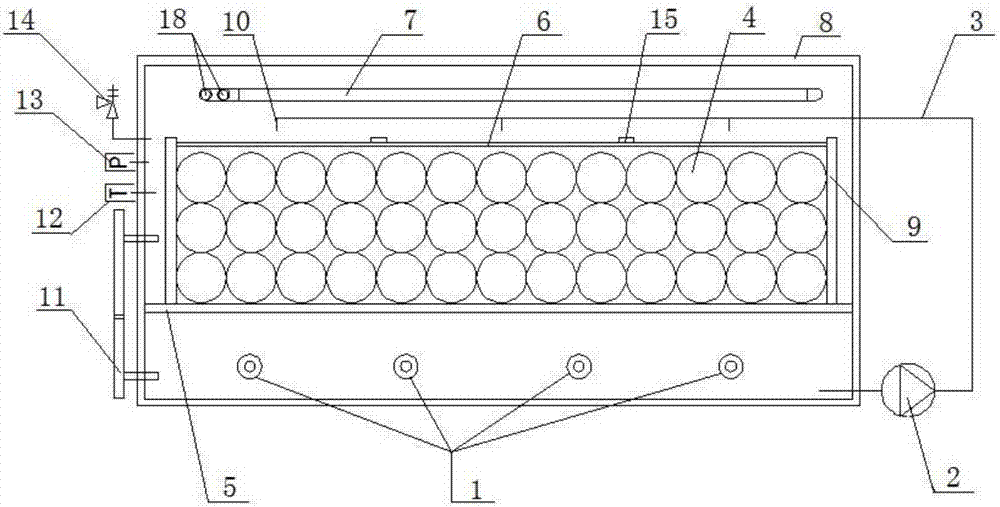

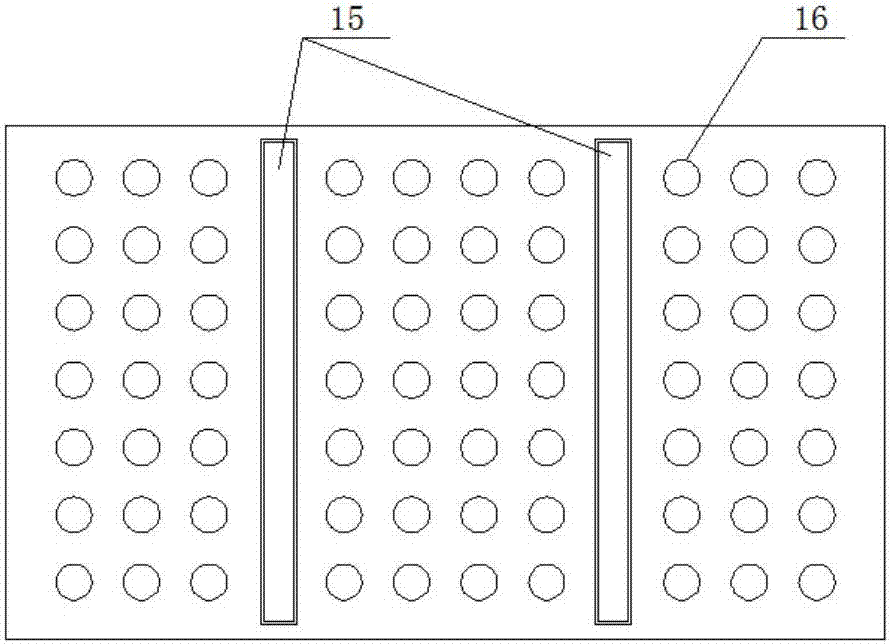

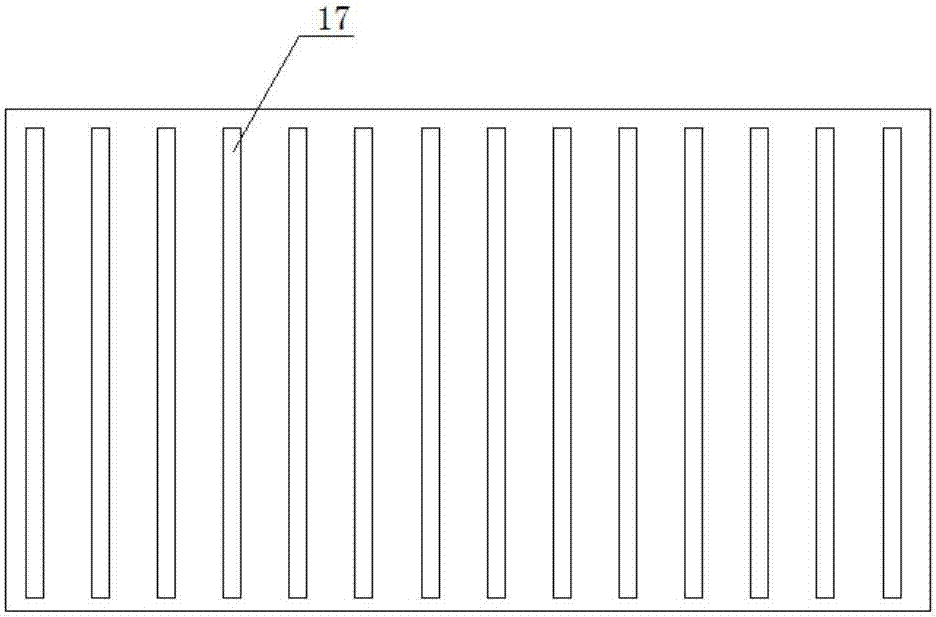

[0021] like figure 1 As shown, the multi-working-condition thermal storage electric boiler of the embodiment of the present invention consists of an electric heater 1, a circulating water pump 2, a circulating pipeline 3, a thermal storage ball 4, a support plate 5, a water distribution tray 6, and a serpentine heat exchange Coil pipe 7, enclosure structure 8, liquid level gauge 11, temperature sensor 12, pressure sensor 13, safety valve 14 and auxiliary pipelines.

[0022] The enclosure structure 8 is provided with an elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com