Gangue spacing filling coal mining method

A technology of filling coal mining and gangue, which is applied in the direction of filling materials, mining equipment, earth cube drilling and mining, etc. It can solve the problems of high auxiliary transportation pressure in mines, impossibility of application in thick coal seams, and large filling workload, so as to reduce auxiliary transportation pressure, Effect of controlling surface subsidence and reducing cost per ton of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

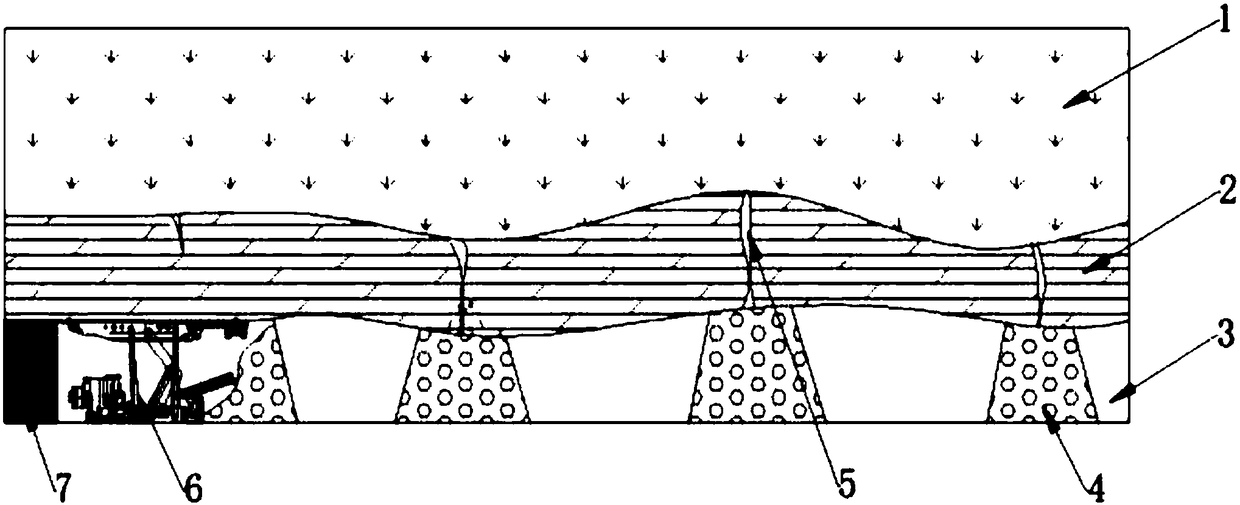

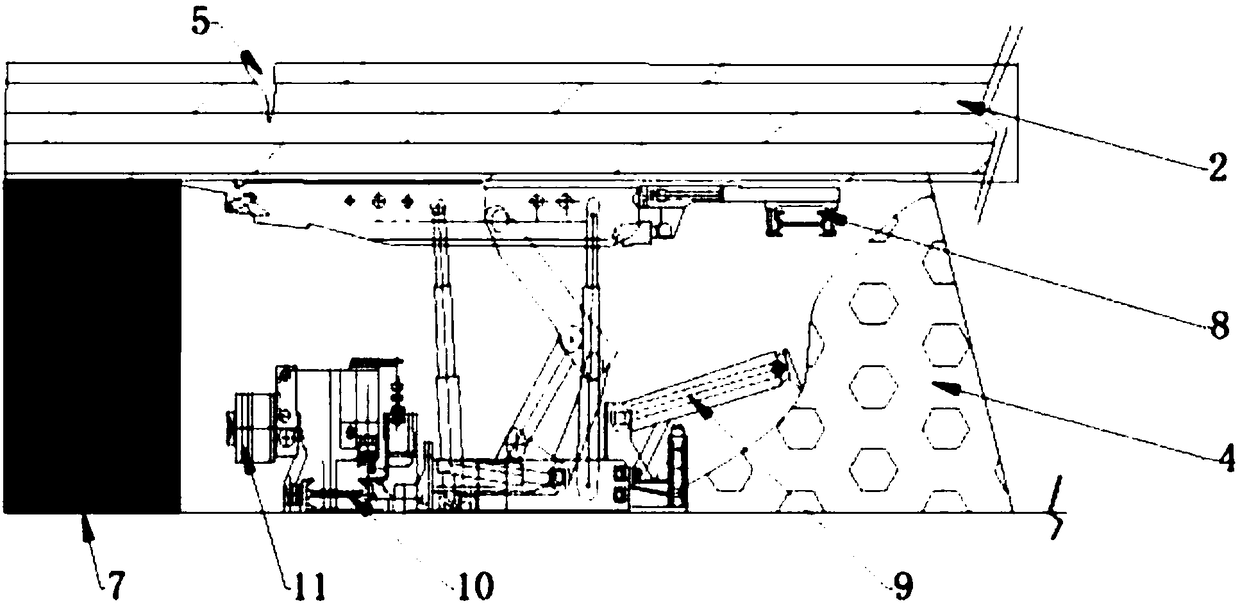

[0012] The implementation of the present invention will be further described below in conjunction with the accompanying drawings:

[0013] Step 1: According to the material composition and lithology of the overlying rock layer 1 and the roof 2, the caving length of the roof 2 is deduced.

[0014] Step 2: Starting from the opening of the cutting hole, the filling and mining hydraulic support 6 supports the roof 2, the coal cutter 11 cuts the coal body 7, and the cut coal is transported out of the coal mining face by the coal scraper conveyor 10, which is not carried out at this stage Filling work to form the goaf 3 .

[0015] Step 3: As the coal mining work proceeds, the filling mining hydraulic support 6 is constantly moved forward. Or when mining coal seam is thicker, described distance gets big value. When the gangue amount that coal mine produces is less or when mining coal seam is thinner, described distance gets small value), open the leakage material of bottom unloading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com