A new type of gel power battery terminal post sealing structure

A power battery and terminal post technology, which is applied in the field of battery terminal post sealing structure, can solve the problem that surface roughness and assembly operation deviation cannot be completely sealed, current carrying capacity and high current safety cannot be guaranteed, connection points and Corrosion of related components and other issues, to achieve the effect of enhancing current carrying capacity and high current safety, current carrying capacity and high current safety performance guarantee, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

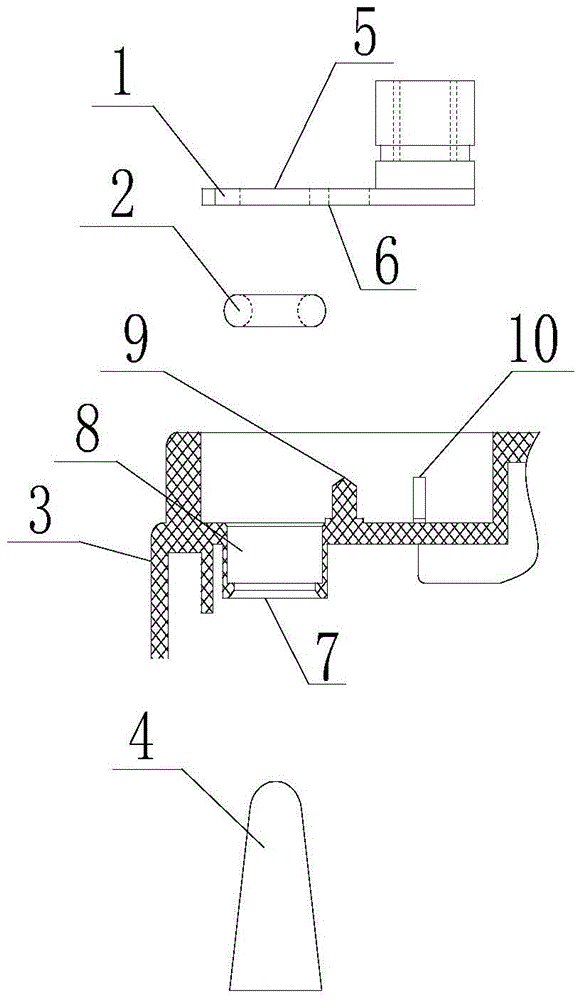

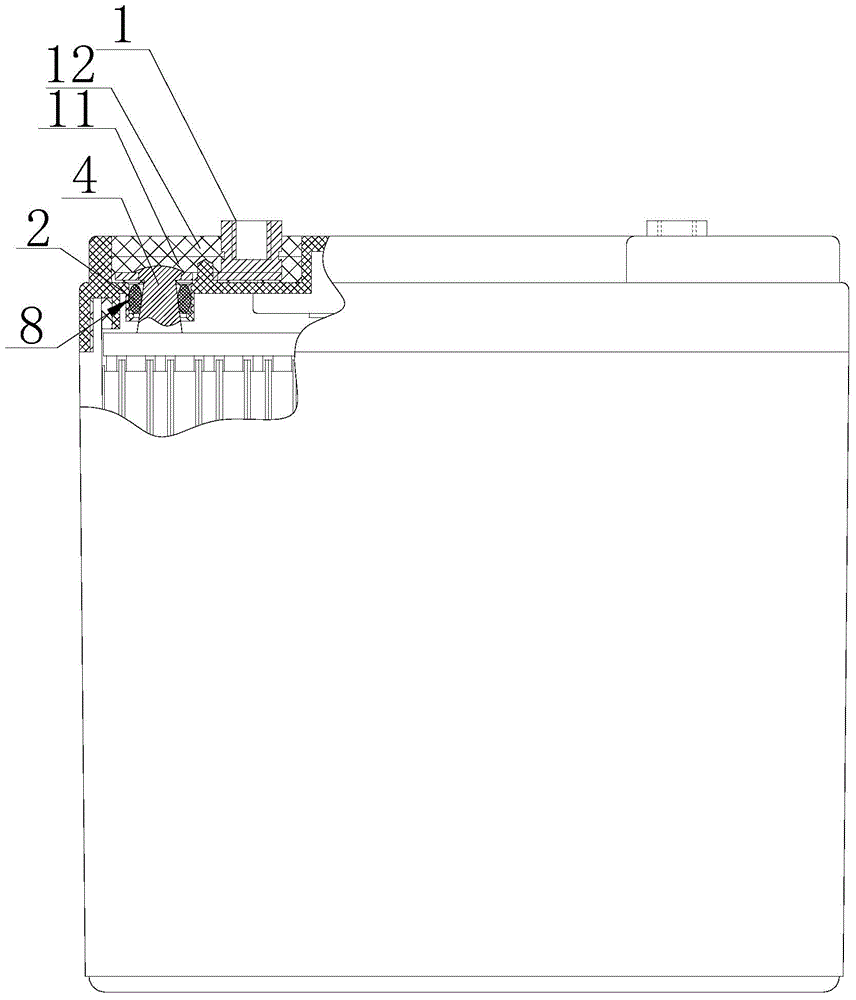

[0014] Such as figure 1 and figure 2 As shown, a novel colloid power battery terminal post sealing structure described in the present invention comprises a copper terminal 1, an O-shaped sealing ring 2, a pool cover terminal post connector 3 and a tapered lead pole post 4. The copper terminal 1 is a right-angled terminal, a welding hole 5 is provided at one end of the copper terminal 1, a fixing hole 6 is provided beside the welding hole 5, and a fixing hole 6 is provided on the terminal column connector 3 of the pool cover. A pool cover end column hole 7, an annular groove 8 is provided above the pool cover end column hole 7, a terminal fixing column 9 is provided beside the annular groove 8, and a terminal fixing column 9 is provided beside the terminal fixing column 9 Limiting card 10; the pool cover end column hole 7 is set on the conical lead po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com