Patents

Literature

31results about How to "Affect welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

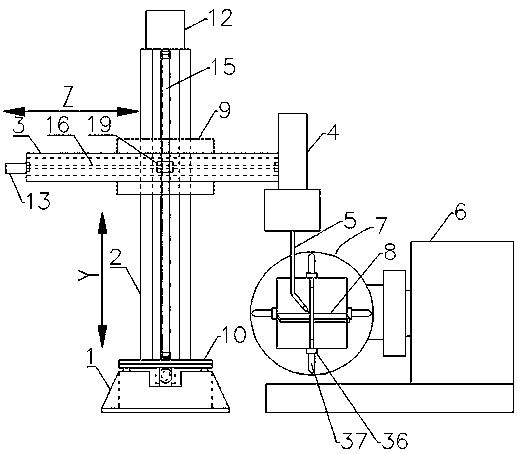

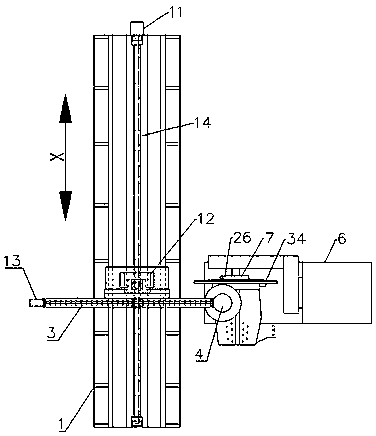

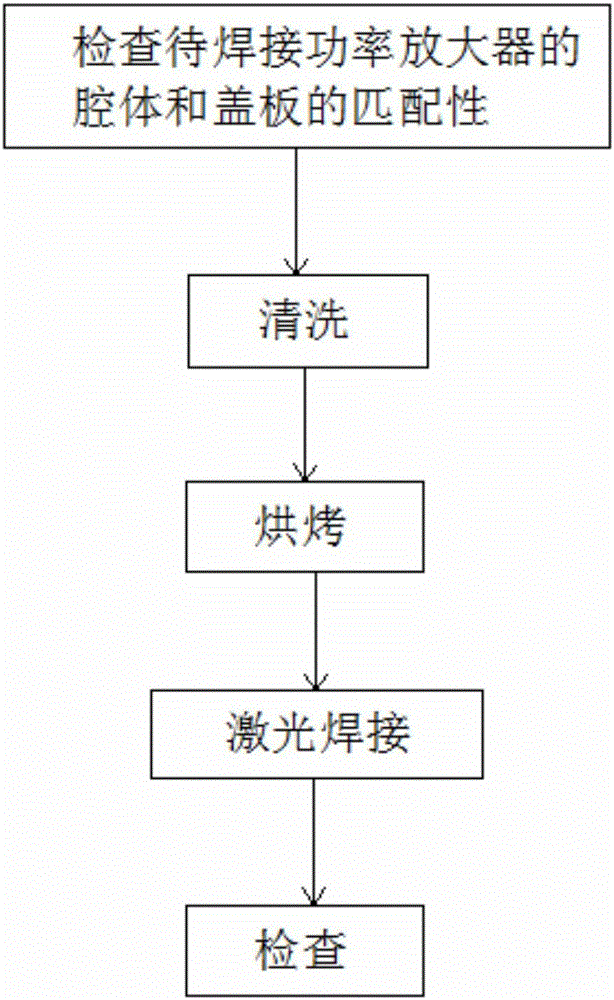

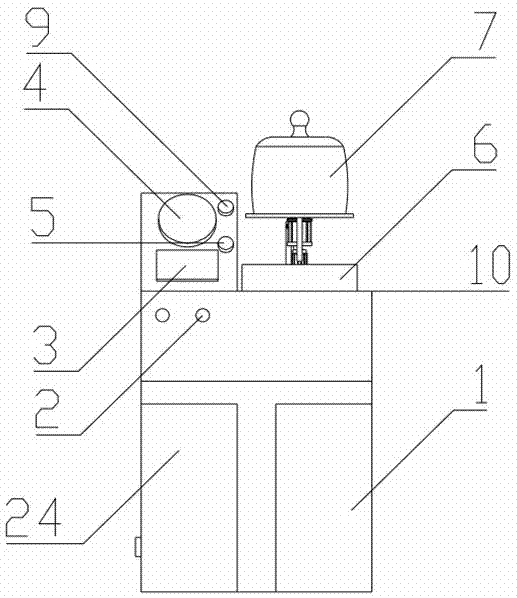

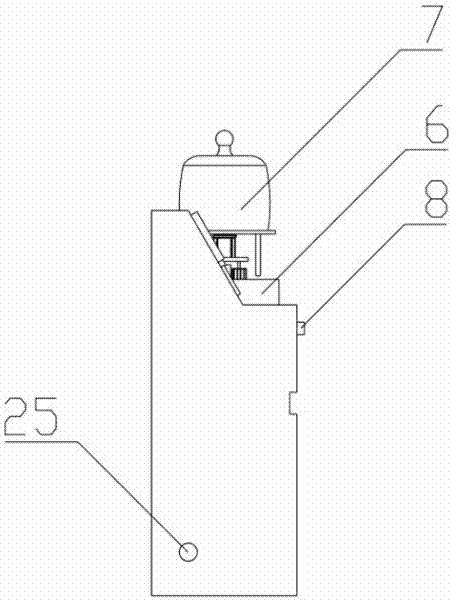

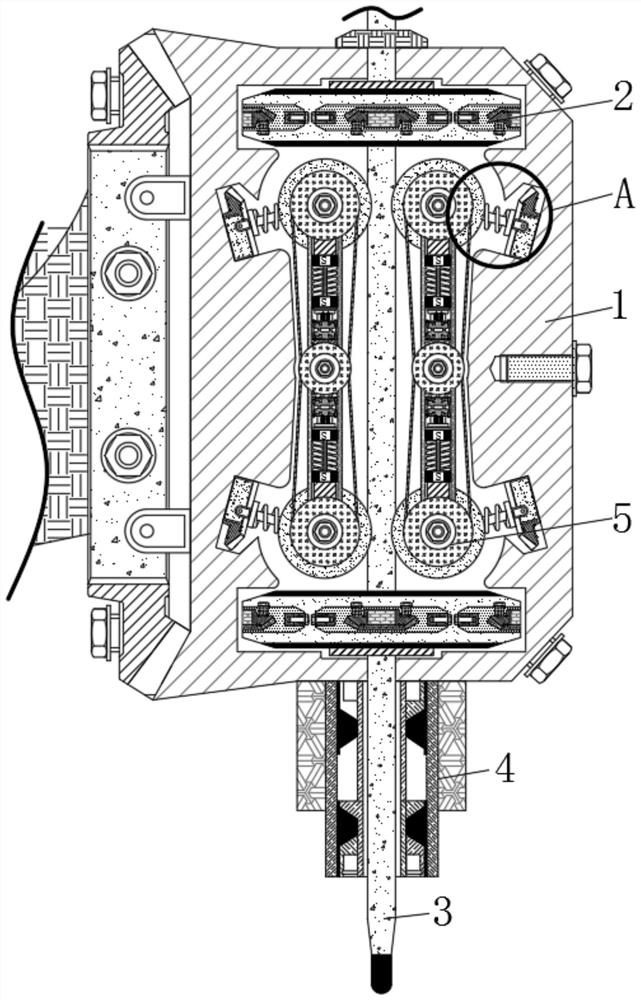

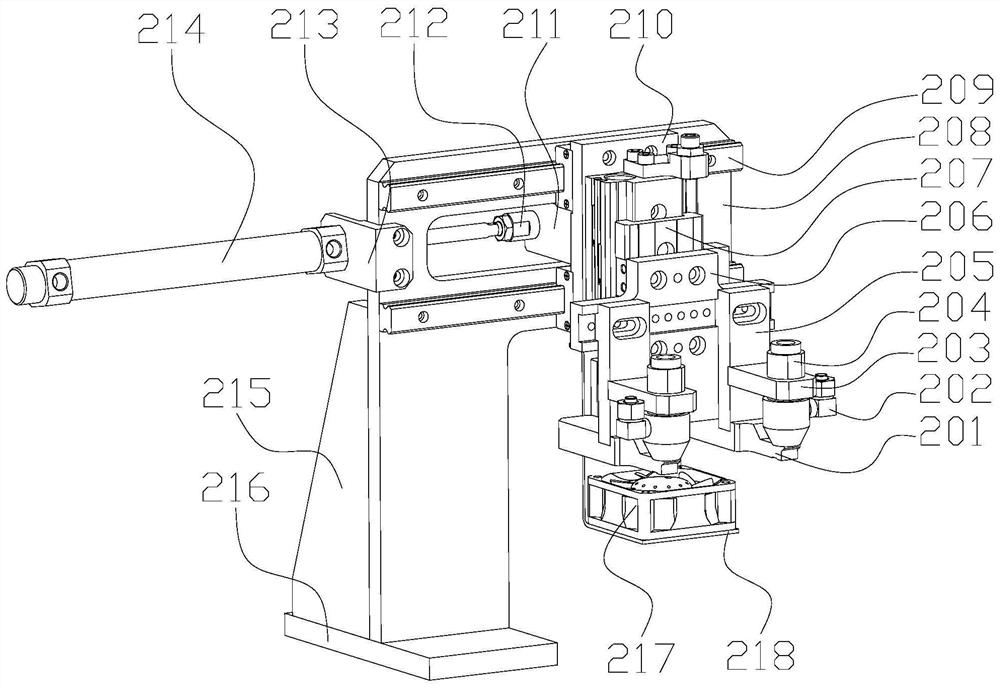

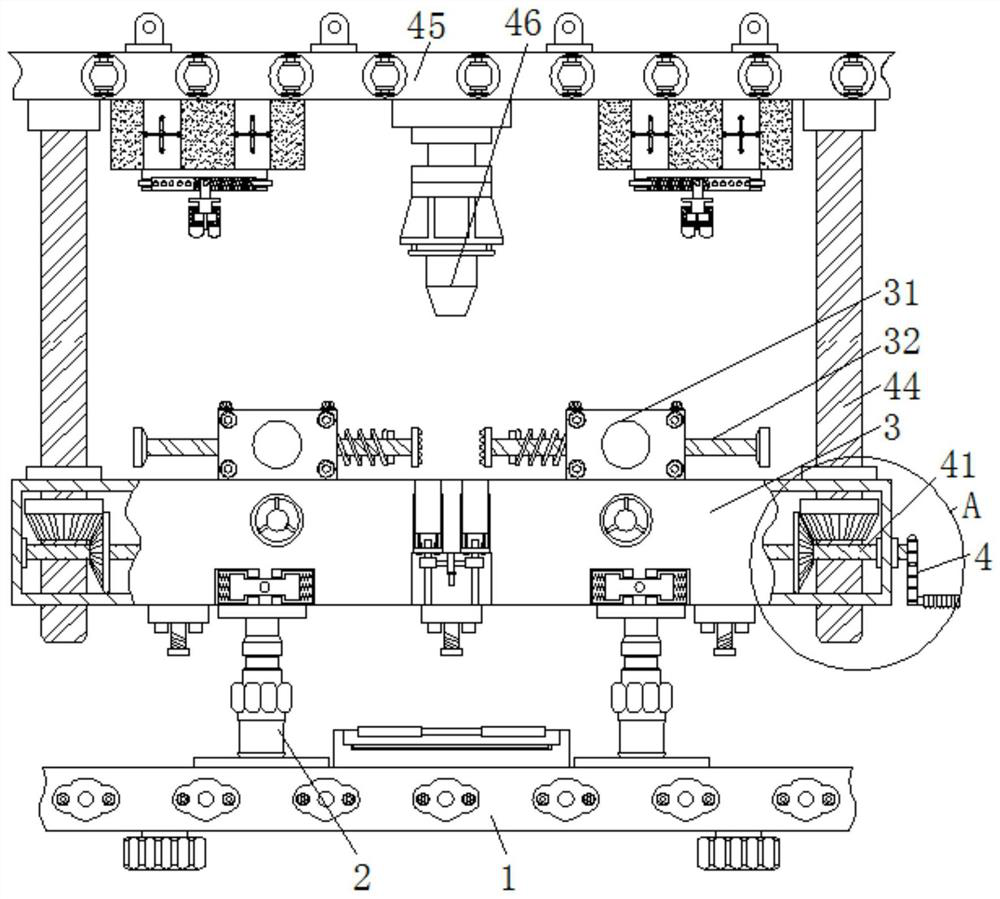

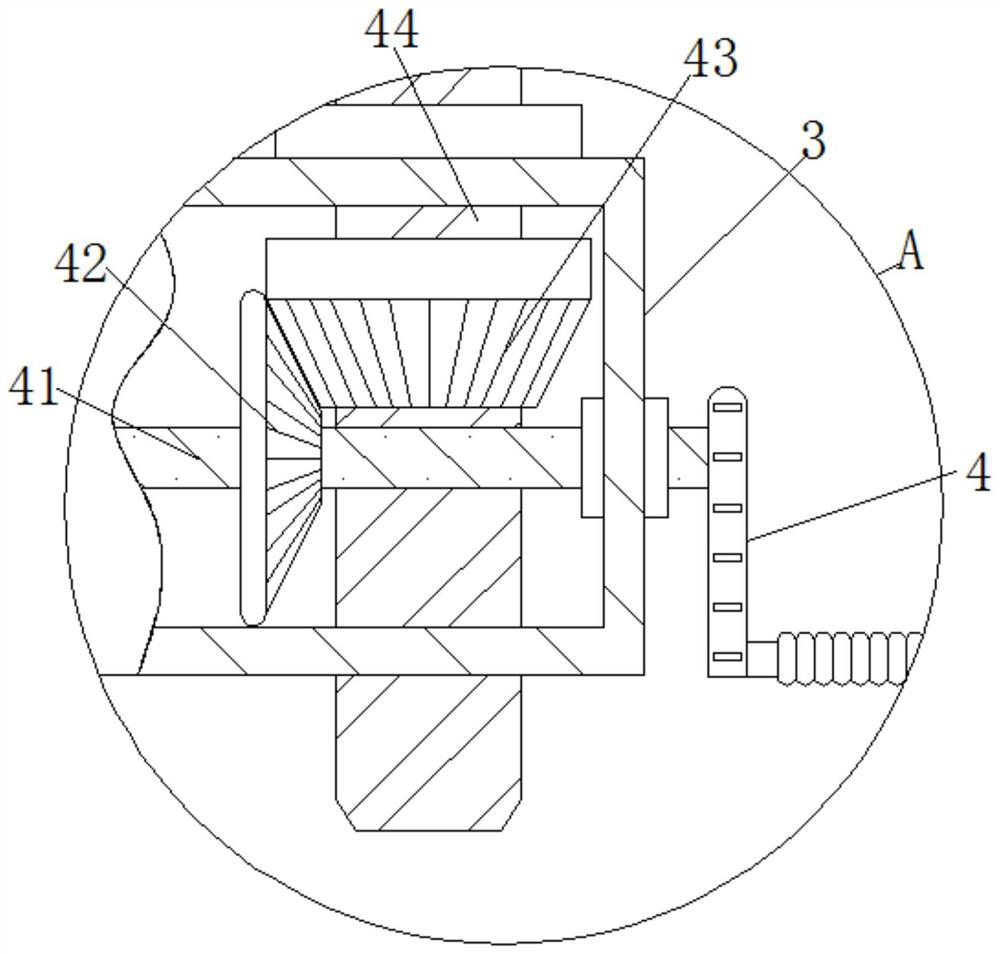

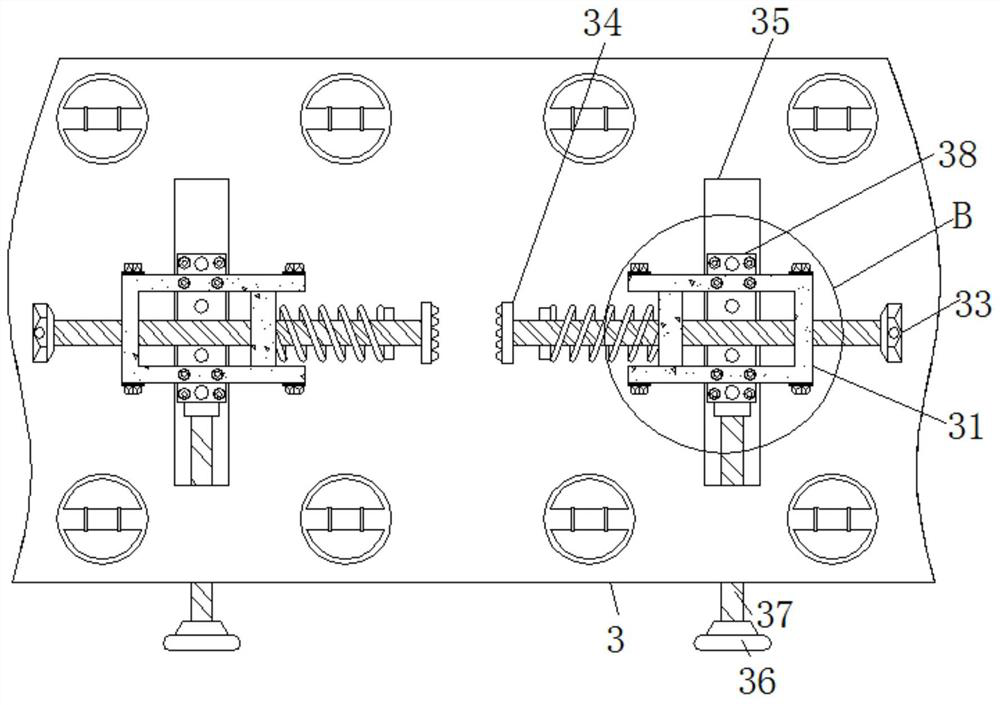

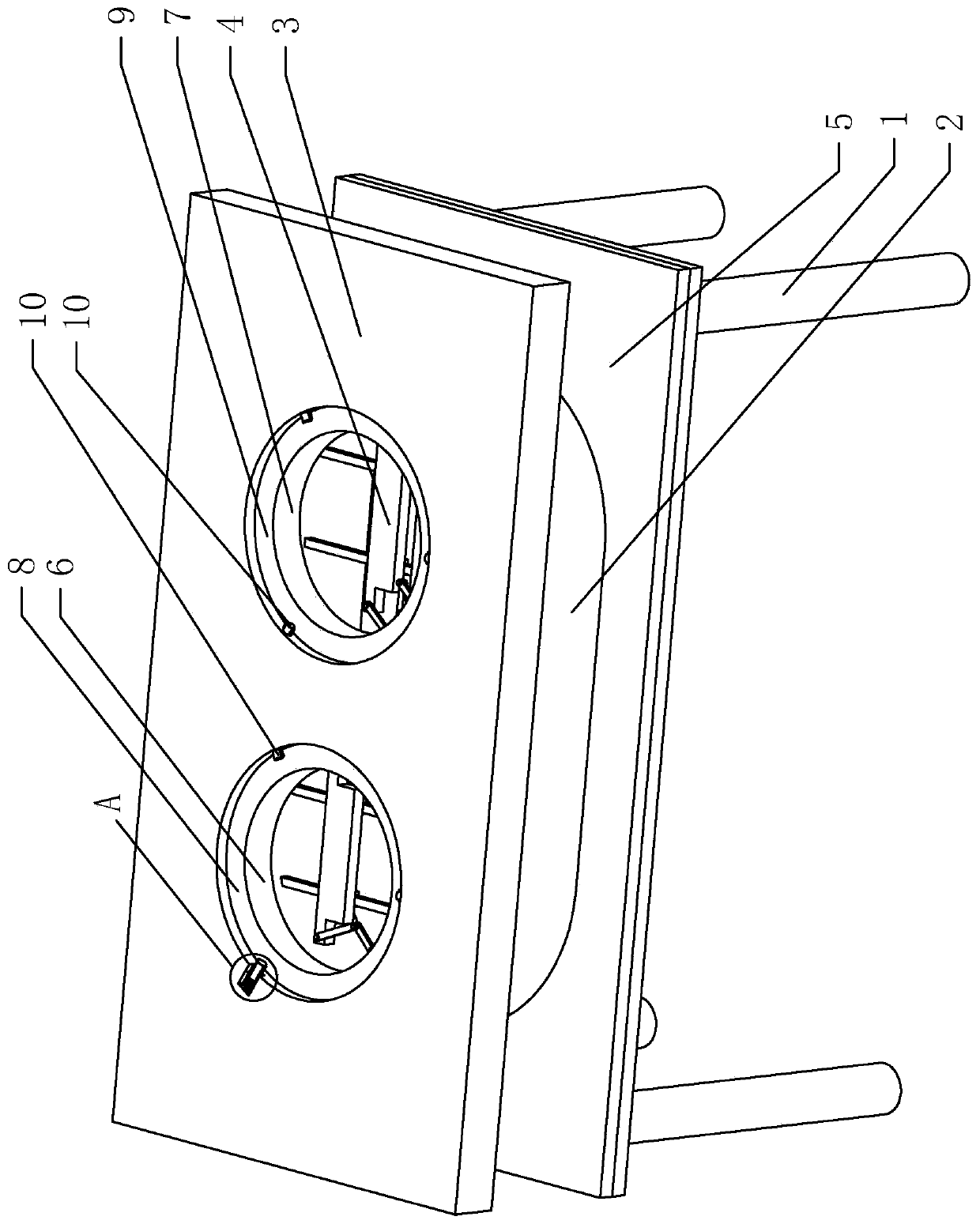

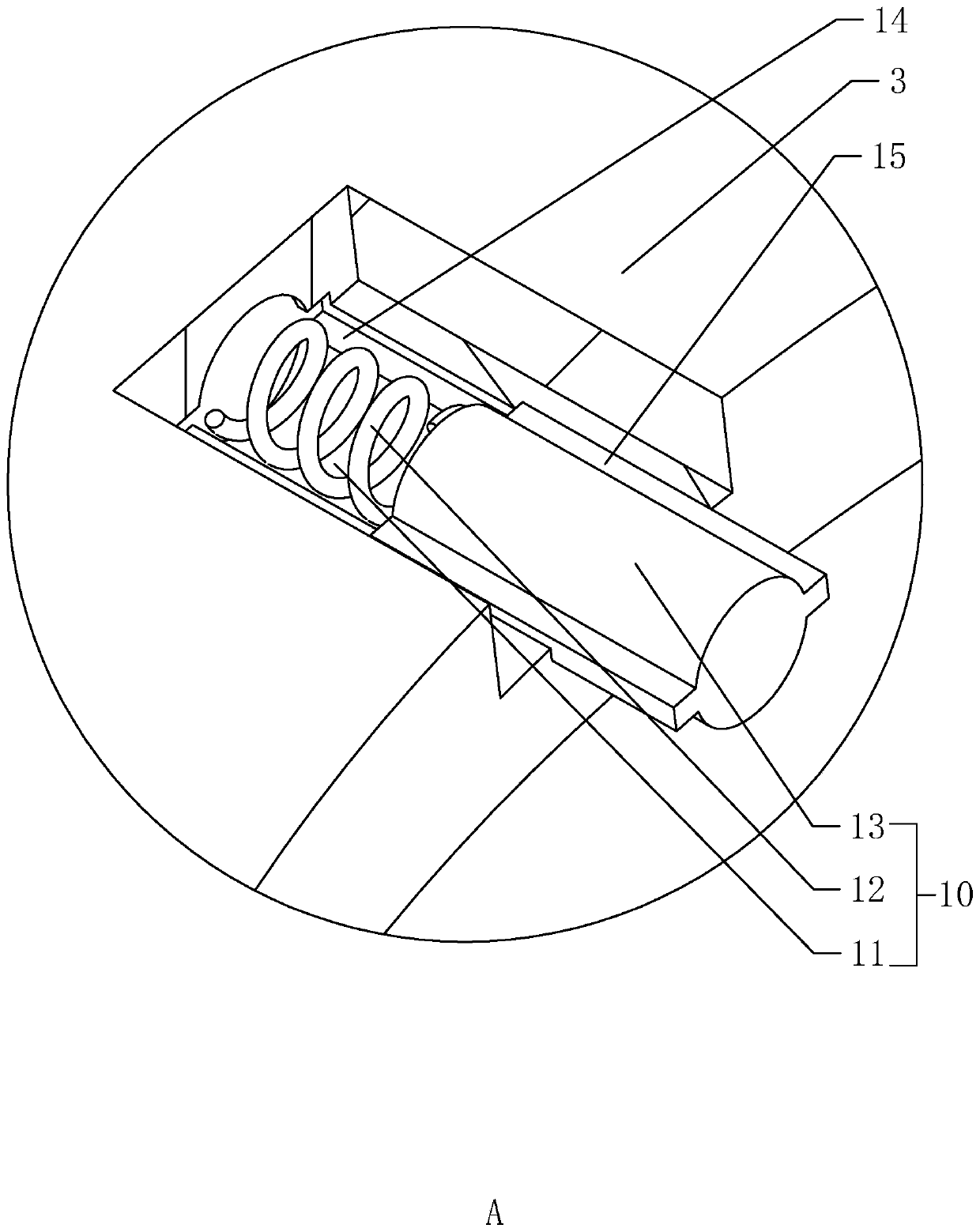

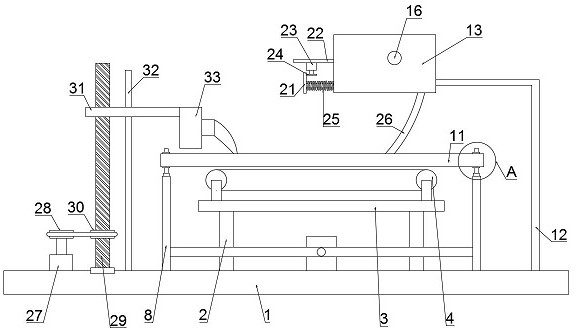

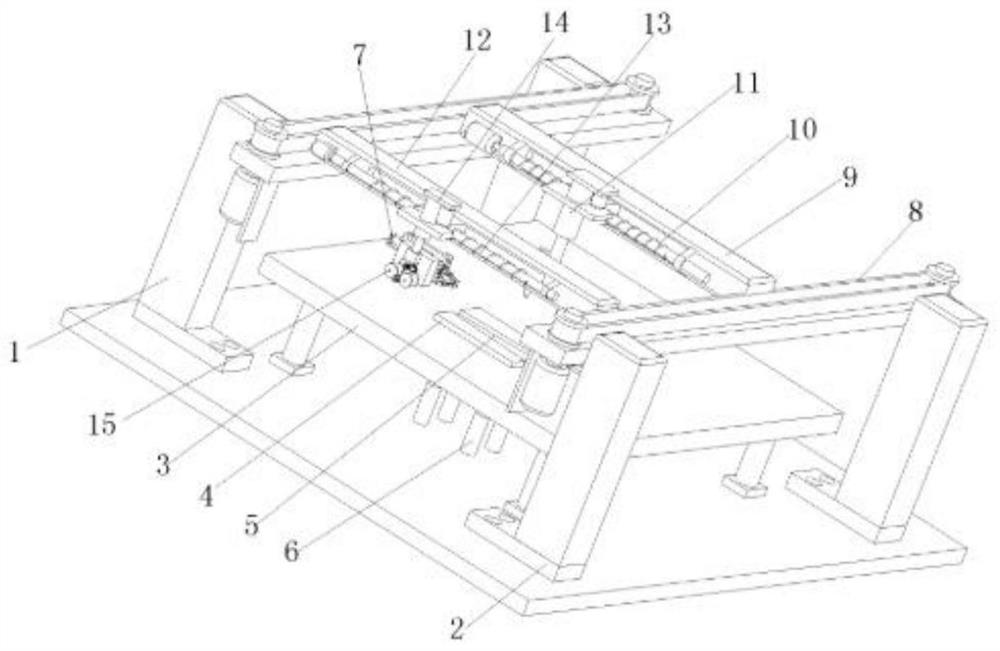

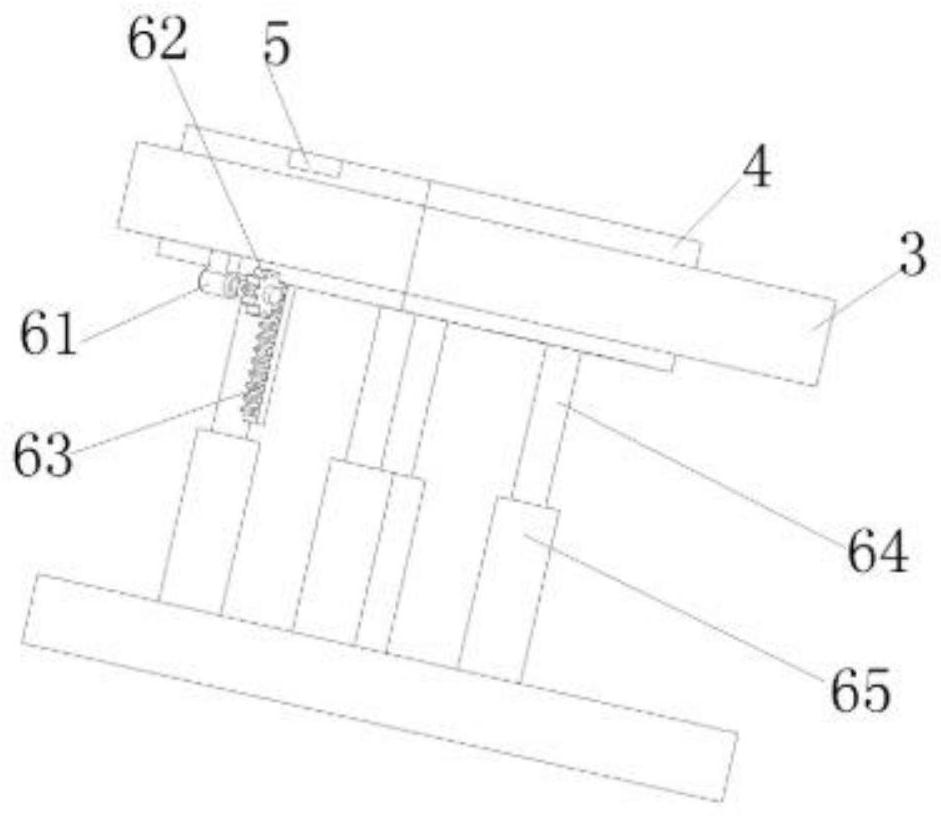

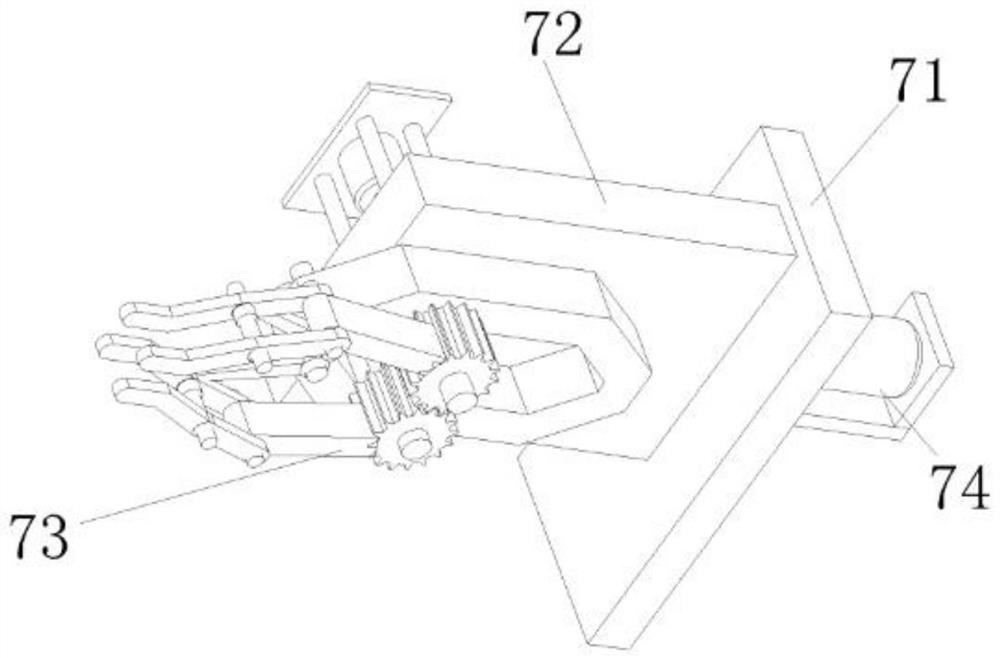

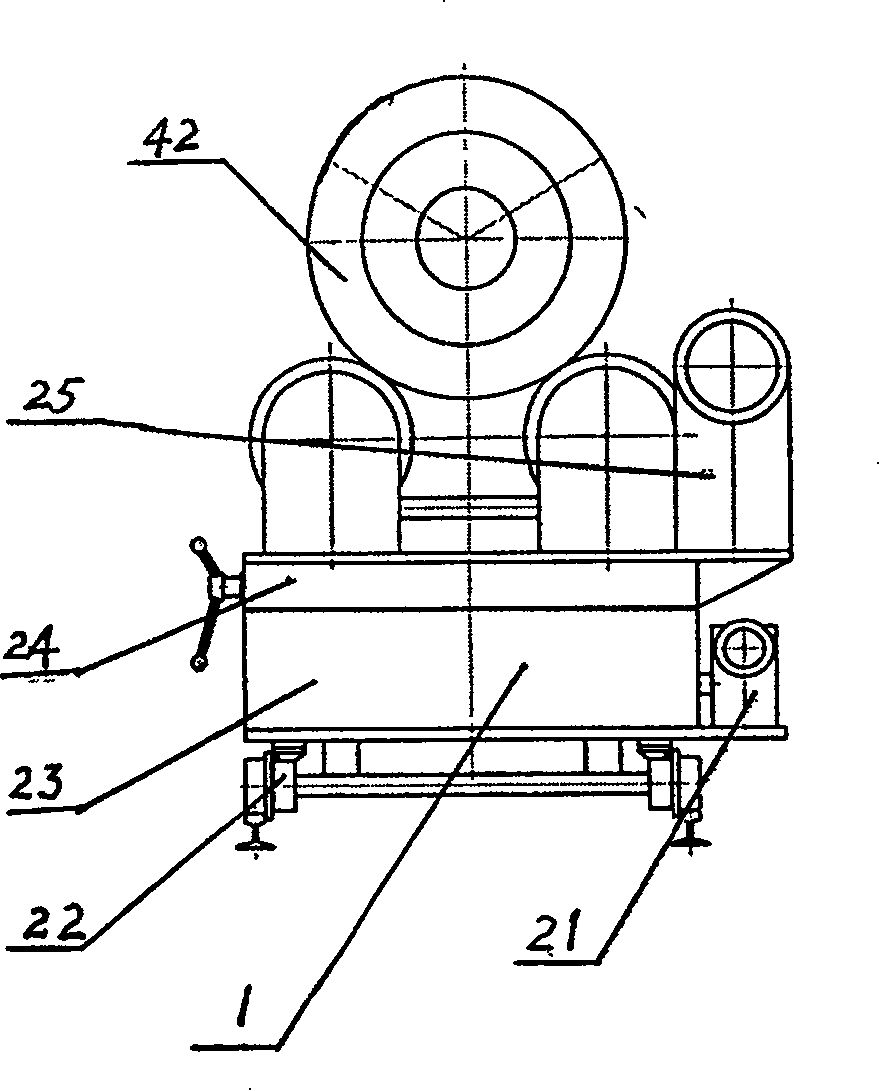

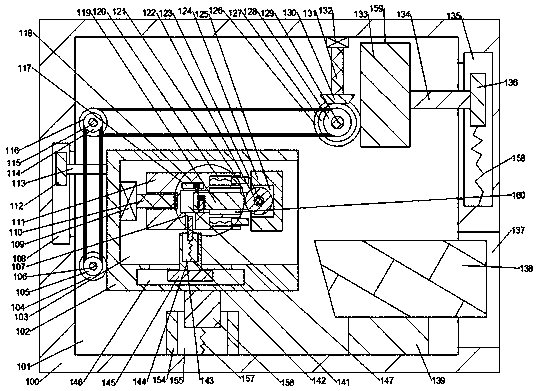

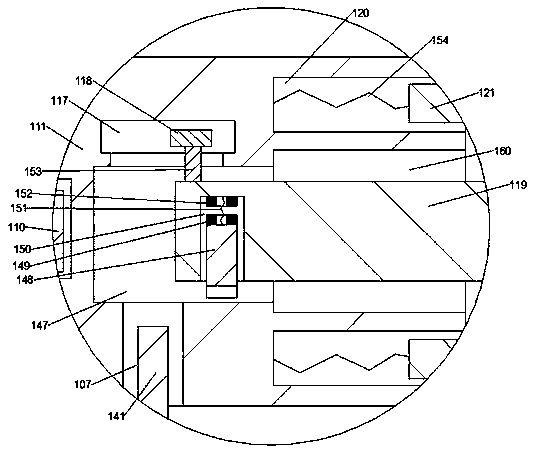

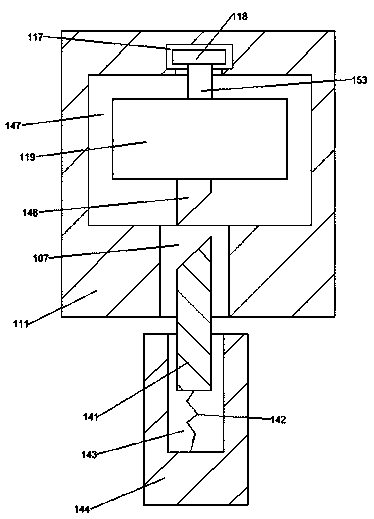

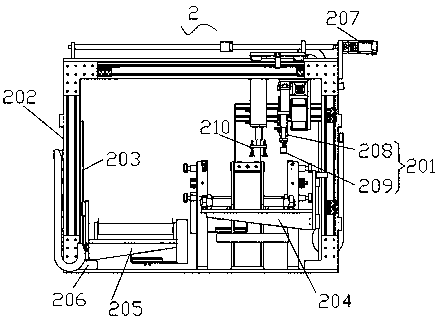

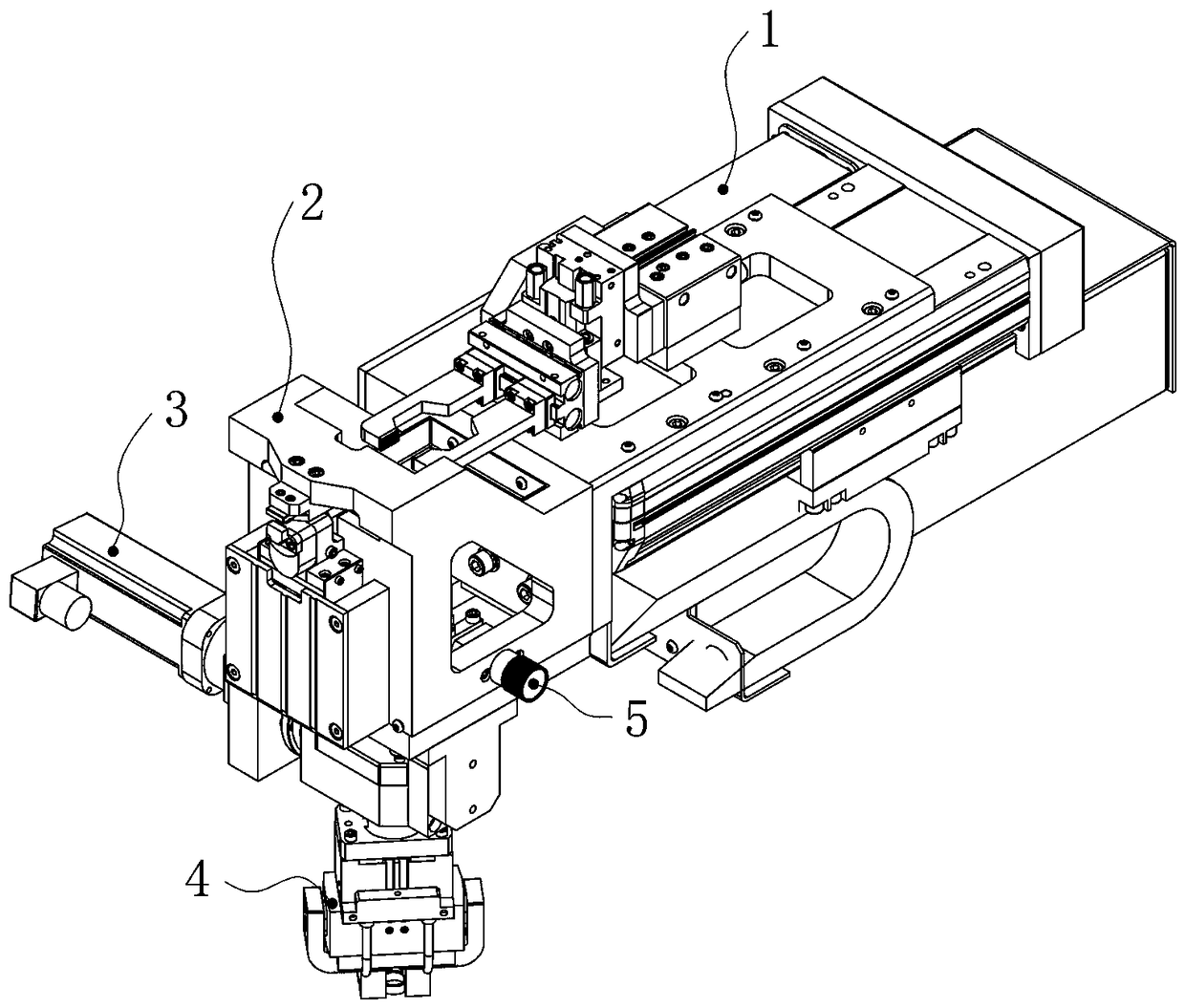

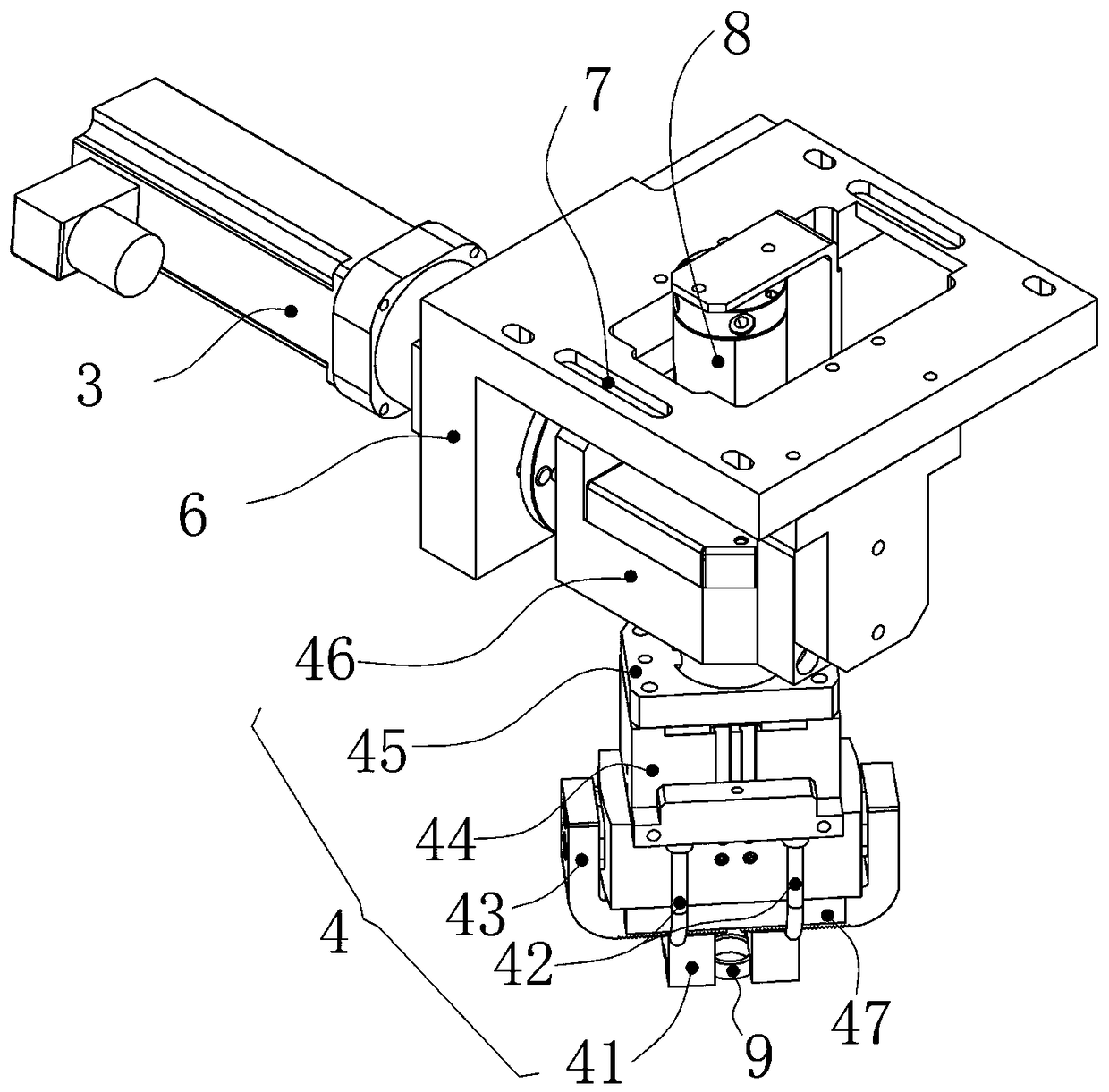

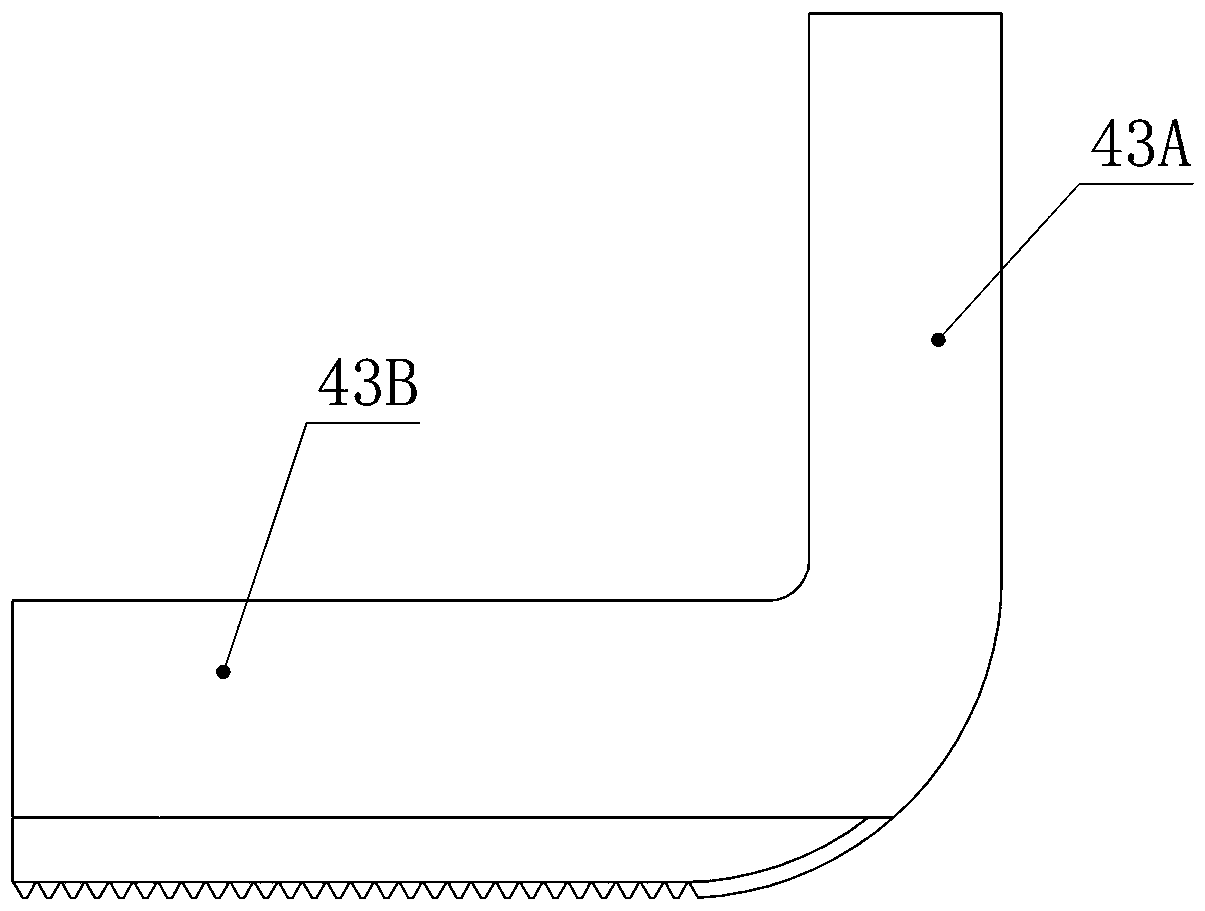

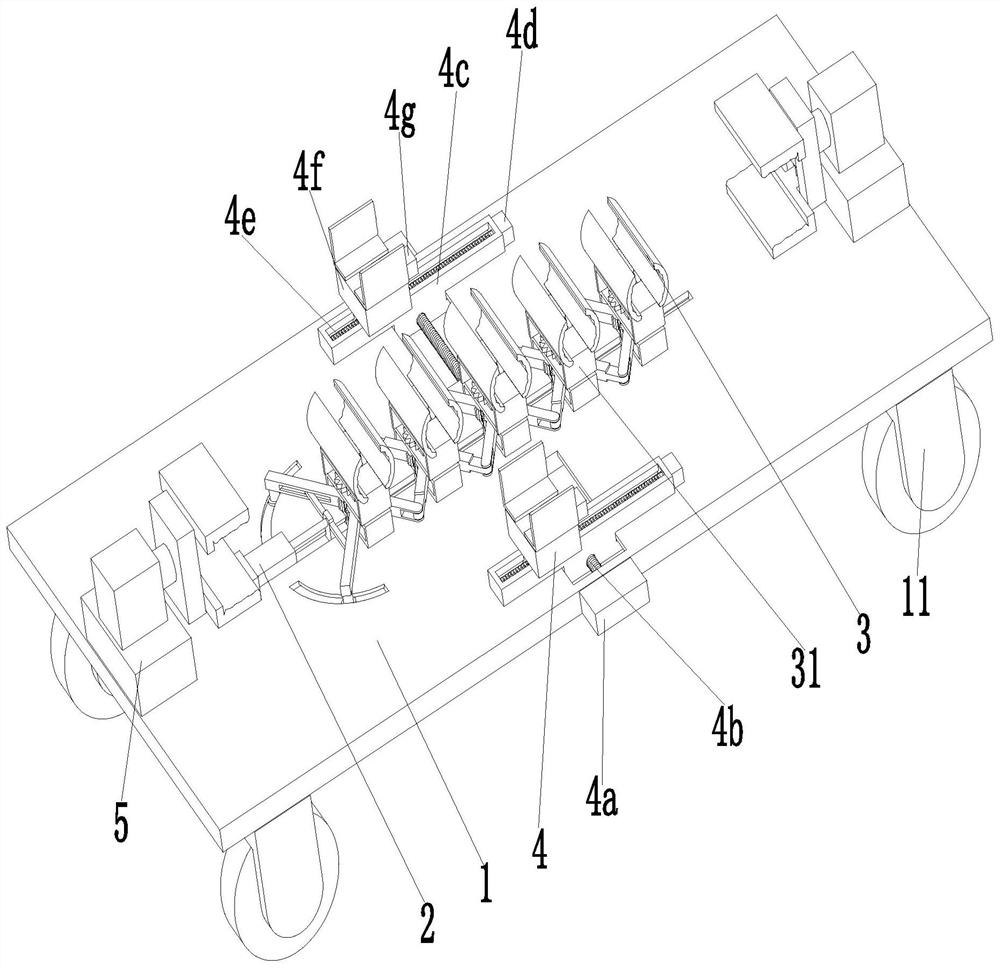

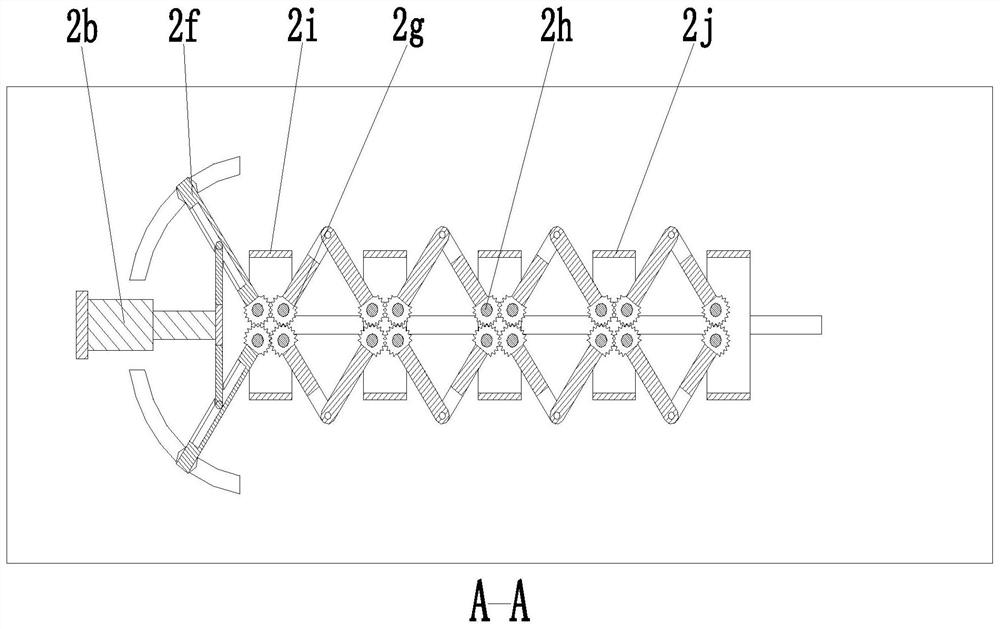

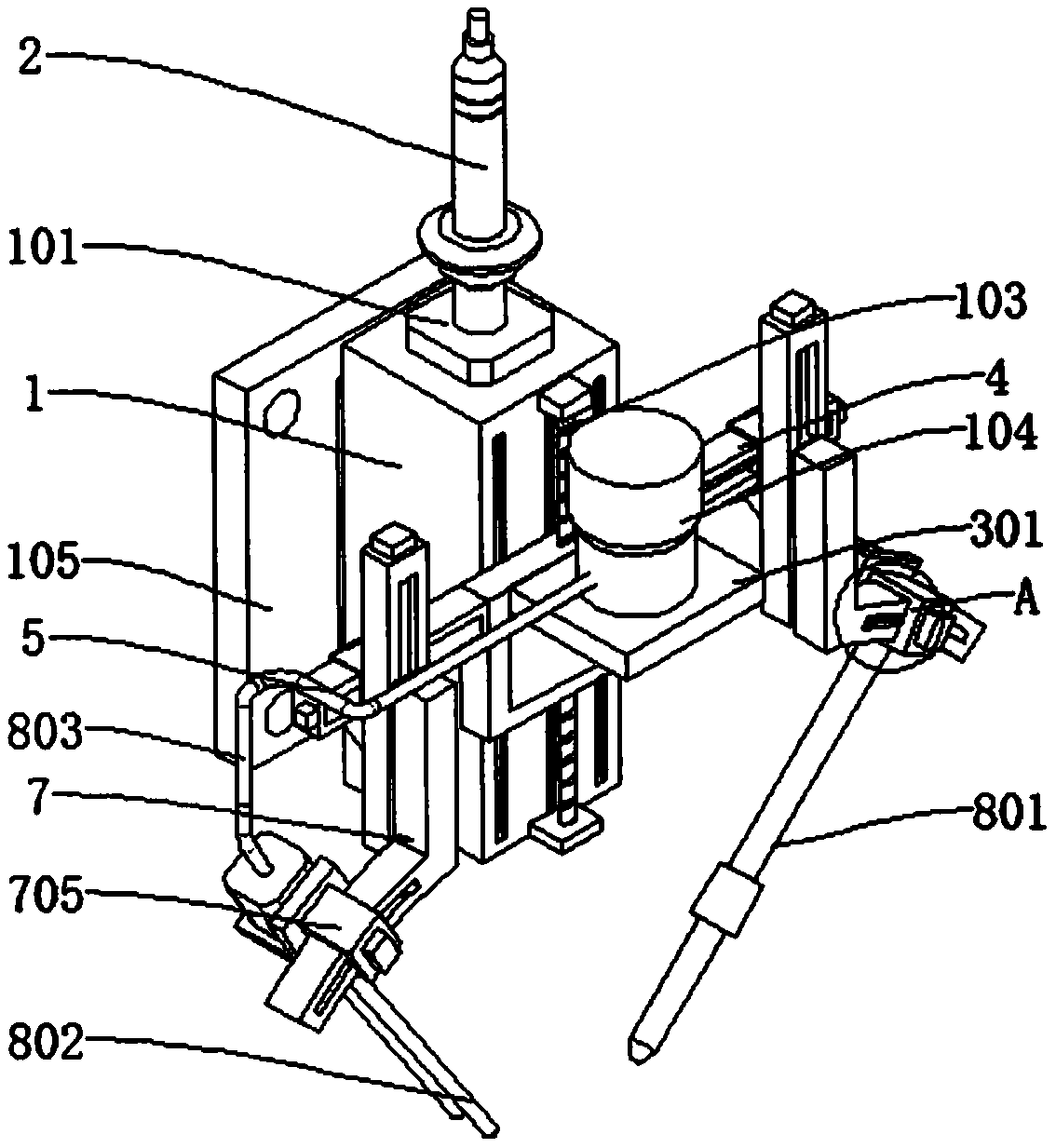

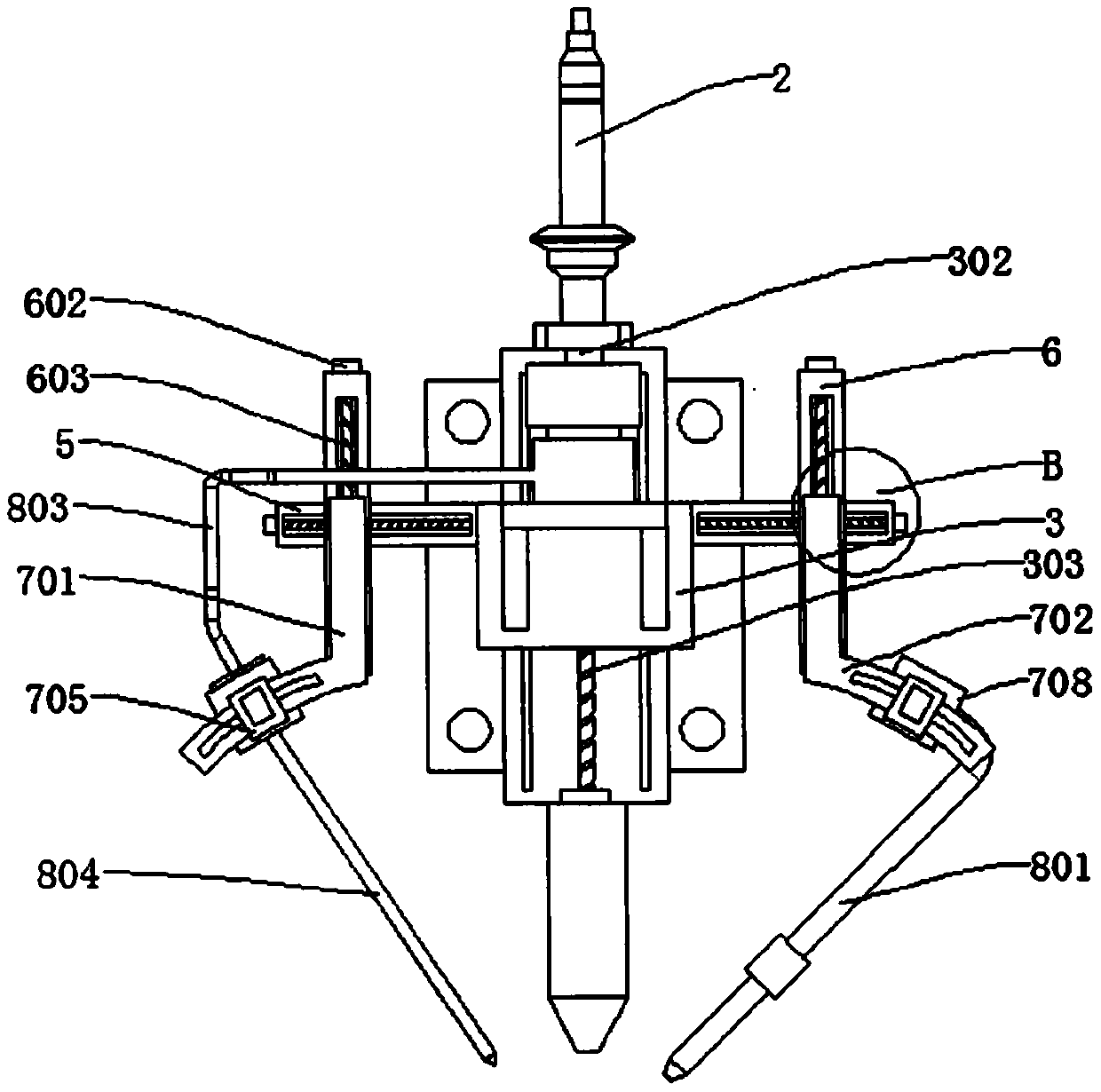

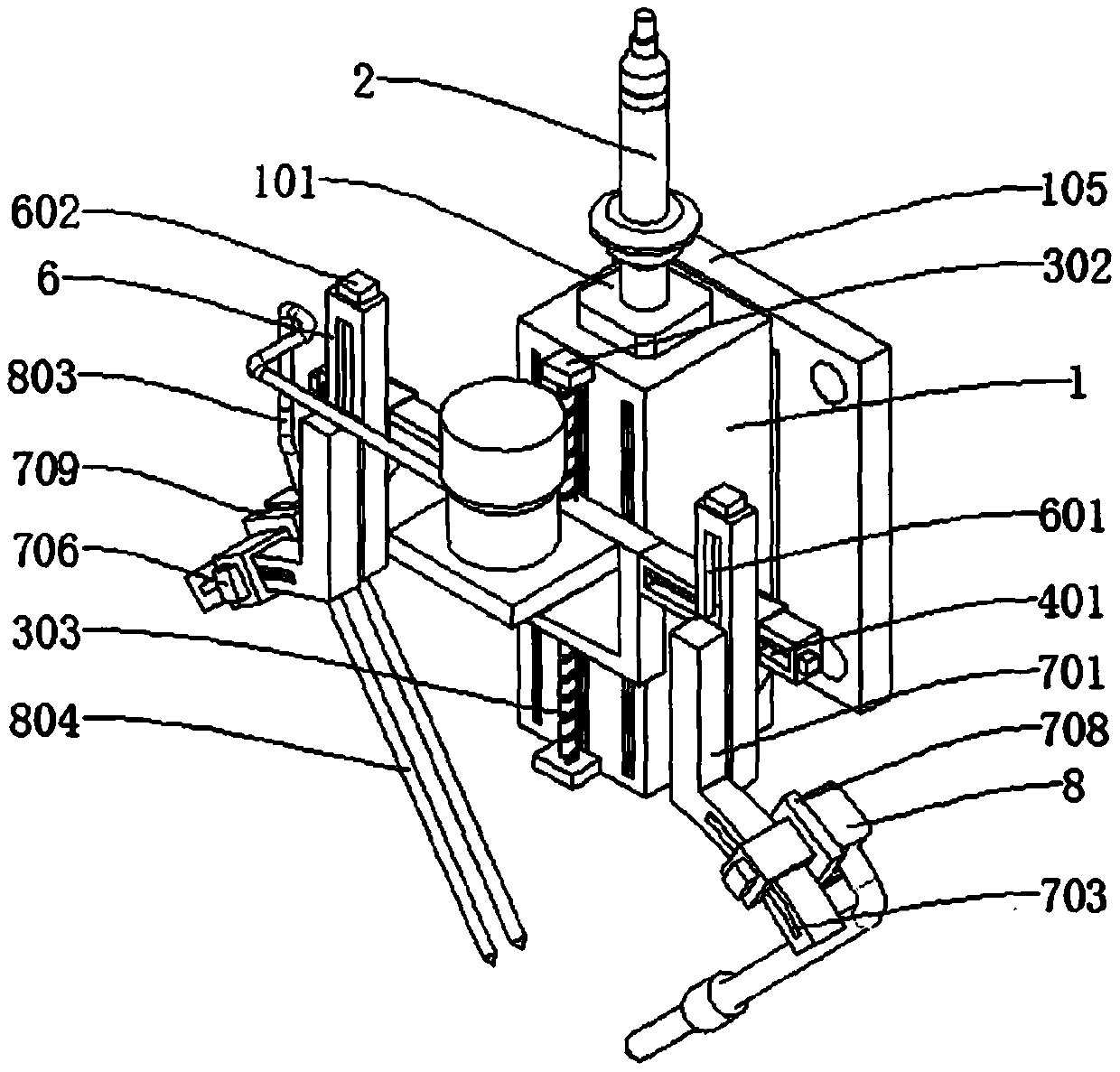

Multifunctional SAW type iron tower welding robot

InactiveCN108746938APrecise positioningFast working environmentWelding/cutting auxillary devicesElectrode supporting devicesNumerical controlSelf locking

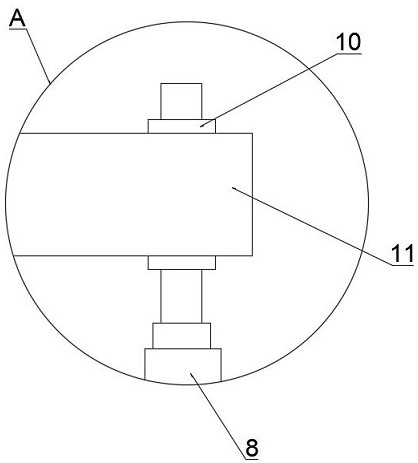

The invention discloses a multifunctional SAW type iron tower welding robot. The multifunctional SAW type iron tower welding robot comprises a base. A bending neck gun body for welding a workpiece ismounted above the base, and the bending neck gun body can be moved and rotated in multiple directions by an azimuth adjusting device. An L-shaped servo numerical control positioner for driving the multi-directional rotation of a welded part is arranged on one side of the azimuth adjusting device. The output end of the L-shaped servo numerical control positioner is fixedly connected with a self-locking four-point positioning mechanism for fixing the position of the welded part. The multifunctional SAW type iron tower welding robot has the advantages of good welding action stability, accurate and quick workpiece positioning, high welding speed, good welding line quality, high production efficiency and the like.

Owner:于涛

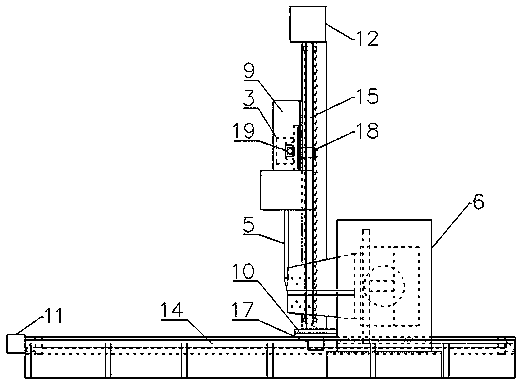

Laser sealed welding method for L-waveband power amplifier cavity

InactiveCN107433392AImprove the one-time pass rateNo influence on welding qualityLaser beam welding apparatusAudio power amplifierCost savings

The invention discloses a laser sealed welding method for an L-waveband power amplifier cavity. The laser sealed welding method for the L-waveband power amplifier cavity comprises the following steps: step 1, examining matching between a cavity of a power amplifier to be welded and a cover plate; step 2, cleaning the cavity of the power amplifier to be welded and the cover plate; step 3, baking the power amplifier to be welded and the cover plate in a vacuum oven; step 4, welding the baked cover plate to the cavity of the power amplifier to be welded; and step 5, examining a welded part. By the laser sealed welding method, one-time qualified rate of laser seal welding is increased; and the laser sealed welding method plays an important role in cost saving, efficiency improving and product improving.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

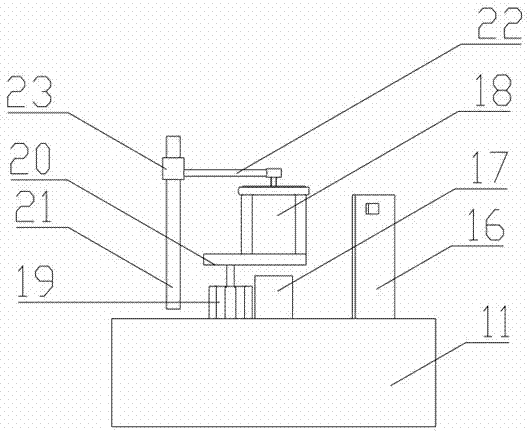

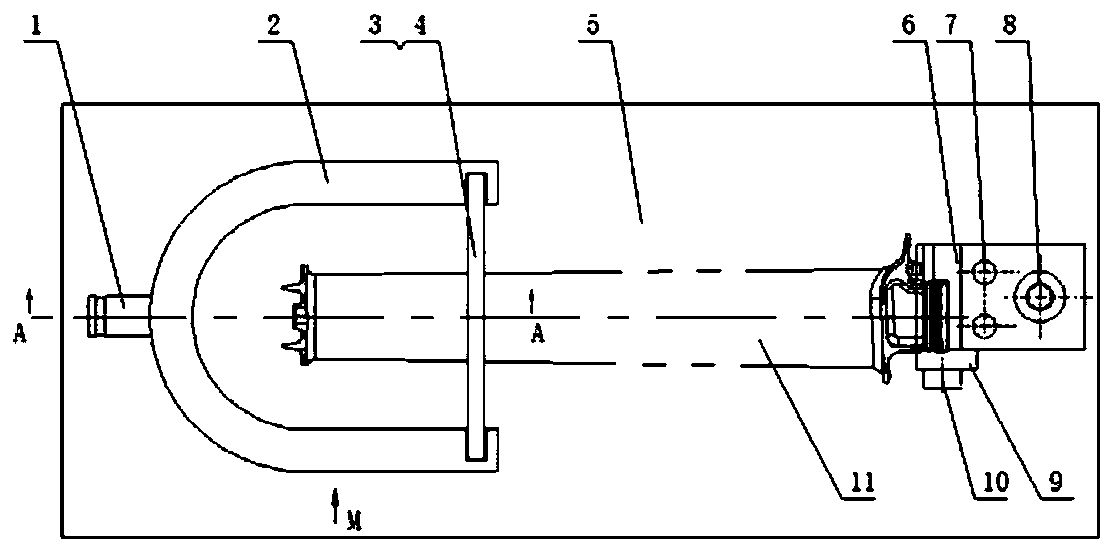

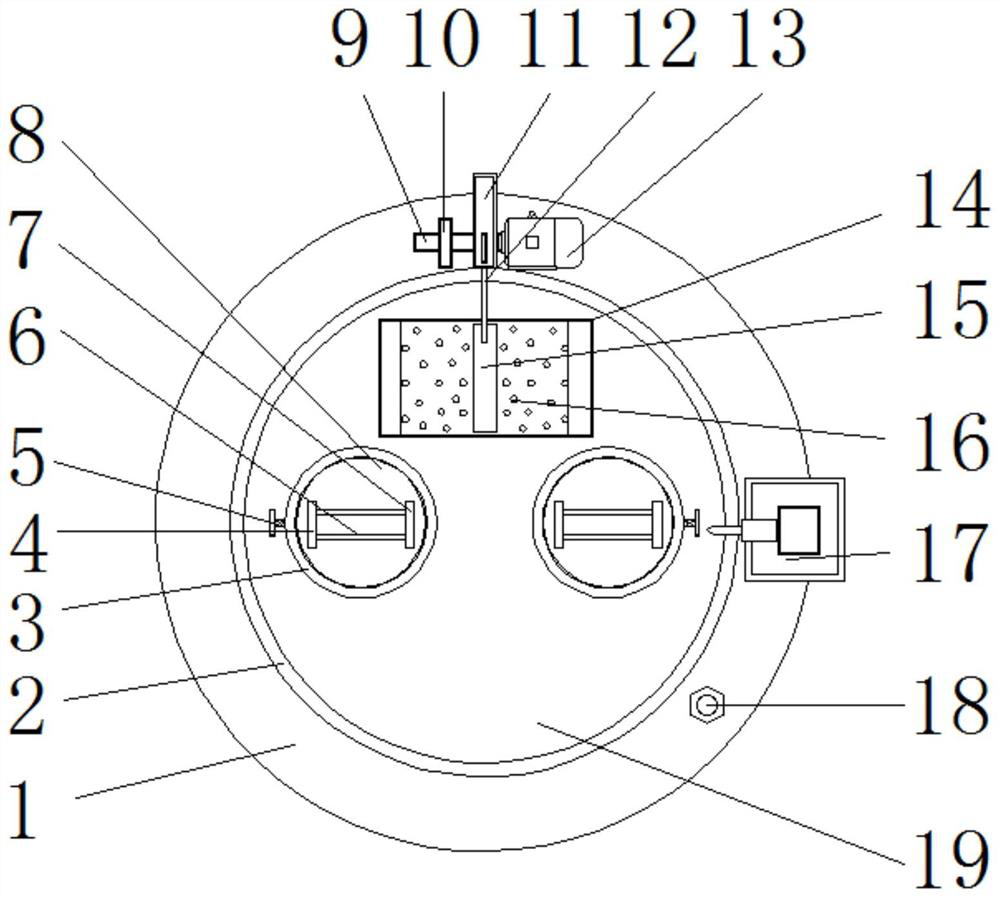

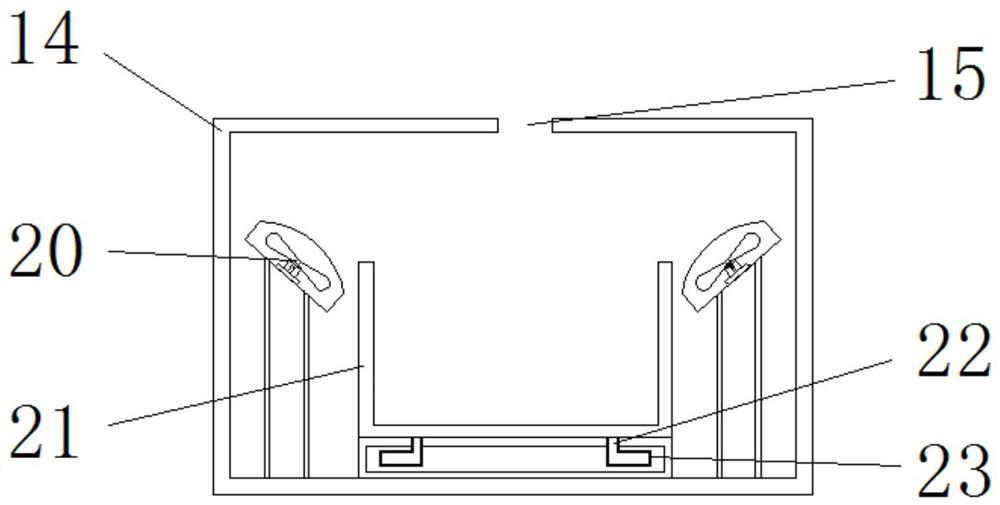

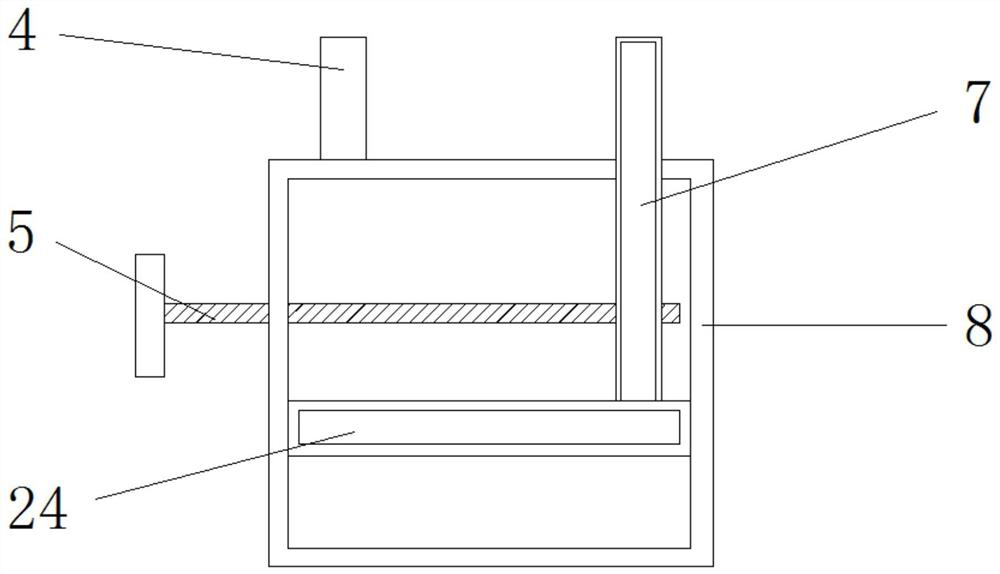

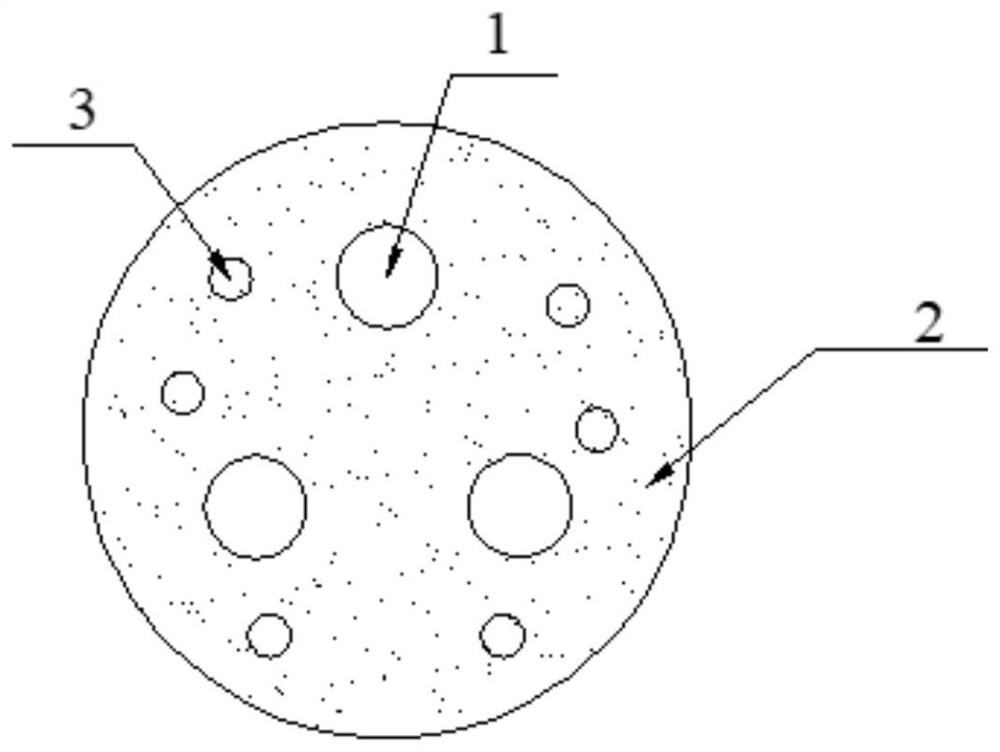

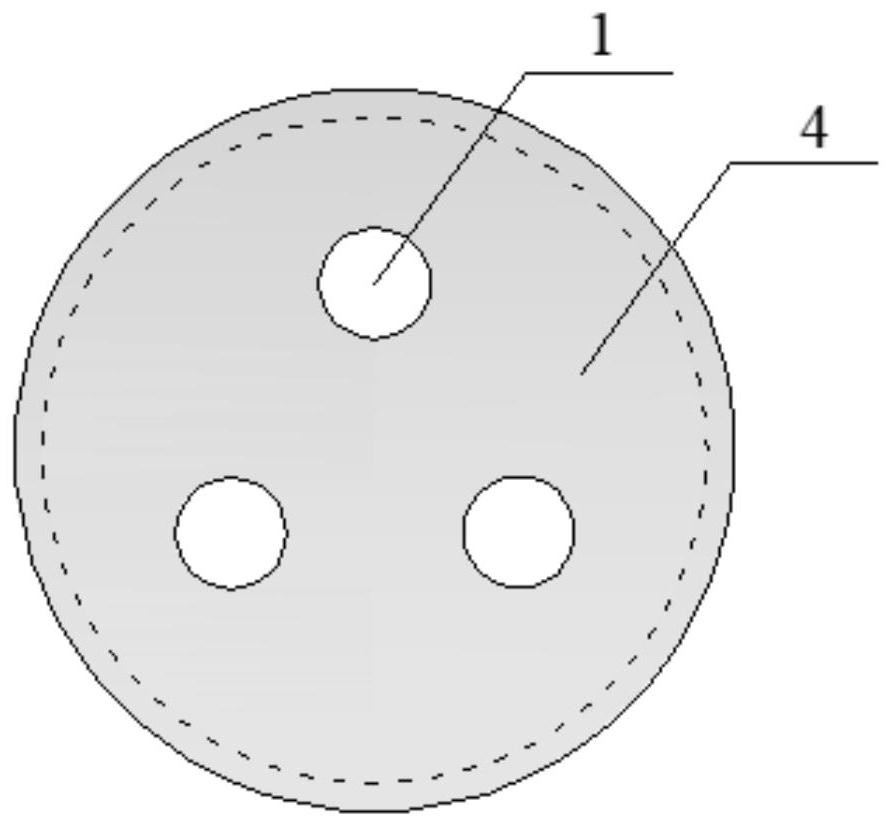

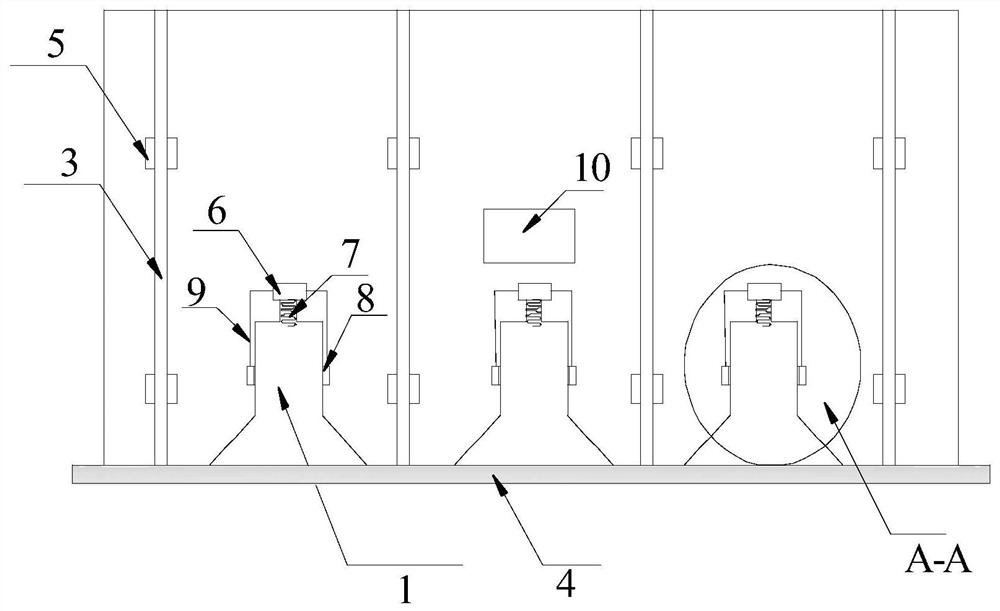

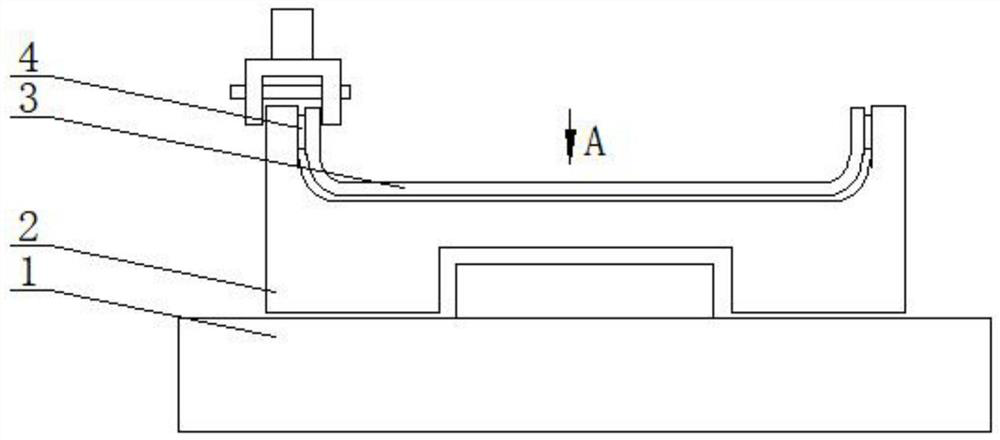

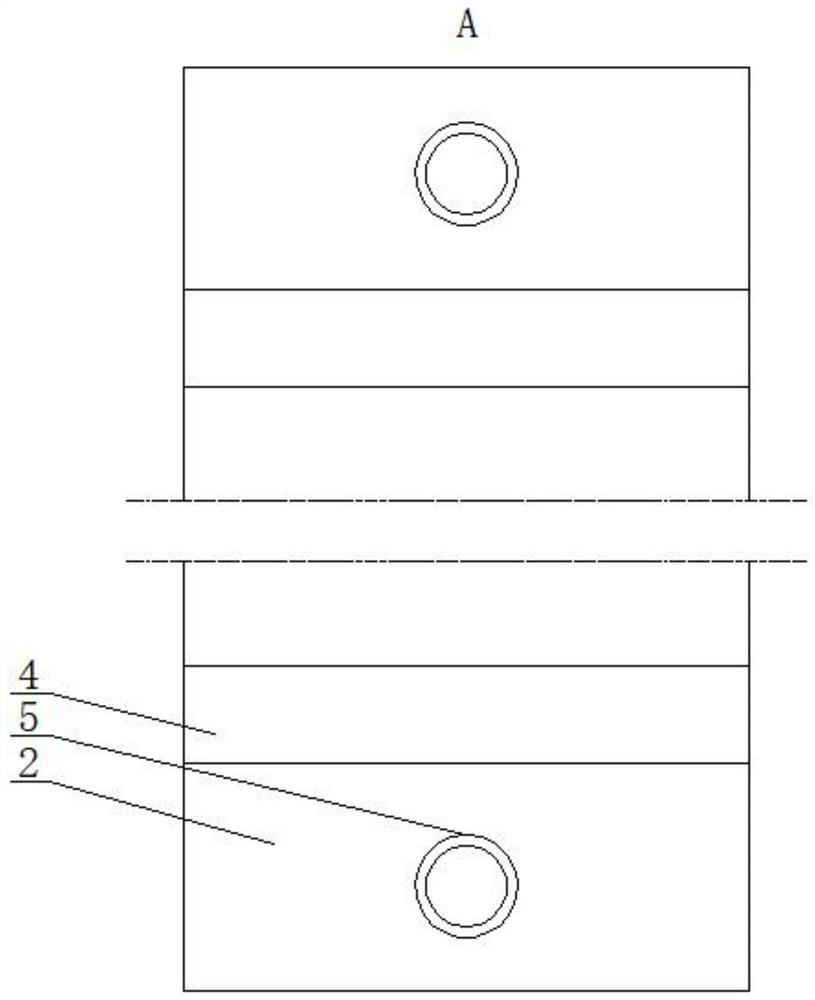

Equipment for automatically welding vacuum corrugated pipe

InactiveCN102500859AEasy to operateEasy maintenanceMetal working apparatusSoldering auxillary devicesProgrammable logic controllerArchitectural engineering

The invention discloses equipment for automatically welding a vacuum corrugated pipe. According to a fixture for automatically welding the corrugated pipe, a round fixture fixing base is adopted; 12 equant round holes are formed in the round fixture fixing base; a fixed baffle plate is arranged between any two adjacent round holes; proximity switches are respectively arranged on two sides of eachfixed baffle plate along a circumferential direction; an air exhaust hole is formed in the round fixture fixing base, and a hollow shaft is arranged in the center of the round fixture fixing base; anair cylinder is fixed on the base on the side face of the hollow shaft; a baffle plate is arranged on a main shaft of the air cylinder; a stepping motor is fixed on the baffle plate; one end of a link rod is connected with a main shaft of the motor, and the other end of the link rod is connected with a welding pen sleeve; a welding pen is vertically arranged in the welding pen sleeve; one end of a power line and one end of an air source line are introduced from the hollow shaft, and are connected with the stepping motor and the air cylinder respectively; and the other end of the power line and the other end of the air source line are connected with an air pump and a programmable logic controller (PLC) respectively. According to the equipment, the shortcomings of low welding precision, complicated operation, high time consumption, low efficiency and high equipment abrasion during manual welding of the corrugated pipe and the shortcoming that the welding quality and the welding speed are limited by the technical level of operators are overcome.

Owner:CHINA JILIANG UNIV

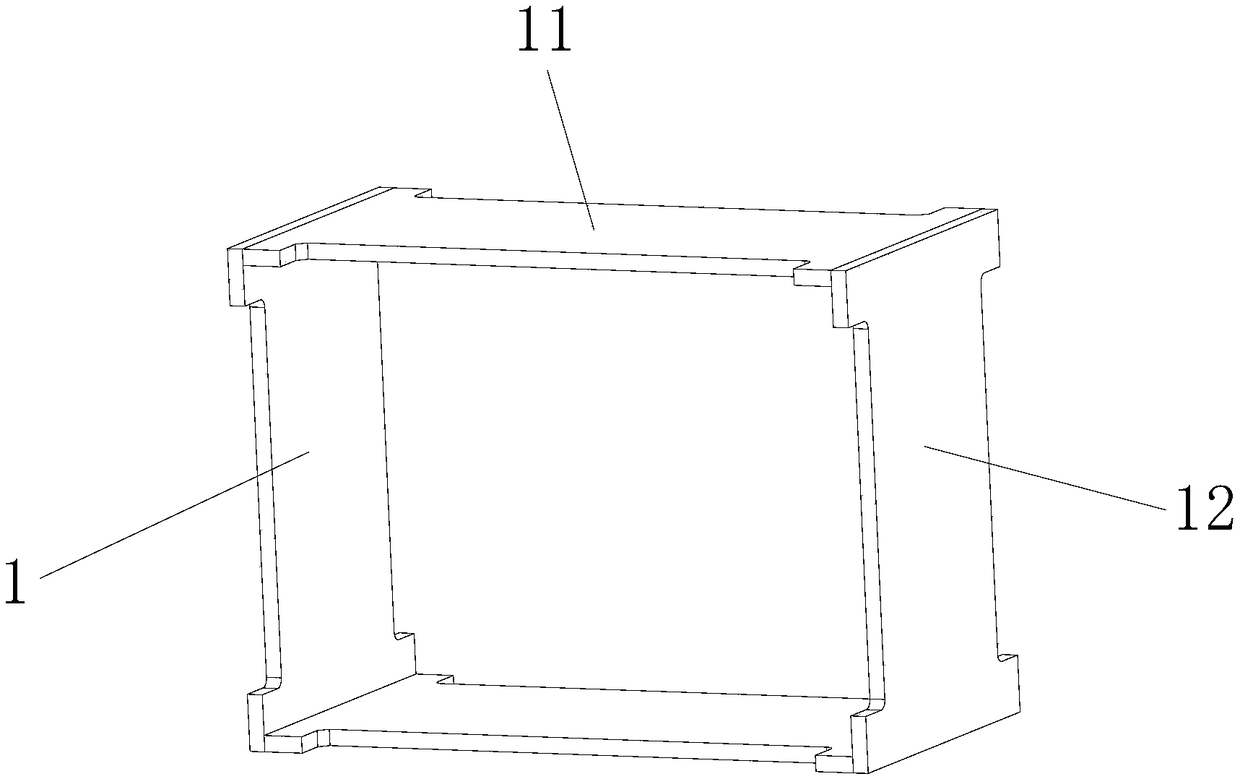

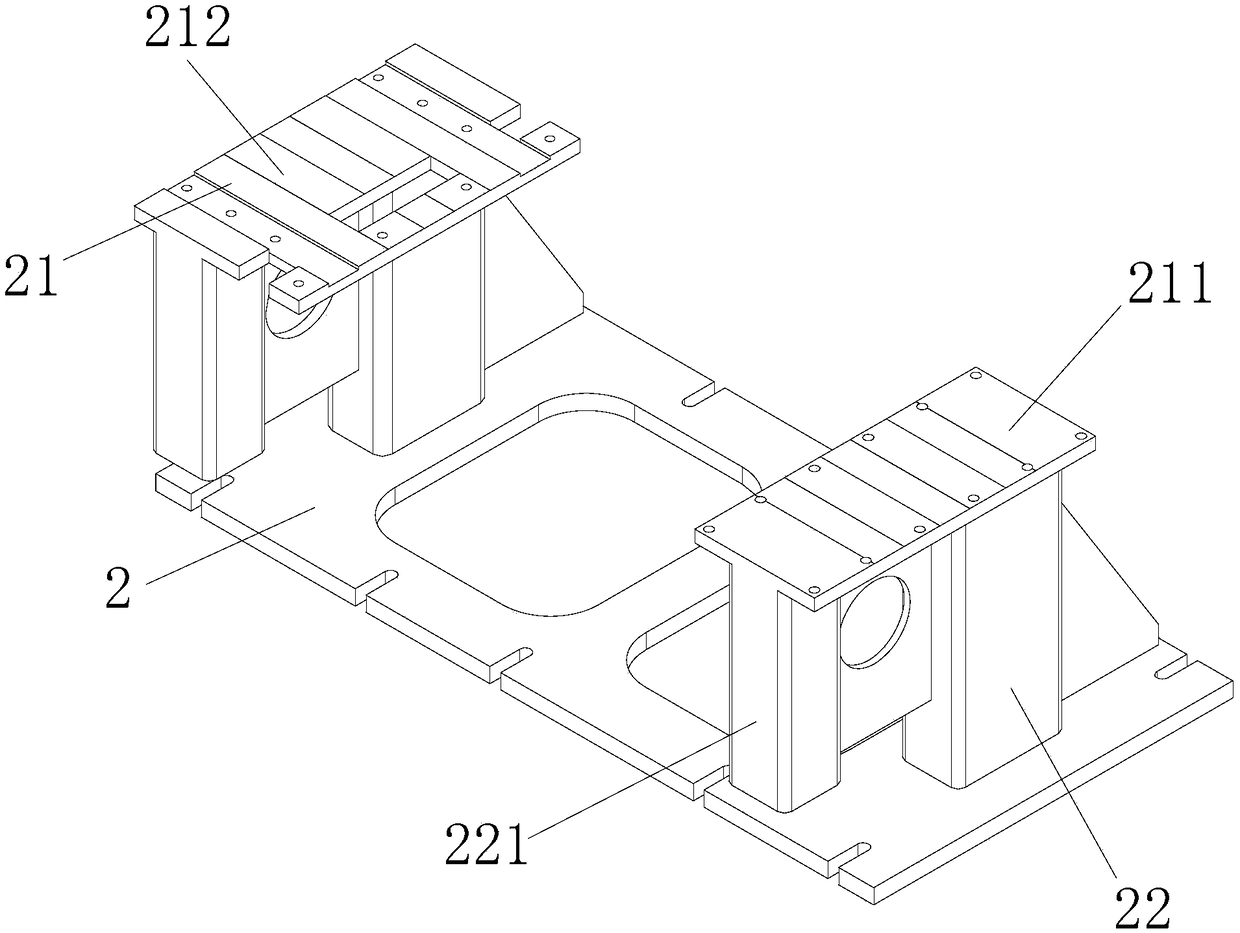

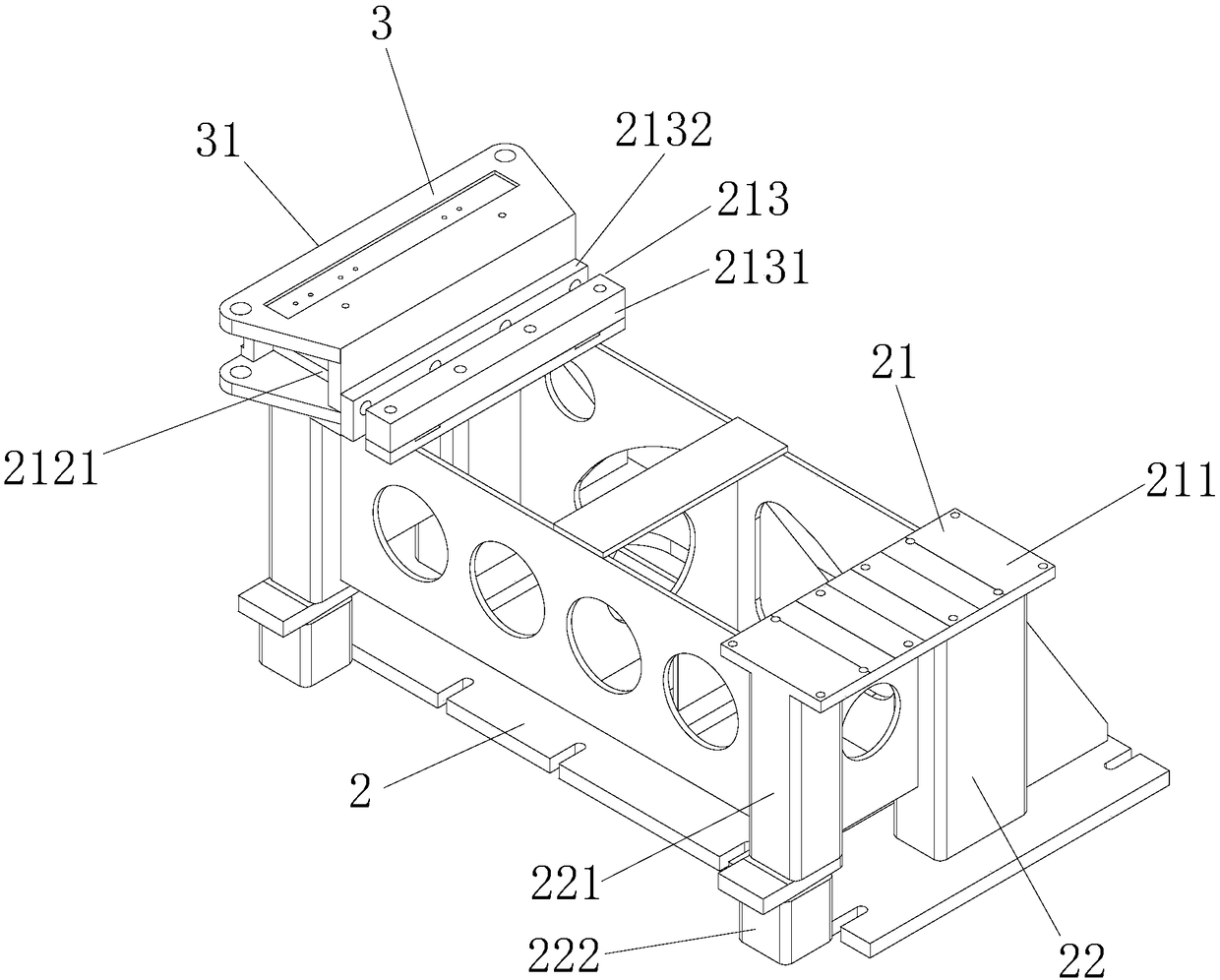

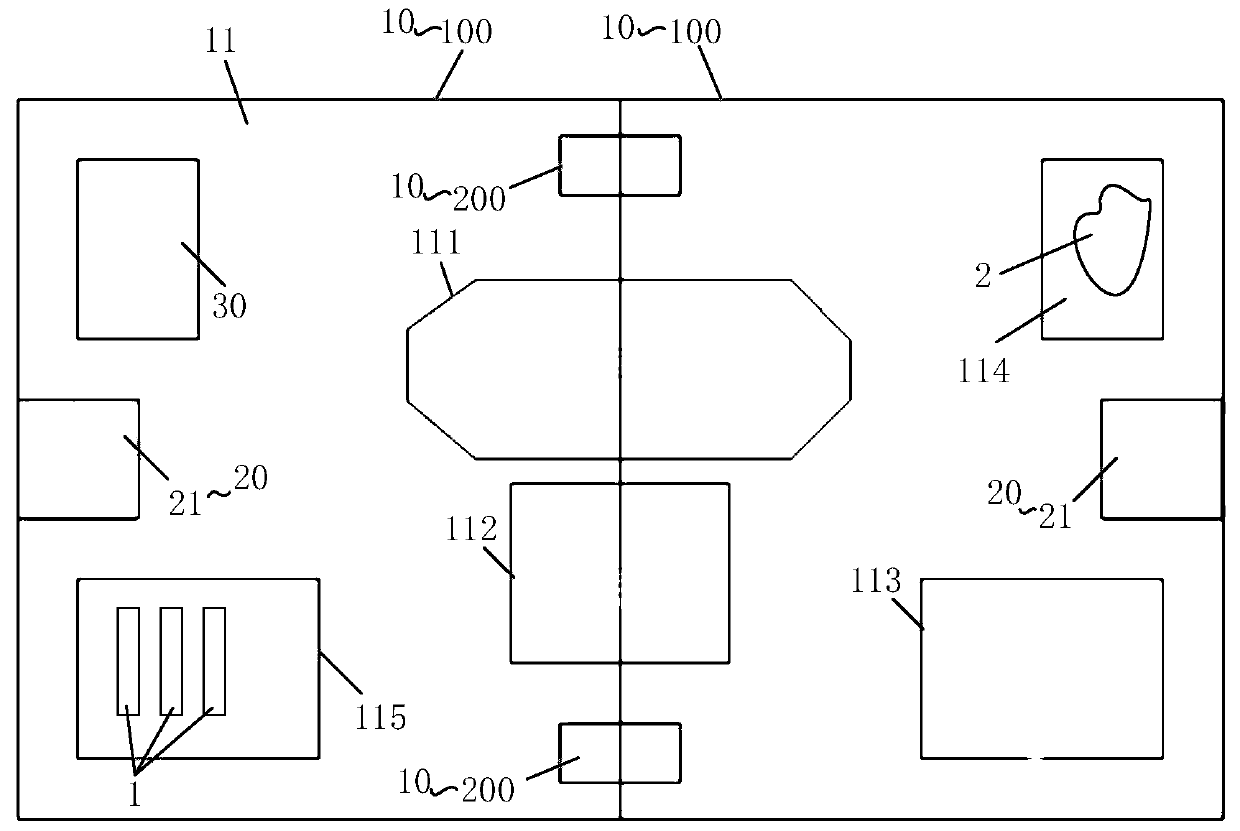

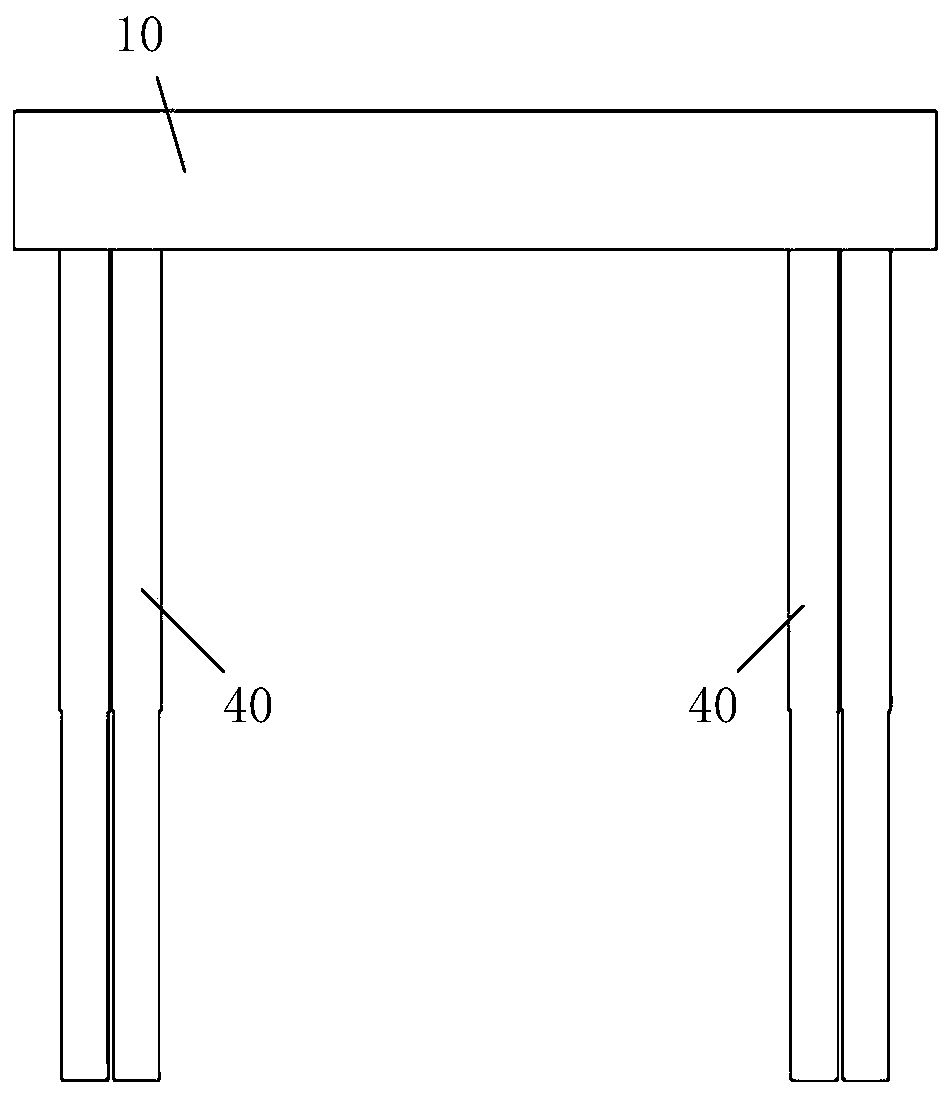

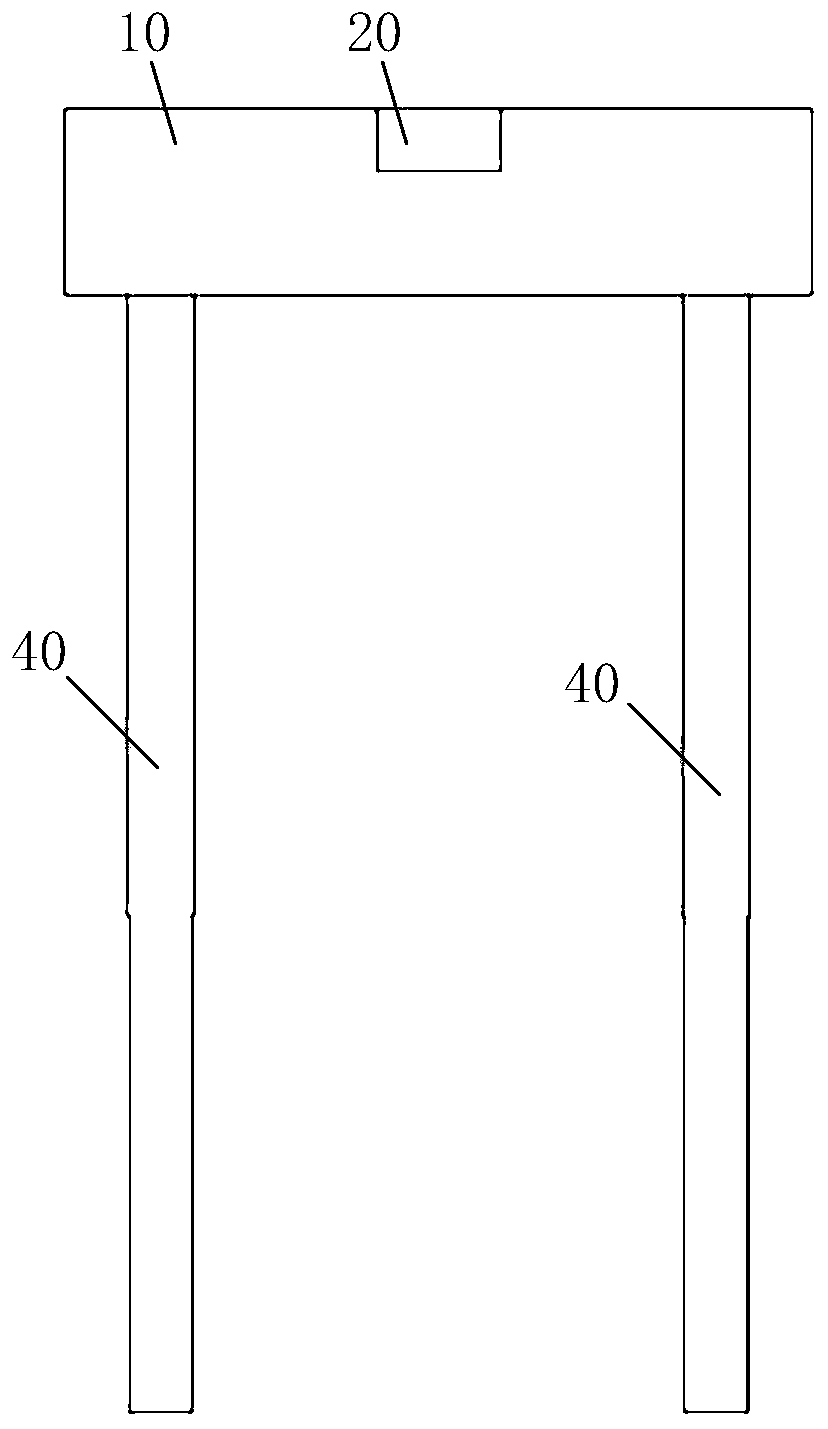

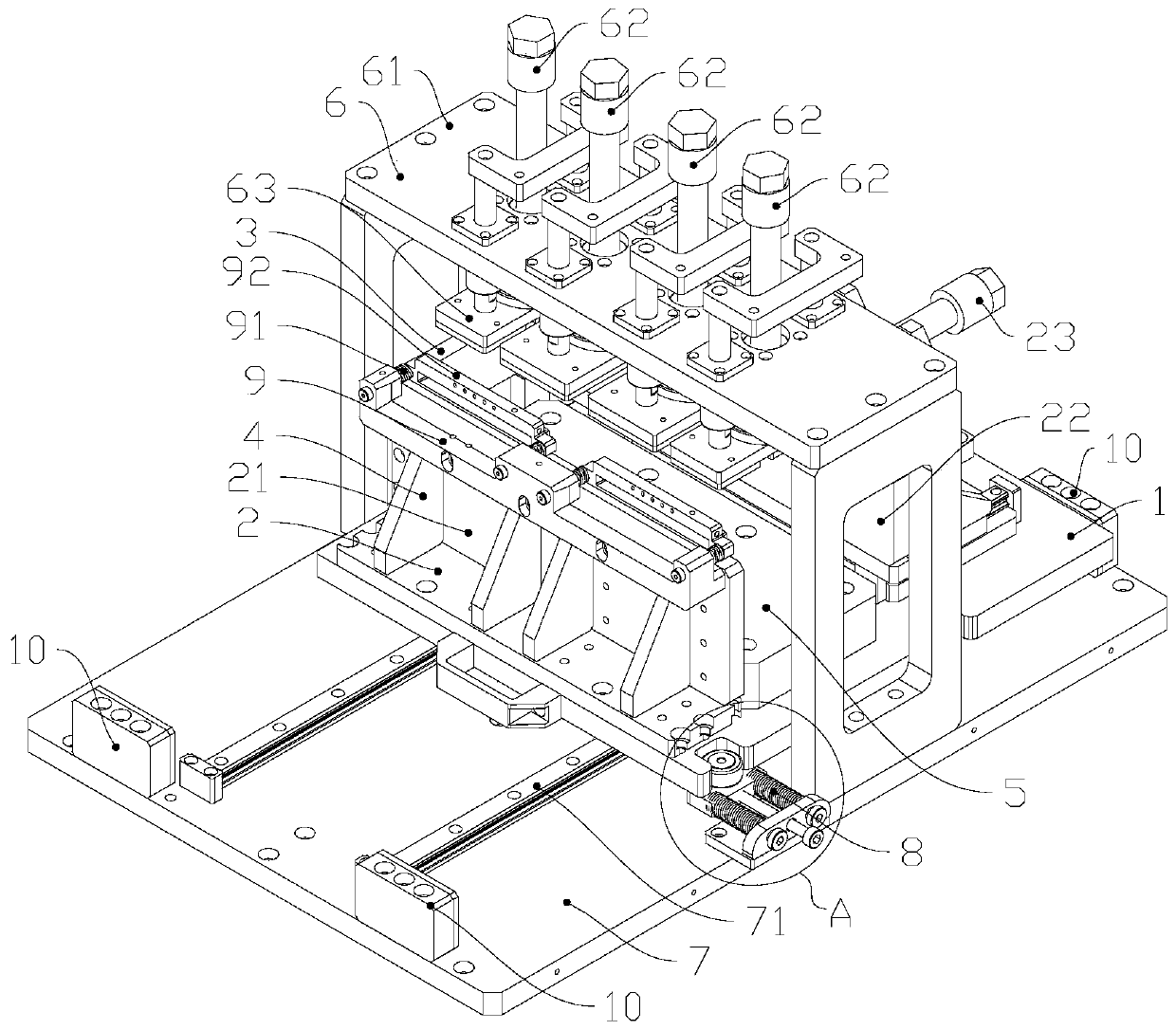

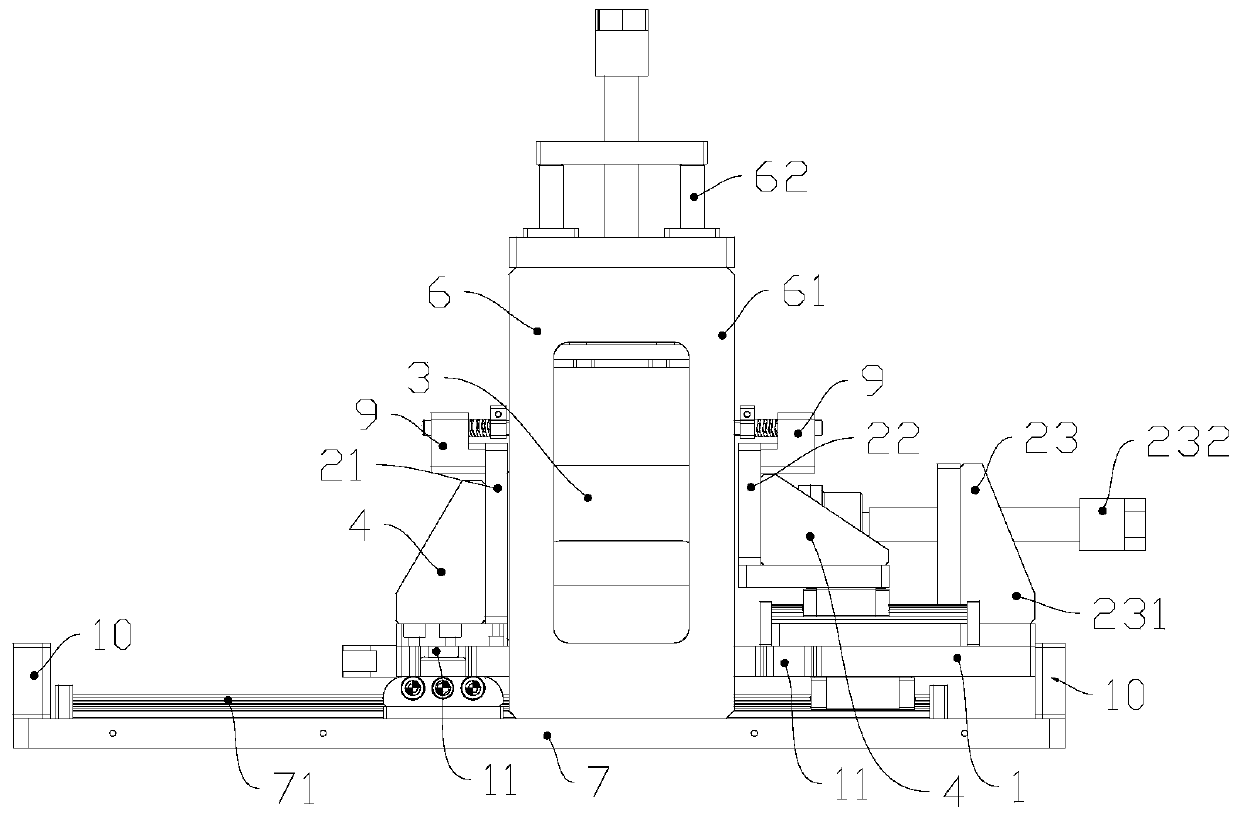

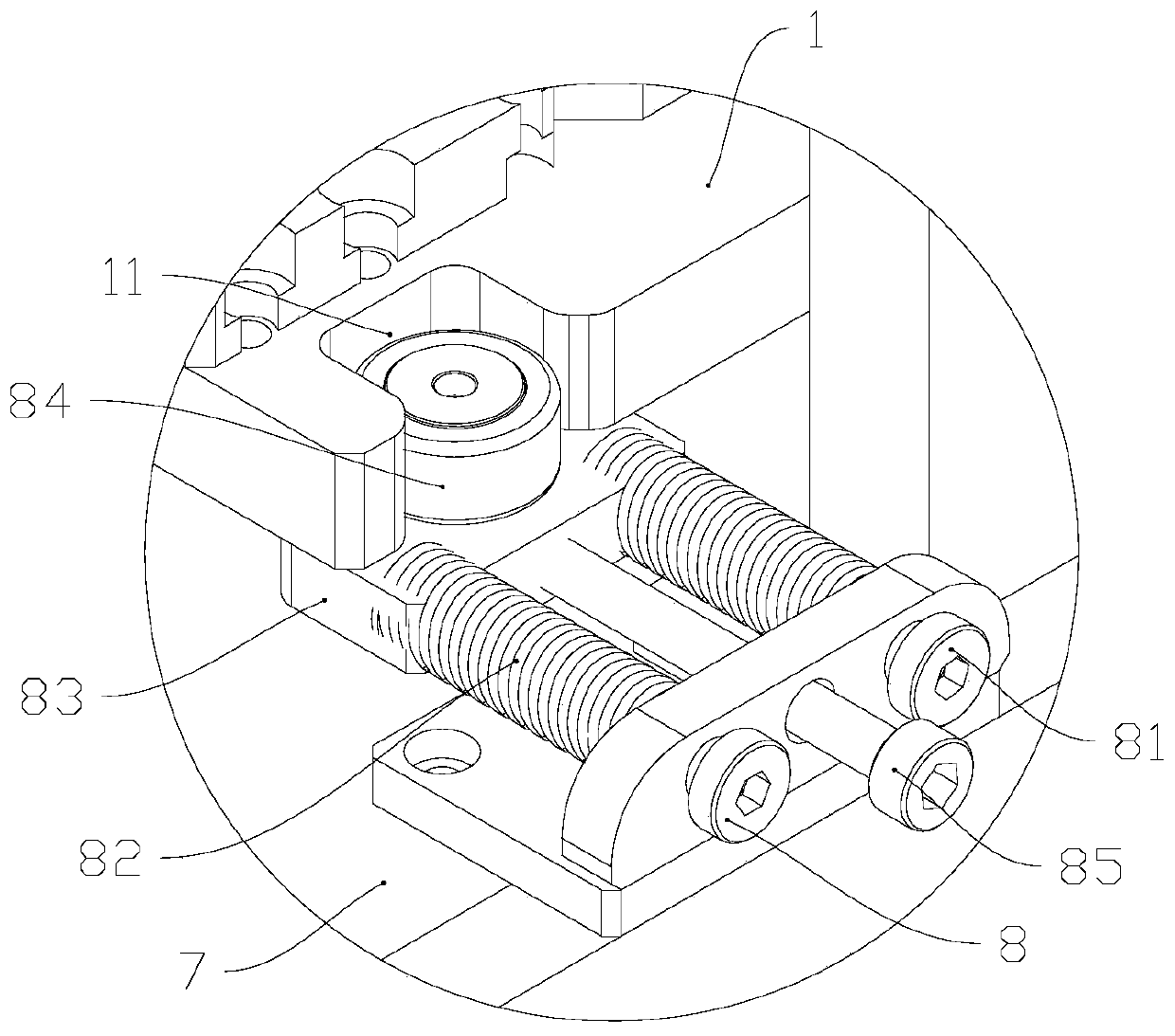

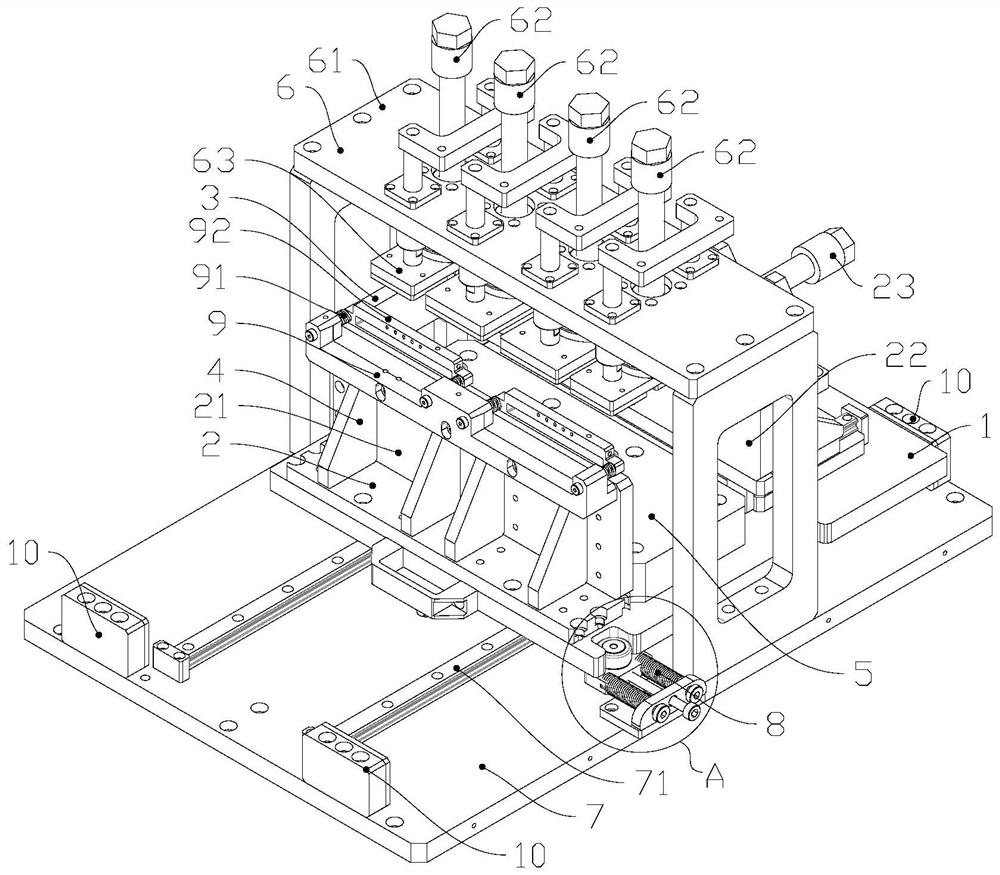

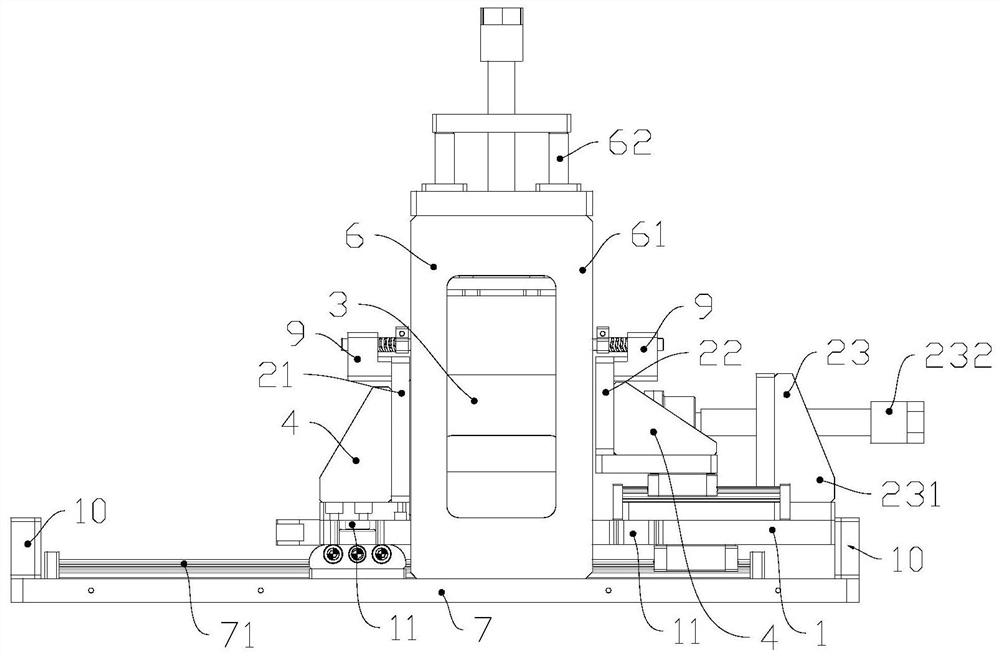

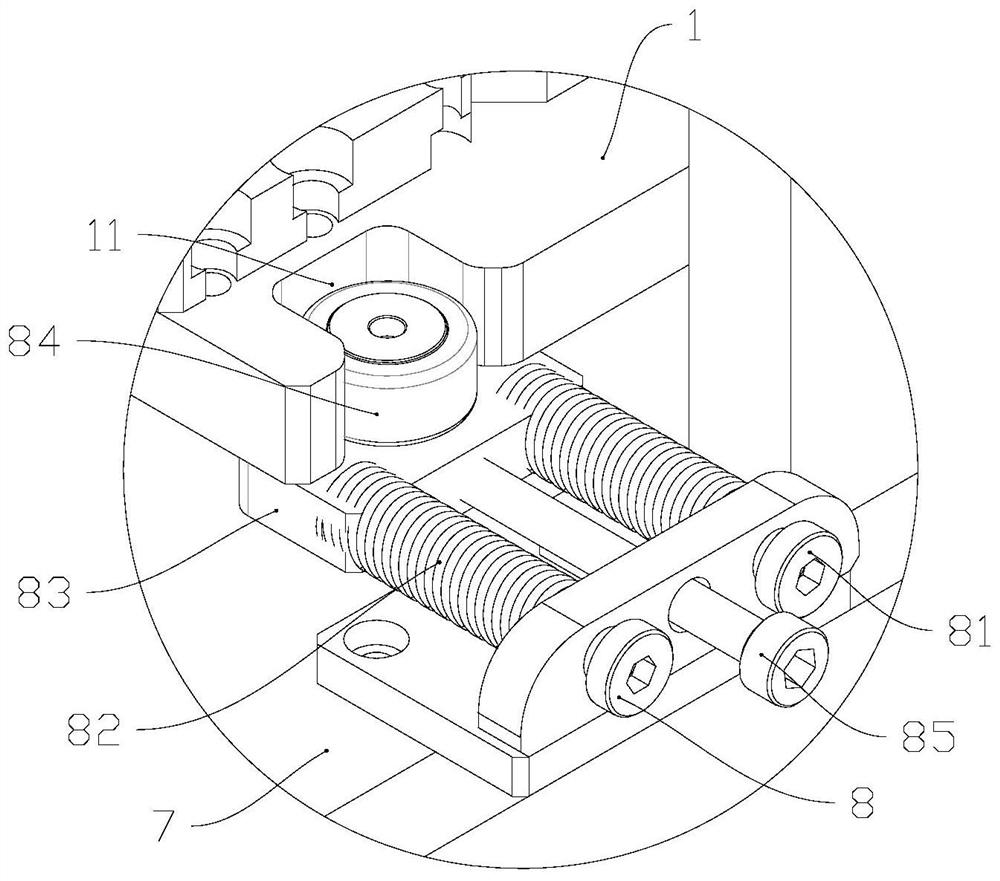

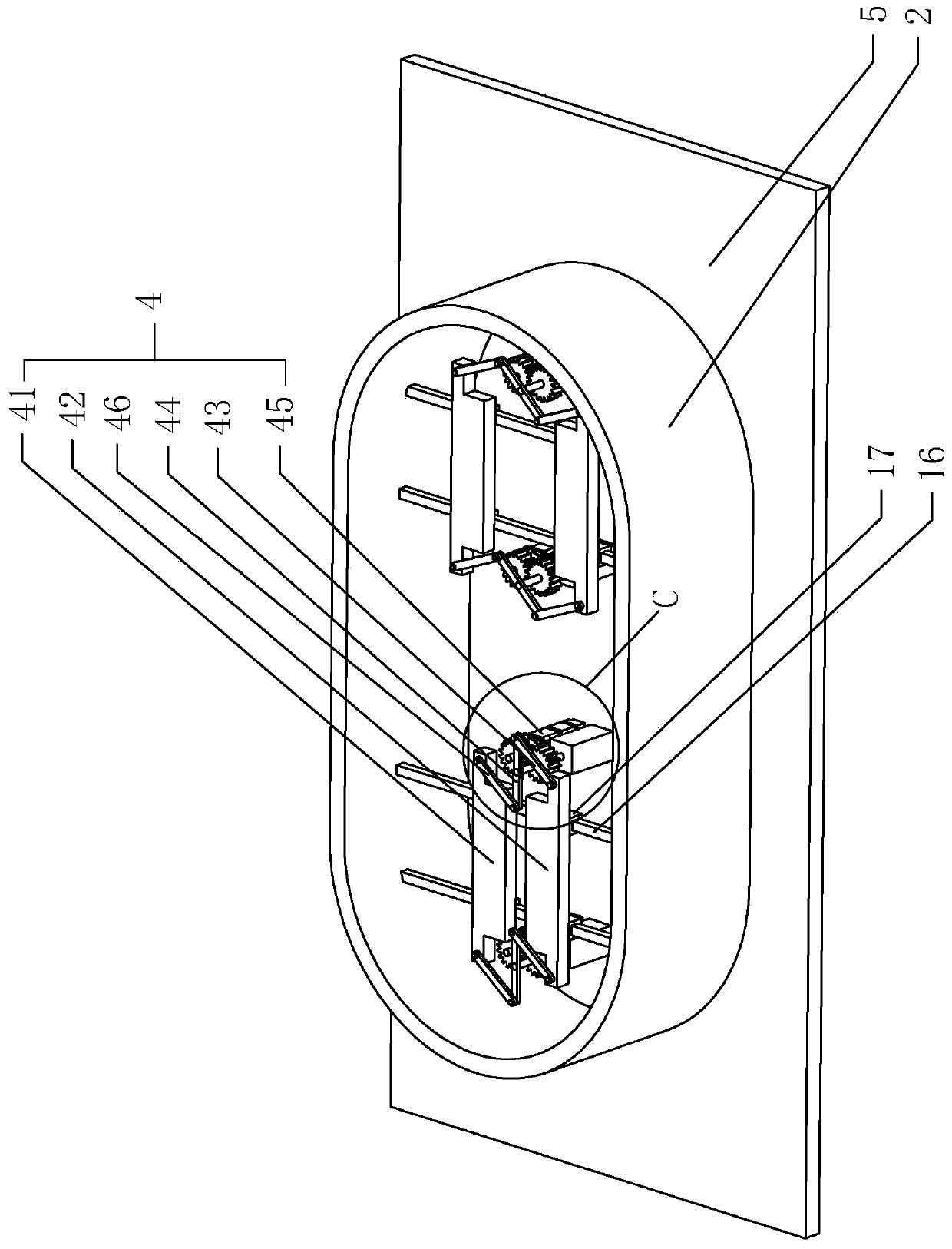

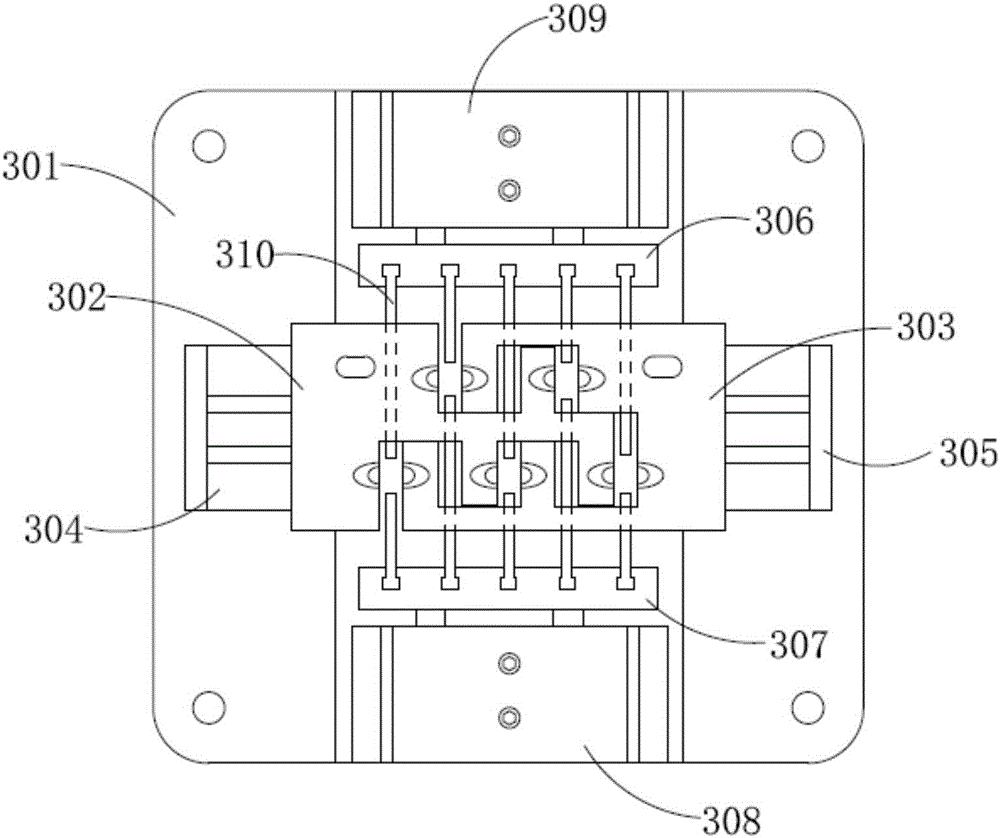

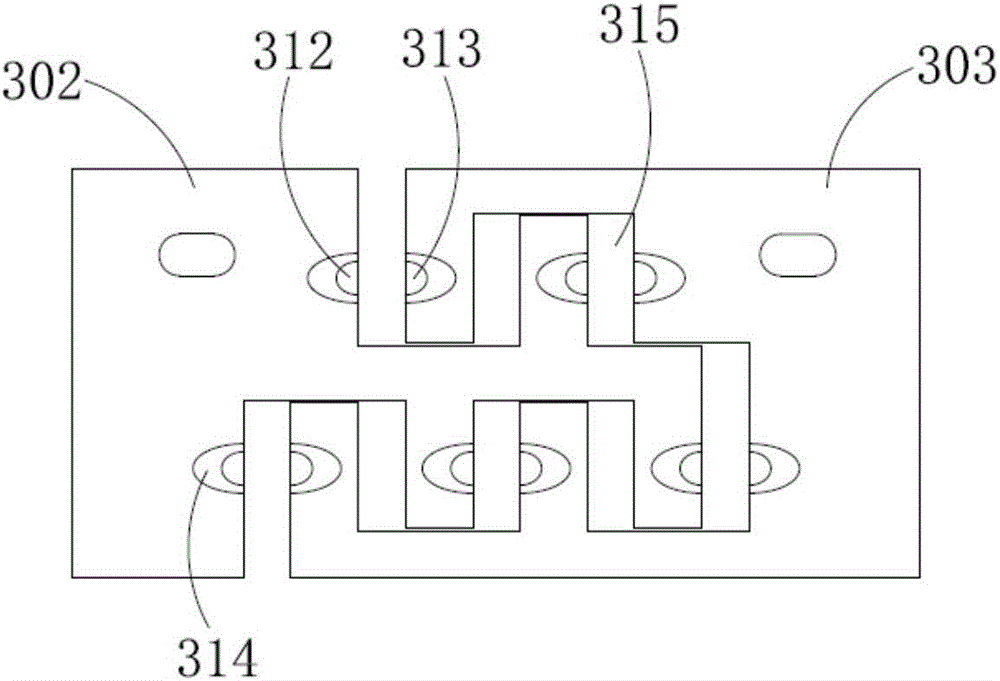

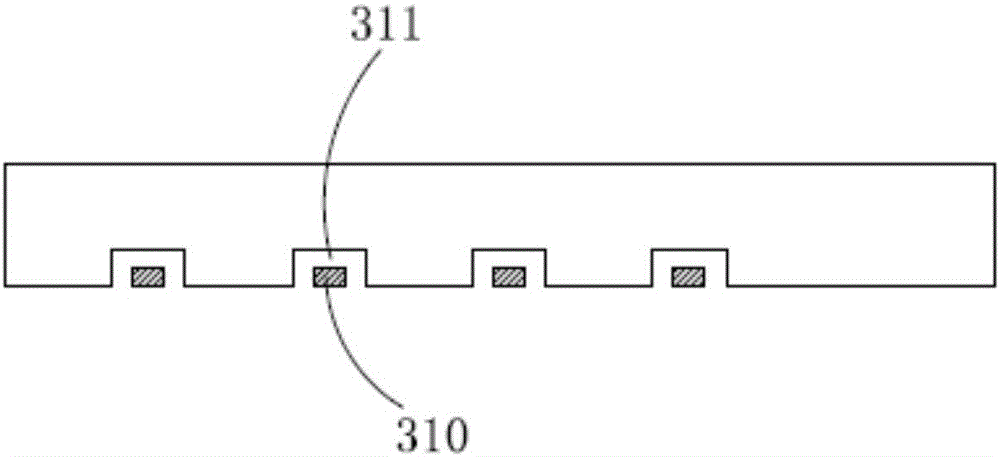

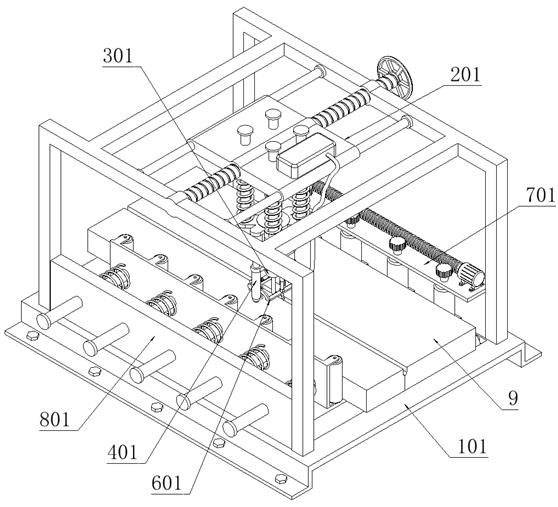

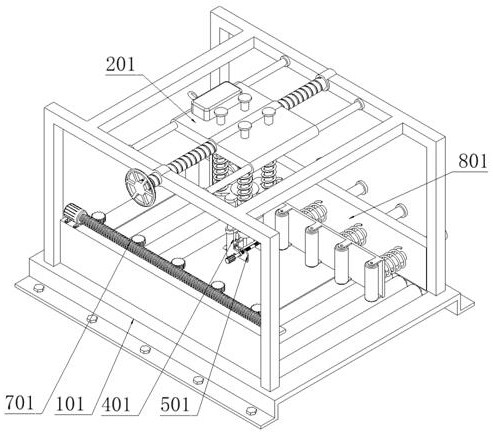

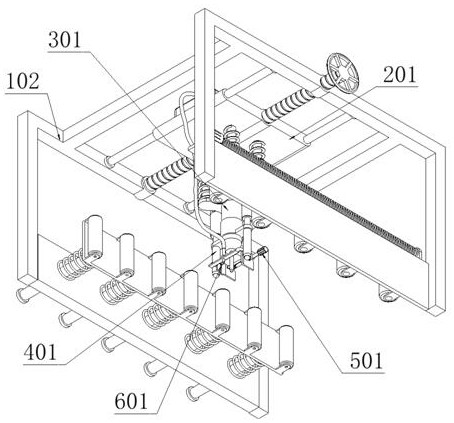

Friction stir welding fixture and method for aluminum alloy frame

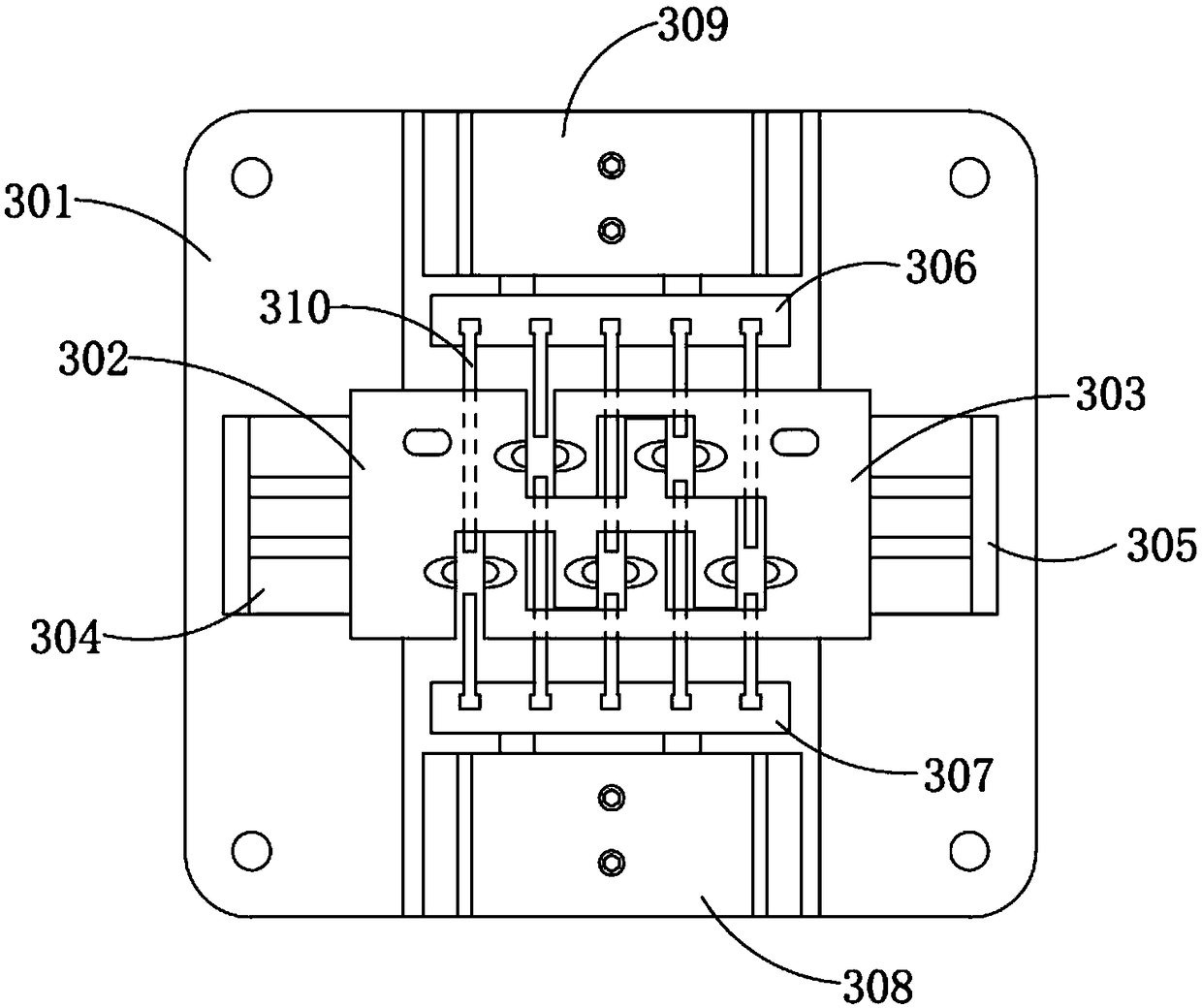

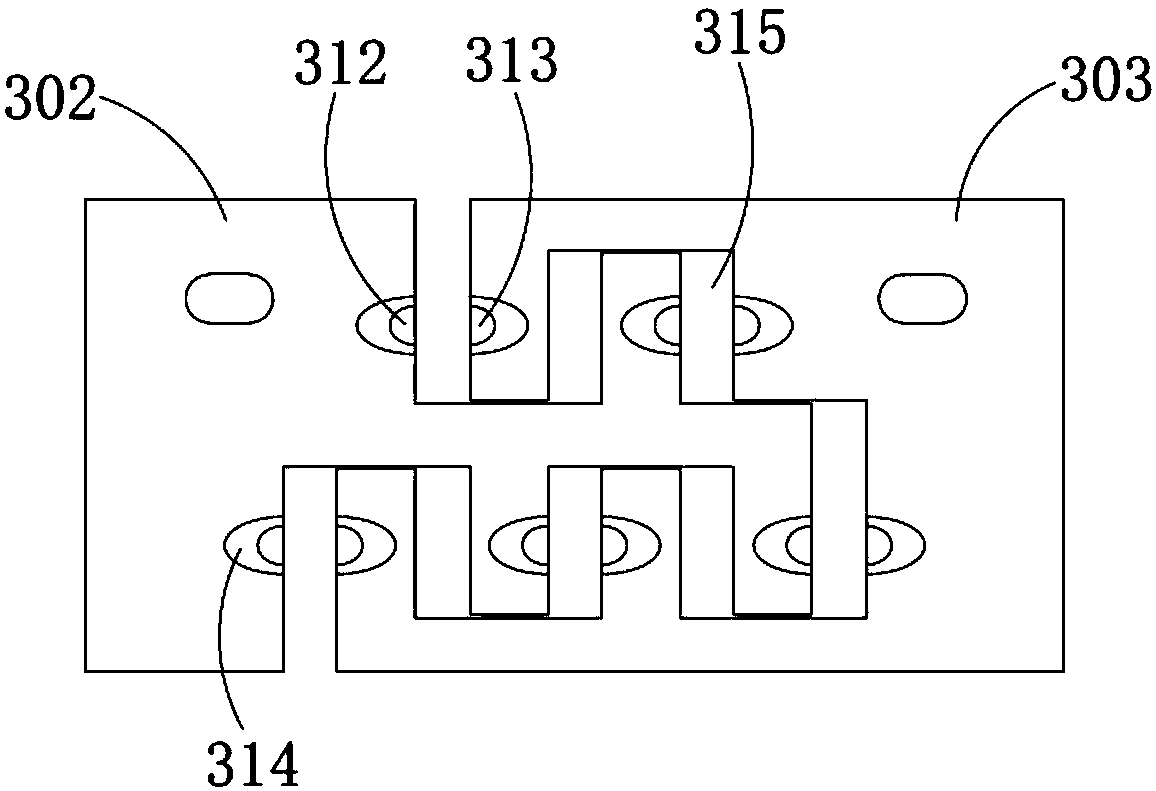

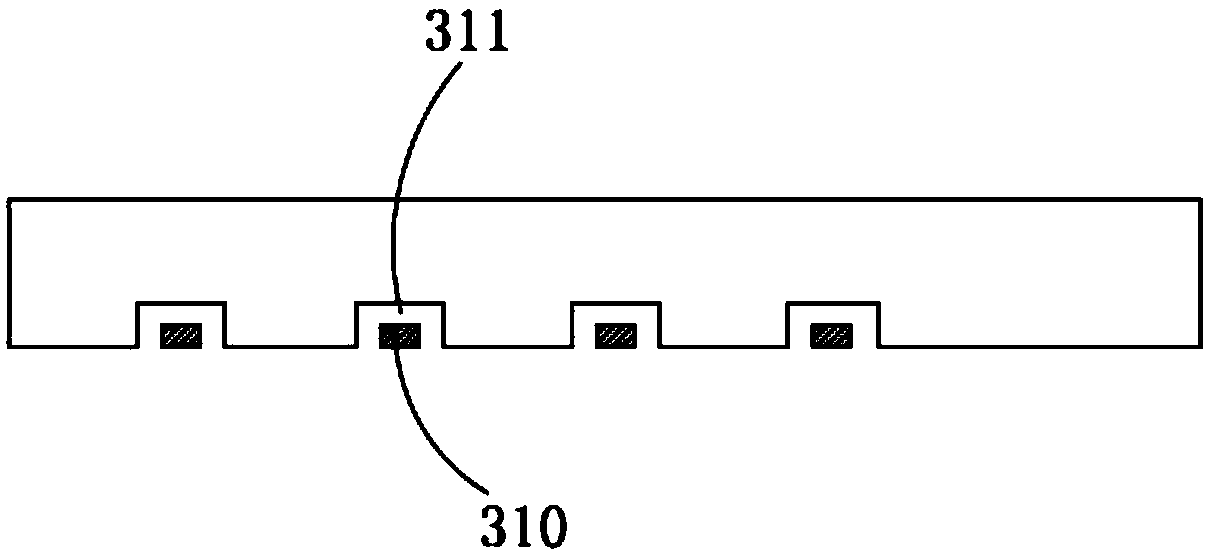

ActiveCN108213692AAvoid deformationEasy to take outWelding/cutting auxillary devicesAuxillary welding devicesMachiningWelding deformation

The invention discloses a friction stir welding fixture for an aluminum alloy frame. The aluminum alloy frame comprises horizontal plates and vertical plates. The friction stir welding fixture comprises a supporting frame and two supporting boxes. The supporting frame comprises a supporting surface and supporting legs. The supporting legs are detachable supporting legs and are arranged on the twosides of the supporting surface. Each supporting box comprises a box body, a positioning mechanism, a pressing mechanism, lateral positioning mechanisms and lateral clamping mechanisms, wherein the positioning mechanism and the pressing mechanism are arranged on the upper surface of the box body, the lateral positioning mechanisms are arranged on the side faces of the box body, and the lateral clamping mechanisms are also arranged on the side faces of the box body. A welding method comprises the steps of clamping of the horizontal plates and the vertical plates, lateral clamping, welding, taking out of a workpiece, and the like. The friction stir welding fixture and method for the aluminum alloy frame have the advantages that the welding deformation is small, clamping and positioning are accurate, the workpiece can be taken out easily after being welded and is not prone to deformation, the welding quality is table, chamfering is not needed, no machining allowance needs to be reserved,and the machining cost is low.

Owner:HUNAN JOINFRONT WELDING TECH

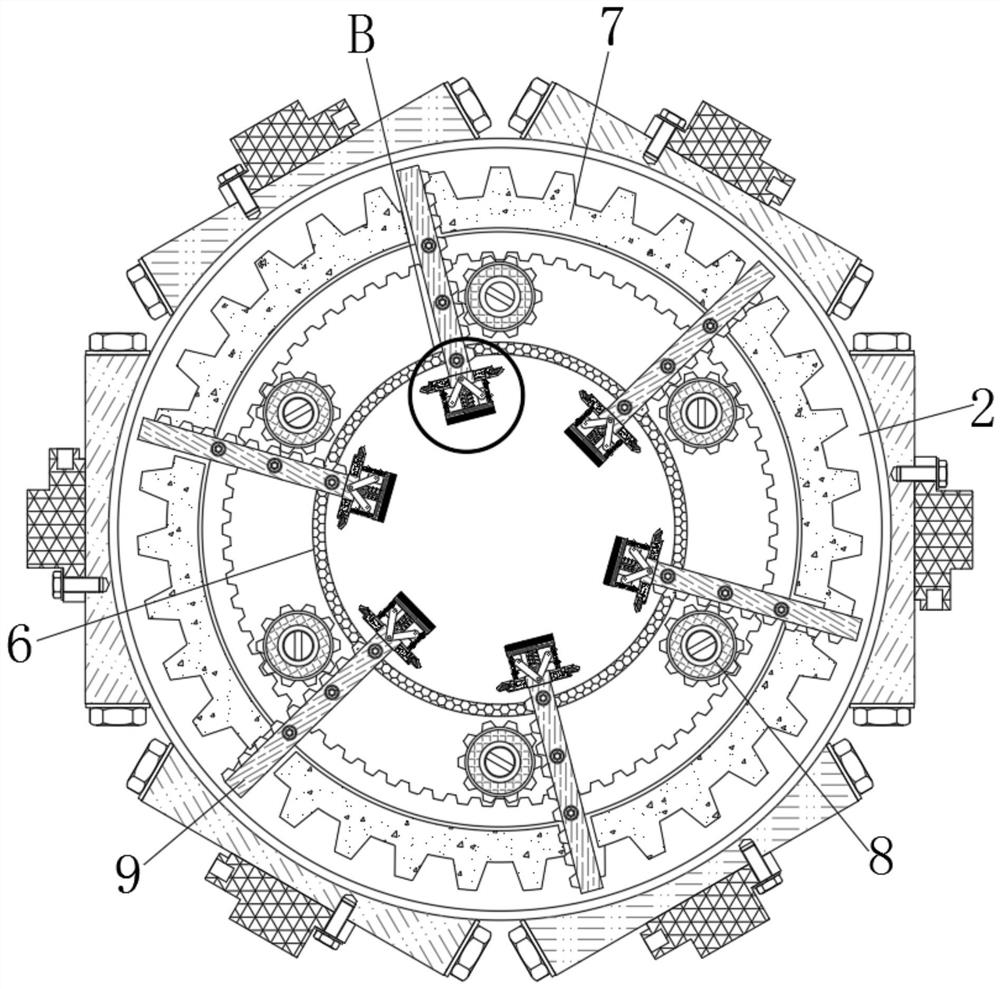

Automatic progressive device suitable for welding rods with different apertures

InactiveCN112872554AStrong applicabilityImprove applicabilityWelding/cutting auxillary devicesArc welding apparatusClassical mechanicsGear drive

The invention relates to the technical field of welding rods, and discloses an automatic progressive device suitable for welding rods with different apertures. The automatic progressive device comprises a rack, the welding rods are inserted into the rack, the outer walls of the welding rods are movably connected with fixing clamps, the opposite ends of the fixing clamps are fixedly connected with driving racks, the outer walls of the driving racks are meshed with transmission gears, the outer walls of the transmission gears are meshed with gear rings, and the outer walls of the gear rings are movably connected with fixing discs. According to the automatic progressive device suitable for the welding rods with the different apertures, the gear rings rotate to drive the transmission gears to rotate, the transmission gears drive the driving racks to move towards the circle centers of the fixing discs so as to drive the fixing clamps to be gathered to fix the welding rods, when the fixing clamps gradually abut against the welding rods, the welding rods apply outward counter-acting force to the fixing clamps to enable metal connectors to be gradually close to each other and abut against each other, when the metal connectors abut against each other, the gear rings stop rotating, the fixing clamps fix the welding rods firmly, and the applicability to the welding rods with the different apertures is higher.

Owner:陈一帆

Optical cable welding platform

PendingCN110109222AImprove welding qualityAffect welding qualityCoupling light guidesOptical fiber cablePetroleum engineering

The invention provides an optical cable welding platform. The optical cable welding platform comprises a platform body with a working surface; and a fixing device arranged on the platform body and used for fixing an optical cable on the working surface. According to the optical cable welding platform provided by the invention, the problems of inconvenient operation, poor welding efficiency and poor welding quality of optical cable welding in the prior art are solved.

Owner:STATE GRID CORP OF CHINA +2

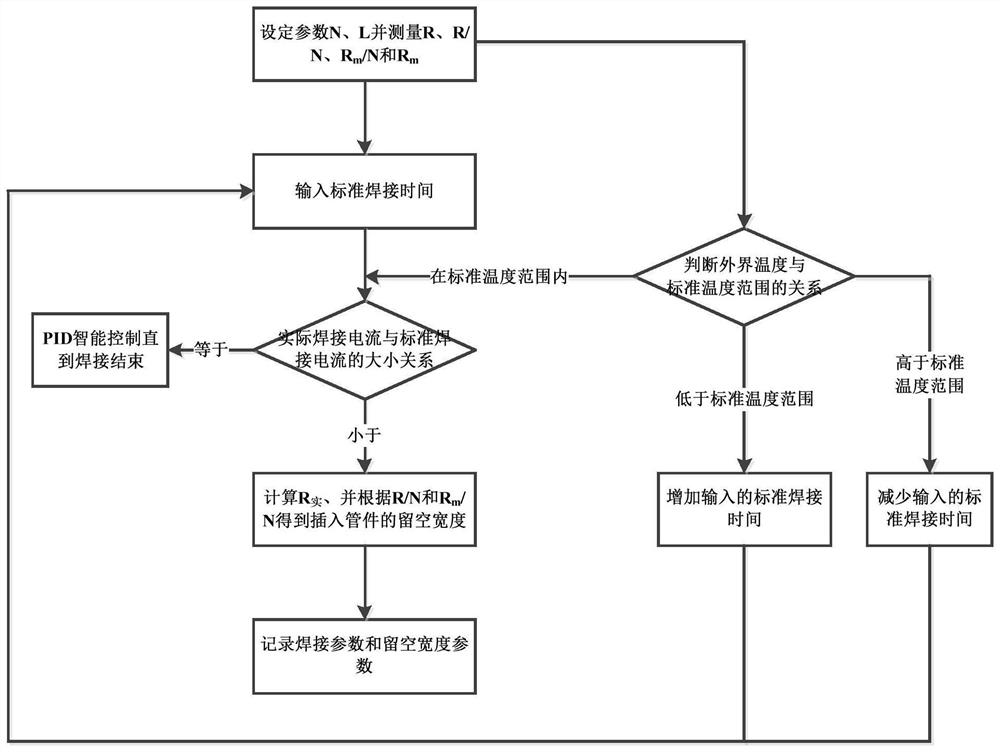

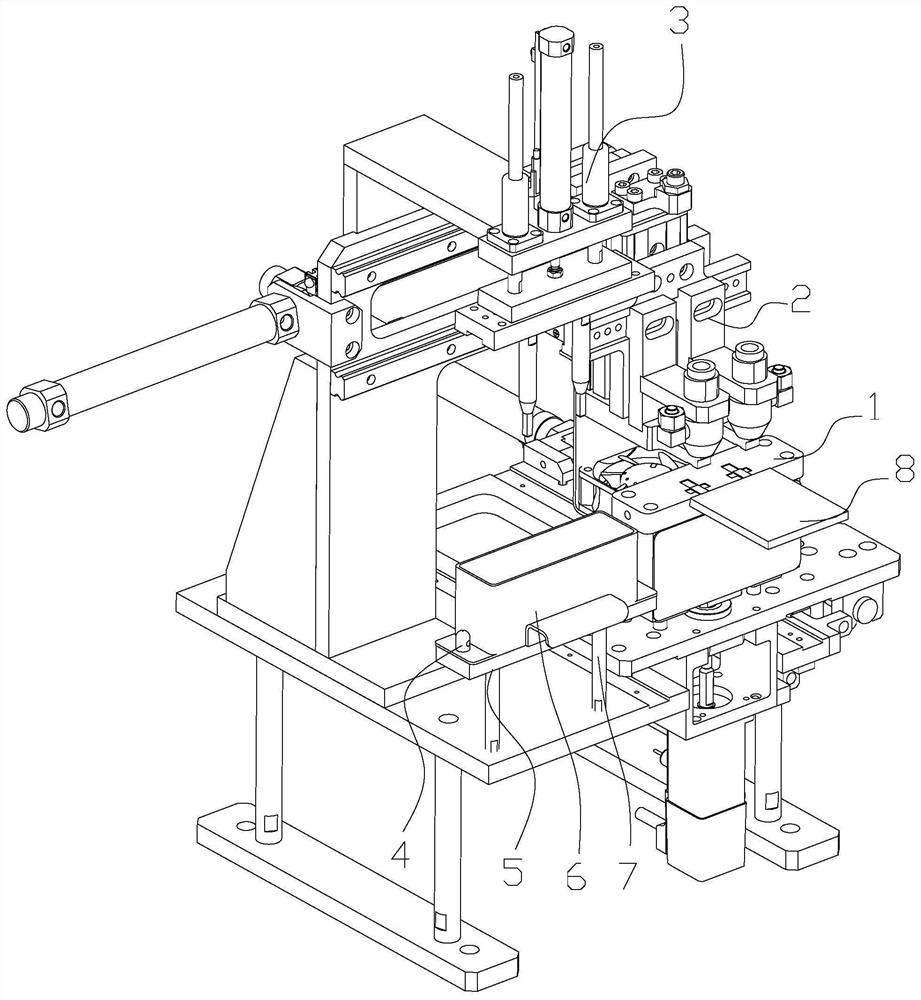

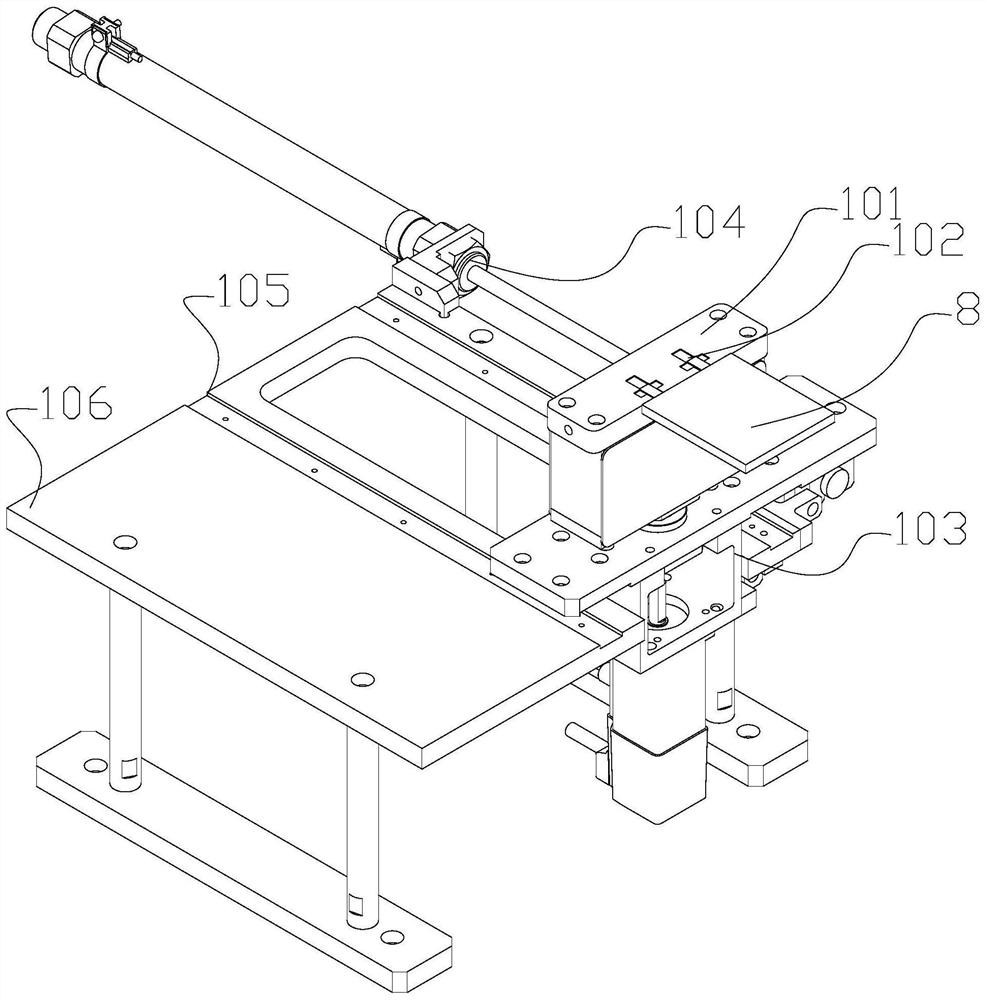

Intelligent welding method for electric smelting pipe fitting based on position detection, storage medium and terminal

PendingCN113334789AImprove welding qualityExtended service lifeTubular articlesElectrical resistance and conductancePipe fitting

The invention relates to an intelligent welding method for an electric melting pipe fitting based on position detection, a storage medium and a terminal. The method comprises the steps that current monitoring is carried out, specifically, an actual relation curve between welding time and welding current in the welding process is monitored in real time, and the actual relation curve and a standard relation curve are compared and analyzed; insertion position judgement is carried out, specifically, if the actual welding current is smaller than the standard current or is not within the error range of the standard current, it is indicated that the inserted pipe fitting is not inserted in place at the moment; and clearance position detection is carried out, specifically, the total actual resistance value R<actual> of a resistance wire at the moment is calculated, and the clearance width of the inserted pipe fitting is calculated by combining R / N and R<m> / N. According to the intelligent welding method, the storage medium and the terminal, the change of the current is calculated through the change of the temperature and the resistance in the resistance wire welding process, the measurement of the resistance of the clearance width and the insertion depth is realized, the specific values of the clearance width and the insertion depth are calculated, whether the inserted pipe fitting is inserted in place is judged, and therefore the welding quality of the pipe fitting is greatly improved, and the service life of the pipe fitting is greatly prolonged.

Owner:上海乔治费歇尔亚大塑料管件制品有限公司

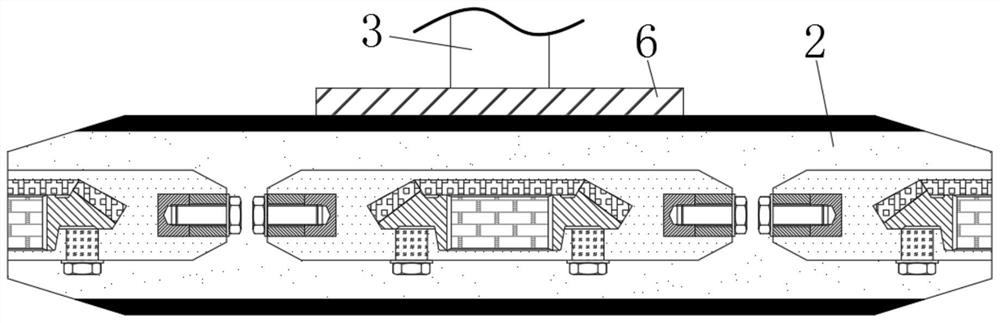

Dust removal and slag removal mechanism for lithium battery laser welding

ActiveCN113172338APrevent splashAffect welding qualityLaser beam welding apparatusSlag (welding)Dust control

The invention discloses a dust removal and slag removal mechanism for lithium battery laser welding. The dust removal and slag removal mechanism comprises a tab transferring mechanism, a welding head pressing mechanism, a welding slag removing mechanism and a welding slag collecting box. The welding head pressing mechanism is mounted on the tab transferring mechanism and is provided with a left station and a right station, namely a slag removal station positioned at the left side and a welding station positioned at the right side; the welding slag removing mechanism is mounted above the slag removal station, and the welding slag collecting box is arranged below the slag removal station; the tab transferring mechanism is arranged below the welding station; and the welding head pressing mechanism is provided with a welding pressing head capable of moving left and right, and the welding pressing head is provided with a laser passing hole for laser welding. The mechanism can effectively prevent molten materials from splashing everywhere, has an adsorption and dust removal function, and can remove smoke dust in time; the laser passing hole of the welding pressing head is subjected to slag removal treatment, so that the welding quality of the welding pressing head is prevented from being influenced due to excessive deposition of welding slag; and the welding pressing head is cooled, so that the problem that tab glue is melted due to over-high temperature of the pressing head can be avoided.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Battery clamp and battery assembly method

ActiveCN110767930AShorten positioning timeImprove assembly efficiencyAssembling battery machinesFinal product manufactureEngineeringStructural engineering

The invention provides a battery clamp comprising a moving base, a fixed plate, a positioning plate, a moving plate, a pushing component and a pressing component, wherein the fixed plate and the positioning plate are both fixed on the moving base, the moving plate is slid on the moving base, and the pushing component is set on the moving base; the fixed plate and the moving plate are respectivelyused to press the two sides of the inverted U-shaped shell, the positioning plate is used to position the end of the U-shaped shell, the pressing component is used to push the bottom plate down, and the pushing component is used to drive the moving plate closer to or away from the fixed plate. The invention also provides a battery assembly method comprising first placing the U-shaped shell betweenthe fixed plate and the moving plate, placing the module in the U-shaped shell, placing the bottom plate on the U-shaped shell, pressing the battery tightly, and finally welding the bottom plate to the U-shaped shell. The battery clamp and battery assembly method provided by the invention save positioning time, improve battery assembly efficiency, prevent the U-shaped shell from being opened under the squeeze of the bottom plate, and improve the compatibility of the battery clamp.

Owner:深圳市大族锂电智能装备有限公司

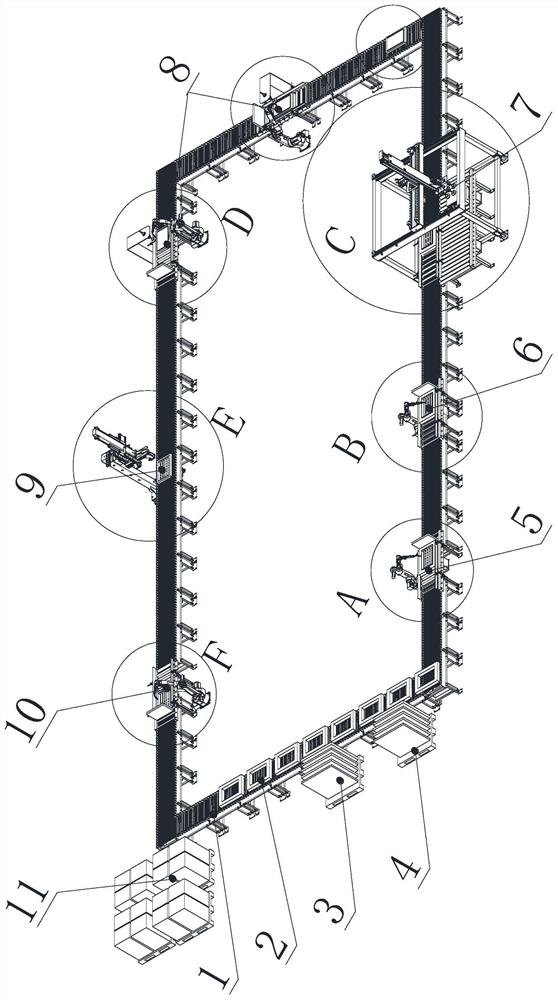

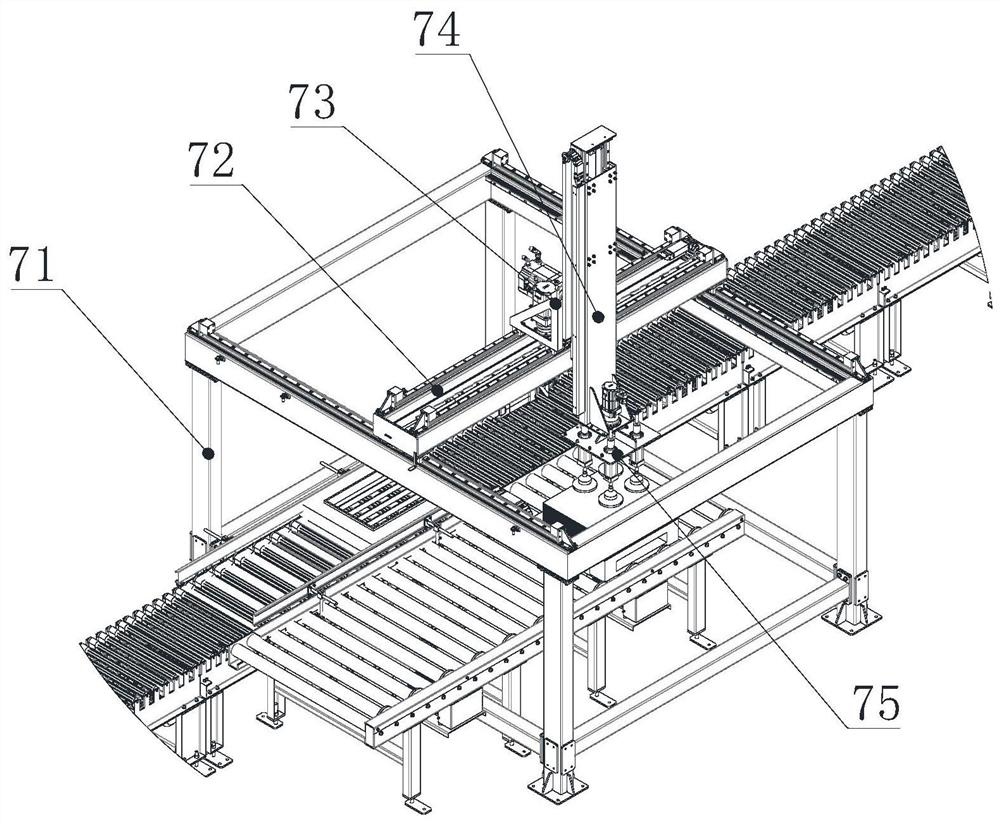

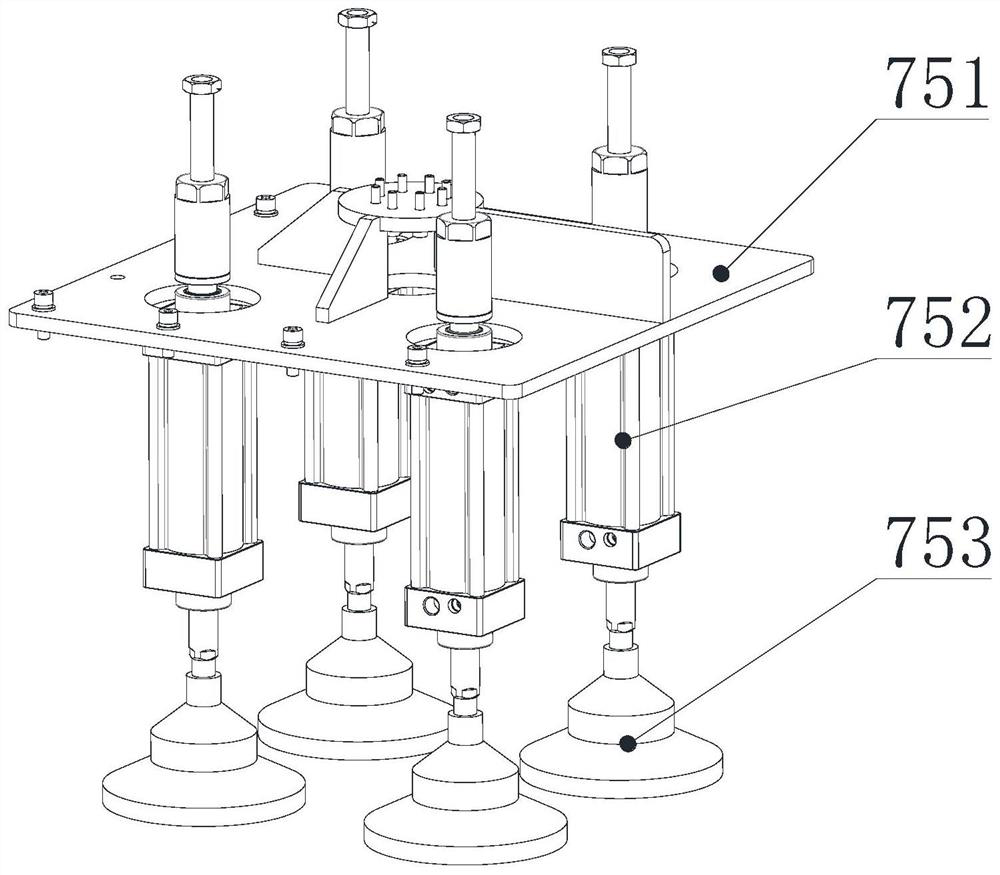

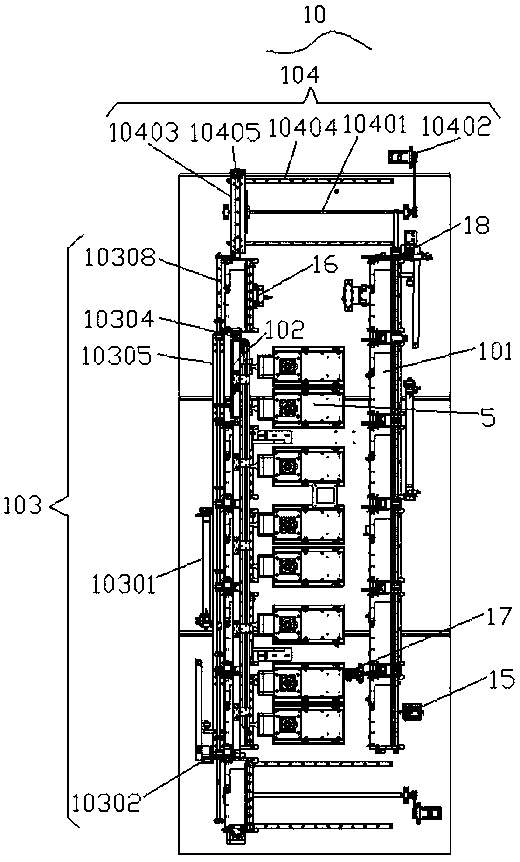

Screen mesh welding production line

PendingCN112872646AGuarantee welding qualityReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesAssembly lineManufacturing line

The invention relates to a water net welding production line which comprises a conveying device. The head end of the conveying device is sequentially provided with a first feeding station and a second feeding station; the tail end of the conveying device is provided with a finished product placing station; a first welding station, a second welding station, a third feeding station, a third welding station, an overturning station and a fourth welding station are sequentially arranged between the second feeding station and the finished product placing station along the conveying device; and welding robots are adopted in the first welding station, the second welding station, the third welding station and the fourth welding station for welding. The conveying device is arranged, so that assembly line conveying of a water net can be achieved; the welding robots are adopted for welding at the different welding stations, so that the welding quality of the water net is guaranteed, the welding speed is increased, the labor intensity of workers is relieved, and welding automation is achieved.

Owner:筋斗云(山东)工业设计有限公司

Welding device capable of preventing welding quality from being affected by infirm fixation of object

InactiveCN112692476AAffect welding qualityEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesCrankEngineering

The invention relates to the technical field of high-frequency welding machines, and discloses a welding device capable of preventing welding quality from being affected by infirm fixation of an object. The welding device comprises a base, a support column is fixedly connected to the top of the base, a workbench is fixedly connected to the top of the support column, a crank is movably connected to the right side of the workbench, and the top of the workbench is movably connected with a fixing frame. According to the welding device capable of preventing the welding quality from being affected by infirm fixation of the object, the crank is rotated, a driving bevel gear drives a driven bevel gear to rotate at the moment, a supporting rod further drives a welding head to move up and down, and the effect of rapidly and conveniently adjusting the height of the welding head is achieved. When a rotating disc is rotated, a second threaded rod drives a sliding block to move front and back, the fixing frame further drives a limiting block to move front and back, a knob is rotated, a first threaded rod drives the limiting block to move left and right, and the effect that workpieces of different specifications can be stably clamped is achieved.

Owner:李淑香

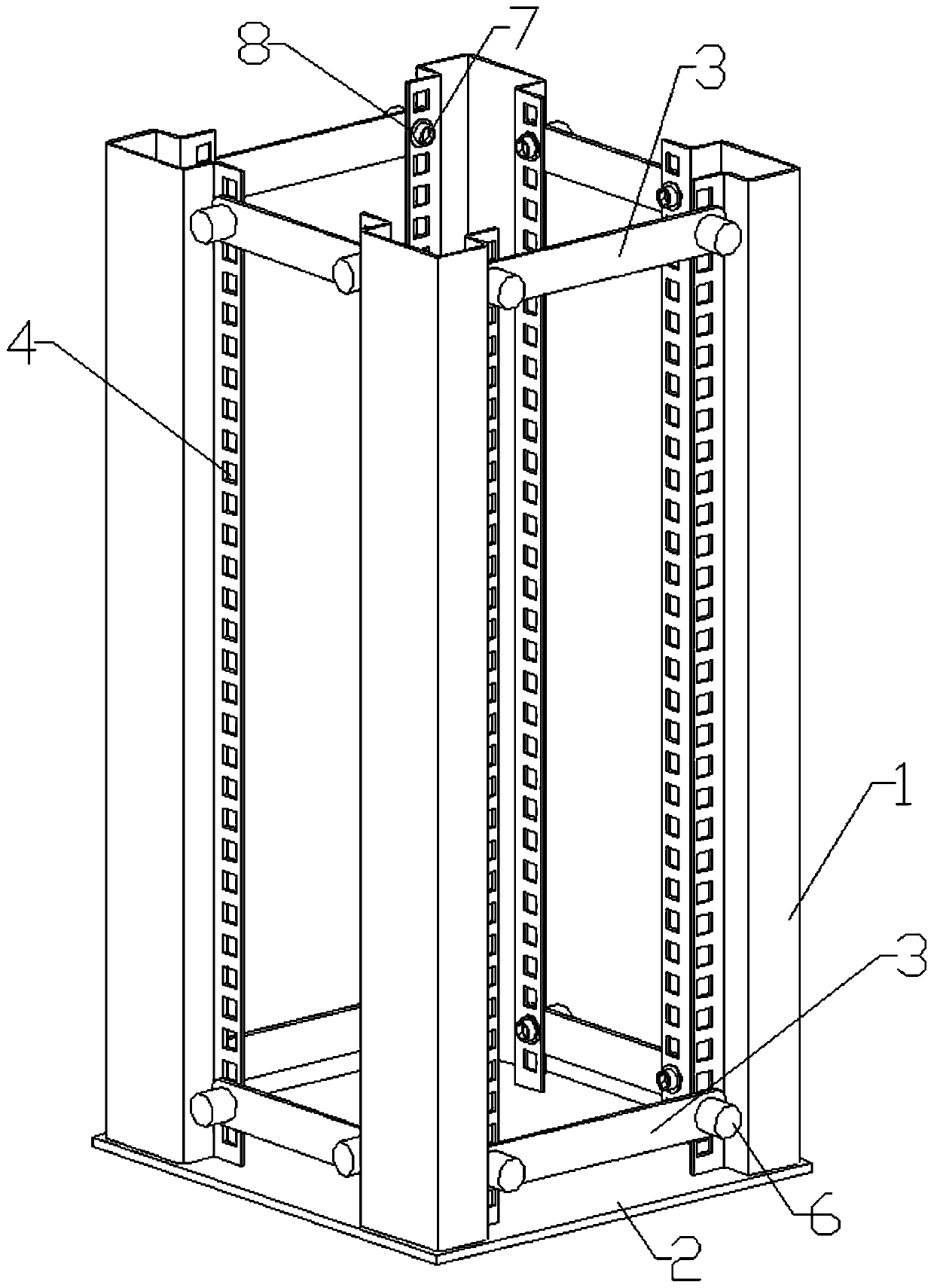

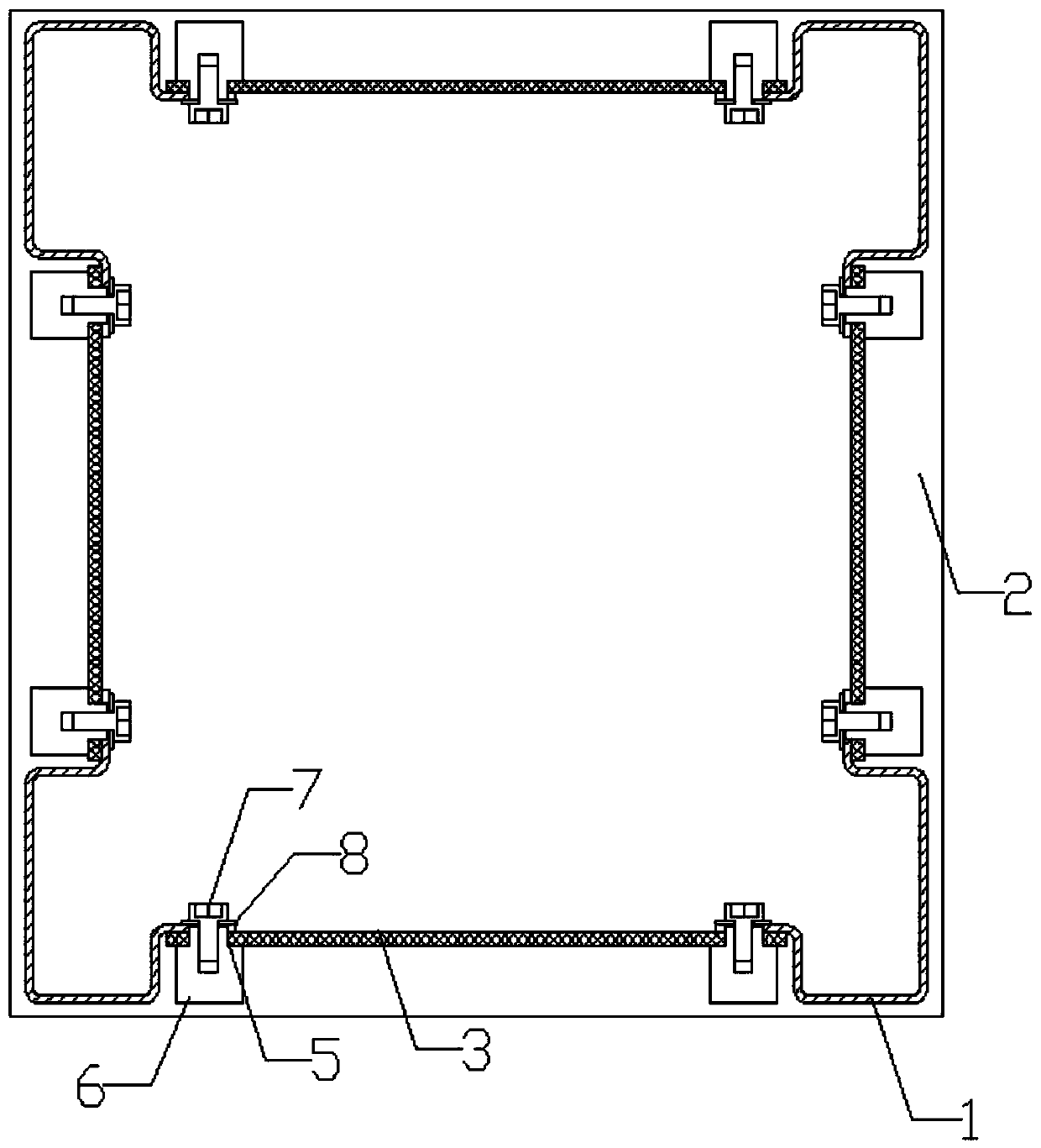

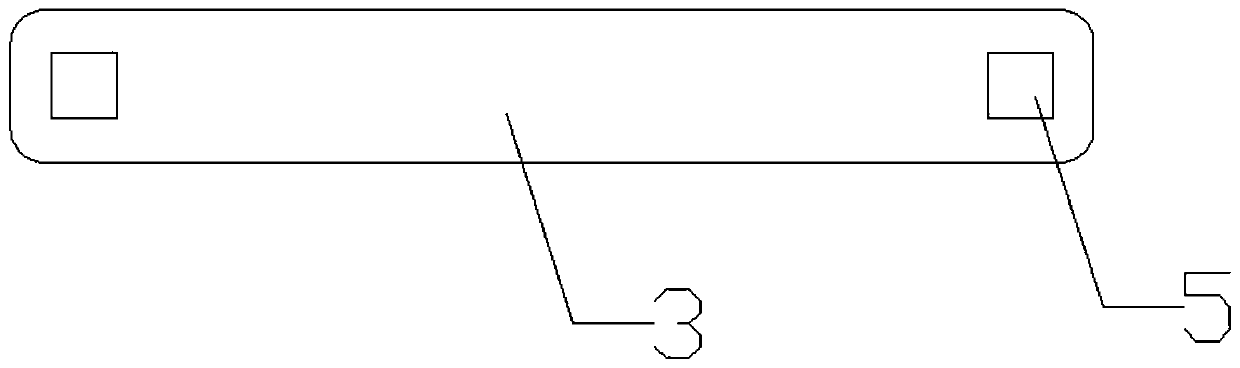

Positioning tool for welding of vertical beams of cabinet

PendingCN110744245ADoes not affect welding positionAffect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a positioning tool for welding of vertical beams of a cabinet. The positioning tool for welding of the vertical beams of the cabinet comprises the vertical beams, a base, positioning plates and positioning pins. A plurality of square holes A are formed in the vertical beams and are distributed on the vertical beams at equal intervals in the length direction of the verticalbeams. The number of the vertical beams is four, and the vertical beams are connected through the positioning plates and are placed on the upper end face of the base. Square holes B are formed in thetwo ends of each positioning plate, and the size of the square holes B is the same as that of the square holes A. One end of each positioning pin sequentially penetrates through the corresponding square hole B and the corresponding square hole A from one side of the corresponding positioning plate and is connected with the corresponding vertical beam through a fastening screw. According to the positioning tool for welding of the vertical beams of the cabinet, the vertical beams are connected through the positioning plates and the positioning pins, and the square holes A in the vertical beams are positioned, so that the vertical beams are kept parallel; the lower end faces of the vertical beams are arranged vertically, the welding position is not affected by the positioning tool during welding, and welding can be completed at a time, so that the working efficiency is improved; and meanwhile, the influence of high-temperature changes to the welding quality can be avoided.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

Battery jig and battery assembly method

ActiveCN110767930BAffect welding qualityImprove assembly efficiencyAssembling battery machinesFinal product manufactureEngineeringStructural engineering

The invention provides a battery clamp, comprising a moving seat, a fixing plate, a positioning plate, a moving plate, a pushing assembly and a pressing assembly, the fixing plate and the positioning plate are fixed on the moving seat, and the moving plate is slidably arranged on the moving seat , the pushing assembly is set on the moving seat; the fixed plate and the moving plate are respectively used to press against the two sides of the inverted U-shaped shell, the positioning plate is used to position the end of the U-shaped shell, and the top pressing assembly is used to press down the bottom plate, pushing The assembly is used to drive the moving plate close to or away from the fixed plate; the invention also provides a battery assembly method, which includes first placing the U-shaped shell between the fixed plate and the moving plate, and then placing the module in the U-shaped shell, Then put the bottom plate on the U-shaped shell, press the battery tightly, and finally weld the bottom plate on the U-shaped shell. The battery clamp and battery assembly method provided by the present invention saves positioning time, improves battery assembly efficiency, prevents the U-shaped shell from opening under the extrusion of the bottom plate, and improves the compatibility of the battery clamp.

Owner:深圳市大族锂电智能装备有限公司

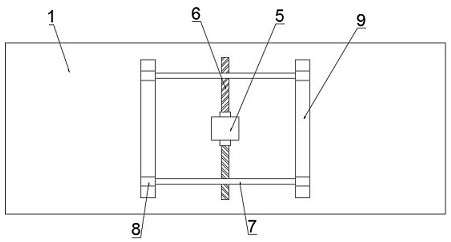

Rotor cage bar and end ring welding bench and welding method

InactiveCN109848502AImprove welding efficiencyUniform tightening forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRotor cage

The invention relates to the technical field of motor welding, and aims to provide a rotor cage bar and end ring welding bench. According to the key points of the technical scheme, the rotor cage barand end ring welding bench comprises a support, a welding barrel and a workbench. A first welding hole, a second welding hole, a first limiting groove and a second limiting groove are formed in the workbench, and the first welding hole and the second welding hole communicate with the welding barrel. Limiting components are arranged on the side wall of the first limiting groove and the side wall ofthe second limiting groove, and each limiting component comprises a limiting hole, a spring and a limiting rod. The limiting holes are formed in the side wall of the first limiting groove and the side wall of the second limiting groove, one end of each spring is connected with the corresponding limiting hole, and the other of the spring is connected with the corresponding limiting rod. When the spring is under compression, the end, back from the spring, of the corresponding limiting rod is outside the corresponding limiting hole. The rotor cage bar and end ring welding bench can weld two groups of rotor cage bars and end rings at a time, and the welding efficiency is high.

Owner:西安阿尔斯通永济电气设备有限公司

Accumulator bridge welding mold

ActiveCN106695186AAffect welding qualitySimple structureWelding/cutting auxillary devicesAuxillary welding devicesTemplate matchWelding process

The invention discloses an accumulator bridge welding mold. The accumulator bridge welding mold comprises a first template and a second template matched with each other, and at least one template is movably mounted; a first welding port is formed in the first template; the second template is provided with a second welding port aligned to the first welding port; and the first welding port and the second welding port are spliced to form a welding hole for inserting in a bridge welding pole column pair after moving the movably mounted template. The accumulator bridge welding mold further comprises slide blocks arranged on the side surfaces of the first template and the second template; and the slide blocks are provided with stop bars inserted between two pole columns from the lower part of the welding hole during welding. The accumulator bridge welding mold is simple in structure and convenient to use; and the welding ports on two templates are spliced to form the welding hole for inserting in the pole column pair, and the stop bars are driven to insert in the pole column gap in the welding process, so that lead liquid is prevented from downwards flowing from the place to influence the bridge welding quality, and the welding efficiency is improved.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Blanking mechanism of steel belt welding robot

PendingCN114131248AOrderly welding workEffective clampingWelding/cutting auxillary devicesAuxillary welding devicesButt jointSlide plate

The invention discloses a steel strip welding robot blanking mechanism which comprises a base, supporting rods are symmetrically and fixedly connected to the upper side wall of the base, the top ends of the supporting rods are jointly and fixedly connected with a mounting table, a conveying device is mounted on the mounting table, a clamping mechanism is arranged on the base, and the clamping mechanism is fixedly connected with the supporting rods. The upper side wall of the base is fixedly connected with a support located on the right side of the sliding plate, and the end of the support is fixedly connected with a storage box located above the conveying device. Intermittent discharging of the steel belts in the storage box can be controlled through left-right movement of the material blocking plate, so that ordered welding work is achieved, the limiting belt moves in the direction close to the outer walls of the steel belts, the limiting belt can effectively clamp the two steel belts which are in butt joint, welding is better completed, the situation that a gap between the two steel belts is too large, and welding quality is improved is avoided. And the welding equipment moves up and down, so that the height of the welding position of the welding equipment and the steel belt is adjusted.

Owner:刘攀

A battery bridge welding mold

ActiveCN106695186BAffect welding qualitySimple structureWelding/cutting auxillary devicesAuxillary welding devicesTemplate matchWelding process

Owner:ZHEJIANG TIANNENG POWER ENERGY

Blade welding device for wind driven generator

InactiveCN113500322AAffect welding qualityReduce gapWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPlanishing

The invention relates to the technical field of blade welding, and discloses a blade welding device for a wind driven generator. The blade welding device comprises a mounting support A and a mounting support B which are combined to form a mounting frame, a machining table is arranged in the mounting frame, a jig seat is movably arranged at the top of the machining table, a limiting groove matched with a wind driven generator blade in shape is formed in the top of the jig seat, a vertical displacement assembly for driving the jig seat to ascend and descend is fixedly arranged at the top of the machining table, a blade clamping assembly is fixedly arranged at the top of the machining table, and a sliding seat moving assembly is fixedly arranged between the mounting support A and the mounting support B. According to the blade welding device for the wind driven generator, the problem that welding is not accurate enough due to the fact that broken blades are not placed accurately is solved, cracks are ground flat while the two broken blades are extruded through a blade extruding and grinding assembly, the two broken blades make full contact, and therefore the welding effect of the wind driven generator blades is improved.

Owner:杨亚文

Device for narrow gap welding and welding method

ActiveCN113731947AEasy to fixAffect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringManufacturing engineering

The invention provides a device for narrow gap welding and a welding method. The device comprises a supporting device, wherein the supporting device is fixedly connected to the bottom of an operation device; the top of the supporting device is fixedly connected with a shrinkage joint structure; the top of the supporting device is fixedly connected with a positioning part; the positioning part is slidably connected with a floating welding part, and the bottom of the floating welding part is slidably sleeved with an adjusting part; the adjusting part is fixedly connected with a protection device; the front side of the adjusting part is fixedly connected with a dust removal device; a welding plate is connected to the supporting device in a sliding mode, the floating welding part is connected with floating shafts in a sliding mode, and the floating shafts are sleeved with springs, so that a welding body can be pushed downwards, and automatic adjustment is achieved according to the height of a welded profile; and according to the adjusting part, two distance adjusting shafts at the bottom of a sliding sleeve frame are driven through two electric telescopic rods, the welding depth of the welding body is intelligently controlled, and the welding quality is improved.

Owner:山东经典重工集团股份有限公司 +1

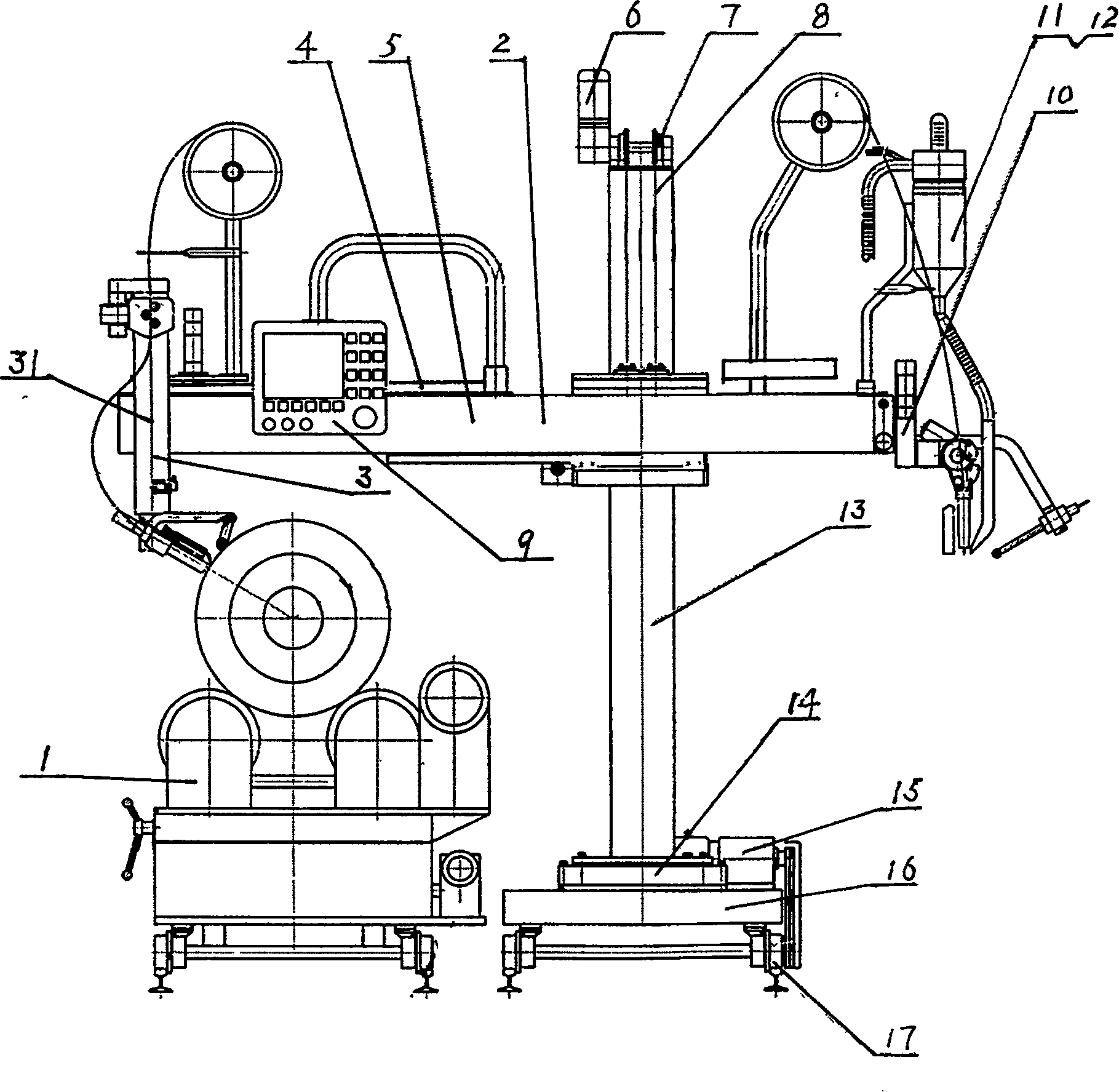

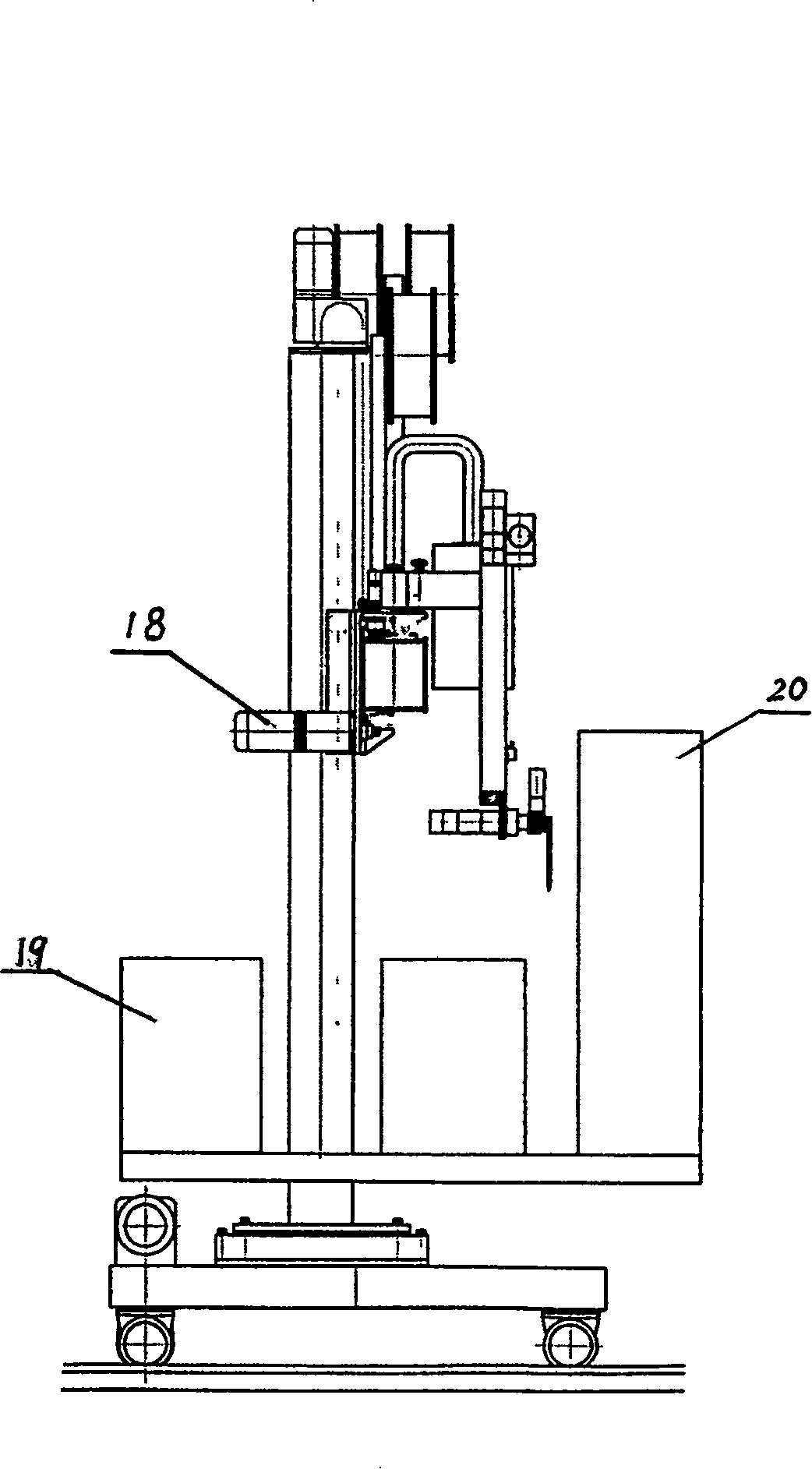

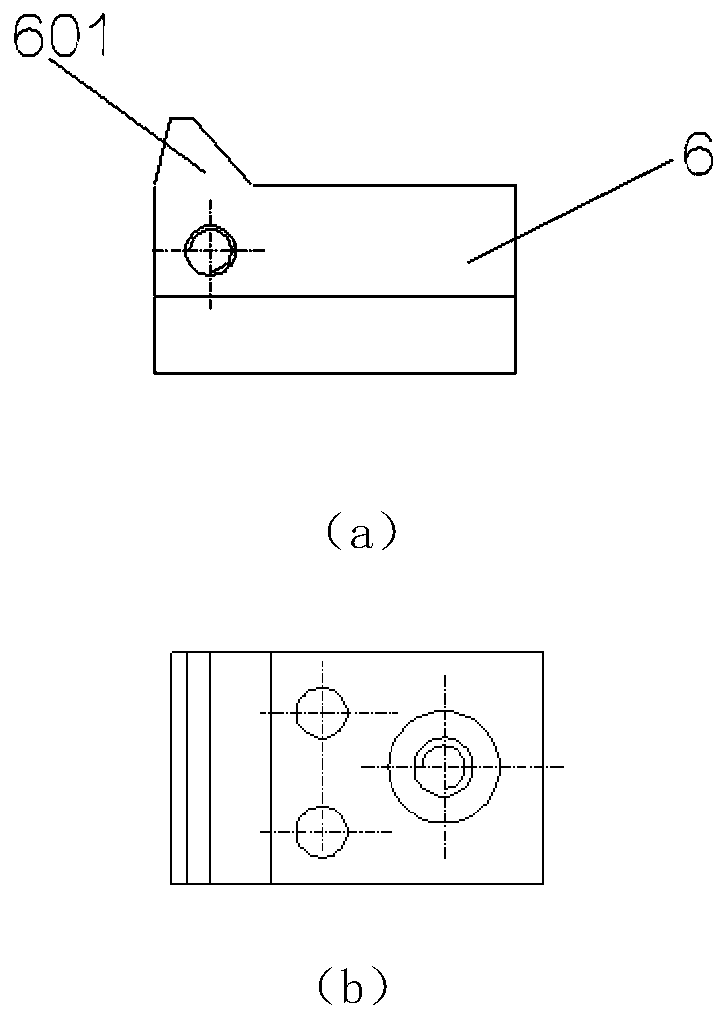

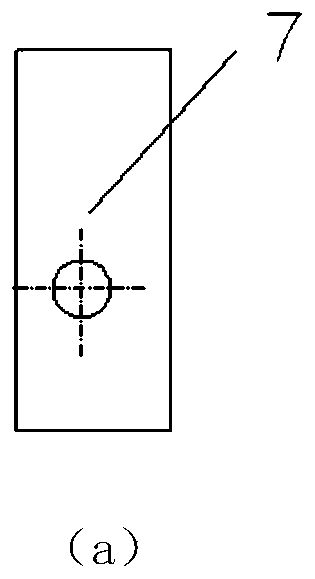

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN100398246CReduce auxiliary timeAffect welding qualityArc welding apparatusBogieHorizontal and vertical

Owner:SHANGHAI BOILER WORKS

A tungsten inert gas welding protection device for turbine blades

ActiveCN107790923BRealize all-round protectionAffect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTurbine bladeEngineering

The invention provides a turbine blade tungsten electrode inert gas welding protective device. Firstly, a low-pressure turbine blade is placed on a bottom plate, the blade root part of the low-pressure turbine blade is fixed through a fixing device simultaneously, the condition that welding quality is influenced due to back-and-forth movement of a welded part during welding is prevented, finally the low-pressure turbine blade is placed in a protective shell with an annular space, and meanwhile, the annular space of the protective shell is filled with inert gas during welding. Therefore, when the part is welded, the front welded face of the welded part is protected through the inert gas flowing out of a welding gun, the side face of the welded part is protected through the inert gas in theannular space of the protective shell, all-round protection of the welded part during welding is achieved, and welding quality of the part is improved.

Owner:AECC AVIATION POWER CO LTD

Resistance welding of aluminum based on sociological principles and usage method thereof

InactiveCN109128473AAffect welding qualitySimple structureGrinding machinesGrinding work supportsElectrical resistance and conductanceElectric resistance welding

The invention discloses resistance welding of aluminum based on sociological principles and a using method of resistance welding. The resistance welding relates to a working box. A working space is arranged in the working box, wherein the front end wall of the working space communicates with the external space. A positioning mechanism is arranged in the working space. A force bearing block is fixedly connected to the lower end wall of the working space. The upper end surface of the force bearing block is internally provided with a force bearing groove, wherein the upper end wall of the force bearing groove communicates with the working space. A pressure spring is fixedly connected to the lower end wall of the force bearing groove. A force bearing block is fixedly connected to the upper endof the pressure spring, wherein the upper end of the force bearing block penetrates through the upper end wall of the force bearing groove, and the force bearing block is positioned in the working space. A grinding block is fixedly connected to the upper end of the force bearing block. A device is simple in structure and convenient to operate, and can perform oxide removal operation on the welding surface of aluminum or aluminum products to be subject to resistance welding, so that the quality of resistance welding, to be carried out next, of the aluminum and the aluminum products can be ensured, and the welding quality of resistance welding positions is not influenced due to interference of aluminum oxide.

Owner:FUZHOU XINGWANGCHENG INFORMATION TECH CO LTD

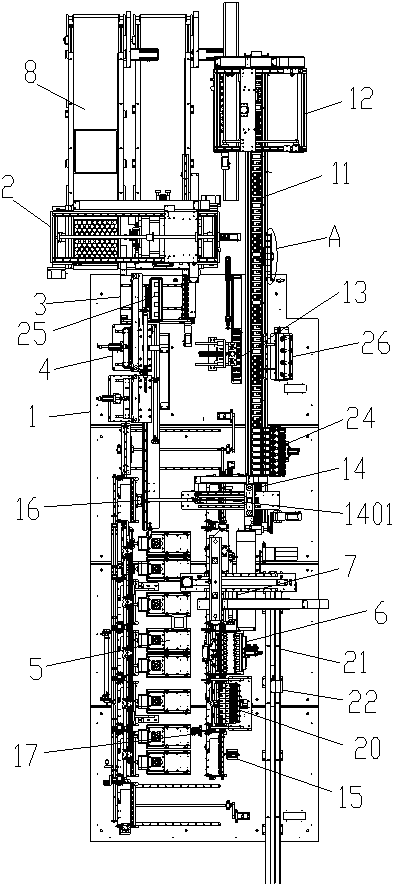

A battery cell cap tab welding equipment and its working method

ActiveCN106735838BImprove brand powerReduce defective rateMetal working apparatusNon-electric welding apparatusWork in processPole piece

The invention discloses welding equipment for a cap and a pole tab of a battery cell. The welding equipment comprises a workbench, wherein a cap taking and discharging mechanism, a cap and pole piece correcting mechanism, a cap picking and shaping mechanism and an overwelding station are sequentially mounted on the lower side of the surface of the workbench from left to right; a pole tab folding and battery cell cap pressing mechanism and a battery blanking mechanism are sequentially mounted on the upper side of the surface of the workbench from right to left; a guide rail is slidingly connected with a battery cell cap carrying return mechanism; and a battery cell removal mechanism and a pole tab correcting mechanism are arranged on one side of the right end of a battery cell charging belt. The welding equipment replaces the traditional manual production with automatic battery cap welding and sealing production tools, so that the production efficiency is improved, and the production cost is greatly lowered. The cap picking and shaping mechanism, the battery cell removal mechanism and a pole tab cleaning mechanism monitor and process the quality of a semi-finished product for producing a battery, so that a defective rate of a finished product is reduced, and the production cost is lowered.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

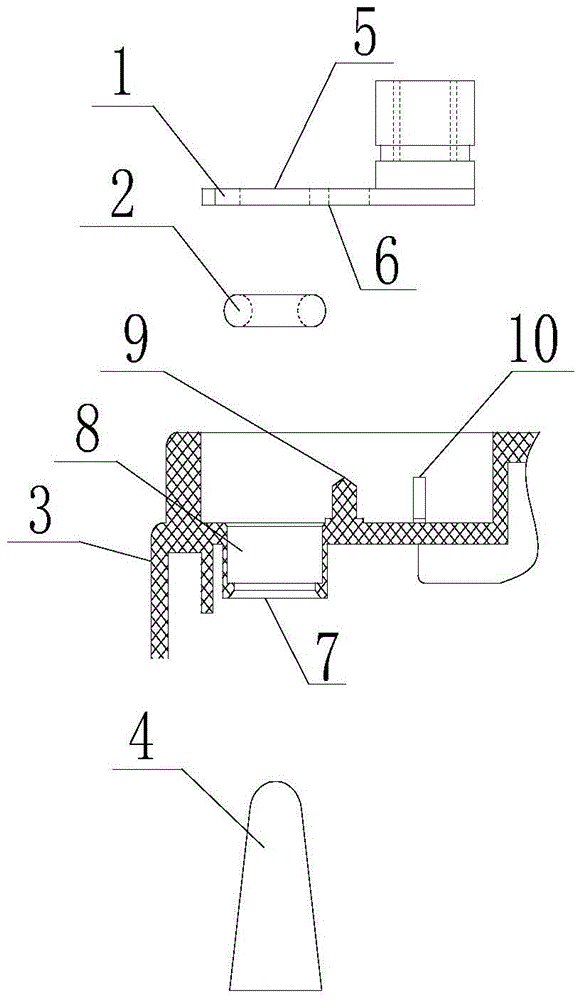

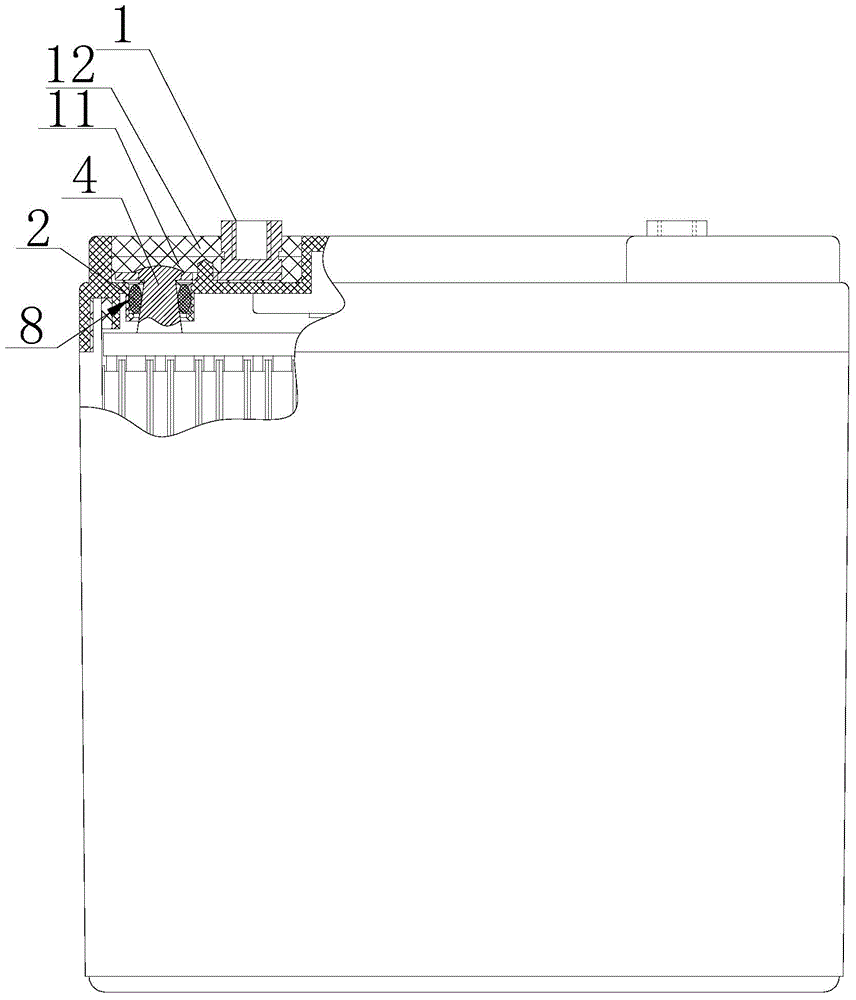

A new type of gel power battery terminal post sealing structure

InactiveCN104576982BLower internal resistanceFit closelySmall-sized cells cases/jacketsCell sealing materialsPower batteryElectrolytic agent

The present invention relates to a new sealing structure for colloid power battery terminals, which consists of copper terminals, O-shaped sealing rings, pool cover terminal connectors and tapered lead poles. The copper terminals are right-angled terminals. A welding hole is provided at one end of the copper terminal, a fixing hole is provided beside the welding hole, a pool cover end post hole is provided on the pool cover end post connector, and above the pool cover end post hole An annular groove is provided, a terminal fixing column is arranged beside the annular groove, and a terminal limit card is arranged beside the terminal fixing column. The invention has good sealing performance, no leakage of acid solution, avoids thermal runaway caused by electrolyte leakage, reduces corrosion risk, reduces internal resistance, improves current carrying capacity and ensures high-current safety performance.

Owner:无锡华燕新电源有限公司

Aluminum alloy machining equipment with heat dissipation function

InactiveCN113319585AEasy to cutEasy to processWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryKnife blades

The invention discloses aluminum alloy machining equipment with a heat dissipation function, comprising a first rotating disc and a second sliding groove. Bolts are installed on the outer surface of the first rotating disc; a first bearing is installed in the first rotating disc; a base is installed in the first bearing; a second bearing is installed in the base; a second rotating disc is installed in the second bearing; a fan is installed on the left side of a dust collecting box; a dustproof cover is installed above a rotating shaft; a cutting blade is installed in the dustproof cover; a motor is installed on the right side of the dustproof cover; and a welding base is installed on the right side of the base. According to the equipment, the first rotating disc rotating on the base through the first bearing is arranged, so that cutting equipment and welding equipment installed on the first rotating disc can be conveniently rotated to designated positions to conduct cutting and welding machining on aluminum alloy, it is avoided that the aluminum alloy is disassembled and clamped many times, then a large amount of time is saved, and the machining efficiency of the equipment is improved.

Owner:蔡芳

Diamond thin-wall drill welding machine ring tooth cutter head welding fixture

ActiveCN106975852BGuarantee welding qualityPlay a positioning roleLaser beam welding apparatusEngineeringAutomation

The invention discloses a welding clamp for an annular toothed tool bit of a diamond thin-wall drill welding machine. The welding clamp comprises a clamping unit for clamping the annular toothed tool bit and a rotating unit for conveying the annular toothed tool bit clamped by the clamping unit to a welding station, and the clamping unit is rotatably arranged on the rotating unit through a connecting assembly. The welding clamp has the advantages that the design is reasonable, the structure is compact, the annular toothed tool bit can be automatically clamped, the clamped annular toothed tool bit can be automatically conveyed to a base body, the degree of automation is high, meanwhile, the concentricity of the tool bit and the base body can be conveniently adjusted, the positioning is accurate, the labor intensity of workers can be greatly reduced, the manual cost can be reduced, and preconditions are provided for an automatic laser welding technology of the diamond thin-wall drill welding machine.

Owner:郑州金海威科技实业有限公司

Machining system for manufacturing stainless steel burglary-resisting window

InactiveCN112296580AAssembly welding efficiency is lowAffect production and installation efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMachining system

The invention relates to a machining system for manufacturing a stainless steel burglary-resisting window, the machining system comprises a bottom plate, telescopic devices, positioning devices, clamping devices and aligning devices, the telescopic devices are arranged on the bottom plate, the positioning devices are arranged on the telescopic devices, the aligning devices are symmetrically arranged at the left end and the right end of the bottom plate, and the clamping devices are symmetrically arranged at the front end and the rear end of the bottom plate. The following problems existing inassembling and welding of an existing stainless steel burglary-resisting window can be solved that a, when the traditional stainless steel burglary-resisting window is assembled and welded, the traditional stainless steel burglary-resisting window needs to be manually held and positioned and then is welded, so that the assembling and welding efficiency of the stainless steel burglary-resisting window is relatively low due to the welding mode, and the production and installation efficiency of the stainless steel burglary-resisting window is influenced; and b, existing stainless steel burglary-resisting window assembling equipment cannot stably clamp stainless steel pipes, the stainless steel burglary-resisting window is liable to shaking in the welding process, and the welding quality of the stainless steel burglary-resisting window is affected. The assembling and welding efficiency and quality of the stainless steel burglary-resisting window can be improved.

Owner:郭玲艳

Double-laser welding integrated welding head

InactiveCN110899970ACircumstances affecting damageAffect welding qualityLaser beam welding apparatusPhysicsLaser soldering

The invention discloses a double-laser welding integrated welding head. The double-laser welding integrated welding head comprises a base; the top wall of the base is connected with a first connectingseat; the top wall of the first connecting seat is connected with a laser emitter; a first sliding groove is formed in the outer wall of the base; a first sliding plate is connected into the first sliding groove; the outer wall of the first sliding plate is connected with a first supporting plate; the top wall of the first supporting plate is connected with a material barrel; the side wall of thefirst sliding plate is connected with a first supporting frame and a second supporting frame; the first supporting frame is movably connected with a feeding assembly; the feeding assembly is communicated with the material barrel; and the outer wall of the second supporting frame is movably connected with a nozzle assembly. According to the welding head, the nozzle assembly and the feeding assembly are of a modular assembly structure, so that the welding head is convenient to disassemble, clean, repair and maintain; and the height angle of the welding head can be adjusted through the nozzle assembly and the feeding assembly, so that the welding head is convenient to machine a workpiece with an irregular surface, and therefore, the practical performance of the welding head is improved.

Owner:JINAN G WEIKE SCI & TECH

A kind of gunpowder ignition type welded prefabricated pile and its welding method

ActiveCN112779909BReduce labor intensityOvercome some problems of traditional weldingBulkheads/pilesNon-electric welding apparatusStrain gaugeUltimate tensile strength

The invention discloses a gunpowder ignition type welded prefabricated pile and a welding method thereof, which can effectively overcome the shortcomings of the previous welding connection methods. Starter device, wire, stress and strain sensor, strain gauge. The present invention has a complete composition, and by changing the welding method of the prefabricated pile, the problems existing in the previous connection method are overcome, and the pile connection is more convenient, the connection is more stable, and the strength is higher. At the same time, a stress-strain detection device is provided to detect the stress-strain and structural integrity.

Owner:CHINA RAILWAY 16TH BUREAU GRP ROAD & BRIDGE ENG CO LTD +1

Workpiece welding equipment and welding method thereof

InactiveCN112108786AAffects welding positionAffect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesMaterials scienceIndustrial engineering

The invention provides workpiece welding equipment and a welding method thereof, and mainly relates to the technical field of welding. The workpiece welding equipment comprises a base, a long profile,a positioning block, a stabilizing block, a limiting block and a nylon rod. The workpiece welding equipment has the beneficial effects that the limiting block is additionally arranged in the weldingprocess of the long profile and the stabilizing block, and the limiting block is inserted between the stabilizing block and the long profile, so that no gap exists between the stabilizing block and the long profile, and the stabilizing block is fixed relative to the long profile; the situation that the stabilizing block moves relative to the long profile in the welding process, so that the weldingposition and the welding quality of the stabilizing block are affected is avoided; and heat generated on the long profile is transferred in the welding process, and the temperature of the long profile is reduced, so that the welding position is prevented from being burnt through in the welding process.

Owner:SHANDONG NANSHAN ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com