Blade welding device for wind driven generator

A technology for wind turbines and welding devices, applied in the field of blade welding, can solve the problems of inaccurate welding and inaccurate placement of broken blades, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

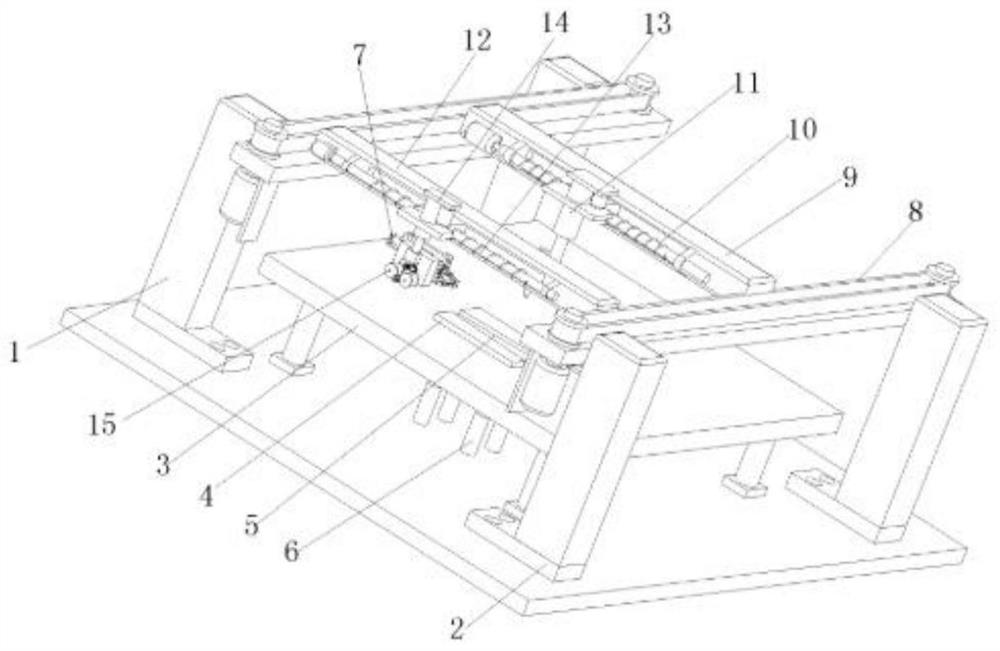

[0037] Such as figure 1As shown, a welding device for wind turbine blades includes a mounting bracket A1 and a mounting bracket B2 that are combined to form a mounting frame, a processing table 3 is arranged in the mounting frame, and a jig seat 4 is movable on the top of the processing table 3 , the top of the jig base 4 is provided with a limit groove 5 matching the shape of the wind turbine blade, the top of the processing table 3 is fixedly provided with a vertical displacement assembly 6 that drives the jig base 4 up and down, and the top of the processing table 3 is fixedly arranged There is a blade clamping assembly 7, a sliding seat moving assembly 8 is fixedly arranged between the mounting bracket A1 and the mounting bracket B2, the output end of the sliding seat moving assembly 8 is installed with a sliding seat A9 and a sliding seat B12, and the front of the sliding seat A9 is fixedly arranged There is a horizontal movement component A10, the output end of the horiz...

Embodiment 2

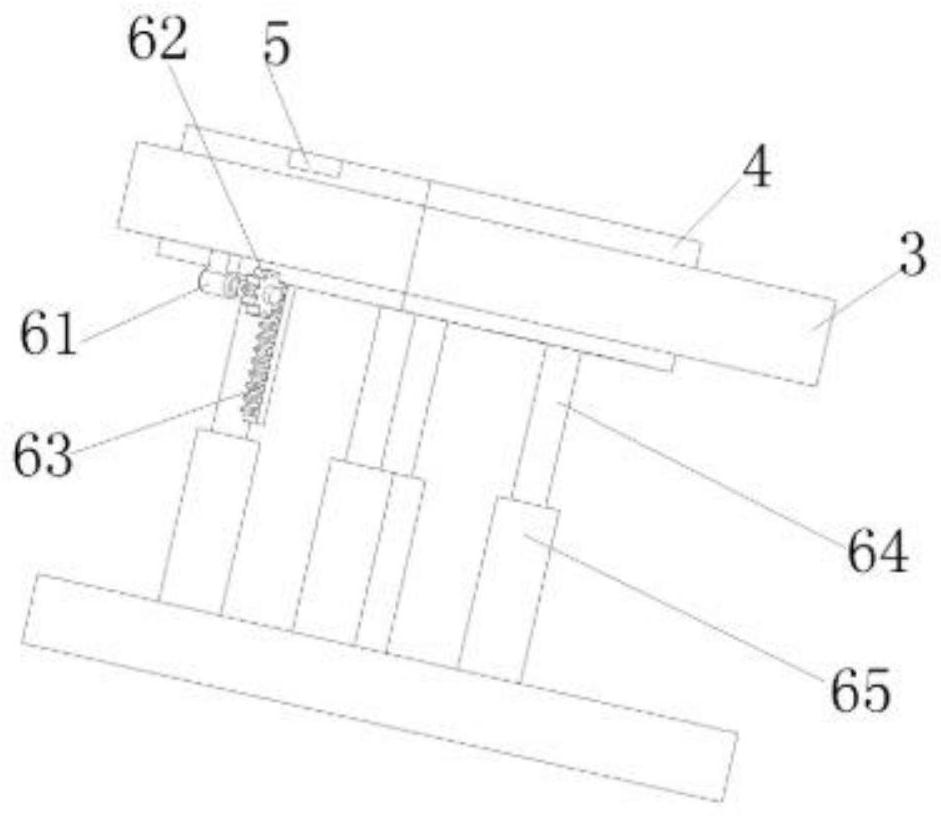

[0039] On the basis of Example 1, such as Figure 1-2 As shown, the vertical displacement assembly 6 includes a motor A61, a spur gear A62 and a chain 63 fixedly arranged at the bottom of the fixture seat 4, the motor A61 is fixedly installed on the bottom of the processing table 3, and the spur gear A62 is installed on the output end of the motor A61. The spur gear A62 and the chain 63 mesh with each other, and the bottom of the jig base 4 is fixedly provided with a limiting rod 64 , which is sleeved on the inner wall of the limiting cylinder 65 .

Embodiment 3

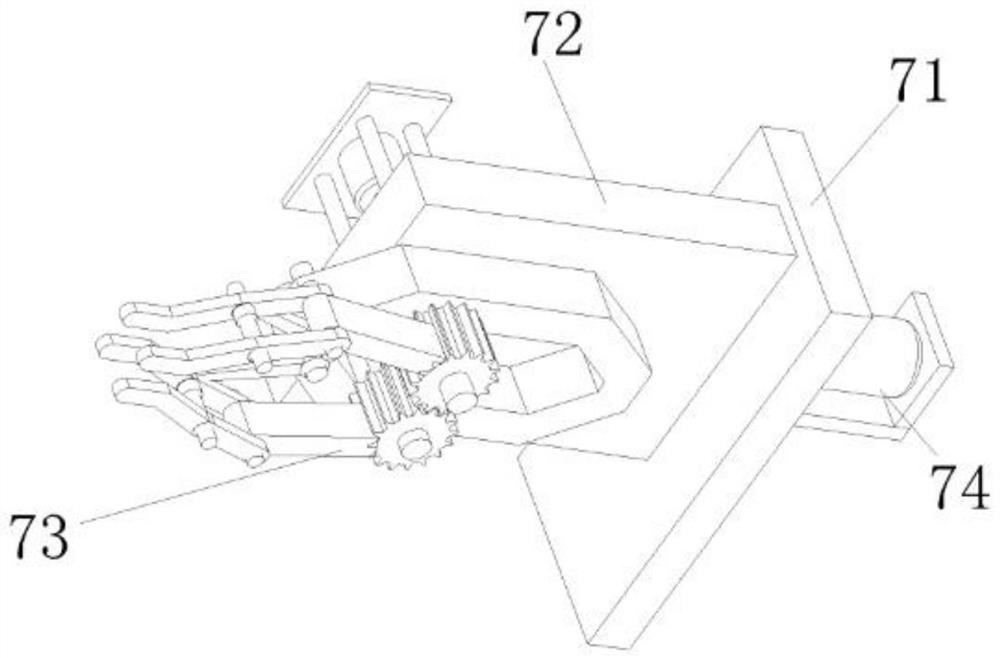

[0041] On the basis of Example 1, such as Figure 1-3 As shown, the blade clamping assembly 7 includes a fixed frame 71 fixedly arranged on the top of the processing table 3, a mounting plate 72 and a clamping manipulator 73, the fixed plate is movably arranged on one side of the fixed frame 71, and the other side of the fixed frame 71 The motor B74 that drives the mounting plate 72 to rotate is fixedly arranged on the side, the manipulator is fixedly arranged on the front of the fixed frame 71 , and the power source of the manipulator is fixedly arranged on the back of the fixed frame 71 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com