Workpiece welding equipment and welding method thereof

A technology for welding equipment and workpieces, which is applied in the field of workpiece welding equipment and its welding, can solve the problems of welding penetration, inaccurate welding position, and increase the processing cost of long profiles, and achieve strong controllability, avoid burn-through, and reduce temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

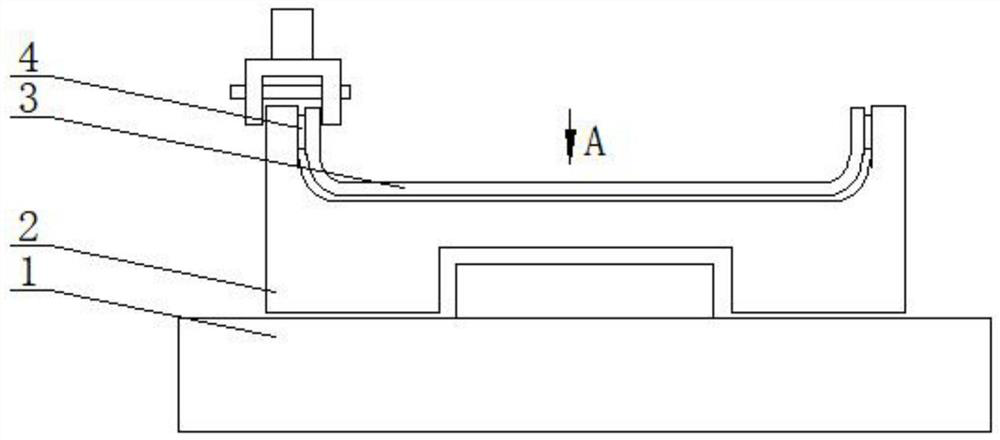

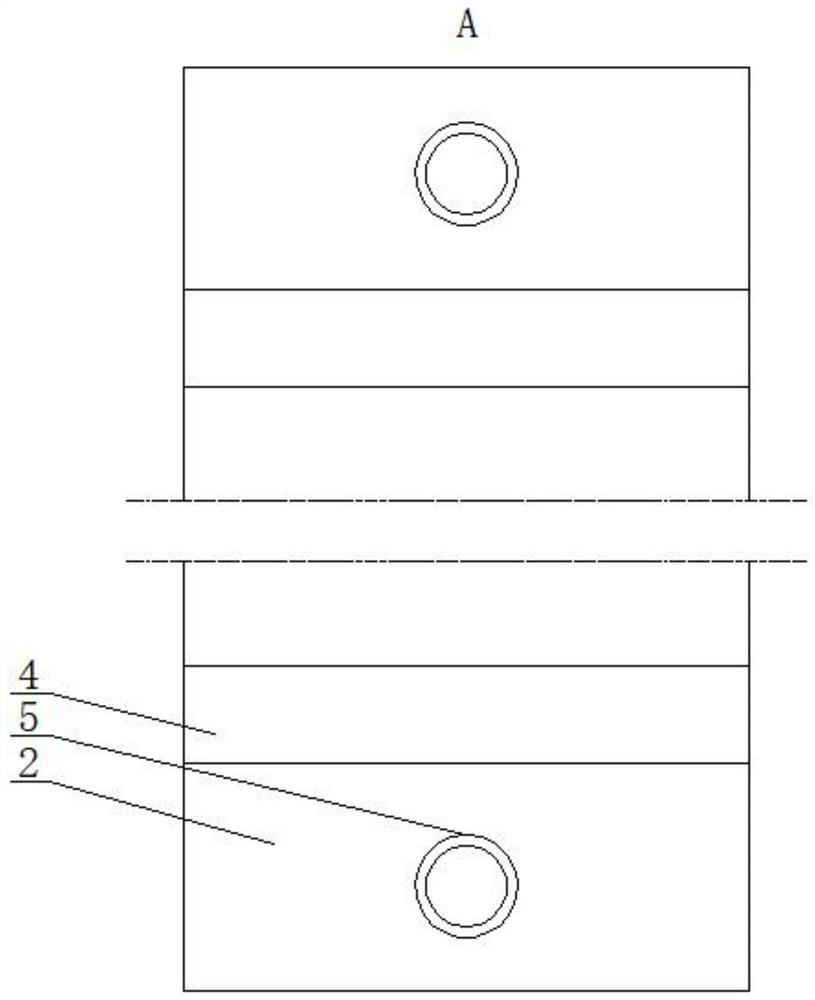

[0039] When using this device, first place the long profile 2 on the base 1, and make the concave part on the long profile 2 cooperate with the convex part of the base 1. This structure makes the contact surface of the long profile and the base completely fit. During the welding process , the heat generated on the long profile can be conducted to the base, the base transfers the heat of the long profile, reduces the temperature of the long profile, avoids the welding place to burn through during the welding process, affects the quality of the long profile, and increases the cost. Then the positioning block, stable The block 3 is placed on the long profile 2, the positioning block is used to position the stable block 3, and the limit block 4 is inserted between the stable block 3 and the long profile, so that there is no gap between the two. gap, and then use a nylon rod to compress the stable block, and weld the stable block to the long profile 2; the present invention adds a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com