A kind of gunpowder ignition type welded prefabricated pile and its welding method

A welding method and prefabricated pile technology, applied in welding equipment, sheet pile walls, manufacturing tools, etc., can solve the problem that the welding quality is easily affected by human factors and weather conditions, the tensile performance is difficult to fully guarantee, and the joints are easy to corrode and rust and other problems to achieve the effect of avoiding the reduction of corrosion strength, convenient pile connection, simple manufacture and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

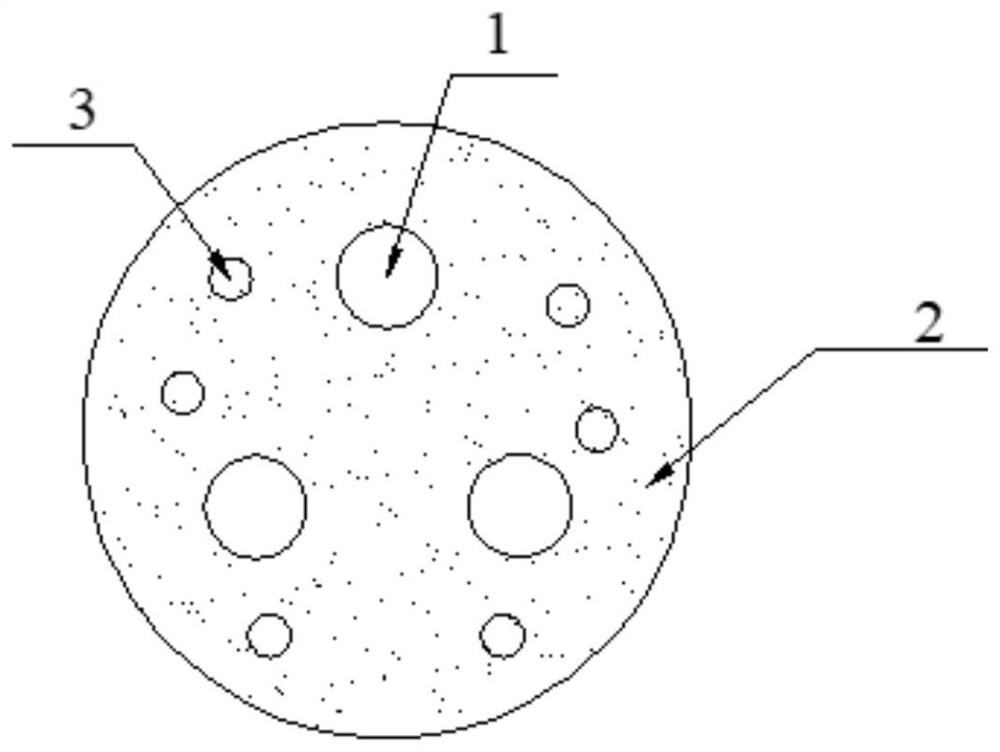

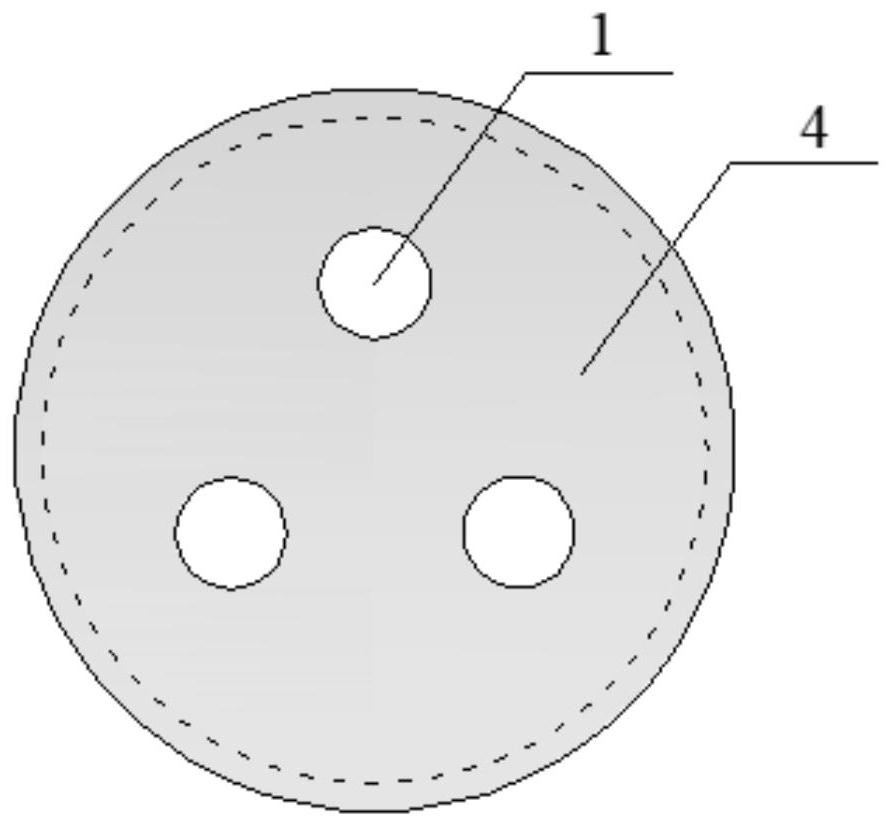

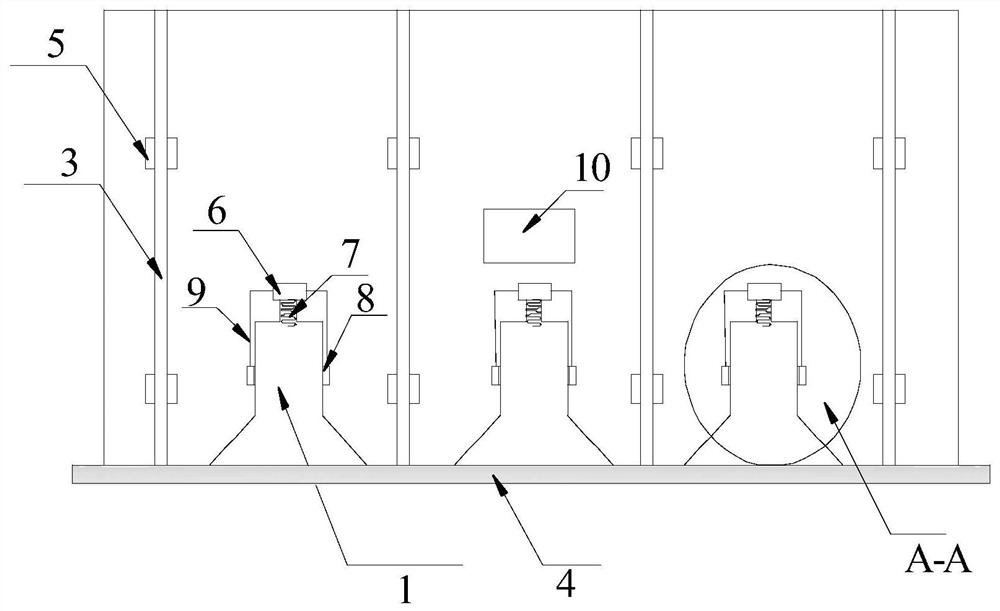

[0035] The present invention provides a gunpowder ignited welding prefabricated pile, comprising a welding groove 1, a gunpowder welding device, a gasket 4, a strain gauge 5, a stress strain sensor 10 and a welding head 12; wherein, the gunpowder welding device includes a gunpowder ignited Starter 6, spring 7, gunpowder storage box 8 and wire 9;

[0036] like figure 1 , 3 As shown in , 4 and 5, the prefabricated pile is a concrete prefabricated pile. In the process of prefabrication, a plurality of stress bars 3 are first set in the mold, and a plurality of strain gauges 5 are arranged at the position of the stress bar 3 close to the welding end. Concrete 2 is poured until the position for placing the stress-strain sensor 10 is preset, and the stress-strain sensor 10 is placed when the concrete is semi-solidified. Continue to pour the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com