Double-laser welding integrated welding head

An integrated welding head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inconvenient cleaning or replacement, affecting the quality of welding, increasing production costs, etc., and achieve the effect of increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

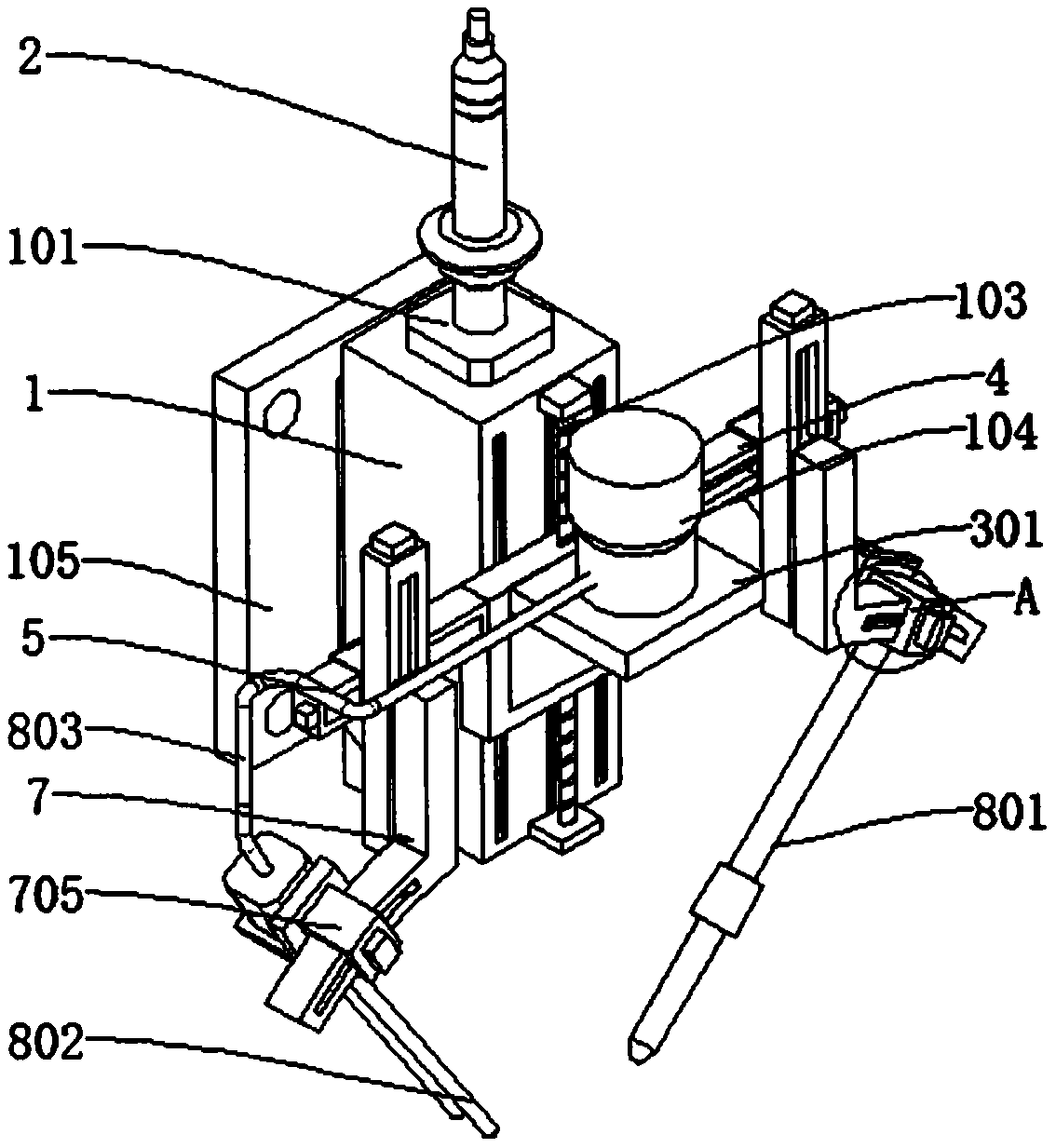

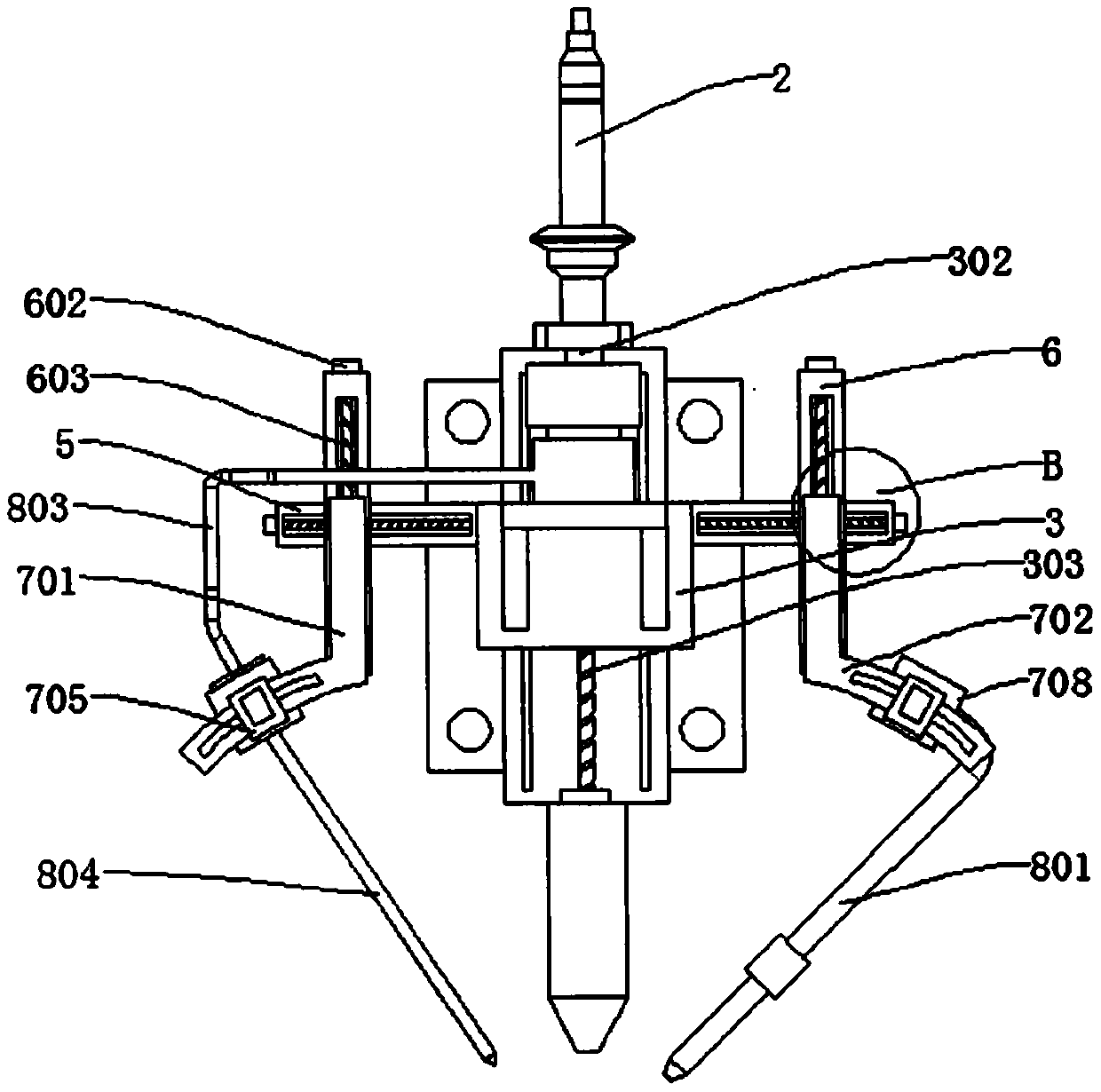

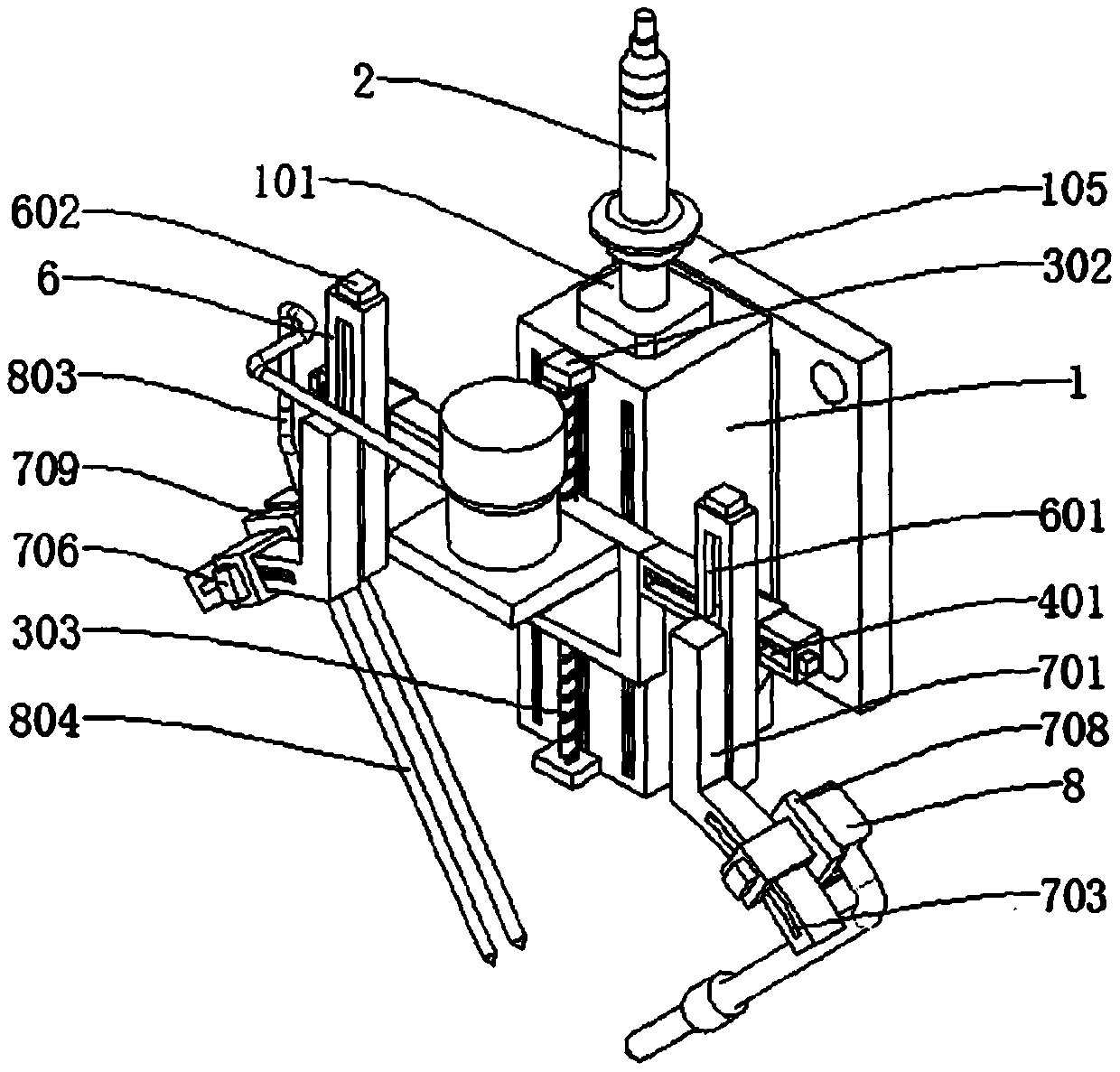

[0032] refer to Figure 1-5 , a double laser welding integrated welding head, including a base 1, a first connection seat 101 is connected to the top wall of the base 1, a laser transmitter 2 is connected to the top wall of the first connection seat 101, and the interior of the base 1 is excavated There is a channel 102 matching the laser transmitter 2, a first chute 103 is dug on the outer wall of the base 1, the first chute 103 is internally connected with a first slide 3, and the outer wall of the first slide 3 is connected with a first support plate 301, a barrel 104 is connected to the top wall of the first support plate 301, a first support frame 4 and a second support frame 5 are respectively connected to the side walls of the first slide plate 3, and a feeding assembly is movably connected to the first support frame 4, and The feeding assembly communicates with the barrel 104 , and a nozzle assembly is movably connected to the outer wall of the second support frame 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com