Device for narrow gap welding and welding method

A welding method and narrow gap technology, applied in the direction of cleaning method using gas flow, welding equipment, auxiliary devices, etc., can solve the problems of reducing welding accuracy, low work efficiency, increasing defective rate, etc., to prevent excessive welding of profiles Large size, convenient positioning and controllable running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

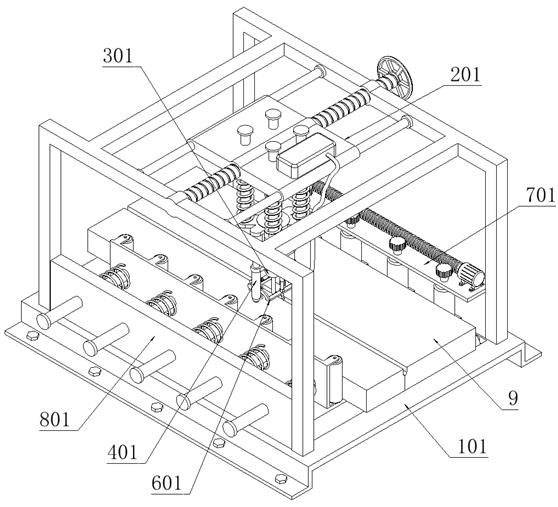

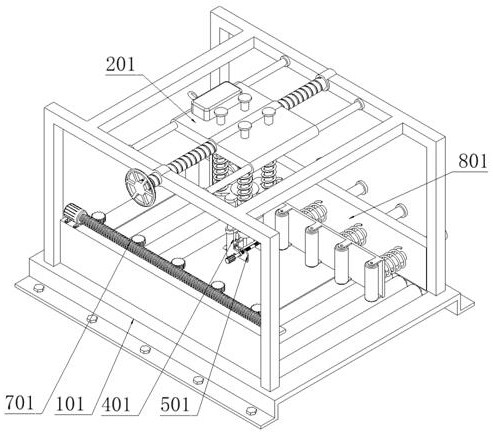

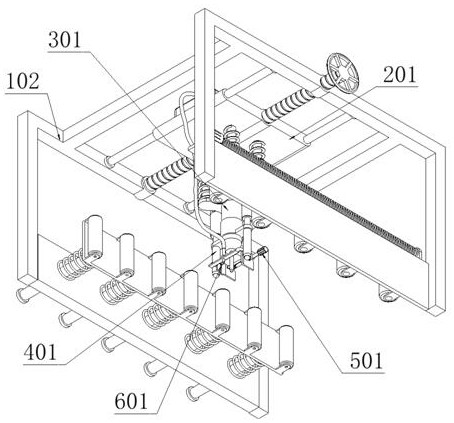

[0080] as attached figure 1 to attach Figure 13 Shown:

[0081] The present invention provides a device for narrow gap welding, comprising a support device 1; a support device 1, which is fixedly connected to the bottom of an operating device 7; a shrinkage joint structure 8 is fixedly connected to the top of the support device 1; the top of the support device 1 The positioning part 2 is fixedly connected; the floating welding part 3 is slidingly connected to the positioning part 2, and the bottom of the floating welding part 3 is slidingly fitted with the adjusting part 4; the adjusting part 4 is fixedly connected with the protection device 5; the front side of the adjusting part 4 A dust removal device 6 is fixedly connected; a welding plate 9 is slidably connected to the supporting device 1 .

[0082] as attached Figure 6 , 12 , 13, the support device 1 includes: the installation base plate 101, the installation base plate 101 is fixedly connected to the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com