A battery bridge welding mold

A technology for welding molds and batteries, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding quality and lead drop in two poles, and achieves improved welding efficiency, simple structure, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

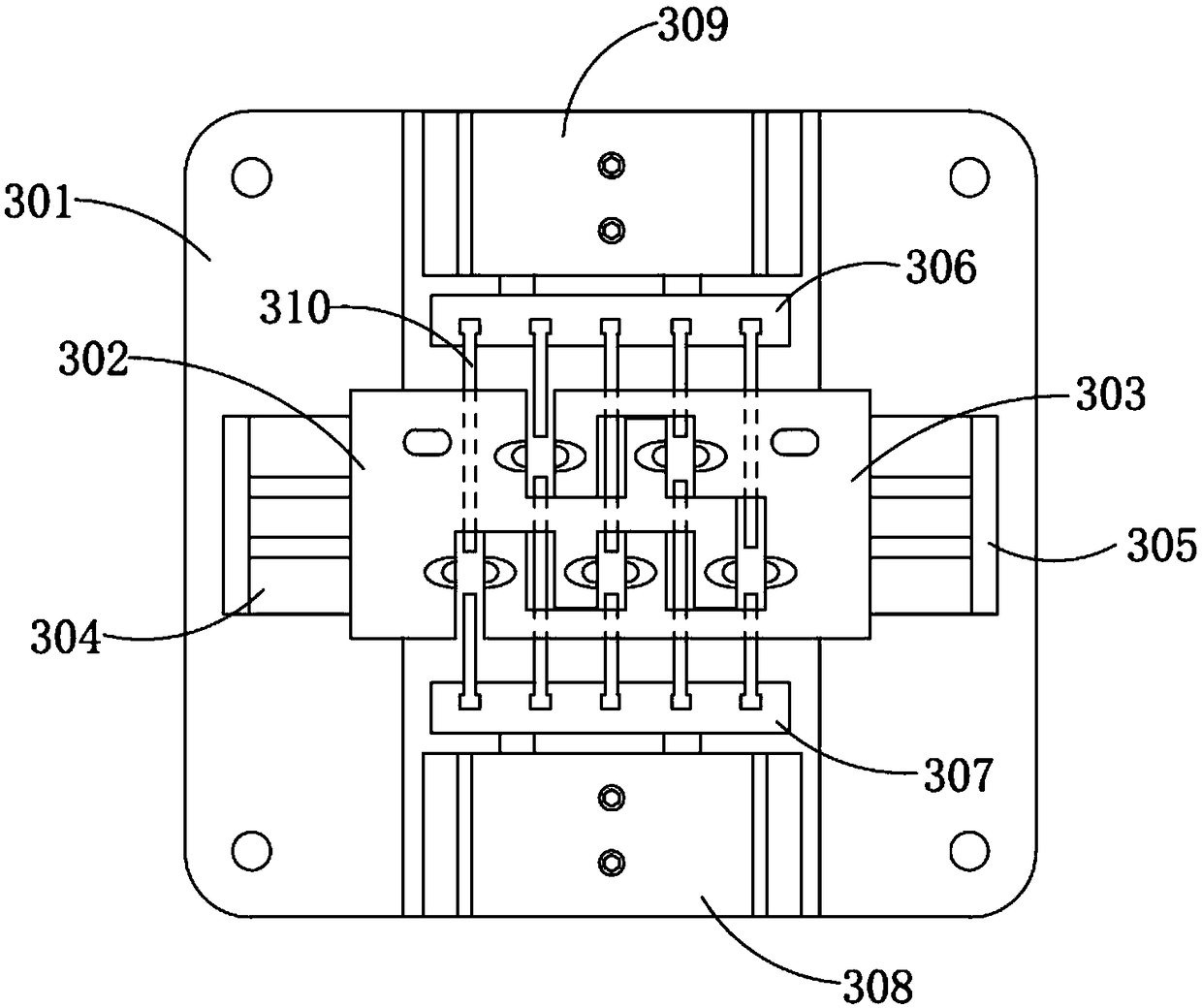

[0025] The bridge welding mold of the present invention will be described in further detail below with reference to the accompanying drawings.

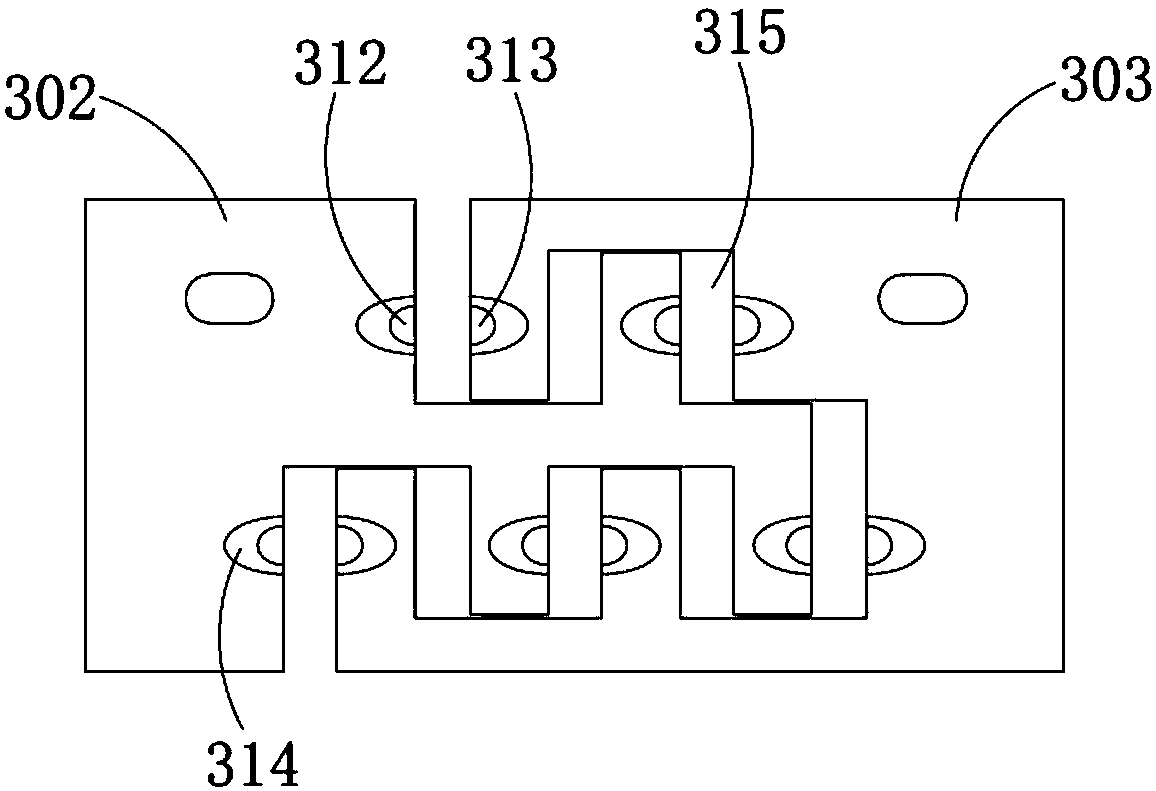

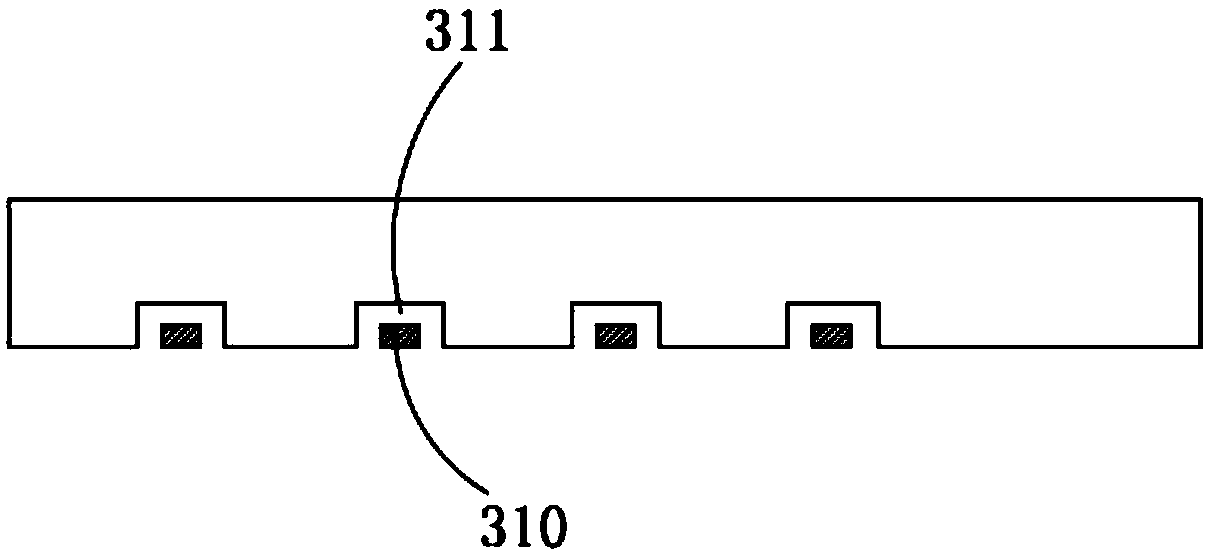

[0026] Such as Figure 1~3 The bridge welding mold shown includes a bottom plate 301, a first template 302, and a second template 303. The middle part of the bottom plate 301 is hollowed out, which is used to compress the storage battery placed at the lower part of the bottom plate 301 and allow the pole pair to be welded to pass through the bottom plate into the first template 302 and the second template 303 for welding. The first template 302 and the second template 303 are slidably fitted above the middle of the bottom plate 301, or a sliding guide rail can be provided on the bottom plate 301 as required.

[0027] The first template 302 is provided with a first welding port 312 for aligning a pole to be welded; the second template 303 is provided with a second welding port 313 aligned with the first welding port 312, which can accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com